Академический Документы

Профессиональный Документы

Культура Документы

SPC Training Contents and Techniques

Загружено:

Purushothama Nanje GowdaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SPC Training Contents and Techniques

Загружено:

Purushothama Nanje GowdaАвторское право:

Доступные форматы

Rev No:02, Date: 01.08.

2004 1

Zero Defect Consultants

Statistical Process Control

WELCOME TO ALL

WELCOME TO ALL

Contact:- Mob: 93412 41356

Rev No:02, Date: 01.08.2004 2

Zero Defect Consultants

Statistical Process Control

Training Contents Training Contents

Introduction to SPC

Types of Process Controls

Introduction to Statistics

Understanding Mean, Mode, Median, Range, Standard Deviation

Concept of Variation Special cause & common causes

Stable & Unstable Process

Approach towards identification of Special Causes

Histogram An illustration

Normal Distribution

Process Capability

Rev No:02, Date: 01.08.2004 3

Zero Defect Consultants

Statistical Process Control

Training Contents Training Contents

Introduction to Control Charts

Types of Control Charts

Understanding application, methodology, interpretations of various

types of charts (Variable and Attribute type covered)

Exercises on Control Charts

SPC implementation methodology

Role of Operator in implementing SPC.

Common mistakes done in implementing SPC

Conclusion

Rev No:02, Date: 01.08.2004 4

Zero Defect Consultants

Statistical Process Control

Introduction to SPC

Process:-

Convert input to output using Man, Machine, Material, Method,

Measurement.

Process

(Man, M/c, Material,

Method)

Input

Output

Measure & give

Feedback

Rev No:02, Date: 01.08.2004 5

Zero Defect Consultants

Statistical Process Control

Process Control:-

Variation in the output of the process is natural. Hence the process needs to

be controlled in order to ensure that output is meeting the customer

requirements.

Tools for Process Control:-

Detection :- A strategy that attempts to identify unacceptable output

after it has been produced and then separate it from the good output.

Prevention :- A future oriented strategy by analysis and action toward

correcting the process itself so that unacceptable parts will not be

produced.

Rev No:02, Date: 01.08.2004 6

Zero Defect Consultants

Statistical Process Control

Techniques for Process Control

Mistake Proofing :- In this technique 100% process control is achieved by

preventing all types of failures by using modern techniques to get defect

free product. Here causes are prevented from making the effect.

100% Inspection : In this technique 100% checking of all the parameters of

all products has been done to get defect free product. Here only defects are

detected.

Statistical Process Control : In this Statistical technique such as Control

Chart, Histogram etc. are used to analyses the process to achieve and

maintain state of statistical control to get defect free product. Causes are

detected and prompting CA before defect occurs

Rev No:02, Date: 01.08.2004 7

Zero Defect Consultants

Statistical Process Control

Statistics

Collection of Data, Analysis and Conclusion

It is a value calculated from or based upon sample data (e.g. a subgroup

average or range) used to make inferences about the process that produces

the output.

E.g. Analysis of rejection data and initiating actions to reduce the rejection

level.

Rev No:02, Date: 01.08.2004 8

Zero Defect Consultants

Statistical Process Control

What is Statistical Process Control

The use of Statistical techniques such as control charts to analyze a process

or its outputs so as to take appropriate actions, to achieve and maintain a

state of statistical control and to improve the process capability.

SPC is

A tool to detect variation

It identifies problems, it does not solve problems

Rev No:02, Date: 01.08.2004 9

Zero Defect Consultants

Statistical Process Control

Introduction to Statistics

Data:

Any facts or numbers or observations made.

Set of observations forms the data.

Types of Data:

Variable data

Attribute data

Rev No:02, Date: 01.08.2004 10

Zero Defect Consultants

Statistical Process Control

Variable Data

Data generated by

Physically measuring the characteristic using an

instrument

Assigning an unique value to each item

Examples:

Hardness, Strength, Weight, Diameter, etc.

Rev No:02, Date: 01.08.2004 11

Zero Defect Consultants

Statistical Process Control

Attribute Data

Data generated by

Classifying the items into different groups based on some criteria

No physical measurement is involved

All the items classified into a group will have same value I.e OK

or Not Ok.

Examples:

Sex, Shade Variation, Surface Defects, Go-No GO, etc.

Rev No:02, Date: 01.08.2004 12

Zero Defect Consultants

Statistical Process Control

Statistical Properties of Data

Observations collected needs to be analyzed using various properties.

Statistical properties of data helps in arriving at one value representing

all observations.

Two types of properties

Measure of location

Measure of Dispersion

Rev No:02, Date: 01.08.2004 13

Zero Defect Consultants

Statistical Process Control

Measure of Location

Mean (Average)

Median

Mode

Measure of Dispersion

Range

Standard Deviation

Rev No:02, Date: 01.08.2004 14

Zero Defect Consultants

Statistical Process Control

Mean:

Numerical value indicating the central value of data

Sum of all data / Total number of data

Suppose x

1

, x

2

, - - - x

n

be the data, then

Mean = (x

1

+ x

2

+ - - -+ x

n

) / n = x

i

/n

Example Hardness Data

Mean:

= (55 + 65 + 59 + 59 + 57 + 61 + 53 + 63 + 59 + 57 + 63 + 55 + 61 + 61 + 57 +

59 + 61 + 57 + 59 + 63) / 20

= 1184 / 20 = 59.2

Rev No:02, Date: 01.08.2004 15

Zero Defect Consultants

Statistical Process Control

Median:

Middle Value

Value which divides data arranged in ascending or descending order

into two equal halves

Case 1: Total number of data is odd

Median: Middle Value

Case 2: Total number of data is even

Median: Average of two middle values

Rev No:02, Date: 01.08.2004 16

Zero Defect Consultants

Statistical Process Control

Median: Example Productivity Data

1.02

1.00

1.02

1.00

1.01

0.99

1.01

0.99

1.01

0.98

1.00

0.98

1.03 1.02 1.01 1.00

1.00 0.99 0.99 0.97

Total Number of data: 20 (even)

The middle Values : 1.00 & 1.00 (10

th

value and 11

th

value)

Median: Average of 2 middle value

(1.00 + 1.00) / 2 = 1.00

Rev No:02, Date: 01.08.2004 17

Zero Defect Consultants

Statistical Process Control

Mode:

Highest no. of times an observation has occurred (Highest frequency)

Mode: Example Productivity Data

1.02

1.00

1.02

1.00

1.01

0.99

1.01

0.99

1.01

0.98

1.00

0.98

1.03 1.02 1.01 1.00

1.00 0.99 0.99 0.97

0.97 - 1

0.98 - 2

0.99 - 4

1.00 - 5 - 1.00 is Mode as this occurred more no. of times

1.01 - 4

1.02 - 3

1.03 - 1

Rev No:02, Date: 01.08.2004 18

Zero Defect Consultants

Statistical Process Control

Range: Definition

Range: Maximum value Minimum Value

Example:

