Академический Документы

Профессиональный Документы

Культура Документы

Characterization of Some Functional Properties of Edible Films

Загружено:

Pablo Emilio Rodriguez FonsecaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Characterization of Some Functional Properties of Edible Films

Загружено:

Pablo Emilio Rodriguez FonsecaАвторское право:

Доступные форматы

Characterization of some functional properties of edible lms

based on muscle proteins of Nile Tilapia

T.M. Paschoalick, F.T. Garcia, P.J.A. Sobral

*

, A.M.Q.B. Habitante

Universite de sao Paulo, FZEA-ZAZ-CP, P.O. Box 23, Pirassununga, SP 13630-900, Brazil

Received 19 July 2002; revised 18 November 2002; accepted 11 December 2002

Abstract

Recently, it was observed that the myobrillar as well as the sarcoplasmatic proteins obtained from sh are capable to form lms. The

objectives of this work was to elaborate and to characterize the water vapor permeability (WVP), the color and opacity, the mechanical

properties, and the viscoelastic properties of lms made with muscle proteins of Nile Tilapia (Oreochromis niloticus). The proteins were

obtained by nely grinding the sh muscle, followed by separation of the connective tissue and freeze-drying after liquid nitrogen freezing.

The lms were prepared from lmogenic solutions (FS) by the casting technique, as follows: 1 g of protein/100 g of FS, 1565 g of

glycerin/100 g of protein, pH 2.7 (acetic acid) and FS thermal treatment of 40, 65 and 90 8C/30 min. The WVP was determined by a

gravimetric method, and the color and opacity of the lms were determined with a colorimeter (model MiniScan XE, HunterLab). The

mechanical properties, force and elongation at puncture, were determined with the help of a texturometer (model TA.XT2i, TA Instruments),

at 25 8C. The viscoelastic properties were determined by dynamic mechanical analysis, with a DMA2980 apparatus (TA Instruments)

operating in the frequency scanning mode, at 30 8C, with the viscoelastic properties being calculated at 1 Hz. It was observed that the WVP

increased with the concentration of glycerin C

g

as expected and that an increase in temperature of FS thermal treatment also caused an

increase in the WVP of the lms. The color and the opacity of the lms decreased with C

g

; and were proportional to the thermal treatment

temperature of the FS. In general, it was observed that increasing the C

g

provoked linear reduction of puncture force and an increase on the

elongation at break, due to its plasticizer effect. It was also observed that increasing the C

g

caused depression on both the storage and loss

moduli values but increased the tan d: The presence of sarcoplasmatic proteins did not affect the quality of functional properties of lms based

on muscle proteins of Nile Tilapia.

q 2003 Elsevier Science Ltd. All rights reserved.

Keywords: Edible lms; Myobrillar protein; Water vapor permeability; Color; Mechanical properties; Viscoelastic properties; Tilapia

1. Introduction

In the middle of the nineties, Cuq, Aymard, Cuq, and

Guilbert (1995) working with Atlantic sardines, demon-

strated that the myobrillar proteins had the capacity to

form transparent and resistant lms. Since then, other works

were done with myobrillar proteins from sh (Cuq et al.,

1995; Cuq, Gontard, Cuq, & Guilbert, 1996a,b; Cuq,

Gontard, Cuq, & Guilbert, 1997a; Cuq, Gontard, &

Guilbert, 1997b; Monterrey-Quintero & Sobral, 1999,

2000; Sobral, 2000) and beef (Ocuno & Sobral, 2000;

Sobral, Ocuno, & Savastano, 1998; Souza, Sobral, &

Menegalli, 1997; Souza, Sobral, & Menegalli, 1998).

To be used in the lm elaboration process, the

myobrillar proteins have to be prepared adequately.

After slaughter and evisceration, the muscles are grounded

and washed conveniently to eliminate the sarcoplasmatic

proteins. After that, the material is minced and passed

through a screen, to separate the connective tissue (insoluble

proteins) (Cuq et al., 1995; Monterrey-Quintero & Sobral,

2000).

For making lms based on myobrillar proteins or on

other macromolecules, the utilization of plasticizers is

necessary to reduce brittleness, i.e. to improve the work-

ability of the material. The plasticizers, which are generally

polyols, reduce the intermolecular interactions between

adjacent chains of the biopolymer, resulting in an increase

of mobility of these chains and consequently, in exible

lms (Gennadios, McHugh, Weller, & Krochta, 1994;

0268-005X/03/$ - see front matter q 2003 Elsevier Science Ltd. All rights reserved.

doi:10.1016/S0268-005X(03)00031-6

Food Hydrocolloids 17 (2003) 419427

www.elsevier.com/locate/foodhyd

* Corresponding author. Fax: 55-19-35654114.

E-mail address: pjsobral@usp.br (P.J.A. Sobral).

Torres, 1994). As a consequence, at a macroscopic level, a

reduction in the mechanical resistance and an increase in the

elasticity and water vapor permeability (WVP) of the lms

may occur.

Considering that this increase in the WVP is undesirable

for the guaranty of quality of some packaged foods,

Sothornvit & Krochta (2000a,b) recommended another

approach for the reduction of intermolecular forces in the

case of whey protein isolate based lms: reduction of the

molecular mass of whey proteins by the utilization of

proteins with certain degree of hydrolysis. According to

these authors, this would make the reduction of the

utilization of plasticizers possible.

In addition to these studies on molecular mass reduction

of whey proteins, Japanese researchers were able to

elaborate lms with the sarcoplasmatic proteins (which

have a low molecular weight) from sh muscles (Iwata,

Ishizaki, Handa, & Tanaka, 2000; Tanaka, Iwata, &

Sanguandeekul, 2001). Iwata et al. (2000) worked with a

unique content of plasticizer, which could be considered as

elevated (50 g of glycerol/100 g of proteins), and studied the

effect of protein concentration, pH and thermal treatment of

the lmogenic solution (FS) upon certain properties of the

lms. On the other side, Tanaka et al. (2001) studied the

effect of the type and concentration of the plasticizer on

some functional properties of these lms.

Considering that the sarcoplasmatic proteins also have

the capacity to form a continuous matrix, it may be

supposed that edible lms can be produced by the mixture

of these proteins with myobrillar proteins, avoiding the

washing process of the muscles. So, the objectives of this

work was the elaboration of edible lms based on muscle

proteins of Nile Tilapia (without the proteins of stroma),

and the characterization of the WVP, color, opacity,

mechanical and viscoelastic properties of these lms as a

function of the concentration of plasticizer and the thermal

treatment of the FS.

