Академический Документы

Профессиональный Документы

Культура Документы

WM c2002m 1ylyd

Загружено:

Janio MimaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WM c2002m 1ylyd

Загружено:

Janio MimaАвторское право:

Доступные форматы

WM-C2002M-1YLYd

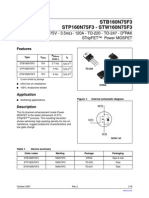

STD

6

WM-C2002M-1YLYd 2/24

History of Version

Version

Chap. Contents Date Note

d1 - New Revision 20.Aug,1996 SPEC.

d2 -

Change as follow by: Wintek

1.Modify SPEC. Style

18.Oct,1996

SPEC. &

Sample

d3 -

Change as follow by: Wintek

1.Modify SPEC. Style

30.Nov.1996

SPEC.

& Sample

d4

Contents

1.1

1.2

1.5

Change as follow by: Wintek

1.Modify IC: KS0066UST7066U-0A

07.Nov200

SPEC.

& Sample

d5

Contents

1.1

1.2

1.5

Change as follow by: Wintek

1.Modify IC: ST7066-0AST7066U-0A

12.Jul.2001

SPEC.

& Sample

d6 -

Change as follow by: Wintek

1.Modify SPEC. Style

16.Oct.2001

SPEC. &

Sample

WM-C2002M-1YLYd 3/24

Contents Page

(1) Electronic Units ............................................................................................... 4

1.1 Absolute Maximum Ratings ........................................................................ 4

1.3 Interface Pin Function................................................................................. 5

1.4 Power Supply for LCD Module ................................................................... 6

1.5 Block Diagram with Display RAM Address

and Initialization Table................................................. 7

1.6 CGROM Map.............................................................................................. 8

(2) Electro-optical Units........................................................................................ 9

2.1 Electro-optical Characteristics .................................................................... 9

2.2 Optical Definitions....................................................................................... 9

(3) Mechanical Units ........................................................................................... 11

3.1 Mechanical Specification .......................................................................... 11

3.2 Mechanical Diagram................................................................................. 11

3.3 Back-light Specification............................................................................. 13

3.4 Packing Method........................................................................................ 14

(4) Quality Units .................................................................................................. 15

4.1 Specification of Quality Assurance............................................................ 15

4.2 Standard Specification for Reliability......................................................... 22

4.3 Precautions in Use of LCM....................................................................... 24

Reference Data :

Sitronix ST7066U-0A&ST7063 Specifications

WM-C2002M-1YLYd 4/24

(1) Electronic Units

1.1 Absolute Maximum Ratings

1.2 Electrical Characteristics(Ta = 25

CV

DD

=4.5 V-5.5V

ITEM SYMBOL CONDITION MIN. TYP. MAX. UNIT

SUPPLY VOLTAGE FOR LOGIC V

DD

-V

SS

Ta = 25

C 4.75 5.0 5.25 V

SUPPLY VOLTAGE FOR LCD

V

DD

V

0

(V

LCD

)

Ta = 25

C - 4.5 - V

INPUT HIGH VOL

V

IH

Ta = 25

C 0.7V

DD

- V

DD

V

INPUT LOW VOL

V

IL

Ta = 25

C - - 0.2V

DD

V

OUTPUT HIGH VOL

V

OH

Ta = 25

C 0.9V

DD

- V

DD

V

OUTPUT LOW VOL.

V

OL

Ta = 25

C - - 0.1V

DD

V

SUPPLY CURRENT FOR LOGIC *IDD V

DD

=5V - 2.0 - mA

USED IC ST7066U-0A&ST7063

*I

DD

Measurement condition is for all pixels on display

V

DD

V

0

V

DD

-V

SS

0

-20

-0.3

-0.3

-0.3

-

-

-

-

-

+7.0

10

+50

+70

V

DD

+0.3

Be sure that you are grounded when handing LCM.

WM-C2002M-1YLYd 5/24

1.3 Interface Pin Function

JP1:

NO SYMBOL I / O FUNCTION

1.

VSS P POWER SUPPLY FOR LOGIC ( 0V )

2.

VDD P POWER SUPPLY FOR LOGIC ( +5V 5% )

3.

VO P CONTRAST ADJUSTMENT

4.

RS I REGISTER SELECT SIGNAL

5.

