Академический Документы

Профессиональный Документы

Культура Документы

IC-ON-LINE - CN dm0365r 44840

Загружено:

MoscandoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

IC-ON-LINE - CN dm0365r 44840

Загружено:

MoscandoАвторское право:

Доступные форматы

2005 Fairchild Semiconductor Corporation

www.fairchildsemi.com

Rev.1.0.8

FPS

TM

is a trademark of Fairchild Semiconductor Corporation.

Features

Internal Avalanche Rugged Sense FET

Consumes only 0.65W at 240VAC & 0.3W load with

Advanced Burst-Mode Operation

Frequency Modulation for EMI Reduction

Precision Fixed Operating Frequency

Internal Start-up Circuit

Pulse-by-Pulse Current Limiting

Abnormal Over Current Protection (AOCP)

Over Voltage Protection (OVP)

Over Load Protection (OLP)

Internal Thermal Shutdown Function (TSD)

Auto-Restart Mode

Under Voltage Lockout (UVLO)

Low Operating Current (3mA)

Adjustable Peak Current Limit

Built-in Soft Start

Applications

SMPS for VCR, SVR, STB, DVD & DVCD Player

SMPS for Printer, Facsimile & Scanner

Adapter for Camcorder

Related Application Notes

AN-4137, 4141, 4147(Flyback) / AN-4134(Forward)

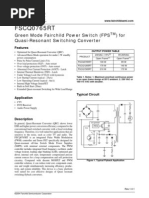

Description

Each product in the FSDx0365RN (x for L, M) family consists

of an integrated Pulse Width Modulator (PWM) and Sense

FET, and is specifically designed for high performance off-line

Switch Mode Power Supplies (SMPS) with minimal external

components. Both devices are integrated high voltage power

switching regulators which combine an avalanche rugged

Sense FET with a current mode PWM control block. The inte-

grated PWM controller features include: a fixed oscillator with

frequency modulation for reduced EMI, Under Voltage Lock

Out (UVLO) protection, Leading Edge Blanking (LEB), an

optimized gate turn-on/turn-off driver, Thermal Shut Down

(TSD) protection, Abnormal Over Current Protection (AOCP)

and temperature compensated precision current sources for

loop compensation and fault protection circuitry. When com-

pared to a discrete MOSFET and controller or RCC switching

converter solution, the FSDx0365RN devices reduce total

component count, design size, weight while increasing effi-

ciency, productivity and system reliability. Both devices pro-

vide a basic platform that is well suited for the design of cost-

effective flyback converters.

Notes:

1. Typical continuous power in a non-ventilated enclosed

adapter with sufficient drain pattern as a heat sinker, at

50C ambient.

2. Maximum practical continuous power in an open frame

design with sufficient drain pattern as a heat sinker, at 50C

ambient.

3. 230 VAC or 100/115 VAC with doubler.

Typical Circuit

OUTPUT POWER TABLE

PRODUCT

230VAC 15%

(3)

85-265VAC

Adapt-

er

(1)

Open

Frame

(2)

Adapt-

er

(1)

Open

Frame

(2)

FSDL321 11W 17W 8W 12W

FSDH321 11W 17W 8W 12W

FSDL0165RN 13W 23W 11W 17W

FSDM0265RN 16W 27W 13W 20W

FSDH0265RN 16W 27W 13W 20W

FSDL0365RN 19W 30W 16W 24W

FSDM0365RN 19W 30W 16W 24W

FSDL321L 11W 17W 8W 12W

FSDH321L 11W 17W 8W 12W

FSDL0165RL 13W 23W 11W 17W

FSDM0265RL 16W 27W 13W 20W

FSDH0265RL 16W 27W 13W 20W

FSDL0365RL 19W 30W 16W 24W

FSDM0365RL 19W 30W 16W 24W

Drain

Source

Vstr

Vfb Vcc

PWM

AC

IN

DC

OUT

Ipk

FSDL0365RN, FSDM0365RN

Green Mode Fairchild Power Switch (FPS

TM

)

www.DataSheet4U.com

FSDL0365RN, FSDM0365RN

2

Figure 1. Typical Flyback Application

Internal Block Diagram

Figure 2. Functional Block Diagram of FSDx0365RN

8V/12V

2 6,7,8

1

3

Vref

Internal

Bias

S

Q

Q

R

OSC

Vcc Vcc

I

DELAY

I

FB

V

SD

TSD

Vovp

Vcc

Vocp

S

Q

Q

R

R

2.5R

Vcc good

Vcc Drain

Vfb

GND

AOCP

Gate

driver

5

Vstr

I

CH

Vcc good

VBURL/VBURH

LEB

PWM

+

-

4

Ipk

Freq.

Modulation

VBURH

Vcc

I

BUR(pk)

Burst

Normal

Soft

Start

FSDL0365RN, FSDM0365RN

3

Pin Definitions

Pin Configuration

Figure 3. Pin Configuration (Top View)

Pin Number Pin Name Pin Function Description

1 GND Sense FET source terminal on primary side and internal control ground.

2 Vcc

Positive supply voltage input. Although connected to an auxiliary transform-

er winding, current is supplied from pin 5 (Vstr) via an internal switch during

startup (see Internal Block Diagram section). It is not until Vcc reaches the

UVLO upper threshold (12V) that the internal start-up switch opens and de-

vice power is supplied via the auxiliary transformer winding.

3 Vfb

The feedback voltage pin is the non-inverting input to the PWM comparator.

It has a 0.9mA current source connected internally while a capacitor and op-

tocoupler are typically connected externally. A feedback voltage of 6V trig-

gers over load protection (OLP). There is a time delay while charging

external capacitor Cfb from 3V to 6V using an internal 5uA current source.

This time delay prevents false triggering under transient conditions, but still

allows the protection mechanism to operate under true overload conditions.