2. Material and methods

2.1. Proteins preparation

The proteins were prepared initially by grounding the

deboned muscle (lets) of Nile Tilapia (Oreochromis

niloticus), ante rigor mortis. A paste was obtained using a

food processor for 10 min, adding ice to avoid the heating of

the material. The proteins of stroma were eliminated using a

screen (ABNT 100). The ne paste obtained was freeze-

dried after quench freezing in liquid nitrogen, in a

laboratory scale freeze-drier (Heto, model FD3). The

freeze-dried muscle proteins were grounded and tamized

in a sieve with an opening of 0.18 mm (ABNT 80),

obtaining a homogeneous powder.

This powder, that constituted the muscle protein of Nile

Tilapia (MPNT), was analyzed to determine the humidity,

lipids and proteins content, using classical methods (AOAC,

1995). The amino acid composition of MPNT was

determined after acid hydrolysis, by ionic exchange

chromatography with derivatization post-column with

ninhidrin (Monterrey-Quintero & Sobral, 2000). These

analyses were realized in duplicate.

2.2. Films elaboration

The MPNT lms were prepared by drying the FS,

conveniently applied on a support. FS were prepared under

the following conditions: protein, 1 g of MPNT/100 g of SF;

plasticizer, 1565 g glycerin/100 g protein; pH maintained

at 2.7 using acetic acid, and thermal treatment of 40, 65 or

90 8C/30 min.

Initially, the adequate amounts of glycerin and water

were added in a beaker, followed by adding MPNT, under

moderate agitation obtained with a magnetic mixer (Hanna,

HI 190 M). After that, the acetic acid was added to reduce

the pH of FS. The pH was measured every time with the

help of a digital pH meter (Tecnal, TEC-2). The FS was

thermally treated in a water bath with digital control

(^0.5 8C) of temperature (Tecnal, TE184), kept at 40, 65 or

90 8C during 30 min. Finally, the FS was conveniently

applied on Plexiglas plates (12 12 cm

2

) previously

prepared and dehydrated in an oven with air renewal and

circulation (Marconi, MA037), with PI control (^0.5 8C) of

temperature, at 30 8C and room relative humidity (55

65%), for 24 h (Monterrey-Quintero & Sobral, 2000).

Weighting (^0.0001 g) of all lms components was

accomplished using an analytical scale (Scientech, SA210).

For functional properties characterization, the lms were

conditioned at 2225 8C and 58% of relative humidity, in

desiccators with saturated solution of NaBr, for 7 days.

Then, the thickness of the lms was measured averaging

nine different positions, with a digital micrometer

(^0.001 mm) with a 6.4 mm diameter probe. All the

characterizations were accomplished in climatized room

conditions (T 2225 8C and relative humidity between

55 and 65%). Only one sample per lm was taken for test,

i.e. each lm originated only one replicate. All tests were

made in quadruplicate.

2.3. Water vapor permeability

The WVP was determined according to a method

proposed by Gontard, Guilbert, and Cuq (1993). The

edible lms were rmly xed onto the opening of cells

containing silica gel. These cells were placed in

desiccators with distilled water maintained in an oven

(Marconi, model MA415/S) with electronic control of

temperature (^0.2 8C), at 25 8C. The cells were weighted

(^0.01 g) daily, in a semi-analytic balance (Marte,

AS2000), for 8 days. The WVP was calculated with

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 420

Eq. (1) (Gontard et al., 1993)

WVP

w

tA

x

DP

1

where x is the average thickness of the MPNT lms, A is

the permeation area (12.29 cm

2

), DP is the difference of

partial vapor pressure of the atmosphere with silica gel

and pure water (2642 Pa, at 22 8C), and the term w=t was

calculated by linear regression from the points of weight

gain and time, in the constant rate period.

2.4. Color

The color of the MPNT lms was determined with a

colorimeter (HunterLab, model Miniscan XE), working

with D

65

(day light) and a measure cell with an opening of

30 mm, being used the CIELab color parameters: L

p

; from

black (0) to white (100); a

p

; from green (2) to red (); and

b

p

; from blue (2) to yellow () (Gennadios, Weller,

Hanna, & Froning, 1996; Kunte, Gennadios, Cuppett,

Hanna, & Weller, 1997). The MPNT lms were applied in

the surface of a white standard plate, the color parameters

were measured, and transferred and calculated (Eq. (2)) in

real time for a microcomputer. The lms color was

expressed as difference of color DE

p

DE

p

DL

p

2

Da

p

2

Db

p

2

q

2

where DL

p

; Da

p

and Db

p

are the differentials between the

color parameter of the samples and the color parameter of

white standard (Table 1).

The color of the freeze-dried MPNT was also determined

using the same colorimeter (Table 1), but in this case, the

powder was put in a quartz sample cup.

2.5. Opacity

The opacity of the MPNT lms was determined

according to a Hunterlab method (Sobral, 2000), with the

same equipment for color measures, also operating in the

reectance mode. The opacity Y of the samples was

calculated as the relationship among the opacity of each

sample on the black standard Y

b

and the opacity of each

sample on the white standard Y

w

: This calculation Y

Y

b

=Y

w

was made automatically by the Universal Software

3.2 (Hunterlab Associates Laboratory).

2.6. Mechanical properties

The force and the deformation at breaking point of the

lm were determined in puncture tests (Gontard et al.,

1993). The lms were xed in a 52.6 mm diameter cell and

perforated by a 3 mm diameter probe, moving at 1 mm/s.

These tests were accomplished with an instrument of

physical measures TA.XT2i (SMS, Surrey, UK). The

puncture force F and the displacement of the probe D

at break were determined with the software Texture Expert

V.1.15 (SMS) directly from the force X displacement

curves. The puncture deformation Dl

0

=l

0

can be calculated

with D considering that stress was perfectly distributed

along the lm at breaking point (Sobral, Menegalli,

Hubinger, & Roques, 2001).

2.7. Viscoelastic properties

The viscoelastic properties of the MPNT lms were

characterized by dynamic mechanical analysis, using an

equipment DMA TA2980 controlled by a TA5000 module

(TA Instruments, New Castle, DE, USA), and with the lm

grips clamps that allowed possible uniaxial traction tests.