R/W I READ / WRITE SELECTION

6.

E I ENABLE SIGNAL

7.

DB0 I/O

8.

DB1 I/O

9.

DB2 I/O

10.

DB3 I/O

11.

DB4 I/O

12.

DB5 I/O

13.

DB6 I/O

14.

DB7 I/O

DATA BUS

15.

N.C. - NO CONNECTION

16.

N.C. - NO CONNECTION

JP2:

1. LED+ P POWER SUPPLY FOR LED (+4.2V)

2. LEDA - CONNECTED TO LED

3. LEDK - CONNECTED TO LED

4. LED- P POWER SUPPLY FOR LED (0V)

WM-C2002M-1YLYd 6/24

1.4 Power Supply for LCD Module

1.Signal Supply Voltage Types

LCM

VDD

V0

VSS

VR

VDD

VDD-VO

V

DD

-V

O

LCD Driving Voltage

VR=10k~20k

2. Dual Supply Voltage Types

VDD

VSS

VO

LCM

VDD

VEE

VR

VDD-VO

V

DD

-V

O

LCD Driving Voltage

VR=10k~20k

WM-C2002M-1YLYd 7/24

1.5 Block Diagram with Display RAM Address and Initialization Table

00 01

02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F 10 11 12 13

40

41 42 43 44 45 46 47 48 49 4A 4B 4C 4D 4E 4F 50 51 52 53

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

LCD PANEL (100*16DOTS)

SEG1 SEG40

SEG40 SEG1 SEG41

SEG41 SEG100

SEG100

VSSVDD V0 RS R/W E DB0-DB7

COM1

COM8

COM1

COM8

COM9

COM9

COM16

COM16

22(PAD)

63(PAD)

54(PAD)

47(PAD)

62(PAD)

55(PAD)

GND

SHL1SHL2GND

CL1

CL2

CL2

CL1

M

M

D

DL1

ST7066U-0A

ST7063

79(PAD) 19(PAD)

LED+

LED-

L

E

D

Relation between DD RAM addresses and positions on the are

shown above.

The DD RAM address(ADD) is set in the address counter(AC)

and is represented in hexadecimal.

Initialization Table:

Instruction Setting Command Description

Function Set

00111***

Duty=1/16,8-bit mode,2-line display,

5x8 dots format display mode

WM-C2002M-1YLYd 8/24

1.6 CGROM Map

WM-C2002M-1YLYd 9/24

(2) Electro-optical Units

2.1 Electro-optical Characteristics

ITEM SYMBOL CONDITION MIN. TYP. MAX. UNIT

VIEW ANGLE (V) CR2 -40 - +40 deg.

VIEW ANGLE (H) CR2 -40 - +40 deg.

CONTRAST RATIO CR Ta=25 - 5 - -

RESPONSE TIME tr Ta=25 - 200 300 ms

RESPONSE TIME td Ta=25 - 200 300 ms

Ta=0 - 4.8 -

Ta=25 - 4.5 -

OPERATING VOLTAGE

FOR LCD

V

LCD

Ta=50 - 4.2 -

V

DUTY 1/16

DRIVE METHOD

BIAS 1/5

LCD TYPE STN-Yellow (Positive / Transflective )

VIEWING DIRECTION 6 OCLOCK

2.2 Optical Definitions

Response Time

Rise Time

Decay Time (fall time tf)

90%

Selected

Condition

10%

td tr

100%

Brightness

Nonselected

Condition

Nonselected

Condition

WM-C2002M-1YLYd 10/24

3:00 9:00

12:00

6:00

Eye

View Angle

y' (front)

x (right)

y (back)

(left) x'

View Direction

Driving Voltage

Brightness curve of

nonselected segment

Brightness cure of selected segment

Brightness

B

B

1

2

Contrast ration =

Brightness at nonselected segment (B2)

Brightness at selected segment (B1)

Contrast ration (CR)

Perpendicular line (=90)

WM-C2002M-1YLYd 11/24

(3) Mechanical Units

3.1 Mechanical Specification

ITEM STANDARD VALUE UNIT

NUMBER OF DOTS

20 CHARACTERS 2 LINES

-

CHARACTER FORMAT

5 8 DOTS

-

MODULE DIMENSION 116.0 (W)

37.0 (H)