4 Ipk

This pin adjusts the peak current limit of the Sense FET. The feedback

0.9mA current source is diverted to the parallel combination of an internal

2.8k resistor and any external resistor to GND on this pin to determine the

peak current limit. If this pin is tied to Vcc or left floating, the typical peak cur-

rent limit will be 2.15A.

5 Vstr

This pin connects directly to the rectified AC line voltage source. At start up

the internal switch supplies internal bias and charges an external storage

capacitor placed between the Vcc pin and ground. Once the Vcc reaches

12V, the internal switch is opened.

6, 7, 8 Drain

The drain pins are designed to connect directly to the primary lead of the

transformer and are capable of switching a maximum of 650V. Minimizing

the length of the trace connecting these pins to the transformer will decrease

leakage inductance.

1

2

3

4 5

6

7

8 GND

Vcc

Vfb

Ipk Vstr

Drain

Drain

Drain

8DIP

8LSOP

FSDL0365RN, FSDM0365RN

4

Absolute Maximum Ratings

(Ta=25C, unless otherwise specified)

Note:

1. Repetitive rating: Pulse width is limited by maximum junction temperature

2. L = 51mH, starting Tj = 25C

Thermal Impedance

(Ta=25C, unless otherwise specified)

Note:

1. Free standing with no heatsink; Without copper clad.

/ Measurement Condition : Just before junction temperature TJ enters into OTP.

2. Measured on the DRAIN pin close to plastic interface.

3. Measured on the PKG top surface.

- all items are tested with the standards JESD 51-2 and 51-10 (DIP).

Characteristic Symbol Value Unit

Drain Pin Voltage VDRAIN 650 V

Vstr Pin Voltage VSTR 650 V

Drain Current Pulsed

(1)

IDM 12.0 A

Single Pulsed Avalanche Energy

(2)

EAS 127 mJ

Supply Voltage VCC 20 V

Feedback Voltage Range VFB -0.3 to VCC V

Total Power Dissipation PD 1.56 W

Operating Junction Temperature TJ Internally limited C

Operating Ambient Temperature TA -25 to +85 C

Storage Temperature TSTG -55 to +150 C

Parameter Symbol Value Unit

8DIP

Junction-to-Ambient Thermal

(1)

JA 80.01 C/W

Junction-to-Case Thermal

(2)

JC 18.85 C/W

Junction-to-Top Thermal

(3)

JT 33.70 C/W

FSDL0365RN, FSDM0365RN

5

Electrical Characteristics

(Ta = 25C unless otherwise specified)

Note:

1. Pulse test: Pulse width 300us, duty 2%

2. These parameters, although guaranteed, are tested in EDS (wafer test) process

3. These parameters, although guaranteed, are not 100% tested in production

Parameter Symbol Condition Min. Typ. Max. Unit

SENSE FET SECTION

Zero-Gate-Voltage Drain Current IDSS

VDS=650V, VGS=0V - - 50 A

VDS=520V, VGS=0V,

TC=125C

- - 200 A

Drain-Source On-State Resistance

(1)

RDS(ON) VGS=10V, ID=0.5A - 3.6 4.5

Input Capacitance CISS

VGS=0V, VDS=25V,

f=1MHz

- 315 - pF

Output Capacitance COSS - 47 -

pF

Reverse Transfer Capacitance CRSS - 9 -

pF

Turn-On Delay Time td(on)

VDS=325V, ID=1.0A

- 11.2 - ns

Rise Time tr - 34 - ns

Turn-Off Delay Time td(off) - 28.2 - ns

Fall Time tf - 32 - ns

CONTROL SECTION

Switching Frequency fOSC

FSDM0365R

61 67 73 KHz

Switching Frequency Modulation fMOD 1.5 2.0 2.5 KHz

Switching Frequency fOSC

FSDL0365R

45 50 55 KHz

Switching Frequency Modulation fMOD 1.0 1.5 2.0 KHz

Switching Frequency Variation

(2)

fOSC -25C Ta 85C - 5 10 %

Maximum Duty Cycle DMAX 71 77 83 %

Minimum Duty Cycle DMIN 0 0 0 %

UVLO Threshold Voltage

VSTART VFB=GND 11 12 13 V

VSTOP VFB=GND 7 8 9 V

Feedback Source Current IFB VFB=GND 0.7 0.9 1.1 mA

Internal Soft Start Time tS/S VFB=4V 10 15 20 ms

BURST MODE SECTION

Burst Mode Voltage

VBURH - 0.4 0.5 0.6 V

VBURL - 0.25 0.35 0.45 V

PROTECTION SECTION

Peak Current Limit ILIM Max. inductor current 1.89 2.15 2.41 A

Current Limit Delay Time

(3)

tCLD - 500 - ns

Thermal Shutdown Temperature TSD - 125 140 - C

Shutdown Feedback Voltage VSD 5.5 6.0 6.5 V

Over Voltage Protection VOVP 18 19 - V

Shutdown Delay Current IDELAY VFB=4V 3.5 5.0 6.5 A

Leading Edge Blanking Time tLEB 200 - - ns

TOTAL DEVICE SECTION

Operating Supply Current (control part only) IOP VCC=14V 1 3 5 mA

Start-Up Charging Current ICH VCC=0V 0.7 0.85 1.0 mA

Vstr Supply Voltage VSTR VCC=0V 35 - - V

FSDL0365RN, FSDM0365RN

6

Comparison Between KA5x0365RN and FSDx0365RN

Function KA5x0365RN FSDx0365RN FSDx0365RN Advantages

Soft-Start not applicable 15ms Gradually increasing current limit

during soft-start further reduces peak

current and voltage stresses

Eliminates external components used

for soft-start in most applications

Reduces or eliminates output

overshoot

External Current Limit not applicable Programmable of

default current limit

Smaller transformer

Allows power limiting (constant over-

load power)

Allows use of larger device for lower

losses and higher efficiency.