The analysis were carried out in the frequency scanning

(0.01200 Hz) mode, with constant temperature (30 8C),

the amplitude of deformation (0.2%) and the ow of N

2

in

the measure cell (1180 ml/min).

Rectangular samples of about 19 mm 5 mm, were

submitted to oscillatory traction (senoidal stress applied)

analysis, obtaining the storage modulus E

0

; the loss

modulus E

00

and the phase angle tan d E

00

=E

0

in

function of the frequency. For the study of the plasticizing

effect of glycerin on viscoelastic properties, E

0

; E

00

and tan d

were calculated from DMA results at 1 Hz frequency

(Lazaridou & Biliaderis, 2002), with the software Universal

Analysis V1.7F (TA Instruments).

2.8. Statistical analysis

The linear regressions necessary to the calculation of

WVP R

2

. 0:98; were accomplished with Excel 2000

software (Microsoft, Seattle, WA). All linear and non-linear

regressions for the functional properties were done with the

Microcal Origin V.4.0 software (Microcal Software, North-

ampton, USA).

3. Results and discussions

The chemical analysis made in samples of freeze-dried

muscle proteins of Nile Tilapia indicated the following

average composition: 80% protein, 7% humidity and 8%

lipids. The protein content obtained was lower than that

determined by Monterrey-Quintero and Sobral (2000), but

of the same order of that obtained by Sobral (2000), who

determined concentration of proteins as 93.2 and 85%,

Table 1

Color parameters of white standard plate and of freeze-dried MPNT

L

p

a

p

b

p

White standard 94.89 20.78 1.43

Freeze-dried MPNT

1

90.02 20.92 11.34

D

2

23.72 0.02 98.21

1

Muscle protein of Nile Tilapia.

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 421

respectively, working with myobrillar proteins of the same

species of Tilapias used in this work. However, the results of

this study were closer to the minimum amounts encountered

by Candido (1998): 84.197.7% proteins, also obtained

with samples of freeze-dried myobrillar protein of Nile

Tilapia. The content of fat obtained was also closer to that

obtained by Sobral (2000) and to the maximum amounts

obtained by Candido (1998), which were 6.75.1%,

respectively; while Monterrey-Quintero and Sobral (2000)

obtained 2.4%.

The amino acid composition of the MPNT is

presented in Table 2. It can be observed that the polar

ionic amino acids are in high concentration (aspartic

acid, glutamic acid, arginine and lysine), such as in the

myobrillar proteins obtained by Monterrey-Quintero and

Sobral (2000). The difference between the composition of

the MPNT and that of myobrillar proteins may be

explained by the presence of sarcoplasmatic proteins

(Candido, 1998).

The freeze-dried proteins obtained showed an inter-

esting uidity, i.e. without a characteristic of agglomera-

tion. However, they were not as bright as the myobrillar

proteins of Nile Tilapia, obtained by Monterrey-Quintero

and Sobral (2000), which were almost white.

In general, the lms prepared with these proteins were

well exible and easily handled, with a good visual aspect.

The average thickness (^standard deviation) of all the lms

utilized in the characterization of optical and viscoelastic

properties and WVP was 0.076 ^ 0.002 mm at

40 8C/30 min, 0.077 ^ 0.003 mm at 65 8C/30 min, and

0.091 ^ 0.005 mm at 90 8C/30 min. In the case of charac-

terization of the mechanical properties, the average thickness

(^standard deviation) of the lms was the following:

0.081 ^ 0.004 mm at 40 8C/30 min; 0.083 ^ 0.002 mm at

65 8C/30 min; and 0.084 ^ 0.008 mm at 90 8C/30 min.

3.1. Water vapor permeability

The results of the WVP tests of the lms elaborated with

1 g of MPNT by 100 g of SF and treated at 40, 65 and 90 8C,

are shown in Fig. 1. As expected, in general the WVP

increased with the increment of C

g

: This behavior is

common in hygroscopic edible lms and it is well-explained

in terms of molecular mobility in the specialized literature

(Cuq et al., 1997a; Gennadios et al., 1994; McHugh, Aujard,

& Krochta, 1994; Ocuno & Sobral, 2000; Sobral et al.,

2001; Sothornvit & Krochta, 2000a; Tanaka et al., 2001;

Torres, 1994).

In general, the variation of the experimental data of WVP

of the lms as a function of the C

g

; followed a parabolic

behavior being well-represented by a second order poly-

nomial equation, with satisfactory adjustments (Table 3).

On the contrary, McHugh et al. (1994) determined that the

WVP of gluten lms, plasticized by glycerin, determined at

25 8C, increased linearly R

2

0:966 with the concen-

tration of plasticizer. This same behavior has been seen by

Gontard et al. (1993) also with gluten lms plasticized with

glycerin.

The study of the WVP as a function of the effect of

thermal treatment was prejudiced by the dispersion of the

experimental data. However, it could be suggested that the

more intense SF thermal treatment (90 8C/30 min) pro-

portioned more permeable lms.

The lms produced in this work showed to be more

permeable to water vapor than those of myobrillar proteins

of Atlantic sardines elaborated by Cuq et al. (1997a),

who determined the WVP in the order of 2:7 10

24

g mm

h

21

m

22

Pa

21

in lms with 40% of glycerin, T 20 8C,

pH 3.0 and 2.6 mg of proteins/cm

2

, and those of

Table 2

Amino acid composition (g amino acids/100 g of protein) for Tilapia

proteins

Muscle proteins

1

Myobrilar proteins

2

Alanine 5.50 (0.12) 5.00

Arginine 6.15 (0.00) 2.71

Aspartic acid 9.20 (0.03) 12.08

Glutamic acid 14.69 (0.03) 12.20

Phenylalanine 3.55 (0.08) 4.07

Cystine 0.78 (0.06) 0.67

Glycine 3.97 (0.03) 4.35

Histidine 2.05 (0.03) 2.57

Isoleucine 4.19 (0.14) 5.86

Leucine 7.35 (0.04) 8.36

Lysine 8.65 (0.07) 10.30

Methionine 2.30 (0.00) 3.15

Proline 3.03 (0.06) 8.95

Serine 3.48 (0.02) 4.41

Tyrosine 2.84 (0.06) 3.43

Threonine 4.18 (0.01) 4.63

Valine 4.29 (0.10) 6.22

1

Average (standard deviation).