2 5 8 9 15

2 3 7 4 5

Maximum Value = 15

Minimum Value = 2

Range = 15 2 = 13

Range: Issues

It depends only on extreme values

Hence affected by outliers

Rev No:02, Date: 01.08.2004 19

Zero Defect Consultants

Statistical Process Control

Range: Issues

0

2

4

6

8

10

12

14

16

1 2 3 4 5 6 7 8 9 10

Range

Rev No:02, Date: 01.08.2004 20

Zero Defect Consultants

Statistical Process Control

Standard Deviation: Definition

0

2

4

6

8

10

12

14

16

1 2 3 4 5 6 7 8 9 10

Square root of the average squared deviation from mean

Indicates On an average how much each value is away from the Mean

Rev No:02, Date: 01.08.2004 21

Zero Defect Consultants

Statistical Process Control

Below data indicates the Money held by ten students in a class room.

Standard Deviation: Example:

2 5 8 9 15

2 3 7 4 5

Step 1:

Calculate Mean

Mean = 6

Rev No:02, Date: 01.08.2004 22

Zero Defect Consultants

Statistical Process Control

Standard Deviation: Example:

2 5 8 9 15

2 3 7 4 5

Step 2:

Take deviations from Mean

-4 -1 2 3 9

-4 -3 1 -2 -1

Rev No:02, Date: 01.08.2004 23

Zero Defect Consultants

Statistical Process Control

Standard Deviation: Example:

Step 2:

Take deviations from Mean

0

2

4

6

8

10

12

14

16

1 2 3 4 5 6 7 8 9 10

Rev No:02, Date: 01.08.2004 24

Zero Defect Consultants

Statistical Process Control

Standard Deviation: Example:

Step 3:

Since some values are positive & rest are negative, while

taking sum they will cancel out.

So square the values & Sum

16 1 4 9 81

16 9 1 4 1

Sum = 142

Rev No:02, Date: 01.08.2004 25

Zero Defect Consultants

Statistical Process Control

Standard Deviation: Example:

Step 4:

Standard Deviation = (Sum of Squares / (n -1))

= (142 / (10 -1))

= 15.77 = 3.972

Rev No:02, Date: 01.08.2004 26

Zero Defect Consultants

Statistical Process Control

Variation

No two things are exactly alike

It is impossible to produce or process two items exactly alike

Variation is natural.

Rev No:02, Date: 01.08.2004 27

Zero Defect Consultants

Statistical Process Control

Example:

Time to reach office : 9:30 am

It is not possible to reach office exactly at 9:30 everyday

Normally there will be a small variation around 9:30 as follows:

9:31 9:34 9:27 9:26 9:34

9:25 9:29 9:28 9:33 9:31

This small variation is difficult to explain.

Rev No:02, Date: 01.08.2004 28

Zero Defect Consultants

Statistical Process Control

Generally

Looking at the past values, it is possible to give some range

around 9:30 am (e.g.: 9:30 5 Minutes) to reach office

Normally it is possible to reach office within this range

Suppose

A particular day , there is vehicle break down

that day it may not be possible to reach office at 9:30 5 Minutes

Say, you reach office at 9:50 am

In other words

If you reach office too late (beyond normal range of 9:30 5 minutes),

there will be some special reason for that or

it is easy to find out the reason for such variation

Rev No:02, Date: 01.08.2004 29

Zero Defect Consultants

Statistical Process Control

Assignable Cause of Variation (Special Causes)

Variations of large magnitude

Easy to identify the causes of variation

Easy to eliminate the cause of variation

Common Cause of Variation

Variations of small magnitude

Difficult to identify the causes of variation

Difficult to eliminate the cause of variation

Rev No:02, Date: 01.08.2004 30

Zero Defect Consultants

Statistical Process Control

Stable Process

No Assignable Causes are present

Process is operating under common causes only

Stable process will be predictable & Statistically under control.

If a process is stable & the data follows normal distribution

Then the variation will be Mean 3 x Standard deviation

Unstable Process

Assignable Causes are present

Process is operating under assignable & common causes.

Unstable process is unpredictable & not under Statistical control.

Rev No:02, Date: 01.08.2004 31

Zero Defect Consultants

Statistical Process Control

HISTOGRAM

Histogram is a graphical representation of data and shows the

frequency of data.

Histogram provides the easiest way to understand the distribution of

data. It gives the Birds eye view of the variation in Data set.

Portrays the information on location, spread and shape that enables

the user to interpret the Process behavior.

It indicates whether the process is operating under Normal / stable

conditions.

Rev No:02, Date: 01.08.2004 32

Zero Defect Consultants

Statistical Process Control

DEFINITIONS

Class:- Is a category with lower and upper boundary value.

Class Width:- Width of the class.

Frequency:- No. of observations falling in the class.

Rev No:02, Date: 01.08.2004 33

Zero Defect Consultants

Statistical Process Control

STEPS FOR CONSTRUCTING HISTOGRAM

Collect Min 50 no. of readings (N). 50 readings should be continuous

data.

Determine Max value and Min value & Calculate Range.

Range = Max Min.

Record the measurement unit (MU) used. This is usually controlled by

the measuring instrument least count.

Rev No:02, Date: 01.08.2004 34

Zero Defect Consultants

Statistical Process Control

STEPS FOR CONSTRUCTING HISTOGRAM Contd..

Determine No. of classes (k), as below.

No. of Class (k) = N

Determine Class Width (CW), as below

Class Width (CW) = Range / k

Construct the Frequency Distribution Table, as shown in the next

slide.

Rev No:02, Date: 01.08.2004 35

Zero Defect Consultants

Statistical Process Control

Where L1 = Minimum value (1/2*Measurement Unit)

U1 = L1 + Class Width

L2 = U1,

U2 = L2 + Class Width & so on.

N Total

Upto Max value

L2 U2

L1 U1

Frequency Tally Class

Frequency Distribution Table

Rev No:02, Date: 01.08.2004 36

Zero Defect Consultants

Statistical Process Control

STEPS FOR CONSTRUCTING HISTOGRAM Contd..

Determine the axis for the graph. Place Class on X axis and

Frequency on Y axis.

Mark off the classes, and draw rectangles with heights corresponding

to the measurement frequencies in that class.

Title the histogram. Give an overall title and identify each axis.

Rev No:02, Date: 01.08.2004 37

Zero Defect Consultants

Statistical Process Control

HISTOGRAM HISTOGRAM GRAPHICAL REPRESENTATION. GRAPHICAL REPRESENTATION.