Frequency Modulation not applicable 2.0KHz @67KHz

1.5KHz @50KHz

Reduces conducted EMI

Burst Mode Operation not applicable Built into controller Improves light load efficiency

Reduces power consumption at no-

load

Transformer audible noise reduction

Drain Creepage at

Package

1.02mm 7.62mm Greater immunity to arcing provoked

by dust, debris and other contami-

nants

FSDL0365RN, FSDM0365RN

7

Typical Performance Characteristics (Control Part)

(These characteristic graphs are normalized at Ta = 25C)

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Operating Frequency (Fosc) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Frequency Modulation (FMOD) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Maximum Duty Cycle (DMAX) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Operating Supply Current (IOP) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Start Threshold Voltage (VSTART) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Stop Threshold Voltage (VSTOP) vs. Ta

FSDL0365RN, FSDM0365RN

8

Typical Performance Characteristics (Continued)

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Feedback Source Current (IFB) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Peak Current Limit (ILIM) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Start Up Charging Current (ICH) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Burst Peak Current (IBUR(pk)) vs. Ta

0.00

0.20

0.40

0.60

0.80

1.00

1.20

-50 0 50 100 150

Temp[

]

N

o

r

m

a

l

i

z

e

d

Over Voltage Protection (VOVP) vs. Ta

FSDL0365RN, FSDM0365RN

9

Functional Description

1. Startup : In previous generations of Fairchild Power

Switches (FPS

TM

) the Vstr pin had an external resistor to the

DC input voltage line. In this generation the startup resistor

is replaced by an internal high voltage current source and a

switch that shuts off when 15ms goes by after the supply

voltage, Vcc, gets above 12V. The source turns back on if

Vcc drops below 8V.

Figure 4. High Voltage Current Source

2. Feedback Control : The FSDx0365RN employs current

mode control, as shown in Figure 5. An opto-coupler (such

as the H11A817A) and shunt regulator (such as the KA431)

are typically used to implement the feedback network. Com-

paring the feedback voltage with the voltage across the

Rsense resistor plus an offset voltage makes it possible to

control the switching duty cycle. When the KA431 reference

pin voltage exceeds the internal reference voltage of 2.5V,

the optocoupler LED current increases, the feedback voltage

Vfb is pulled down and it reduces the duty cycle. This event

typically happens when the input voltage is increased or the

output load is decreased.

Figure 5. Pulse Width Modulation (PWM) Circuit

3. Leading Edge Blanking (LEB) : At the instant the inter-

nal Sense FET is turned on, the primary side capacitance and

secondary side rectifier diode reverse recovery typically

cause a high current spike through the Sense FET. Excessive

voltage across the Rsense resistor leads to incorrect feedback

operation in the current mode PWM control. To counter this

effect, the FPS employs a leading edge blanking (LEB) cir-

cuit. This circuit inhibits the PWM comparator for a short

time (tLEB) after the Sense FET is turned on.

4. Protection Circuits : The FPS has several protective

functions such as over load protection (OLP), over voltage

protection (OVP), abnormal over current protection

(AOCP), under voltage lock out (UVLO) and thermal shut-

down (TSD). Because these protection circuits are fully inte-

grated inside the IC without external components, the

reliability is improved without increasing cost. Once a fault

condition occurs, switching is terminated and the Sense FET

remains off. This causes Vcc to fall. When Vcc reaches the

UVLO stop voltage VSTOP (8V), the protection is reset and

the internal high voltage current source charges the Vcc

capacitor via the Vstr pin. When Vcc reaches the UVLO

start voltage VSTART (12V), the FPS resumes its normal

operation. In this manner, the auto-restart can alternately

enable and disable the switching of the power Sense FET

until the fault condition is eliminated.

4.1 Over Load Protection (OLP) : Overload is defined as

the load current exceeding a pre-set level due to an unex-

pected event. In this situation, the protection circuit should

be activated in order to protect the SMPS. However, even

when the SMPS is operating normally, the over load protec-

tion (OLP) circuit can be activated during the load transition.

In order to avoid this undesired operation, the OLP circuit is

designed to be activated after a specified time to determine

whether it is a transient situation or an overload situation. In

conjunction with the Ipk current limit pin (if used) the cur-

rent mode feedback path would limit the current in the Sense

FET when the maximum PWM duty cycle is attained. If the

output consumes more than this maximum power, the output

voltage (Vo) decreases below its rating voltage. This reduces

the current through the opto-coupler LED, which also

reduces the opto-coupler transistor current, thus increasing

the feedback voltage (VFB). If VFB exceeds 3V, the feed-

back input diode is blocked and the 5uA current source (IDE-

LAY) starts to charge Cfb slowly up to Vcc. In this condition,

VFB increases until it reaches 6V, when the switching opera-

tion is terminated as shown in Figure 6. The shutdown delay

time is the time required to charge Cfb from 3V to 6V with

5uA current source.

Vin,dc

Vstr

Vcc

15ms after

Vcc12V

UVLO off

Vcc<8V

UVLO on

I

STR

J-FET

I

CH

3 OSC

Vcc Vcc

5uA 0.9mA

V

SD

R

2.5R

Gate

driver

OLP

D1 D2

V

FB

Vfb

431

C

FB

Vo

+

-

V

FB,in

FSDL0365RN, FSDM0365RN

10

Figure 6. Over Load Protection (OLP)

4.2 Thermal Shutdown (TSD) : The Sense FET and the

control IC are integrated, making it easier for the control IC

to detect the temperature of the Sense FET. When the tem-

perature exceeds approximately 140C, thermal shutdown is

activated.