2

From Monterrey-Quintero and Sobral (2000).

Fig. 1. Water vapor permeability of lms based on the muscle protein of

Nile Tilapia: (W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 422

myobrillar proteins of Nile Tilapia plasticized by 45% of

glycerin, pH 2.7 and treated at 40 8C/30 min, in which the

WVPcould be calculated as 4.8 10

24

g mm h

21

m

22

Pa

21

(x 0:077 mm) and 5.4 10

24

g mm h

21

m

22

Pa

21

(x 0:087 mm) (Sobral, 2000). In the present work, the

lms with glycerin concentration around 40% presented

Pva . 6 10

24

g mm h

21

m

22

Pa

21

. These lms were

more permeable to water vapor, possibly due to the

plasticizing effect of the proteins with low molecular weight

present in the freeze-dried product, contrary to the lms based

only on myobrillar proteins with fat content of the same

order (Cuq et al., 1997a; Sobral, 2000).

3.2. Color

The results of the determination of lm color, expressed

as the difference of color DE

p

in relation to the white

standard plate, are shown in Fig. 2. It can be observed that

the lms produced in this study, and which SF was treated at

30 and 65 8C/30 min, showed a DE

p

which decreased

linearly (Table 4) with the increment of C

g

; while in the case

of SF treated at 90 8C/30 min, this behavior is the opposite.

The reduction of lms color with the increase of C

g

should

probably be an effect of the dilution of the proteins because

glycerin is an uncolored compound. This means that as the

glycerin concentration increases, the lm should present

less and less color in such a manner that the difference of

color will tend to zero. On the other hand, the increase of

DE

p

; with the concentration of C

g

; at 90 8C/30 min, can be

explained by some alteration of the macromolecular

structure which may have occurred, however, more analyses

are necessary to conrm this explanation. In general, it

could be suggested that the increase of temperature caused a

slight increase of lms color, possibly due to the occurrence

of reaction among the glycerin molecules and the reactive

group of lysine.

Comparing the behaviors and the values of DE

p

presented in Fig. 2 with the results (not shown) of the

differences of chrome DL

p

; Da

p

; Db

p

; it could be suggested

that the behavior of color difference was mainly due to the

variation of chrome b

p

: On another side, the initial values of

DE

p

were well related with the color DE

p

11:04 of

freeze-dried MPNT. The important difference noted in the

parameter b

p

(Table 1) indicated that the lms color was

tending to yellow.

Using equations determined by Sobral (2000), for lms

elaborated with 1 g of myobrillar proteins/100 g of SF,

45% of glycerin, pH 2.7 and SF thermal treatment of

40 8C/30 min, it can be calculated DE

p

values around 7 and

8 for lms with 0.077 and 0.087 mm of thickness,

respectively. These values were comparable to those

determined in lms of this work elaborated with 45% of

glycerin and treated at 40 8C/30 min (Fig. 2). The increase

Table 3

Parameters of the second order polynomial equation Y A BX CX

2

calculated by non-linear regression

Properties Thermal

treatment

(8C/30 min)

A B C R

2

WVP 40 3.719 0.097 23.647 10

24

0.969

65 1.132 0.192 21.460 10

23

0.722

90 20.227 0.371 23.700 10

23

0.885

E

0

40 935.98 224.130 0.187 0.963

65 974.62 227.103 0.216 0.984

90 1128.92 236.636 0.321 0.961

E

00

40 100.23 21.672 0.009 0.947

65 118.02 22.731 0.020 0.991

90 150.67 24.333 0.036 0.960

Fig. 2. Color difference of lms based on the muscle protein of Nile Tilapia:

(W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

Table 4

Parameters of the linear equation Y A BX calculated by linear

regression

Properties Thermal treatment

(8C/30 min)

A B R

2

DE

p

40 10.403 20.055 0.834

65 14.425 20.110 0.929

90 9.201 0.082 0.571

Opacity 40 6.046 20.036 0.754

65 8.721 20.043 0.335

90 7.575 20.096 0.921

Puncture force 40 7.45 20.078 0.978

65 9.54 20.115 0.951

90 5.81 20.059 0.972

Puncture deformation 40 2.99 0.054 0.674

65 1.98 0.098 0.908

90 2.16 0.068 0.738

tan d 40 0.110 1.47 10

23

0.961

65 0.112 1.40 10

23

0.991

90 0.117 1.85 10

23

0.966

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 423

of protein concentration in SF or treatment temperature

provoked an increase of lm color in relation to those

elaborated with myobrillar proteins of Nile Tilapia

(Sobral, 2000). In addition, the lm color elaborated

in this work was higher than that based on egg albumins

DE

p

1:72:3; x 0:099 mm (Gennadios et al., 1996)

and pigskin gelatin DE

p

, 3; x , 0:090 mm (Sobral,

1999). However, it was comparable to the color of soybean

protein lms DE

p

8:511:6; x 0:0540:065 mm

(Kunte et al., 1997).

3.3. Opacity

With relation to the opacity, it could be observed that it

also decreased with the increase of C

g

(Fig. 3), possibly due

to the diluting effect of glycerin, which is a transparent

compound (low opacity). The opacity behavior in function

of the C

g

could be represented by the linear equation with

satisfactory regression coefcients (Table 4), except in the

lms treated at 65 8C/30 min due to data dispersion,

problem reported in some works about this property (Sobral,

1999, 2000).

The opacity of lms produced in this work was greater

than the opacity of pigskin gelatin lms Y , 0:5; x , 0:1

mm; which were extremely transparent, but were compar-

able to the opacity of lms based on myobrillar proteins of

Nile Tilapia Y , 3:5; x , 0:090 mm; especially in the

case of lms elaborated with more than 40% of glycerin.

3.4. Mechanical properties

The mechanical properties determined by perforation

tests, also were inuenced by C

g

; as expected. In Fig. 4, it

could be observed that the increase of C

g

provoked a linear

reduction (Table 4) of the puncture force, in the domain of

C

g

studied. This behavior was according to Cuq et al.