Rev No:02, Date: 01.08.2004 38

Zero Defect Consultants

Statistical Process Control

HSITOGRAM INTERPRETATIONS:

NORMAL

Depicted by a bell-shaped curve. Most frequent measurement

appears as center of distribution & less frequent measurements taper

gradually at both ends of distribution.

Indicates that a process is running normally (only common causes are

present).

Rev No:02, Date: 01.08.2004 39

Zero Defect Consultants

Statistical Process Control

HSITOGRAM INTERPRETATIONS:

BIMODAL

Distribution appears to have two peaks. May indicate that data from

more than one process are mixed together

Materials may come from 2 separate vendors

Samples may have come from 2 separate machines.

Rev No:02, Date: 01.08.2004 40

Zero Defect Consultants

Statistical Process Control

HSITOGRAM INTERPRETATIONS:

SKEWED

Appears as an uneven curve; values seem to taper to one side.

Can be skewed left side or right side.

Rev No:02, Date: 01.08.2004 41

Zero Defect Consultants

Statistical Process Control

Normal Distribution

Consider the following data on the case depth(mm) of 9 jobs:

2.3 2.7 2.4 2.6 2.5

2.5 2.4 2.5 2.6

Plot of the Data:

0

1

2

3

4

2.2 2.3 2.4 2.5 2.6 2.7 2.8

Rev No:02, Date: 01.08.2004 42

Zero Defect Consultants

Statistical Process Control

Plot of the Data:

0

1

2

3

2.3 2.4 2.5 2.6 2.7

Bell Shaped

Symmetric

Total Area under the curve is 1

Then : Normal Curve & Data follows Normal Distribution

Rev No:02, Date: 01.08.2004 43

Zero Defect Consultants

Statistical Process Control

Standard Normal Distribution:

If

Data follows Normal Distribution

then

(Data - Mean) / SD will follow Standard Normal Distribution

For Standard Normal Distribution:

Mean = 0

SD = 1

Rev No:02, Date: 01.08.2004 44

Zero Defect Consultants

Statistical Process Control

Standard Normal Distribution: Properties

0

1

2

3

4

-3 -2 -1 0 1 2 3

68.26%

95.46%

99.73%

Rev No:02, Date: 01.08.2004 45

Zero Defect Consultants

Statistical Process Control

Normal Distribution: Properties

Between

Mean 1 SD : 68.26 % of Values will lie

Mean 2 SD : 95.46 % of Values will lie

Mean 3 SD : 99.73 % of Values will lie

Rev No:02, Date: 01.08.2004 46

Zero Defect Consultants

Statistical Process Control

Process Capability

A methodology to check whether a process is capable of meeting customer

requirements

Expressed as Process Capability Indices

Process Capability Indices

1. Process Potential Index ( Pp or Cp )

2. Process Performance Index ( Ppk or Cpk )

Types of Process Capability Study

1. Preliminary Process Capability Study (Pp & Ppk)

2. Ongoing Process Capability Study (Cp & Cpk)

Rev No:02, Date: 01.08.2004 47

Zero Defect Consultants

Statistical Process Control

Process Potential Index (Pp or Cp)

A methodology to check whether the process have the potential to meet the

customer requirements

Generally

Customer requirements are given as specification on product characteristics

Example

Specification on Heat Treatment Process:

Hardness should be within 55 5 HRC

Rev No:02, Date: 01.08.2004 48

Zero Defect Consultants

Statistical Process Control

Customer Requirement:

Variation allowed by the customer Or

Variation acceptable to customer

Example:

Specification: 55 5 HRC

Meaning:

As long as Hardness of the heat treated jobs are between 50 HRC to 60

HRC, Customer is satisfied

Customer requirements are also expressed as

Lower Specification Limit (LSL) = 50 HRC

Upper Specification Limit (USL) = 60 HRC

Rev No:02, Date: 01.08.2004 49

Zero Defect Consultants

Statistical Process Control

Process Potential Index (Pp or Cp(:

A process have the potential to meet customer requirement, if

Total variation in process < Allowed variation

Example:

Specification: 55 5 HRC

Allowed variation = 50 HRC to 60 HRC

Total Variation = 52 HRC to 58 HRC

Total Variation < Allowed variation

Hence

Process have the potential to satisfy customer

Rev No:02, Date: 01.08.2004 50

Zero Defect Consultants

Statistical Process Control

Example:

Specification: 55 5 HRC

Allowed variation = 50 HRC to 60 HRC

Total Variation = 48 HRC to 62 HRC

Total Variation > Allowed Variation

Then

Process doesnt have the potential to satisfy customer

Rev No:02, Date: 01.08.2004 51

Zero Defect Consultants

Statistical Process Control

Process Potential Index Pp:

If the data is normally distributed, then

Total variation : Mean 3 SD

Example:

Mean = 55 HRC & SD = 1HRC

Total Variation = 55 3 x 1 to 55 + 3 x 1

= 52 HRC to 58 HRC

Rev No:02, Date: 01.08.2004 52

Zero Defect Consultants

Statistical Process Control

Process Potential Index Pp: Definition

Ratio of allowed variation to Total variation

Pp = Allowed variation / total variation

= (USL LSL) / ((Mean + 3 SD) (Mean - 3 SD))

= (USL LSL) / 6 SD

A Process has the potential to meet customer requirements if

total variation < allowed variation

6 SD < (USL LSL)

Pp > 1

Rev No:02, Date: 01.08.2004 53

Zero Defect Consultants

Statistical Process Control

Process Potential Index Pp: Example

20 data on acid content (mm) is given in the table below. If the specification on

acid content is 0.70 0.2 mm. Check whether the process has the potential to

meet the customer requirement ?

0.60

0.70

0.75

0.75

0.70

0.65

0.70

0.80

0.75

0.75

0.65 0.50 0.85 0.75 0.80

0.60 0.75 0.80 0.60 0.85

Specification = 0.70 0.2 mm

USL = 0.90 mm

LSL = 0.50 mm

Mean = 0.715

SD = 0.092

Rev No:02, Date: 01.08.2004 54

Zero Defect Consultants

Statistical Process Control

Process Potential Index Pp: Example

Pp = (USL LSL) / 6 SD

= (0.90 0.50) / (6 x 0.092)

= 0.4 / 0.552 = 0.72

Rev No:02, Date: 01.08.2004 55

Zero Defect Consultants

Statistical Process Control

Process Potential Index (Pp or Cp): Issues

Pp or Cp checks only whether the process has the potential to meet the

requirements

Pp or Cp never checks whether the Process is actually meeting requirements

Rev No:02, Date: 01.08.2004 56

Zero Defect Consultants

Statistical Process Control

Process Performance Index (Ppk or Cpk): Definition

Ppk = Min [Ppl, Ppu]