4.3 Abnormal Over Current Protection (AOCP) : Even

though the FPS has OLP (Over Load Protection) and current

mode PWM feedback, these are not enough to protect the

FPS when a secondary side diode short or a transformer pin

short occurs. In addition to start-up, soft-start is also

activated at each restart attempt during auto-restart and when

restarting after latch mode is activated. The FPS has an

internal AOCP (Abnormal Over Current Protection) circuit,

as shown in Figure 7. When the gate turn-on signal is applied

to the power Sense FET, the AOCP block is enabled and

monitors the current through the sensing resistor. The

voltage across the resistor is then compared with a preset

AOCP level. If the sensing resistor voltage is greater than the

AOCP level, pulse-by-pulse AOCP is triggered regardless of

uncontrollable LEB time. Here, pulse-by-pulse AOCP stops

the Sense FET within 350ns after it is activated.

Figure 7. Abnormal Over Current Protection (AOCP)

4.4 Over Voltage Protection (OVP) : In the event of a mal-

function in the secondary side feedback circuit, or an open

feedback loop caused by a soldering defect, the current

through the opto-coupler transistor becomes almost zero

(refer to Figure 5). Then, VFB climbs up in a similar manner

to the over load situation, forcing the preset maximum cur-

rent to be supplied to the SMPS until the over load protection

is activated. Because excess energy is provided to the output,

the output voltage may exceed the rated voltage before the

over load protection is activated, resulting in the breakdown

of the devices in the secondary side. In order to prevent this

situation, an over voltage protection (OVP) circuit is

employed. In general, Vcc is proportional to the output volt-

age and the FPS uses Vcc instead of directly monitoring the

output voltage. If VCC exceeds 19V, OVP circuit is activated

resulting in termination of the switching operation. In order

to avoid undesired activation of OVP during normal opera-

tion, Vcc should be properly designed to be below 19V.

V

FB

t

3V

6V

Over Load Protection

t

12

= C

FB

(V(t

2

)-V(t

1

)) / I

DELAY

t

1

t

2

V t V V t V A I

I

t V t V

C t

DELAY

DELAY

FB

6 ) ( , 3 ) ( , 5 ;

) ( ) (

2 1

1 2

12

= = =

=

Vsense

V

FB,in

Gate Driver

Rsense

CLK

Drain

V

AOCP

PWM

COMPARATOR

AOCP

COMPARATOR

LEB

R

S Q

FSDL0365RN, FSDM0365RN

11

5. Soft Start : The FPS has an internal soft start circuit that

slowly increases the feedback voltage together with the

Sense FET current after it starts up. The typical soft start

time is 15msec, as shown in Figure 8, where progressive

increments of the Sense FET current are allowed during the

start-up phase. The pulse width to the power switching

device is progressively increased to establish the correct

working conditions for transformers, inductors, and capaci-

tors. The voltage on the output capacitors is progressively

increased with the intention of smoothly establishing the

required output voltage. It also helps to prevent transformer

saturation and reduce the stress on the secondary diode.

Figure 8. Soft Start Function

6. Burst Operation : In order to minimize power dissipation

in standby mode, the FPS enters burst mode operation. As

the load decreases, the feedback voltage decreases. As

shown in Figure 9, the device automatically enters burst

mode when the feedback voltage drops below

VBURH(500mV). Switching still continues but the current

limit is set to a fixed limit internally to minimize flux density

in the transformer. The fixed current limit is larger than that

defined by VFB = VBURH and therefore, VFB is driven

down further. Switching continues until the feedback voltage

drops below VBURL(350mV). At this point switching stops

and the output voltages start to drop at a rate dependent on

the standby current load. This causes the feedback voltage to

rise. Once it passes VBURH(500mV), switching resumes.

The feedback voltage then falls and the process repeats.

Burst mode operation alternately enables and disables

switching of the power Sense FET thereby reducing switch-

ing loss in Standby mode.

Figure 9. Burst Operation Function

7. Frequency Modulation : Modulating the switching fre-

quency of a switched power supply can reduce EMI. Fre-

quency modulation can reduce EMI by spreading the energy

over a wider frequency range than the bandwidth measured

by the EMI test equipment. The amount of EMI reduction is

directly related to the depth of the reference frequency. As

can be seen in Figure 10, the frequency changes from 65KHz

to 69KHz in 4ms for the FSDM0365RN (48.5KHz to

51.5KHz for FSDL0365RN). Frequency modulation allows

the use of a cost effective inductor instead of an AC input

mode choke to satisfy the requirements of world wide EMI

limits.

Figure 10. Frequency Modulation Waveform

1ms

15steps

Current limit

0.98A

2.15A

t

Drain current

V

BURH

Switching

OFF

Current

Waveform

Burst

Operation

Normal

Operation

V

FB

V

BURL

Switching

OFF

Burst

Operation

3

Vcc Vcc

I

DELAY

I

FB

R

2.5R

Vfb

VBURL/VBURH

PWM

+

- VBURH

Vcc

I

BUR(pk)

Burst

Normal

MOSFET

Current

t

s

f

s

=1/t

s

67kHz

69kHz

65kHz

4ms

t

Drain

Current

FSDL0365RN, FSDM0365RN

12

Figure 11. KA5-series FPS Full Range EMI scan(67KHz,

no Frequency Modulation) with DVD Player SET

Figure 12. FSDX-series FPS Full Range EMI Scan (67KHz,

with Frequency Modulation) with DVD Player SET

8. Adjusting Peak Current Limit : As shown in Figure 13,

a combined 2.8k internal resistance is connected to the

non-inverting lead on the PWM comparator. A external

resistance of Rx on the current limit pin forms a parallel

resistance with the 2.8k when the internal diodes are

biased by the main current source of 900uA.

Figure 13. Peak Current Limit Adjustment

For example, FSDx0365RN has a typical Sense FET peak

current limit (ILIM) of 2.15A. ILIM can be adjusted to 1.5A

by inserting Rx between the Ipk pin and the ground. The

value of the Rx can be estimated by the following equations:

2.15A : 1.5A = 2.8k : Xk ,

X = Rx || 2.8k .