(1997a) and Monterrey-Quintero and Sobral (1999), who

also observed a linear reduction of puncture force of similar

lms, between 0 and 40 g of glycerol/100 g of myobrillar

protein of Atlantic Sardine, and 30 and 70 g of glycerol/

100 g of myobrillar proteins of Nile Tilapia, respectively.

On the other hand, Sobral et al. (1998) observed that the

puncture force in perforation tests with lms based on

myobrillar protein from beef and acidied by acetic or

lactic acid, was reduced exponentially with the C

g

between

25 and 100% of glycerin. This same exponential behavior

was observed by Ghorpade, Gennadios, Hanna, and Weller

(1995) in soybean protein lms and by Sothornvit and

Krochta (2001) in lms of b-lactoglobulin, both working

with traction tests.

It can be observed in the work of Monterrey-Quintero

and Sobral (1999), that the lms of 1.25% of myobrillar

protein of Nile Tilapia in SF and with 30 and 50% glycerin,

presented a puncture force of about 6.7 and 4.3 N,

respectively. This was equivalent to that of the lms

produced in this project under similar conditions. However,

all these lms were less resistant than the lms of

myobrillar protein of beef, with 30% of glycerin and

acidied by acetic acid, which presented a puncture force

around 8.7 N. Possibly, these disagreements may be

explained by differences in the amino acids compositions

between these two myobrillar proteins that caused

different macromolecular interactions.

It can be observed in Fig. 5 that the puncture deformation

of the lms increased linearly (Table 3) with C

g

: This

behavior agrees with the results observed by Sobral et al.

(1998), working with lms of myobrillar protein of bovine

meat and acidied by acetic acid. However, Gontard et al.

(1993) observed an increase of 620% in the puncture

deformation of lms based on gluten, caused by the increase

of 1633 g of glycerin/100 g of dry material, following a

segment of parabola, while Cuq et al. (1997a), working with

lms of myobrillar protein of Atlantic Sardine, observed a

sigmoid behavior, for values of C

g

lower than 40%.

Fig. 3. Opacity of lms based on the muscle protein of Nile Tilapia: (W)

40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

Fig. 4. Puncture force of lms based on the muscle protein of Nile Tilapia:

(W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 424

The lms of MPNT produced in this work presented values

of puncture deformation slightly lower to that of the

respective lms of myobrillar proteins of Nile Tilapia

(Monterrey-Quintero and Sobral, 1999). However, they were

equivalent to lms of myobrillar protein of Atlantic Sardine

at similar conditions of formulation (Cuq et al., 1997a).

3.5. Viscoelastic properties

The viscoelastic properties of the lms of MPNT varied

subtly as a function of the oscillation frequency of the strain

applied by the dynamic-mechanical analyzer (except

between 100 and 200 Hz due to resonance problem).

Examples of responses obtained during analyses at 30 8C

of the lms elaborated with 15% of glycerin and thermal

treatment of 40 8C/30 min, and 65% of glycerin and thermal

treatment of 90 8C/30 min could be observed in Fig. 6: E

0

was always greater than E

00

in the entire frequency domain,

which is a characteristic of physical gels; and tan d

decreased smoothly with the increase of frequency, while

E

0

increased after 0.1 Hz, a typically post glass transition

material behavior (Ferry, 1980). Effectively, based on the

glass transition of the lms of myobrillar protein of Nile

Tilapia (Sobral, Monterrey-Quintero, & Habitante, 2002), it

could be supposed that under the conditions of these

analyses, the lms of this work were in the rubbery state. A

similar behavior of E

0

; between 0.1 and 100 Hz, could be

observed in the work of Lazaridou and Biliaderis (2002).

The values of E

0

and E

00

calculated at 1 Hz, are presented

in Figs. 7 and 8, respectively, as a function of C

g

: These

properties decreased with the increase of C

g

due to the

plasticizing effect of glycerin. In general, the values of E

0

and E

00

dropped around 80 and 70%, respectively, following

a parabolic segment in both the cases. Thus, these behaviors

could be represented by a second order polynomial equation

with very good regression coefcients (.0.94) observed in

Table 3.

It can be observed in Figs. 7 and 8, that the increasing of

temperature of thermal treatment caused more important

reduction in E

0

and E

00

as a function of C

g

: In molecular

terms, this would occur due to possible reduction of

molecular weight of proteins, which was not probable.

Normally, heating of SF could provoke the formation of

aggregates by disulphide bonds involving residues of amino

acids with sulfur (Perez-Gago & Krochta, 2001; Vachon

et al., 2000), which might implicate on an increment of

apparent molecular weight of the protein in such a way that,

for a same concentration of glycerin, this lm would be less

plasticized. This way, the observed behavior, contrarily to

the one described, was difcult to explain.

The results of the last viscoelastic property, the phase

angle, well called tan d and calculated as the relation

between E

00

and E

0

; are shown in Fig. 9. It could be observed

that, contrarily to E

0

and E

00

; tan d increased with the C

g

in

Fig. 5. Puncture deformation of lms based on the muscle protein of Nile

Tilapia: (W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

Fig. 6. Examples of results of dynamic mechanical analysis of lms based on the muscle protein of Nile Tilapia: () C

g

15%; 40 8C/30 min; (- - -)

C

g

65%; 90 8C/30 min.

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 425

all the thermal treatments. This could be explained,

according to Ferry (1980), by the fact that both the solvent

(glycerin) and the solute (proteins) contributed to E

00

; while

only the solute contributed to E

0

: This way, the greater

inuence (reduction) of glycerin on E

0

; caused the increment

in tan d:

Moreover, considering that the reductions of E

0

and E

00

followed the same behavior, evidently with different

intensities, the consequent increase in tan d was linear. It

could be observed in Table 4, that the adjustments of the

linear equation to the experimental points, in general, were

very good with only one value of R

2

lower than 0.96.

The values of the viscoelastic properties (E

0

; E

00

and

tan d) determined in this work, were of the same order of

magnitude of the values observed in the papers of Cuq et al.

(1997b), who worked with lms of myobrillar protein of

Atlantic Sardine, and Cherian, Gennadios, Weller, and

Chinachoti (1995) and Gontard and Ring (1996), who

worked with gluten lms containing various plasticizers. In

general, it is very difcult to compare these types of results,

because most of the authors worked with temperature

scanning, and above all, because they veried the plasticizer

effect of the sample humidity, and not necessarily of the

added plasticizer agent, as in the present work.