14.5 MAX.(T) mm

VIEW AREA 84.0 (W)

18.6 (H) mm

ACTIVE AREA 73.5 (W)

11.5 (H) mm

CHARACTER SIZE 3.20 (W)

5.55 (H) mm

CHARACTER PITCH 3.70 (W)

5.95 (H) mm

DOT SIZE 0.60 (W)

0.65 (H) mm

DOT PITCH 0.65 (W)

0.70 (H) mm

APPROX. WEIGHT 54 g

BACK LIGHT LED (YELLOW-GREEN)

WM-C2002M-1YLYd 12/24

3.2 Mechanical Diagram

WM-C2002M-1YLYd 13/24

3.3 Back-light Specification

1. LED Backlight Styles (Bottom Type):

The LED chips are distributed over the whole light area of the illumination unit, which gives the most

uniform light.

2. Data About LED Backlight :

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST

CONDITION

NOTE

Supply Current I - 750 1050 mA V = 4.2 V -

Supply Voltage V - 4.2 4.6 V - -

Reverse Voltage V

R

- - 10 V - -

Luminous Intensity I

V

60 - -

cd

m

2

V = 4.2 V 1,2

Luminous Intensity

Uniformity

- - - 50 % V = 4.2 V 3

Peak Emission Wavelength

P

- 572 - nm V = 4.2 V -

Life Time - - 20000 - Hr.

V 4.6 V

-

Color Yellow - Green

NOTE

3.Luminous Intensity Tolerance =

MAX - MIN

MAX

100 %

2. Average Luminous Intensity Of P1 - P5

1. Backlight Only

3 : MEASURED METHOD :

P 1 P 2 P 3 P 4 P 5

( Effective spatial Distribution )

Hole Diameter

;1 to 5 per Position Measured Luminous Intensity

Uniformity=

WM-C2002M-1YLYd 14/24

x no per column

x quantity per tray

x quantity per box (3) Total LCM quantity in carton : no of boxes

Remark

Total Weight

Product Box

Packaging Material : (per carton)

Packaging Specifications and Quantity :

(1) LCM quantity per tray : no per row

(2) LCM quantity per box : no of trays

2.

1.

5

NO

2

3

4

1

Carton

Tray

LCM Module

Item

C61

PETA

Model

475*345*389

320*219*70

Dimensions (mm)

=

Kg 5%

=

=

0.131

1.208

Unit Weight (Kg) Quantity

1

10

Package Bag C5 467*321*0.08 0.023 10

6

Rotate tray 180 degrees and place on top of stack.

Check the tray stack using Fig. B.

A

Tray 4

Tray 2

Tray 3

Tray 1

+

=

Tray stacking

A

B

Put products into the tray

Detail B

Use empty tray

The tape to seal carton

Carton label

Use package bag

Scotch tape

QC inspection label

V146

WM-C2002M-1YLYd

C01

116.0*37.0

320*217

0.054

0.06

240

40

17.9

2

8

24

4

3

10

8

24

240

3.

3

2

.

0

105.0

Purchase Order No:

Wintek Part No:

Q'ty:

(According to shipping)

(According to each order)

WM-C2002M-1YLYd

(1) QC Inspection Label

90.0

Label Specifications :

(2) Carton Label

MODEL:

LOT NO:

QC CHECK:

DATE:

Label Color----White

4

2

.

4

Label Color----Green

3.4 Packing Method

Kg5%

WM-C2002M-1YLYd 15/24

(4) Quality Units

4.1 Specification of Quality Assurance

WM-C2002M-1YLYd 16/24

WM-C2002M-1YLYd 17/24

6. Inspection specification

WM-C2002M-1YLYd 18/24

WM-C2002M-1YLYd 19/24

WM-C2002M-1YLYd 20/24

WM-C2002M-1YLYd 21/24

WM-C2002M-1YLYd 22/24

4.2 Standard Specification for Reliability

50

0

70

-20

40 90

WM-C2002M-1YLYd 23/24

WM-C2002M-1YLYd 24/24

4.3 Precautions in Use of LCM

Вам также может понравиться

- LCDD Data Bc1602aДокумент34 страницыLCDD Data Bc1602aAnkit AgrawalОценок пока нет