(X represents the resistance of the parallel network)

Frequency (MHz)

A

m

p

l

i

t

u

d

e

(

d

B

V

)

Frequency (MHz)

A

m

p

l

i

t

u

d

e

(

d

B

V

)

3

Vcc Vcc

I

DELAY

I

FB

2k Vfb

PWM

Comparator

4

Ipk

0.8k

Rx

SenseFET

Current

Sense

900uA 5uA

FSDL0365RN, FSDM0365RN

13

Application Tips

1. Methods of Reducing Audible Noise

Switching mode power converters have electronic and

magnetic components, which generate audible noises when

the operating frequency is in the range of 20~20,000 Hz.

Even though they operate above 20 kHz, they can make

noise depending on the load condition. Designers can

employ several methods to reduce these noises. Here are

three of these methods:

Glue or Varnish

The most common method involves using glue or varnish

to tighten magnetic components. The motion of core, bobbin

and coil and the chattering or magnetostriction of core can

cause the transformer to produce audible noise. The use of

rigid glue and varnish helps reduce the transformer noise.

But, it also can crack the core. This is because sudden

changes in the ambient temperature cause the core and the

glue to expand or shrink in a different ratio according to the

temperature.

Ceramic Capacitor

Using a film capacitor instead of a ceramic capacitor as a

snubber capacitor is another noise reduction solution. Some

dielectric materials show a piezoelectric effect depending on

the electric field intensity. Hence, a snubber capacitor

becomes one of the most significant sources of audible

noise. It is considerable to use a zener clamp circuit instead

of an RCD snubber for higher efficiency as well as lower

audible noise.

Adjusting Sound Frequency

Moving the fundamental frequency of noise out of 2~4 kHz

range is the third method. Generally, humans are more sensi-

tive to noise in the range of 2~4 kHz. When the fundamental

frequency of noise is located in this range, one perceives the

noise as louder although the noise intensity level is identical.

Refer to Figure 14. Equal Loudness Curves.

When FPS acts in Burst mode and the Burst operation is

suspected to be a source of noise, this method may be help-

ful. If the frequency of Burst mode operation lies in the

range of 2~4 kHz, adjusting feedback loop can shift the

Burst operation frequency. In order to reduce the Burst oper-

ation frequency, increase a feedback gain capacitor (CF),

opto-coupler supply resistor (RD) and feedback capacitor

(CB) and decrease a feedback gain resistor (RF) as shown in

Figure 15. Typical Feedback Network of FPS.

Figure 14. Equal Loudness Curves

Figure 15. Typical Feedback Network of FPS

2. Other Reference Materials

AN-4134: Design Guidelines for Off-line Forward Convert-

ers Using Fairchild Power Switch (FPS

TM

)

AN-4137: Design Guidelines for Off-line Flyback Convert-

ers Using Fairchild Power Switch (FPS)

AN-4140: Transformer Design Consideration for Off-line

Flyback Converters using Fairchild Power Switch

(FPS

TM

)

AN-4141: Troubleshooting and Design Tips for Fairchild

Power Switch (FPS

TM

) Flyback Applications

AN-4147: Design Guidelines for RCD Snubber of Flyback

AN-4148: Audible Noise Reduction Techniques for FPS

Applications

FSDL0365RN, FSDM0365RN

14

Typical Application Circuit

Features

High efficiency (>76% at universal input)

Low standby mode power consumption (<1W at 230Vac input and 0.6W load)

Low component count

Enhanced system reliability through various protection functions

Low EMI through frequency modulation

Internal soft-start (15ms)

Key Design Notes

The delay time for over load protection is designed to be about 30ms with C106 of 47nF. If faster/slower triggering of OLP

is required, C106 can be changed to a smaller/larger value(eg. 100nF for about 60ms).

Using a resistor R104(39) on Ipk pin (#4), the pule-by-pulse peak current limit level(ILIM) is adjusted to about 2A.

The branch formed by D103, C108 and R106 provides another ILIM adjustment having a negative slope to the input

voltage. The ILIM value decreases as the input voltage level increases.

1. Schematic

Application Output power Input voltage Output voltage (Max current)

DVD Player 21W

Universal input

(85-265Vac)

3.3V (1.0A)

5.1V (0.8A)

12V (0.5A)

16V (0.5A)

3

4

C102

100nF

AC275V

LF101

55mH

C101

100nF

AC275V

F101

FUSE

C103

47uF

400V

R102

56k

C104

3.3nF

630V

D101

UF 4007

IC101

FSDM0365RN

C107

47nF

50V

C106

47uF

50V

D102

UF 4004

R103

5

1

2

3

4

5

8

9

6

12

10

11

T101

EER2828

D203

EGP20D

C205

470uF

35V

C206

470uF

35V

L203 10uH

L207 4.7uH

L206 4.7uH

D204

EGP20D

C207

470uF

35V

C208

470uF

35V

C214

1000uF

10V

C213

1000uF

10V

D207

SB360

D205

SB360

C209

1000uF

10V

C210

1000uF

10V

R201

510

R202

1k

R203

6.2k

R204

20k

C215

100nF

R205

6k

IC302

FOD817A

BD101

L205 10uH

Vstr

Ipk

Vfb Vcc

Drain

GND

6

1

2 3

4

5

1

2

Drain

Drain

7

8

IC301

KA431

16V

R104

39k

TNR

R105

200k

R106

300k

D103

UF 4004

C108

1uF

100V

C302

2.2nF

12V

5.1V

3.3V

RT101

5D-9

FSDL0365RN, FSDM0365RN

15

2. Transformer Schematic Diagram

3. Winding Specification

4. Electrical Characteristics

5. Core & Bobbin

Core : EER2828 ( Ae = 86.66 mm

2

)

Bobbin : EER2828

EER2828

N

12V

1

6

7

8

9

10

11

12

N

16V

N

5.1V

N

3.3V

N

p

/2

N

a

2

3

4

5

N

p

/2

6mm 3mm

N

16V

N

12V

N

a

N

5.1V

N

3.3V

N

p

/2

N

p

/2

Pin(S F) Wire Turns Winding Method

Np/2 3 2 0.25 1 50 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 2Layers

N3.3V 9 8 0.33 2 4 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 2Layers

N5.1V 6 9 0.33 1 2 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 2Layers

Na 4 5 0.25 1 16 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 2Layers

N12V 10 12 0.33 1 14 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 3Layers