Ppl = (Mean LSL) / 3 SD

Ppu = (USL - Mean) / 3 SD

Ppk checks whether the process is centered at the middle of the specification

Rev No:02, Date: 01.08.2004 57

Zero Defect Consultants

Statistical Process Control

Process Performance Index Ppk: Graphical Representation

0

0.2

0.4

0.6

0.8

1

1.2

1 2 3 4 5 6 7

USL

LSL

Mean + 3 SD 3 SD

b a

c d

Ppl = a / c = (Mean LSL ) / 3 SD

Ppu = b / d = (USL - Mean ) / 3 SD

Rev No:02, Date: 01.08.2004 58

Zero Defect Consultants

Statistical Process Control

0

0.2

0.4

0.6

0.8

1

1.2

5 6 7 8 9 10 11

12

6

Mean + 3 SD - 3 SD

4 2

3 3

Example:

USL : 12 LSL: 6

Mean : 8 SD : 1

Ppu = 4 / 3 = 1.33

Ppl = 2 / 3 = 0.66

Ppk = Min [1.33,0.66] = 0.66

Ppk < 1, performance is not OK

Rev No:02, Date: 01.08.2004 59

Zero Defect Consultants

Statistical Process Control

0

0.2

0.4

0.6

0.8

1

1.2

6 7 8 9 10 11 12

12

6

Mean + 3 SD - 3 SD

3 3

3 3

Example:

USL : 12 LSL: 6

Mean : 9 SD : 1

Ppu = 3 / 3 = 1

Ppl = 3 / 3 = 1

Ppk = Min [1 , 1] = 1

Ppk = 1

Rev No:02, Date: 01.08.2004 60

Zero Defect Consultants

Statistical Process Control

0

0.2

0.4

0.6

0.8

1

1.2

6 7 8 9 10 11 12

12

6

Mean + 3 SD - 3 SD

3 3

3 3

Conclusion:

Ppu = 3 / 3 = 1

Ppl = 3 / 3 = 1

Ppk = Min [1 , 1] = 1

Pp = (USL LSL) / 6 SD = 6 /6 = 1

When Mean is at middle of

Specification [(USL + LSL) / 2] then

Ppu = Ppl = Ppk = Pp

Otherwise

Ppk < Pp

When Ppk < Pp

Performance is not optimum

Rev No:02, Date: 01.08.2004 61

Zero Defect Consultants

Statistical Process Control

Preliminary Process Capability Study

Is a Short term Study performed during New Product Development.

Indices are represented as Pp & Ppk.

Standard deviation calculated using first principle formulae - Sigma(n-1).

Acceptance value for Pp / Ppk is Min 1.66

Ongoing Process Capability Study

Is a Long term Study performed to monitor the ongoing Production.

Indices are represented as Cp & Cpk.

Standard deviation calculated using sigma = Rbar/d2

Acceptance value for Cp / Cpk is Min 1.33

Rev No:02, Date: 01.08.2004 62

Zero Defect Consultants

Statistical Process Control

A statistical tool to ensure that process is stable or in control

A statistical tool to detect the presence of Assignable Causes in the process.

CONTROL CHARTS

Rev No:02, Date: 01.08.2004 63

Zero Defect Consultants

Statistical Process Control

For Normally distributed Data

If the process is stable then

Variation will be between Mean 3 x SD

Theory of Control Charts

Rev No:02, Date: 01.08.2004 64

Zero Defect Consultants

Statistical Process Control

A Graphical Tool with three horizontal lines

1. Lower Control Limit (LCL)

2. Center Line (CL)

3. Upper Control Limit (UCL)

Control Charts

UCL

CL

LCL

Control Chart

Rev No:02, Date: 01.08.2004 65

Zero Defect Consultants

Statistical Process Control

UCL & LCL are such that

if the value lies between UCL & LCL then the process is stable or in

control

Control Charts

UCL

CL

LCL

Control Chart

Rev No:02, Date: 01.08.2004 66

Zero Defect Consultants

Statistical Process Control

For Normal Data

UCL =Mean + 3 x SD

CL = Mean

LCL = Mean 3 x SD

Control Charts

UCL

CL

LCL

Control Chart

Rev No:02, Date: 01.08.2004 67

Zero Defect Consultants

Statistical Process Control

1. Calculate the Control Limits from past data

2. Plot the values in the chart

3. If the values are within the limits, the process is stable. Otherwise not.

Control Charts: Working

Control Chart

0

2

4

6

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Rev No:02, Date: 01.08.2004 68

Zero Defect Consultants

Statistical Process Control

Continuous Data

Xbar & R Chart ( or Median R Chart)

Individual X & Moving range Chart

Xbar & S Chart ( or Median S Chart)

Types of Control Charts

Discrete Data

Control Chart for Defectives

p chart

np chart

Control Chart for Defects

c chart

u chart

Rev No:02, Date: 01.08.2004 69

Zero Defect Consultants

Statistical Process Control

Determine

Characteristics to be

charted

Are the data

variable

Is interest in

monitoring %

bad parts

Is it

homogeneous

in nature

Selection Procedure for Control Charts

Use X-MR Chart

Is interest in

monitoring

nonconformities

Is the sample

size constant

Is the sample

size constant

Can sub group

avg. easily

calculated

Is the subgroup

size 9 or more

Is s,

calculated

easily

Use Xbar-S Chart

Use Median Chart

Use Xbar-R Chart

Use Xbar-R Chart

Use U Chart

Use C Chart

Use p Chart

Use np Chart

Y

N

N

N

N

N

N

N

N

Y

Y

Y

Y

Y

Y

Y

Y

Rev No:02, Date: 01.08.2004 70

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Methodology

Conduct initial study :-

Decide on the Total Number of Samples N . (N >19)

Decide on Sub Group Size n. (n > 3)

Decide on Frequency of Sampling. ( eg: Once in a hour, Once in 2 hours,

Once in every 50 items, etc.)

Collect Data & Calculate Control Limits

Plot Control Chart

Calculate Process Capability Indices (Pp/Ppk).

If Capable, Set Control Limits for Ongoing study.

Monitor Process through plotting control chart.

Rev No:02, Date: 01.08.2004 71

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Process: Turning Characteristic: Inner diameter (4.90 5.10)

Sample Size N: 9 Sub Group Size n: 4

Frequency of Sampling: Once in a Hour

Step 1: Collect Data

5.00 5.00 5.01 5.02 10:00 3

5.00 5.00 4.98 5.01 9:00 2

5.00 4.98 5.01 5.00 8:00 1

4.98 5.00 4.99 5.02 13:00 6

4.99 5.01 4.98 4.98 12:00 5

5.00 5.00 5.00 5.00 11:00 4

16:00

15:00

14:00

Hour

4.98 5.01 5.00 4.98 9

5.00 5.02 5.01 5.00 8

4.98 4.98 4.99 4.99 7

x4 x3 x2 x1 Sample No.