4. Conclusion

The utilization of muscle proteins of Nile Tilapia that is,

including the sarcoplasmatic proteins and excluding the

proteins from stroma, for the elaboration of the edible lms

with glycerin is an alternative for the utilization only of the

myobrillar proteins, once that reduces the washing stage of

the ground muscle. By this way, the industrial process can

be considered starting from sh collecting, slaughter,

cleaning, evisceration and lleting, where the llet will be

directly taken to the elaboration line of lms, starting by

grinding.

The presence of sarcoplasmatic proteins caused little

alteration of the functional properties of lms, in relation to

the lms elaborated only with myobrillar proteins. But, the

WVP, the color, the opacity, and the mechanical and

viscoelastic properties of the lms elaborated in this work

were of the same order of magnitude of those based on the

myobrillar protein of Nile Tilapia. Moreover, it should be

emphasized that the differences of the functional properties

would not constitute necessarily a disadvantage, because

there could be a demand for packages with these

characteristics.

Acknowledgements

To FAPESP, for the nancial support (00/14091-8,

02/03203-5) and IC fellowship of TMP (00/14466-1); to

CAPES for the MS fellowship of FTG and to CNPq for the

research fellowship of PJAS (522953/95-6).

Fig. 7. Storage modulus, at 1 Hz, of lms based on the muscle protein of

Nile Tilapia: (W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

Fig. 8. Loss modulus, at 1 Hz, of lms based on the muscle protein of Nile

Tilapia: (W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

Fig. 9. Phase angle tan d; at 1 Hz, of lms based on the muscle protein of

Nile Tilapia: (W) 40 8C/30 min; (A) 65 8C/30 min; (K) 90 8C/30 min.

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 426

References

AOAC (1995). Ofcial Methods of analysis of AOAC International (16th

ed). Washington: Association of Ofcial Analytical Chemists.

Candido, L. M (1998). Obtencao de concentrados e hidrolisados proteicos

de Tilapia do nilo (Oreochromis niloticus): composicao, propriedades

nutritivas e funcionais (207 pp.). Dr These. Campinas: Faculdade de

Engenharia de Alimentos da UNICAMP.

Cherian, G., Gennadios, A., Weller, C., & Chinachoti, P. (1995).

Thermomechanical behavior of wheat gluten lms: effect of sucrose,

glycerin and sorbitol. Cereal Chemistry, 72, 16.

Cuq, B., Aymard, C., Cuq, J. L., & Guilbert, S. (1995). Edible packaging

lms based on sh myobrillar proteins: formulation and functional

properties. Journal of Food Science, 60(6), 13691374.

Cuq, B., Gontard, N., Cuq, J. L., & Guilbert, S. (1996a). Functional

properties of myobrilar protein-based biopackaging as affected by lm

thickness. Journal of Food Science, 61(3), 580584.

Cuq, B., Gontard, N., Cuq, J. L., & Guilbert, S. (1996b). Stability of

myobrillar protein-based biopackagings during storage. Lebensmittel-

Wissenschaft-und-Technologie, 29(4), 344348.

Cuq, B., Gontard, N., Cuq, J. L., & Guilbert, S. (1997a). Selected functional

properties of sh myobrillar protein-based lms as affected by

hydrophilic plasticizers. Journal of Agricultural and Food Chemistry,

45, 622626.

Cuq, B., Gontard, N., & Guilbert, S. (1997b). Thermal properties of sh

myobrillar protein-based lms as affected by moisture content.

Polymer, 38, 23992405.

Ferry, J. D. (1980). Viscoelastic properties of polymers. New York: Wiley.

Gennadios, A., Mchugh, T. H., Weller, C. L., & Krochta, J. M. (1994).

Edible coatings and lms based on proteins. In J. M. Krochta, E. A.

Baldwin, & M. Nisperos-Carriedo (Eds.), Edible Coatings and Films to

Improve Food Quality (pp. 210278). Lancaster: Technomic Pub. Co.,

Inc.

Gennadios, A., Weller, C. L., Hanna, M. A., & Froning, G. W. (1996).

Mechanical and barrier properties of egg albumen lms. Journal of

Food Science, 61(3), 585589.

Ghorpade, V. M., Gennadios, A., Hanna, M. A., & Weller, C. L. (1995).

Soy protein isolate/poly(ethylene oxide) lms. Cereal Chemistry, 72(6),

559563.

Gontard, N., Guilbert, S., & Cuq, J.-L. (1993). Water and glycerol as

plasticizer affect mechanical and water vapor barrier properties of an

edible wheat gluten lm. Journal of Food Science, 58(1), 206211.

Gontard, N., & Ring, S. (1996). Edible wheat gluten lm: inuence of water

content on glass transition temperature. Journal of Agricultural and

Food Chemistry, 44, 34743478.

Iwata, K., Ishizaki, S., Handa, A., & Tanaka, M. (2000). Preparation and

characterization of edible lms from sh water-soluble proteins.

Fisheries Science, 66, 372378.

Kunte, L. A., Gennadios, A., Cuppett, S. L., Hanna, M. A., & Weller, C. L.

(1997). Cast lms from soy protein isolates and fractions. Cereal

Chemistry, 74(2), 115118.

Lazaridou, A., & Biliaderis, C. G. (2002). Thermophysical properties of

chitosan, chitosan-starch and chitosan-pullulan lms near the glass

transition. Carbohydrates Polymers, 48, 179190.

Mchugh, T. H., Aujard, J. F., & Krochta, J. M. (1994). Plasticized whey

protein edible lms: water vapor permeability properties. Journal of

Food Science, 59, 416419. see also pp. 423.

Monterrey-Quintero, E. S., & Sobral, P. J. A. (1999). Caracterizacao de

propriedades mecanicas e oticas de biolmes a` base de prote nas

miobrilares de tilapia do nilo usando uma metodologia de superf cie-

resposta. Ciencia e Tecnologia de Alimentos, 19(2), 294301.

Monterrey-quintero, E. S., & Sobral, P. J. A. (2000). Preparo e

caracterizacao de prote nas miobrilares de tilapia do nilo (Oreochro-

mis niloticus) para elaboracao de biolmes. Pesquisa Agropecuaria

Brasileira, 35(1), 179189.

Ocuno, D., & Sobral, P. J. A. (2000). Permeabilidade ao vapor de agua de

biolmes a` base de prote nas miobrilares de carne. Brazilian Journal

of Food Technology, 3, 1116.