N16V 11 12 0.33 1 18 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 2Layers

Np/2 2 1 0.25 1 50 Center Solenoid winding

Insulation : Polyester Tape t = 0.050mm, 2Layers

P i n S p e c . R e m a r k

I n d u c t a n c e 1 3 1 . 4 m H 1 0 % 1 0 0 k H z , 1 V

L e a k a g e 1 3 2 5 u H M a x . S h o r t a l l o t h e r p i n s

FSDL0365RN, FSDM0365RN

16

6. Demo Circuit Part List

Part Value Note Part Value Note

Resistor Inductor

R102 56K 1W L203 10uH -

R103 5 1/4W L205 10uH -

R104 39K 1/4W L206 4.7uH -

R105 200K 1/4W L207 4.7uH -

R106 300K 1/4W Diode

R201 510 1/4W D101 UF4007 PN Ultra Fast

R202 1K 1/4W D102 UF4004 PN Ultra Fast

R203 6.2 K 1/4W D103 UF4004 PN Ultra Fast

R204 20K 1/4W D203 EGP20D PN Ultra Fast

R205 6K 1/4W D204 EGP20D PN Ultra Fast

Capacitor D205 SB360 Schottky

C101 100nF/275AC Box D207 SB360 Schottky

C102 100nF/275AC Box IC

C103 47uF/400V Electrolytic IC101 FSDM0365RN FPS

C104 3.3nF/630V Film IC301 KA431(TL431)

Voltage

reference

C106 47uF/50V Electrolytic IC302 FOD817A Opto-Coupler

C107 47nF/50V Ceramic

C108 1uF/100V Electrolytic Fuse

C205 470uF/35V Electrolytic FUSE 2A/250V

C206 470uF/35V Electrolytic

C207 470uF/35V Electrolytic NTC

C208 470uF/35V Electrolytic RT101 5D-9

C209 1000uF/10V Electrolytic

C210 1000uF/10V Electrolytic Bridge Diode

C213 1000uF/10V Electrolytic BD101 2KBP06M 2N257 Bridge Diode

C214 1000uF/10V Electrolytic

C215 100nF/50V Ceramic Line Filter

C302 2.2nF AC Ceramic LF101 55mH -

FSDL0365RN, FSDM0365RN

17

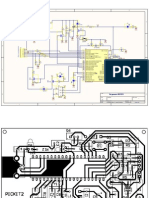

7. Layout

7.1 Top image of PCB

7.2 Bottom image of PCB

FSDL0365RN, FSDM0365RN

18

Package Dimensions

8DIP

FSDL0365RN, FSDM0365RN

19

Package Dimensions (Continued)

8LSOP

FSDL0365RN, FSDM0365RN

9/29/05 0.0m 001

2005 Fairchild Semiconductor Corporation

LIFE SUPPORT POLICY

FAIRCHILDS PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

www.fairchildsemi.com

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY

PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY

LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER

DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

Ordering Information

Product Number Package Marking Code BVDSS fOSC RDS(ON)

FSDM0365RN 8DIP DM0365R 650V 67KHz 3.6

FSDL0365RN 8DIP DL0365R 650V 50KHz 3.6

FSDM0365RL 8LSOP DM0365R 650V 67KHz 3.6

FSDL0365RL 8LSOP DL0365R 650V 50KHz 3.6

Вам также может понравиться

- FSDM07652R DatasheetДокумент16 страницFSDM07652R Datasheetmarianos67Оценок пока нет

- PIC16 Sine-Wave InverterДокумент2 страницыPIC16 Sine-Wave InverterNon DorelОценок пока нет

- Analog Devices CD ReferenceДокумент8 страницAnalog Devices CD ReferenceAcody Ie SyОценок пока нет

- I2C LCD Module Schematic DiagramДокумент1 страницаI2C LCD Module Schematic DiagramVasi ValiОценок пока нет

- Hardware Used - Power Supply and MicrocontrollerДокумент46 страницHardware Used - Power Supply and MicrocontrollerRocky SinghОценок пока нет

- Digital Power-Conversion For The Analog EngineerДокумент12 страницDigital Power-Conversion For The Analog EngineerfjwoemcuОценок пока нет

- Bd9423efv e 1223519 PDFДокумент61 страницаBd9423efv e 1223519 PDFVươngОценок пока нет

- Letterbox Letter CounterДокумент27 страницLetterbox Letter CounterSAMEULОценок пока нет

- DDS RF Signal Generator Design GuideДокумент9 страницDDS RF Signal Generator Design GuideIan McNairОценок пока нет

- Piq201 Piq201: Pid101 Pid102 Piq502 Piq203 Piq403 Pid102 Pid101 Piq502Документ3 страницыPiq201 Piq201: Pid101 Pid102 Piq502 Piq203 Piq403 Pid102 Pid101 Piq502dejanОценок пока нет

- Digital Control of Switching Power ConvertersДокумент6 страницDigital Control of Switching Power ConvertersNISHANT VATSОценок пока нет

- Develop Ineo-250 Error C2557Документ2 страницыDevelop Ineo-250 Error C2557Tariq MajeedОценок пока нет

- Zero Voltage Switching Resonant Power Devices by Bill AndrecakДокумент28 страницZero Voltage Switching Resonant Power Devices by Bill AndrecakRekhamtrОценок пока нет

- PIC18F97J60 Microcontroller SchematicДокумент5 страницPIC18F97J60 Microcontroller SchematicThùy Đào100% (1)

- Op-Amp IC Tester Circuit Under 40 CharactersДокумент2 страницыOp-Amp IC Tester Circuit Under 40 CharactersSrihari ThammisettiОценок пока нет