Rev No:02, Date: 01.08.2004 72

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Step 2: Calculate Sub Group Mean & Range

4.98

5.00

4.98

4.98

4.99

5.00

5.00

5.00

5.00

x4

5.01

5.02

4.98

5.00

5.01

5.00

5.00

5.00

4.98

x3

0.02 5.008 5.01 5.02 10:00 3

0.03 4.998 4.98 5.01 9:00 2

0.03 4.998 5.01 5.00 8:00 1

0.04 4.998 4.99 5.02 13:00 6

0.03 4.990 4.98 4.98 12:00 5

0.00 5.00 5.00 5.00 11:00 4

16:00

15:00

14:00

Hour

0.03 4.993 5.00 4.98 9

0.02 5.008 5.01 5.00 8

0.01 4.985 4.99 4.99 7

Range Mean x2 x1 Sample No.

Rev No:02, Date: 01.08.2004 73

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Step 3: Calculate Control Limits for R Chart

Center Line

CL = Mean = Rbar = Sum of all Range Values / Total Number

of Values

= 0.21 / 9 = 0.0233

Upper Control Limit

UCL = Mean + 3 SD = D

4

Rbar, For n = 4, D

4

= 2.282

= 2.282 x 0.0233 = 0.053

Lower Control Limit

LCL = Mean - 3 SD = D

3

Rbar, For n = 4, D

3

= 0

= 0 x 0.0233 = 0.0

Rev No:02, Date: 01.08.2004 74

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Step 4: Plot R values in R chart as shown below:

R Chart

0

0.02

0.04

0.06

1 2 3 4 5 6 7 8 9

Step 5: If any value is beyond Control Limits, Do Homogenization

Homogenization:

Remove the out of control value

Recalculate the limits

Rev No:02, Date: 01.08.2004 75

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Step 6: Calculate Control Limits for Xbar Chart

Center Line

CL = Mean = Xdoublebar = Sum of all Means / Total Number

of Values

= 44.975 / 9 = 4.997

Upper Control Limit

UCL = Mean + 3 SD = xdoublebar + A

2

Rbar, For n = 4, A

2

= 0.729

= 4.997 + 0.729 x 0.0233 = 5.014

Lower Control Limit

LCL = Mean - 3 SD = xdoublebar - A

2

Rbar, For n = 4, A

2

= 0.729

= 4.997 - 0.729 x 0.0233 = 4.98

Rev No:02, Date: 01.08.2004 76

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Step 7: Plot mean values in xbar chart as shown below:

xbar Chart

4.96

4.98

5

5.02

1 2 3 4 5 6 7 8 9

Step 8: If any value is beyond Control Limits, Do Homogenization

Step 9: If all values are within limit, Calculate Standard deviation

.

= Rbar/d2 , Where d2 is constant

= 0.023/2.059

= 0.0111

Rev No:02, Date: 01.08.2004 77

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Example

Step 10: Calculate Process Capability Indices

Cp = Tol / 6 = 0.2 / 6 * 0.0111 = 3.03

Cpk = Min { (Xbar LSL)/3 , (USL-Xbar)/3 }

Cpk = Min { 2.91 , 3.09 } = 2.91.

Process is Capable.

Step 11: If Capable, Set the Control limits for ongoing monitoring.

Rev No:02, Date: 01.08.2004 78

Zero Defect Consultants

Statistical Process Control

Control Chart Constants

n d2 A2 D3 D4 E2

2 1.128 1.880 0 3.268 2.66

3 1.693 1.023 0 2.574 1.77

4 2.059 0.729 0 2.282 1.46

5 2.326 0.577 0 2.114 1.29

6 2.534 0.483 0 2.004 1.18

Rev No:02, Date: 01.08.2004 79

Zero Defect Consultants

Statistical Process Control

Xbar R Chart: Exercise

6.3

5.7

6.0

5.2

5.0

5.5

6.5

5.2

6.9

6.1

x3

6.4

4.9

5.8

5.1

5.2

6.5

5.7

5.8

6.4

5.8

x2

4.3

5.5

6.0

5.6

5.8

6.7

5.0

5.5

5.2

6.0

x1

10

9

8

7

6

5

4

3

2

1

Sample

Number

6.8 5.2 6.2 14

7.4 6.9 6.1 13

6.2 7.1 6.7 12

5.0 6.9 6.2 11

6.8 7.0 6.6 18

6.7 6.5 5.4 17

6.1 6.4 7.0 16

6.6 6.6 4.9 15

6.7 5.4 6.7 20

7.1 6.2 4.7 19

x3 x2 x1 Sample

Number

The following are the data on Time (in Minutes) to Process Transactions in a

BPO company. Construct an Xbar R chart to monitor the process

Rev No:02, Date: 01.08.2004 80

Zero Defect Consultants

Statistical Process Control

Individual X & Moving Range Chart: Example

2.1 7

2.5

2.9

2.4

2.6

2.8

2.3

2.5

Data

8

6

5

4

3

2

1

Sample Number

For Short Run Process / Bulk Material Processing. Can be used when the

testing method is a destructive type.

Not possible to collect data in Sub Groups

Process: Heat Treatment Characteristic: Case Depth

Rev No:02, Date: 01.08.2004 81

Zero Defect Consultants

Statistical Process Control

Individual X & Moving Range Chart: Example

2.5

2.1

2.9

2.4

2.6

2.8

2.3

2.5

Date

0.8 7

0.4

0.5

0.2

0.2

0.5

0.2

MR

8

6

5

4

3

2

1

Sample Number

Step 2: Calculate Moving Range

Rev No:02, Date: 01.08.2004 82

Zero Defect Consultants

Statistical Process Control

Individual X & Moving Range Chart: Example

Step 3: Calculate Control Limits for M R Chart

Center Line

CL = Mean = MRbar = Sum of all MR Values / Total Number

of Values

= 2.8 / 7 = 0.4

Upper Control Limit

UCL = Mean + 3 SD = D

4

MRbar, For n = 2, D

4

= 3.276

= 3.276 x 0.4 = 1.31

Lower Control Limit

LCL = Mean - 3 SD = D

3

MRbar, For n = 2, D

3

= 0

= 0 x 0.4 = 0.0

Rev No:02, Date: 01.08.2004 83

Zero Defect Consultants

Statistical Process Control

Step 4: Plot MR values in MR chart as shown below:

MR Chart

0

0.5

1

1.5

1 2 3 4 5 6 7

Step 5: If any value is beyond Control Limits, Do Homogenization

Individual X & Moving Range Chart: Example

Rev No:02, Date: 01.08.2004 84

Zero Defect Consultants

Statistical Process Control

Step 6: Calculate Control Limits for Individual X Chart

Center Line

CL = Mean = Xbar = Sum of all Data / Total Number

of Values

= 20.1 / 8 = 2.512

Upper Control Limit

UCL = Mean + 3 SD = xbar + A

2

MRbar, For n = 1, A

2

= 2.66

= 2.512 + 2.66 x 0.4 = 3.58

Lower Control Limit

LCL = Mean - 3 SD = xbar - A

2

MRbar, For n = 1, A

2

= 2.66

= = 2.512 - 2.66 x 0.4 = 1.45

Individual X & Moving Range Chart: Example

Rev No:02, Date: 01.08.2004 85

Zero Defect Consultants

Statistical Process Control

Step 7: Plot individual values in Individual X chart as shown below:

Individual X Chart

0

1

2

3

4

1 2 3 4 5 6 7 8

Step 8: If any value is beyond Control Limits, Do Homogenization

Individual X & Moving Range Chart: Example

Rev No:02, Date: 01.08.2004 86

Zero Defect Consultants

Statistical Process Control

Individual X & Moving Range Chart: Exercise

The data given below are surface Finish values of 30 jobs after chromium

plating. Construct an Individual X & Moving Range chart to monitor the

process?

0.08

0.073

0.075

0.074

0.08

0.074

0.073

0.081

0.076

0.068

0.08

0.077

0.075

0.078

0.079

0.07 0.074 0.076 0.081 0.072

0.074 0.078 0.082 0.079 0.075

0.077 0.078 0.069 0.072 0.078

Rev No:02, Date: 01.08.2004 87

Zero Defect Consultants

Statistical Process Control

Control Charts for Defectives: np Chart

Used when sample size is constant

Used to measure no of nonconforming items in an inspection.

42 2

47 1

58 4

48 3

38 6

32 5

68 8

53 7

37

45

Number of Defectives

10

9

Sample Number

Example: Inspection results of video of the month shipment to customers for 10

consecutive days are given in table. The number of inspection each day

is constant and is equal to 1000. Construct np chart to control the

defectives?

Rev No:02, Date: 01.08.2004 88

Zero Defect Consultants

Statistical Process Control

np Chart : Calculation of Control Limits

CL = Mean

UCL = Mean + 3 SD

LCL = Mean 3 SD

pbar = Sum of Defectives / total Number Inspected

= 468 /(1000*10) = 0.0468

Mean = npbar = 1000 x 0.0468 = 46.8

SD = npbar(1-pbar) = (46.8 x (1-0.0468) = 6.67

CL = npbar = 1000 x 0.0468 = 46.8

UCL = Mean + 3 SD = 46.8 + 3 x 6.68 = 66.84

LCL = Mean - 3 SD = 46.8 - 3 x 6.68 = 26.76

Rev No:02, Date: 01.08.2004 89

Zero Defect Consultants

Statistical Process Control

Plot the number of defectives in np chart as shown below:

np Chart

0

20

40

60

80

1 2 3 4 5 6 7 8 9 10

If any value is beyond Control Limits, Do Homogenization

np chart: Example

Rev No:02, Date: 01.08.2004 90

Zero Defect Consultants

Statistical Process Control

np Chart: Exercise

0

3

7

6

2

20

6

4

6

3

Number of

Defectives

20

19

18

17

16

15

14

13

12

11

Sample

Number

9 2

6 1

6 4

5 3

4 6

7 5

7 8

5 7

0

5

Number of Defectives

10

9

Sample

Number

The following are the data on defectives in payment of dental insurance

claims. Control the dental insurance payment process with np chart.

Sample Size is 300

Rev No:02, Date: 01.08.2004 91

Zero Defect Consultants

Statistical Process Control

Control Charts for Defectives: p Chart

Used when sample size is not constant

650

475

600

450

550

700

625

700

550

500

Number Inspected

6 2

5 1

9 4

8 3

8 6

7 5

6 8

10 7

6

9

Number of Defectives

10

9

Sample Number

Example: The daily inspection results for electric carving knives are given

below. Construct a control chart to monitor the process ?

Rev No:02, Date: 01.08.2004 92

Zero Defect Consultants

Statistical Process Control

p Chart : Calculation of Control Limits

CL = Mean

UCL = Mean + 3 SD

LCL = Mean 3 SD

pbar = Sum of Defectives / Total Number Inspected

= 74 / 5800 = 0.0128

Mean = pbar = 0.0128

SD = pbar(1-pbar) / n

i

Rev No:02, Date: 01.08.2004 93

Zero Defect Consultants

Statistical Process Control

p Chart : Calculation of Control Limits

0.009

0.019

0.010

0.022

0.015

0.010

0.014

0.011

0.011

0.010

p

0

0

0

0

0

0

0

0

0

0

LCL

6

9

6

10

8

7

9

8

6

5

Number of

Defectives

0.026

0.028

0.027

0.029

0.027

0.026

0.026

0.026

0.027

0.028

UCL

650

475

600

450

550

700

625

700

550

500

Number

Inspected

2

1

4

3

6

5

8

7

10

9

Sample

Number

Rev No:02, Date: 01.08.2004 94

Zero Defect Consultants

Statistical Process Control

Plot the proportion of defectives in p chart as shown below:

p Chart

0

0.01

0.02

0.03

0.04

1 2 3 4 5 6 7 8 9 10

If any value is beyond Control Limits, Do Homogenization

p chart: Example

Rev No:02, Date: 01.08.2004 95

Zero Defect Consultants

Statistical Process Control

p Chart: Exercise

159

141

167

175

170

165

189

165

115

181

Number

Inspected

180

195

155

45

170

137

135

170

167

171

Number

Inspected

36

30

11

3

30

26

13

8

6

31

Number of

Defectives

20

19

18

17

16

15

14

13

12

11

Sample

Number

33 2

38 1

15 4

26 3

35 6

16 5

6 8

12 7

26

50

Number of

Defectives

10

9

Sample

Number

Daily inspection results for the model 305 electric range assembly line are

given in the table. Construct a control chart to monitor the process?

Rev No:02, Date: 01.08.2004 96

Zero Defect Consultants

Statistical Process Control

Control Charts for Defects: c Chart

Used when sample size is constant

19 2

8 1

18 4

14 3

16 6

11 5

15 8

8 7

8

21

Number of nonconformities

10

9

Day

Example: A leading bank has compiled the data in the table showing the

count of nonconformities for 100 accounting transactions per

day. Construct a control chart to monitor the process?