- 5V Powered Multi-Channel RS-232 Drivers and Receivers: Feature SummaryДокумент19 страниц5V Powered Multi-Channel RS-232 Drivers and Receivers: Feature SummaryJosé PerezОценок пока нет

- BC1602K Series VER01Документ28 страницBC1602K Series VER01Jeremiah DayОценок пока нет

- 1-Mbit (128 K × 8) Static RAM: Features Functional DescriptionДокумент18 страниц1-Mbit (128 K × 8) Static RAM: Features Functional DescriptionLeslie StewartОценок пока нет

- JHD639Документ23 страницыJHD639kaifansariОценок пока нет

- Dmf5005n Coe DDN Eng 3Документ16 страницDmf5005n Coe DDN Eng 3roozbehxoxОценок пока нет

- Approval Sheet: LCD ModuleДокумент24 страницыApproval Sheet: LCD ModuleJoaquinОценок пока нет

- Chimei N173O6 L02Документ29 страницChimei N173O6 L02alelujaОценок пока нет

- P-Tec Corporation: PTFT320240CT-3.5-A03Full SpecДокумент20 страницP-Tec Corporation: PTFT320240CT-3.5-A03Full Specapi-62031994Оценок пока нет

- Samsung Lta320w2-L03 LCD Panel DatasheetДокумент25 страницSamsung Lta320w2-L03 LCD Panel DatasheetChanChongОценок пока нет

- mc14518bcp en PDFДокумент8 страницmc14518bcp en PDFdellcoОценок пока нет

- 2.7V Dual Channel 12-Bit A/D Converter With SPI Serial InterfaceДокумент34 страницы2.7V Dual Channel 12-Bit A/D Converter With SPI Serial InterfaceManjunatha Ac100% (1)

- MCP 3201Документ28 страницMCP 3201Nacer MezghicheОценок пока нет

- EW162G0YMYДокумент11 страницEW162G0YMYdemodlОценок пока нет

- L1710S (L1710sm-Al - R, Au - R, Ad - R, Ag - R) CL-61Документ18 страницL1710S (L1710sm-Al - R, Au - R, Ad - R, Ag - R) CL-61Deki PericОценок пока нет

- Mgd1602b FL YbsДокумент10 страницMgd1602b FL YbsAnonymous zLJm1QiPОценок пока нет

- Displaytech 162AДокумент17 страницDisplaytech 162AjanepriceОценок пока нет

- Tm162vca6 SpecДокумент23 страницыTm162vca6 SpecMarius FerdyОценок пока нет

- 6-Line EMI Filter&ESD For SD Card UQFN16Документ12 страниц6-Line EMI Filter&ESD For SD Card UQFN16conti51Оценок пока нет

- Features: Single Bilateral SwitchДокумент15 страницFeatures: Single Bilateral SwitchGaryTechОценок пока нет

- Stx30N65M5: N-Channel 650 V, 0.130, 21 A, Mdmesh™ V Power Mosfet D Pak, I Pak, To-220Fp, To-220, To-247Документ15 страницStx30N65M5: N-Channel 650 V, 0.130, 21 A, Mdmesh™ V Power Mosfet D Pak, I Pak, To-220Fp, To-220, To-247Oscar PortelaОценок пока нет

- MCP3202 PDFДокумент28 страницMCP3202 PDFblue11111Оценок пока нет

- Mgd2004d FL YbsДокумент10 страницMgd2004d FL YbsEverton NascimentoОценок пока нет

- LTA320AP08 SamsungДокумент27 страницLTA320AP08 SamsungJuan HerreraОценок пока нет

- DispleyДокумент20 страницDispleyRoman KelharОценок пока нет

- Display LCD 16x2 PDFДокумент10 страницDisplay LCD 16x2 PDFDavid_MacielОценок пока нет

- t315xw02 VFДокумент29 страницt315xw02 VFIonescu CristinaОценок пока нет

- Auo t370hw02 v1 Lcdpanel DatasheetДокумент28 страницAuo t370hw02 v1 Lcdpanel DatasheetIonescu CristinaОценок пока нет

- VC1622 SeriesДокумент30 страницVC1622 SeriesShakti SinghОценок пока нет

- Datasheet LCD 128x64 ATM12864DДокумент21 страницаDatasheet LCD 128x64 ATM12864DRafael MendozaОценок пока нет