Perez-Gago, M. B., & Krochta, J. M. (2001). Denaturation time and

temperature effects on solubility, tensile properties, and oxygen

permeability of whey protein edible lms. Journal of Food Science,

66(5), 705710.

Sobral, P. J. A. (1999). Propriedades funcionais de biolmes de gelatina em

funcao da espessura. Ciencia & Engenharia, 8(1), 6067.

Sobral, P. J. A. (2000). Inuencia da espessura sobre certas propriedades de

biolmes a` base de prote nas miobrilares. Pesquisa Agropecuaria

Brasileira, 35(6), 12511259.

Sobral, P. J. A., Menegalli, F. C., Hubinger, M. D., & Roques, M. A. (2001).

Mechanical, water vapor barrier and thermal properties of gelatin based

edible lms. Food Hydrocolloids, 15(4/6), 423432.

Sobral, P. J. A., Monterrey-quintero, E. S., & Habitante, A. M. Q. B. (2002).

Glass transition of Nile tilapia myobrillar protein lms plasticized by

glycerin and water. Journal of Thermal Analysis and Calorimetry,

67(2), 499504.

Sobral, P. J. A., Ocuno, D., & Savastano, H., Jr. (1998). Preparo de

prote nas miobrilares de carne e elaboracao de biolmes com dois

tipos de acidos: propriedades mecanicas. Brazilian Journal of Food

Technology, 1(1/2), 4452.

Sothornvit, R., & Krochta, J. M. (2000a). Water vapor permeability and

solubility of lms from hydrolyzed whey protein. Journal of Food

Science, 65(4), 700703.

Sothornvit, R., & Krochta, J. M. (2000b). Oxygen permeability and

mechanical properties of lms from hydrolyzed whey protein. Journal

of Agricultural and Food Chemistry, 48, 39133916.

Sothornvit, R., & Krochta, J. M. (2001). Plasticizer effect on mechanical

properties of b-lactoglobulin lms. Journal of Food Engineering, 50,

149155.

Souza, S. M. A., Sobral, P. J. A., & Menegalli, F. C (1997).

Desenvolvimento de lmes comest veis a` base de prote nas miobri-

lares extra das de carne bovina. Proceedings of Workshop sobre

Bipol meros, Pirassununga (SP) (pp. 102106).

Souza, S. M. A., Sobral, P. J. A., & Menegalli, F. C (1998). Glass transition

of a meat myobrilar protein based edible lm. Proceedings of

Workshop on Biopolymer Science, Montpellier, France (pp. 183188).

Tanaka, M., Iwata, K., Sanguandeekul, R., et al. (2001). Inuence of

plasticizers on the properties of edible lms prepared from sh water-

soluble proteins. Fisheries Sciences, 67(2), 346351.

Torres, J. A. (1994). Edible lms and coatings from proteins. In N. S.

Hettiarachchy, & G. R. Ziegler (Eds.), Protein Functionality in Food

Systems (pp. 467507). New York: Marcel Dekker.

Vachon, C., Yu, H.-L., Yefsah, R., Alain, R., St-Gelais, D., & Lacroix, M.

(2000). Mechanical and structural properties of milk protein edible

lms cross-linked by heating and g-irradiation. Journal of Agricultural

and Food Chemistry, 48, 32023209.

T.M. Paschoalick et al. / Food Hydrocolloids 17 (2003) 419427 427

Вам также может понравиться

- Detección de Etileno en La Cadena de Proveedores PDFДокумент21 страницаDetección de Etileno en La Cadena de Proveedores PDFPablo Emilio Rodriguez FonsecaОценок пока нет

- Designing W1OW2 Double Emulsions Stabilized by Proteinepolysaccharide PDFДокумент9 страницDesigning W1OW2 Double Emulsions Stabilized by Proteinepolysaccharide PDFPablo Emilio Rodriguez FonsecaОценок пока нет

- Arracacha Revision PDFДокумент98 страницArracacha Revision PDFPablo Emilio Rodriguez FonsecaОценок пока нет

- Efecto Pelletizado Sobre ProteinasДокумент18 страницEfecto Pelletizado Sobre ProteinasPablo Emilio Rodriguez FonsecaОценок пока нет

- A Method For The Measurement of The Oxygen Permeability of Edible FilmsДокумент9 страницA Method For The Measurement of The Oxygen Permeability of Edible FilmsEstefania Medina QuiñonezОценок пока нет

- Protein LivestogДокумент7 страницProtein LivestogPablo Emilio Rodriguez FonsecaОценок пока нет

- Antimicrobial Activity of Soy Edible Films Incorporated With Thyme and OreganoДокумент6 страницAntimicrobial Activity of Soy Edible Films Incorporated With Thyme and OreganoPablo Emilio Rodriguez FonsecaОценок пока нет

- Characterization of Sodium Caseinate Based Edible Films Incorporated With PDFДокумент10 страницCharacterization of Sodium Caseinate Based Edible Films Incorporated With PDFPablo Emilio Rodriguez FonsecaОценок пока нет

- Moisture Diffusivity and Shrinkage of Fruit and Cladode of PDFДокумент10 страницMoisture Diffusivity and Shrinkage of Fruit and Cladode of PDFPablo Emilio Rodriguez FonsecaОценок пока нет

- Taro en Ratas PDFДокумент7 страницTaro en Ratas PDFPablo Emilio Rodriguez FonsecaОценок пока нет

- Estrusion AlfalfaДокумент12 страницEstrusion AlfalfaPablo Emilio Rodriguez FonsecaОценок пока нет

- Antimicrobial Activity of Soy Edible Films Incorporated With Thyme and OreganoДокумент6 страницAntimicrobial Activity of Soy Edible Films Incorporated With Thyme and OreganoPablo Emilio Rodriguez FonsecaОценок пока нет

- Extrusion Sobre LipoxygenasaДокумент15 страницExtrusion Sobre LipoxygenasaPablo Emilio Rodriguez FonsecaОценок пока нет

- Influiencia de La Extrusion Sobre Compuestos BioactivosДокумент12 страницInfluiencia de La Extrusion Sobre Compuestos BioactivosPablo Emilio Rodriguez FonsecaОценок пока нет