- RK Engineering Earth Leakage RelayДокумент1 страницаRK Engineering Earth Leakage RelaySEO BDMОценок пока нет

- Slis 140 AДокумент33 страницыSlis 140 AAlvaro RoqueОценок пока нет

- Full Control of A PWM DCAC Converter For AC Voltage RegulationДокумент9 страницFull Control of A PWM DCAC Converter For AC Voltage RegulationAndrés Felipe CelisОценок пока нет

- Green-Mode PWM Controller With High-Voltage Start-Up CircuitДокумент18 страницGreen-Mode PWM Controller With High-Voltage Start-Up Circuitgoaltech100% (1)

- Digital Power Suply ControlДокумент30 страницDigital Power Suply ControlPaul RomanОценок пока нет

- Panasonic TX-25lk1p TX-28lk1p Chassis z8Документ22 страницыPanasonic TX-25lk1p TX-28lk1p Chassis z8drrebyОценок пока нет

- PWM Inverters ExplainedДокумент29 страницPWM Inverters ExplainedandersonОценок пока нет

- U Supply Bench Rev BДокумент1 страницаU Supply Bench Rev BStoica Valentin CatalinОценок пока нет

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesДокумент13 страницPWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygОценок пока нет

- AC Voltage Controllers for Inductive LoadsДокумент15 страницAC Voltage Controllers for Inductive LoadsSumukha KumarОценок пока нет

- General Description Features: High Performance Current Mode PWM ControllerДокумент11 страницGeneral Description Features: High Performance Current Mode PWM ControllerPhạm Tấn HảiОценок пока нет

- 3250 L532M DatasheetДокумент2 страницы3250 L532M DatasheetJavaid HosanyОценок пока нет

- Electrical Schematics - tm2002 - Service ADVISOR™ PDFДокумент3 страницыElectrical Schematics - tm2002 - Service ADVISOR™ PDFdaniel5morales5castaОценок пока нет

- Uc 3843 Data SheetДокумент56 страницUc 3843 Data Sheetmeepow100% (1)

- Enhancement Mode N-Channel Power MOSFET: OSG65R900xTFДокумент10 страницEnhancement Mode N-Channel Power MOSFET: OSG65R900xTFCube7 Geronimo100% (1)

- Build a 1.3GHz Frequency CounterДокумент1 страницаBuild a 1.3GHz Frequency Counteredosvirac100% (1)

- Steady State Converter Analysis: Anjana S Ap, EeeДокумент23 страницыSteady State Converter Analysis: Anjana S Ap, Eeemridul mpОценок пока нет

- Scanning LIB. SPECIFICATION FOR APPROVALДокумент14 страницScanning LIB. SPECIFICATION FOR APPROVALgeorgelu100% (1)

- Power measurement and control schematicДокумент15 страницPower measurement and control schematichbaocrОценок пока нет

- EDN 0504 SupplementДокумент36 страницEDN 0504 Supplementmcpa-tum100% (2)

- Duo Range Type PotentiometerДокумент19 страницDuo Range Type Potentiometersaikarthick023Оценок пока нет

- Intelligent Power Supply Design SolutionsДокумент16 страницIntelligent Power Supply Design SolutionsMeselao Meselao MeselaoОценок пока нет

- Panel Chimei Innolux v320bj3-p02 0Документ30 страницPanel Chimei Innolux v320bj3-p02 0doniОценок пока нет

- Max 17126Документ34 страницыMax 17126918329078250% (2)

- LG Chassis MC 049a RT 29fd15Документ31 страницаLG Chassis MC 049a RT 29fd15Alana Clark100% (2)

- Circuit Diagram for 5V USB Power SupplyДокумент1 страницаCircuit Diagram for 5V USB Power Supplyelectro med100% (1)

- Assembly Manual K2639Документ32 страницыAssembly Manual K2639Asse NavОценок пока нет

- CHF100A Series High Performance Universal InverterДокумент153 страницыCHF100A Series High Performance Universal InverterAnang Widhi Prasetia0% (1)

- BGH3299A Manual Servicio PDFДокумент36 страницBGH3299A Manual Servicio PDFaldoОценок пока нет

- Build a NiCd Battery Charger CircuitДокумент1 страницаBuild a NiCd Battery Charger CircuitdewasuryantoОценок пока нет

- Precision Rectifier CircuitsДокумент13 страницPrecision Rectifier CircuitsWaqas PervaizОценок пока нет

- Schematic KIT PIC V3 MinhHaGroupДокумент2 страницыSchematic KIT PIC V3 MinhHaGroupTrần MạnhОценок пока нет

- MT8222Документ13 страницMT8222Glaucio Almeida100% (1)

- Zero CrossingДокумент16 страницZero CrossingAryan KapsОценок пока нет

- Ac Meters Part 1Документ22 страницыAc Meters Part 1Vam ArmodiaОценок пока нет

- TLC 2721Документ17 страницTLC 2721minaikka25Оценок пока нет

- Logic Analyzer 4Документ1 страницаLogic Analyzer 4Rick BazzaОценок пока нет

- Characteristics of ThyristorsДокумент7 страницCharacteristics of ThyristorsSubaskaran SalavanОценок пока нет

- DM0265Документ19 страницDM0265liberthОценок пока нет

- DL 0165 RДокумент20 страницDL 0165 Rledu035Оценок пока нет

- DatasheetДокумент20 страницDatasheetWellington DiasОценок пока нет

- DM 0565 RДокумент20 страницDM 0565 R81968Оценок пока нет

- FSDH0265RN, FSDM0265RN: Green Mode Fairchild Power Switch (FPS)Документ20 страницFSDH0265RN, FSDM0265RN: Green Mode Fairchild Power Switch (FPS)Wsad WsadОценок пока нет

- CQ 0765RTДокумент24 страницыCQ 0765RTsonivitel100% (2)