Rev No:02, Date: 01.08.2004 97

Zero Defect Consultants

Statistical Process Control

c Chart : Calculation of Control Limits

CL = Mean

UCL = Mean + 3 SD

LCL = Mean 3 SD

cbar = Sum of nonconformities / No. of days

= 138 /10 = 13.8

Mean = cbar = 13.8

SD = cbar = 13.8 = 3.71

CL = cbar = 13.8

UCL = Mean + 3 SD = 13.8 + 3 x 3.71 = 24.93

LCL = Mean - 3 SD = 13.8 - 3 x 3.71 = 2.67

Rev No:02, Date: 01.08.2004 98

Zero Defect Consultants

Statistical Process Control

Plot the number of nonconformities in c chart as shown below:

c Chart

0

10

20

30

1 2 3 4 5 6 7 8 9 10

If any value is beyond Control Limits, Do Homogenization

c chart: Example

Rev No:02, Date: 01.08.2004 99

Zero Defect Consultants

Statistical Process Control

c Chart: Exercise

29

31

11

34

16

20

17

25

29

22

Number of

Nonconformities

20

19

18

17

16

15

14

13

12

11

Day

10 2

15 1

23 4

33 3

15 6

27 5

17 8

17 7

22

19

Number of Nonconformities

10

9

Day

100 product labels are inspected every day for surface nonconformities.

The data for the past 20 days is given below. Construct a suitable control

chart to monitor the nonconformities

Rev No:02, Date: 01.08.2004 100

Zero Defect Consultants

Statistical Process Control

Control Charts for Defects: u Chart

Used when sample size is not constant

8

8

8

10

10

10

9

10

10

10

Number Inspected

51 2

45 1

48 4

36 3

5 6

42 5

27 8

33 7

22

31

Number of Defects

10

9

Lot Number

Example: The inspection results for the surface finish of rolls of white

paper for 10 lots is given below. Construct a control chart to

monitor the process ?

Rev No:02, Date: 01.08.2004 101

Zero Defect Consultants

Statistical Process Control

u Chart : Calculation of Control Limits

CL = Mean

UCL = Mean + 3 SD

LCL = Mean 3 SD

ubar = Sum of Defects / Total Number Inspected

= 340 / 93 = 3.66

Mean =ubar = 3.66

SD = (ubar / n

i

)

Rev No:02, Date: 01.08.2004 102

Zero Defect Consultants

Statistical Process Control

u Chart : Calculation of Control Limits

2.8

3.9

3.4

3.3

0.5

4.2

5.3

3.6

5.1

4.5

u

2.44

2.63

2.56

2.66

1.09

2.77

2.83

2.70

2.86

2.80

LCL

22

31

27

33

5

42

48

36

51

45

Number of

Defects

5.69

5.69

5.69

5.47

5.47

5.47

5.57

5.47

5.47

5.47

UCL

8

8

8

10

10

10

9

10

10

10

Number

Inspected

2

1

4

3

6

5

8

7

10

9

Lot

Number

Rev No:02, Date: 01.08.2004 103

Zero Defect Consultants

Statistical Process Control

Plot the defects / unit (u) of in u chart as shown below:

u Chart

0

2

4

6

1 2 3 4 5 6 7 8 9 10

If any value is beyond Control Limits, Do Homogenization

u chart: Example

Rev No:02, Date: 01.08.2004 104

Zero Defect Consultants

Statistical Process Control

u Chart: Exercise

52

40

40

40

40

40

52

52

52

52

Number of

bottles

Inspected

52

52

52

52

52

40

40

40

40

40

Number of

bottles

inspected

54

73

50

60

79

62

43

33

40

45

Number of

Defects

20

19

18

17

16

15

14

13

12

11

Sample

Number

74 2

55 1

61 4

43 3

32 6

43 5

33 8

45 7

28

50

Number of Defects

10

9

Sample

Number

Construct a suitable control chart for the data in the table for empty bottle

inspections of a soft drink manufacturer?

Rev No:02, Date: 01.08.2004 105

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

A Process Under Control

A1 Values are distributed uniformly

within control limits:

UCL The course of process is

determined only by common

causes

No intervention is required.

LCL

Rev No:02, Date: 01.08.2004 106

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

B. Process Out of Control

B1 Points outside the control Limits

UCL Find out the reasons

immediately

Sort out the parts

manufactured

LCL

Document remedial actions

Rev No:02, Date: 01.08.2004 107

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

B. Process Out of Control

B2 Trend : 7 and ,More consecutive

points are within the control limits

but ascending or descending pattern

UCL

Has the manufacturing process a trend ?

Had the interference with

process been too late?

Trend (reasons) more than

LCL

normal?

Other influences (4M)?

Rev No:02, Date: 01.08.2004 108

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

B. Process Out of Control

B3 Repeated patterns of points within

control limits

UCL

Is it possible to attribute

external influence (shift change

temperature variations)

Since when these samples

LCL

are experienced?

Remedial actions ?

Other influences (4M)?

Rev No:02, Date: 01.08.2004 109

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

B. Process Out of Control

B4 Shift in average value :7 and more

points to one side of average

(Central Positions)

UCL

QC Chart is not understood ?

any deliberate shop practice?

Has the process ,despite

resetting not reacted?

LCL

Different material Charge?

Other influences (4M)?

Why the process scatter is

less (Is it always so )?

Rev No:02, Date: 01.08.2004 110

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

B. Process Out of Control

B 5 Low scatter : more than2/3 of all

points are within 1/3 of control limits

UCL

Control limits : are they

calculated correctly?

Measuring instruments :

correctly calibrated ? If So:

LCL

Determine reasons for

reduced process variation

How can this conditions be

maintained permanently ?

Calculate control limits a fresh

Rev No:02, Date: 01.08.2004 111

Zero Defect Consultants

Statistical Process Control

Interpretation of Control Charts

B. Process Out of Control

B 6 Big scatter : more than 2/3 of all

points are between the outer

thirds of Control limits

UCL

Distribution of process

is it normal ?

Why does the process

fluctuate ?

LCL

Are Control Limits calculated

correctly

Measuring instrument:

Correctly calibrated ?

Other influences (4M)?