- LCD Module Specification: First Edition Production Div. Approved byДокумент18 страницLCD Module Specification: First Edition Production Div. Approved bySanty JijonОценок пока нет

- LCD DatasheetДокумент17 страницLCD DatasheetJuan SánchezОценок пока нет

- LCM1602A DatasheetДокумент21 страницаLCM1602A DatasheetjohnluzardoОценок пока нет

- Acer S190WL S196WL 2chip 20120602 A00 Service ManualДокумент66 страницAcer S190WL S196WL 2chip 20120602 A00 Service ManualDoru RazvanОценок пока нет

- Diagram or Service ManualДокумент70 страницDiagram or Service ManualWasantha MunasinghaОценок пока нет

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetДокумент16 страницStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyОценок пока нет

- MC 14521Документ12 страницMC 14521rrebollarОценок пока нет

- Tda 9556Документ16 страницTda 9556Miloud ChouguiОценок пока нет

- LTN150XB L03Документ25 страницLTN150XB L03bertzukas100% (1)

- N156B6 L08Документ31 страницаN156B6 L08JozefОценок пока нет

- LCD Panel M236MWF1-R0Документ29 страницLCD Panel M236MWF1-R0ВМалиновОценок пока нет

- MTC C162dply 2n v10 LCDДокумент17 страницMTC C162dply 2n v10 LCDashwin_mcseОценок пока нет

- Emerging Display: - CAS-10042:NOV.18,1999Документ12 страницEmerging Display: - CAS-10042:NOV.18,1999Rahul JoeОценок пока нет

- Everbouquet International Co., LTD.: NO.: FOR Messrs.Документ9 страницEverbouquet International Co., LTD.: NO.: FOR Messrs.Fabio Fix CassaràОценок пока нет

- Lc420eud Sca2Документ40 страницLc420eud Sca2Masimba1Оценок пока нет

- FOR Approval Specification: 47.0" Wuxga TFT LCD TitleДокумент28 страницFOR Approval Specification: 47.0" Wuxga TFT LCD TitleIonescu CristinaОценок пока нет

- Cas Lta320hm01-Ga FHD 20100316Документ29 страницCas Lta320hm01-Ga FHD 20100316Terence TseОценок пока нет

- ArduinoДокумент15 страницArduinoAlvarez TomasОценок пока нет

- MC75T01BДокумент20 страницMC75T01BteimoОценок пока нет

- LG - Philips Lc420w02-Sla1 Lcdpanel DatasheetДокумент28 страницLG - Philips Lc420w02-Sla1 Lcdpanel DatasheetJeffrey EvansОценок пока нет

- sc7001q Ay 961Документ18 страницsc7001q Ay 961r2c1Оценок пока нет

- rg12864b Biw VДокумент23 страницыrg12864b Biw VDanailaDragosОценок пока нет

- Graphic Display AGM-12864A-801Документ15 страницGraphic Display AGM-12864A-801Anonymous nMZN9dJvaZОценок пока нет

- LCD Grafico Wg12864aДокумент25 страницLCD Grafico Wg12864aseykarimОценок пока нет

- Til311 DatasheetДокумент7 страницTil311 DatasheetgetmicrosОценок пока нет

- FOR Approval Specification: 47.0" Wuxga TFT LCD TitleДокумент44 страницыFOR Approval Specification: 47.0" Wuxga TFT LCD TitlesujithamohanОценок пока нет

- CD4511Документ13 страницCD4511mario2000Оценок пока нет

- OpAmp - MCP6244Документ38 страницOpAmp - MCP6244Ludwig SchmidtОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Demand Elasticity of LCD Television MarketДокумент10 страницDemand Elasticity of LCD Television Marketpmorgan76Оценок пока нет

- Smart Coffee Vending Machine Using RFID: Rahul Jadhv, Mrunali Jejurkar, Pranita Kave & Prof. H.P. ChaudhariДокумент8 страницSmart Coffee Vending Machine Using RFID: Rahul Jadhv, Mrunali Jejurkar, Pranita Kave & Prof. H.P. Chaudharisonny septiansyahОценок пока нет

- LCD InterfacingДокумент5 страницLCD InterfacingRokibul hasanОценок пока нет

- Rivertrace Engineering Smart Cell Bilge ManualДокумент29 страницRivertrace Engineering Smart Cell Bilge ManualTaufiq Omar Hasan100% (1)