- RC0805Документ10 страницRC0805MoscandoОценок пока нет

- SCX-4600/4623 series Parts CatalogДокумент60 страницSCX-4600/4623 series Parts CatalogFernando GambinoОценок пока нет

- Tps 65192Документ25 страницTps 65192MoscandoОценок пока нет

- Msi Ms-7586 Rev 0a SCHДокумент39 страницMsi Ms-7586 Rev 0a SCHMoscandoОценок пока нет

- DC2004 01Документ1 страницаDC2004 01MoscandoОценок пока нет

- ASRock Z68 Extreme4Документ81 страницаASRock Z68 Extreme4Nelutu PuscaОценок пока нет

- LinkSwitch-TN2 Family DatasheetДокумент22 страницыLinkSwitch-TN2 Family DatasheetMoscandoОценок пока нет

- 02 2016 PDFДокумент56 страниц02 2016 PDFMoscandoОценок пока нет

- Corona Multi Service R410A ManualДокумент25 страницCorona Multi Service R410A Manualautrera100% (1)

- BEE-Unit - IДокумент44 страницыBEE-Unit - Ipavankumar tvvОценок пока нет

- Circuit Theory I-LEC Mohamed MegahedДокумент137 страницCircuit Theory I-LEC Mohamed MegahedHussien HassanОценок пока нет

- Electric Circuits Ch05 Revised by SJДокумент21 страницаElectric Circuits Ch05 Revised by SJNazmul islamОценок пока нет

- Digital Logic Families PDFДокумент49 страницDigital Logic Families PDFdineep90% (10)

- Study and Testing of Different Kinds of Electric Meter - An Internship Report of PESU, Patna.Документ19 страницStudy and Testing of Different Kinds of Electric Meter - An Internship Report of PESU, Patna.Anurag Aryan0% (2)

- IES Bangalore Analog Electronics Old GATE ECE QuestionsДокумент74 страницыIES Bangalore Analog Electronics Old GATE ECE QuestionsPrateek Khare100% (2)

- Components of Modern User InterfacesДокумент35 страницComponents of Modern User Interfacesduke_doОценок пока нет

- A.C. Network Anaylsis: Learning ObjectivesДокумент28 страницA.C. Network Anaylsis: Learning ObjectivesDio Ilham Tirta AdiОценок пока нет

- Analog Circuits 2020 21Документ1 страницаAnalog Circuits 2020 21Padirikuppam PavithraОценок пока нет

- Pulsed IV by AgilentДокумент22 страницыPulsed IV by AgilentAlberto_Zamudi_1172Оценок пока нет

- Re95200 2007-11Документ20 страницRe95200 2007-11renatОценок пока нет

- Basic Electronics:: Carnegie Mellon Lab ManualДокумент145 страницBasic Electronics:: Carnegie Mellon Lab ManualPalak AriwalaОценок пока нет

- Power SystemДокумент23 страницыPower SystemM VetriselviОценок пока нет

- Principles & ApplicationsДокумент85 страницPrinciples & ApplicationsMrToxic01Оценок пока нет

- ch08 1Документ44 страницыch08 1zmxncbv08090526Оценок пока нет

- Government College of Engineering Network Theory NotesДокумент55 страницGovernment College of Engineering Network Theory NotesSa'idu SunusiОценок пока нет

- Thevenin - Norton Equivalents and Maximum Power TransferДокумент32 страницыThevenin - Norton Equivalents and Maximum Power TransferMahmoud AlaaОценок пока нет

- Network Theorems - Electrical Multiple Choice Questions and Answers PDF - Preparation For EngineeringДокумент8 страницNetwork Theorems - Electrical Multiple Choice Questions and Answers PDF - Preparation For Engineeringramanaidu157% (7)

- Introdution To Radio Frequency Design - 41840-1994Документ396 страницIntrodution To Radio Frequency Design - 41840-1994suzycreamcheeze80% (5)

- KA7630/KA7631: Fixed Multi-Output RegulatorДокумент6 страницKA7630/KA7631: Fixed Multi-Output RegulatorTecnico GenioОценок пока нет

- Basic Circuit Analysis Concepts and Kirchhoff's LawsДокумент258 страницBasic Circuit Analysis Concepts and Kirchhoff's LawsDominic Savio0% (1)

- Experiments in Principles of Electronic Devices and Circuits (PDFDrive)Документ321 страницаExperiments in Principles of Electronic Devices and Circuits (PDFDrive)Ralph Jason Alvarez100% (1)

- Engineers Guide Signal ConditioningДокумент162 страницыEngineers Guide Signal Conditioningabdur135Оценок пока нет

- 100 Top Electronic Devices and Circuits Questions and Answers PDF Electronic Devices and Circuits QuestionsДокумент15 страниц100 Top Electronic Devices and Circuits Questions and Answers PDF Electronic Devices and Circuits QuestionsAnandPrakashSinhaОценок пока нет

- Lab Manual: EGCI 232 Engineering ElectronicsДокумент26 страницLab Manual: EGCI 232 Engineering ElectronicsgapswitОценок пока нет

- LabJack U6 Datasheet Export 20160108Документ112 страницLabJack U6 Datasheet Export 20160108jaferreroОценок пока нет

- Chapter 3 1Документ20 страницChapter 3 1Ch AliОценок пока нет

- Basic Instrumentation & Basic Pid ControlДокумент20 страницBasic Instrumentation & Basic Pid ControlakankshaОценок пока нет

- EC 8453 LINEAR INTEGRATED CIRCUITS Unit 1Документ16 страницEC 8453 LINEAR INTEGRATED CIRCUITS Unit 1Madhavan Sam0% (1)

- Experiments in Principles of Electronic Devices and Circuits by David E. Lalond and John A. RossДокумент321 страницаExperiments in Principles of Electronic Devices and Circuits by David E. Lalond and John A. Rosshanan faour100% (1)