- 2012 JMPR Summary Report F2Документ38 страниц2012 JMPR Summary Report F2Pablo Emilio Rodriguez FonsecaОценок пока нет

- Pesticidas QuEChERS VegetalesДокумент12 страницPesticidas QuEChERS VegetalesPablo Emilio Rodriguez FonsecaОценок пока нет

- Olive Oil Digestion and AbsorptionДокумент10 страницOlive Oil Digestion and AbsorptionPablo Emilio Rodriguez FonsecaОценок пока нет

- Antimicrobial Activity of Whey Protein Based Edible Films Incorporated With Oregano, Rosemary and Garlic Essential Oils 2006 Food Research InternationalДокумент6 страницAntimicrobial Activity of Whey Protein Based Edible Films Incorporated With Oregano, Rosemary and Garlic Essential Oils 2006 Food Research InternationalValeria ArroyoОценок пока нет

- Enzymatic Activity of Lipase in PostmetamorphicДокумент5 страницEnzymatic Activity of Lipase in PostmetamorphicPablo Emilio Rodriguez FonsecaОценок пока нет

- Characterization of Alkaline Lipase From Fusarium OxysporumДокумент5 страницCharacterization of Alkaline Lipase From Fusarium OxysporumPablo Emilio Rodriguez FonsecaОценок пока нет

- Enzymatic Transesterification of Palm StearinДокумент8 страницEnzymatic Transesterification of Palm StearinPablo Emilio Rodriguez FonsecaОценок пока нет

- Enzymatic Interesterification of Palm StearinДокумент6 страницEnzymatic Interesterification of Palm StearinPablo Emilio Rodriguez FonsecaОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Enzymatic interesterification of fats reviewДокумент11 страницEnzymatic interesterification of fats reviewPablo Emilio Rodriguez FonsecaОценок пока нет

- Efecto de La Extrusion Sobre Proteinas Del Suero de LecheДокумент15 страницEfecto de La Extrusion Sobre Proteinas Del Suero de LechePablo Emilio Rodriguez FonsecaОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Effects of Enzymatic Hydrolysis On Crude PalmДокумент15 страницEffects of Enzymatic Hydrolysis On Crude PalmPablo Emilio Rodriguez FonsecaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- ABSCESSДокумент35 страницABSCESSlax prajapatiОценок пока нет

- Nursing Plan of Care Concept Map - Immobility - Hip FractureДокумент2 страницыNursing Plan of Care Concept Map - Immobility - Hip Fracturedarhuynh67% (6)

- Lease Practice QuestionsДокумент4 страницыLease Practice QuestionsAbdul SamiОценок пока нет

- Supply Chain Management of VodafoneДокумент8 страницSupply Chain Management of VodafoneAnamika MisraОценок пока нет

- Use Acupressure to Conceive FasterДокумент15 страницUse Acupressure to Conceive Fastersale18100% (1)

- Đề cương ôn tập tiếng anh 9Документ28 страницĐề cương ôn tập tiếng anh 9Nguyễn HoaОценок пока нет

- A&P 2 - Digestive System Flashcards - QuizletДокумент1 страницаA&P 2 - Digestive System Flashcards - QuizletMunachande KanondoОценок пока нет

- WSO 2022 IB Working Conditions SurveyДокумент42 страницыWSO 2022 IB Working Conditions SurveyPhạm Hồng HuếОценок пока нет

- HierbasДокумент25 страницHierbasrincón de la iohОценок пока нет

- Chemical and Physical Properties of Refined Petroleum ProductsДокумент36 страницChemical and Physical Properties of Refined Petroleum Productskanakarao1Оценок пока нет

- RA8485 Animal Welfare Act (Carabao Slaughter)Документ2 страницыRA8485 Animal Welfare Act (Carabao Slaughter)Jazreth Gaile100% (1)

- Book 1Документ94 страницыBook 1JOHNОценок пока нет

- Operating Instructions: Katflow 100Документ52 страницыOperating Instructions: Katflow 100Nithin KannanОценок пока нет

- Perforamance Based AssessmentДокумент2 страницыPerforamance Based AssessmentJocelyn Acog Bisas MestizoОценок пока нет

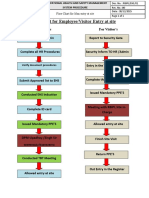

- fLOW CHART FOR WORKER'S ENTRYДокумент2 страницыfLOW CHART FOR WORKER'S ENTRYshamshad ahamedОценок пока нет

- Practical Examination Marking Guideline Grade 12 Physical Science 2019 PDFДокумент5 страницPractical Examination Marking Guideline Grade 12 Physical Science 2019 PDFWonder Bee Nzama100% (1)

- UMR Introduction 2023Документ110 страницUMR Introduction 2023tu reves mon filsОценок пока нет

- Parasitology Lecture Hosts, Symbiosis & TransmissionДокумент10 страницParasitology Lecture Hosts, Symbiosis & TransmissionPatricia Ann JoseОценок пока нет

- Tugas B InggrisДокумент9 страницTugas B InggrisDellyna AlmaОценок пока нет

- ERS M22 PC4 FerryДокумент2 страницыERS M22 PC4 FerryouakgoodОценок пока нет

- Marketing-Aspect 4Документ10 страницMarketing-Aspect 4Leiren RingorОценок пока нет

- Proper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle JДокумент15 страницProper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle Jjoannamhay ceraldeОценок пока нет

- Magnetic FieldДокумент19 страницMagnetic FieldNitinSrivastava100% (2)

- QRF HD785-7Документ2 страницыQRF HD785-7Ralf MaurerОценок пока нет

- The National Building Code of The PhilippinesДокумент390 страницThe National Building Code of The PhilippinesJohn Joseph EstebanОценок пока нет

- FinalsДокумент8 страницFinalsDumpОценок пока нет

- Mabuhay Wedding Package2006Документ3 страницыMabuhay Wedding Package2006Darwin Dionisio ClementeОценок пока нет

- Spec BoilerДокумент9 страницSpec BoilerAchmad MakmuriОценок пока нет

- ME JBP 70A Pen Dissolved Oxygen Meter PDFДокумент1 страницаME JBP 70A Pen Dissolved Oxygen Meter PDFpiknikmonsterОценок пока нет

- Analisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiДокумент10 страницAnalisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiSYIFA ABIYU SAGITA 08211840000099Оценок пока нет