- 04 STS Module 1 Lesson 2 Historical AntecedentsДокумент28 страниц04 STS Module 1 Lesson 2 Historical AntecedentsBET-MECH1D John Carlo LagunsingОценок пока нет

- Micro LED (Yole)Документ36 страницMicro LED (Yole)pebble527100% (2)

- HT1621 An2343Документ9 страницHT1621 An2343rkj111191Оценок пока нет

- XP30-90 Hardware ManualДокумент88 страницXP30-90 Hardware ManualNisal AmarasingheОценок пока нет

- 9619 LG 42LK520 42LK520-UA Chassis LA01U Televisor LCD Manual de Entrenamiento+diagramasДокумент119 страниц9619 LG 42LK520 42LK520-UA Chassis LA01U Televisor LCD Manual de Entrenamiento+diagramasJose RioboОценок пока нет

- Automated Medicine Dispenser in Pharmacy: August 2019Документ7 страницAutomated Medicine Dispenser in Pharmacy: August 2019marjoriegloduve02Оценок пока нет

- BRC1E61 ManualДокумент56 страницBRC1E61 Manualbookslover1Оценок пока нет

- LG 42LC46 Ld73a (SM)Документ47 страницLG 42LC46 Ld73a (SM)Jose Maria Cambero100% (1)

- Usn Series PDFДокумент6 страницUsn Series PDFMarco Antonio Peña PlataОценок пока нет

- Physiologic Monitoring Systems, Acute Care Neonatal ECG Monitors Monitors, Central Station - 060421011312Документ12 страницPhysiologic Monitoring Systems, Acute Care Neonatal ECG Monitors Monitors, Central Station - 060421011312Katlheen KrautzОценок пока нет

- Electronic Blood Pressure Monitor Model: ZK-W863: Models 100 300 Units 300-1000units 1000unitsДокумент5 страницElectronic Blood Pressure Monitor Model: ZK-W863: Models 100 300 Units 300-1000units 1000units许江鹏Оценок пока нет

- B170PW06 V.2Документ33 страницыB170PW06 V.2barlow00Оценок пока нет

- LED ScreensДокумент2 страницыLED ScreensA WОценок пока нет

- G9Fj 79A5Bi5@: Tvipslgt - S (PTLKPHGZ Z (LTG P (Ogg I PKLGKPNP (HSG (V - Jogzjylluggsjkgtvup (VyДокумент52 страницыG9Fj 79A5Bi5@: Tvipslgt - S (PTLKPHGZ Z (LTG P (Ogg I PKLGKPNP (HSG (V - Jogzjylluggsjkgtvup (VyСергей БеловОценок пока нет

- KT-6200 V2.0 Spare Parts List V5.0eДокумент8 страницKT-6200 V2.0 Spare Parts List V5.0eChristian PintoОценок пока нет

- Toshiba 32a3000p Ver.2.00 PDFДокумент180 страницToshiba 32a3000p Ver.2.00 PDFgiacmochapiОценок пока нет

- Aoc Schematic Diagram MonitorДокумент61 страницаAoc Schematic Diagram MonitorNita AntonioОценок пока нет

- Magellan™: Router Control PanelsДокумент6 страницMagellan™: Router Control PanelsJose MedinaОценок пока нет

- LG Swot PDFДокумент8 страницLG Swot PDFKeshav AnandОценок пока нет

- Magelis XBTGT User ManualДокумент190 страницMagelis XBTGT User ManualLouis ChenОценок пока нет

- 32pht400160 43pft400160 Ver.2Документ69 страниц32pht400160 43pft400160 Ver.2Serp1972Оценок пока нет

- LCD Module Mcc162a4 5Документ17 страницLCD Module Mcc162a4 5alfredo de la hozОценок пока нет

- Philips LCD Monitor 220VW8FB Service ManualДокумент71 страницаPhilips LCD Monitor 220VW8FB Service Manualpagy snv67% (3)

- It Era Final ModuleДокумент103 страницыIt Era Final ModuleLeonso Visto JrОценок пока нет

- Adafruit GFX Graphics LibraryДокумент20 страницAdafruit GFX Graphics LibraryfelixdobrescuОценок пока нет

- 3015577Документ24 страницы3015577Halit YalçınkayaОценок пока нет