Rev No:02, Date: 01.08.2004 112

Zero Defect Consultants

Statistical Process Control

Select the

characteristics &

Process for SPC

Plan for Data

Collection

Is Process

Capable

Is Process

Stable

Establish Control

Limits

Improve the Process

Find

Assignable

Cause & Fix it

N

N

Y

Y

Perform MSA Study

Collect Data & Plot

Control Chart

Prepare Reaction Plan

Ongoing Process

Control

SPC Implementation:-

Rev No:02, Date: 01.08.2004 113

Zero Defect Consultants

Statistical Process Control

Collect Data

Is Process in

Control (I.e no

special cause)

Refer Reaction Plan

N

Y

Plot on the Control

Chart

Take Corrective Action

Take Disposition

action, if required

Operator Role in SPC:-

Rev No:02, Date: 01.08.2004 114

Zero Defect Consultants

Statistical Process Control

REACTION PLAN

Corrective

Action

Disposition Action Possible

Causes

Condition Chart

Doc No.:-

Rev. No./Date:-

Process:-

Parameter:-

Rev No:02, Date: 01.08.2004 115

Zero Defect Consultants

Statistical Process Control

Any Questions

Rev No:02, Date: 01.08.2004 116

Zero Defect Consultants

Statistical Process Control

Thank You

Вам также может понравиться

- SPC Course MaterialДокумент115 страницSPC Course MaterialMukesh Krishna RОценок пока нет

- Are We Doing Well SlidesДокумент10 страницAre We Doing Well SlidessahajОценок пока нет

- Leanmap FREE Quality Processes OverviewДокумент2 страницыLeanmap FREE Quality Processes OverviewWixi MundoОценок пока нет

- Knowledge About SPC Tools (Statical Process Control)Документ6 страницKnowledge About SPC Tools (Statical Process Control)VarunОценок пока нет

- Lean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTДокумент16 страницLean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTRohit SatijaОценок пока нет

- Chapter - 3 Six SigmaДокумент32 страницыChapter - 3 Six Sigmakem SanОценок пока нет

- Quality Systems, Techniques & Leaders - PKДокумент29 страницQuality Systems, Techniques & Leaders - PKPrabhat KhareОценок пока нет

- Risk Assessment Techniques (IEC 31010Документ9 страницRisk Assessment Techniques (IEC 31010kanchana rameshОценок пока нет

- List of QSP and IATF 16949 ClauseДокумент129 страницList of QSP and IATF 16949 ClauseDamodaran Rajanayagam100% (1)

- 2022 PGDip DAY 4Документ190 страниц2022 PGDip DAY 4Hope MashozheraОценок пока нет

- Hse 301 A - Study MaterialДокумент76 страницHse 301 A - Study Materialkiller sha100% (1)

- 02-Quality Management Process 128Документ128 страниц02-Quality Management Process 128QUADRI AYODELEОценок пока нет

- 2022 PGDip DAY 3Документ177 страниц2022 PGDip DAY 3Hope MashozheraОценок пока нет

- Measurement System AnalysisДокумент1 страницаMeasurement System AnalysisPrakash KancharlaОценок пока нет

- Basics of Defining ProcessesДокумент18 страницBasics of Defining ProcessesFaried Putra SandiantoОценок пока нет

- Bootcamp d1 Present.Документ24 страницыBootcamp d1 Present.LissaОценок пока нет

- KRA FormatДокумент1 страницаKRA FormatSushil RautОценок пока нет

- MRM 2022 SafetyДокумент22 страницыMRM 2022 SafetyHA PLОценок пока нет

- Measure 6 Gage R&R - Short MethodДокумент2 страницыMeasure 6 Gage R&R - Short Methodanjo0225Оценок пока нет

- Six Sigma Control PDFДокумент74 страницыSix Sigma Control PDFnaacha457Оценок пока нет

- Effective Problem SolvingДокумент1 страницаEffective Problem Solvingmuthuswamy77Оценок пока нет

- KPIs boards optimize factory performanceДокумент7 страницKPIs boards optimize factory performanceAhmed HassanОценок пока нет

- Statistical Process Control ChartДокумент69 страницStatistical Process Control ChartLeechel Ella Recalde (Ellie)Оценок пока нет

- IMS-TUL-01-IMS Turtil DiagramДокумент1 страницаIMS-TUL-01-IMS Turtil DiagramRohit SoniОценок пока нет

- VDA6.3 Process Audit ChecklistДокумент32 страницыVDA6.3 Process Audit Checklistpkj009Оценок пока нет

- FR21-Esclation Flow With Time LimitДокумент1 страницаFR21-Esclation Flow With Time Limitkumar QAОценок пока нет

- Promblem Solving Combined March 2017 AnelleДокумент25 страницPromblem Solving Combined March 2017 AnelleSravan DasariОценок пока нет

- Lean CTR TrainingДокумент36 страницLean CTR TrainingSanjib KumarОценок пока нет

- Enterprise Risk Management Guide Identifying and Understanding RisksДокумент20 страницEnterprise Risk Management Guide Identifying and Understanding RisksPeterpaul SilacanОценок пока нет

- SEO & Plant Manager: Emad Abu-Zaid: Production TeamДокумент7 страницSEO & Plant Manager: Emad Abu-Zaid: Production TeamGovind MaheshwariОценок пока нет

- ISO 45001 Lead Auditor EN v.2.1 - Day 1Документ128 страницISO 45001 Lead Auditor EN v.2.1 - Day 1Rodney SeepersadОценок пока нет

- Module 1, Strategic Planning, AmrSukkarДокумент45 страницModule 1, Strategic Planning, AmrSukkarHanan AdelОценок пока нет

- Clause Wise Tutorials-7.1.4 Change Control ExplanationДокумент2 страницыClause Wise Tutorials-7.1.4 Change Control ExplanationBharathОценок пока нет

- Six Sigma Black Belt Improve ChapterДокумент135 страницSix Sigma Black Belt Improve ChapterMedia TeamОценок пока нет

- Session - 1Документ12 страницSession - 1kanchana rameshОценок пока нет

- B 04 - Tree DiagramДокумент10 страницB 04 - Tree DiagramNupesh katreОценок пока нет

- Workplace Safety Signs ExplainedДокумент3 страницыWorkplace Safety Signs ExplainedBaharudin HelmyОценок пока нет

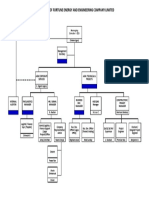

- Overview of Fortune Energy and Engineering CompanyДокумент1 страницаOverview of Fortune Energy and Engineering CompanyGodwin A.udo-akanОценок пока нет

- Electric Wire PDFДокумент102 страницыElectric Wire PDFGoswami kinjalОценок пока нет

- MDA - 1.module 1 - BI Introduction - Data PrepДокумент131 страницаMDA - 1.module 1 - BI Introduction - Data PrepBui KietОценок пока нет

- Asset Performance MetricsДокумент10 страницAsset Performance MetricsRogelio SotoОценок пока нет

- SPC FormatДокумент1 страницаSPC FormatJaydeep PoteОценок пока нет

- Innovation Management Week-5 Feb 08Документ70 страницInnovation Management Week-5 Feb 08PRAKASH CHANTIBABU DIDLA PRAKASH CHANTIBABU DIDLAОценок пока нет

- TQM - TRG - F-07 - Cluster Analysis - Rev02 - 20180421Документ42 страницыTQM - TRG - F-07 - Cluster Analysis - Rev02 - 20180421pradeep1987coolОценок пока нет

- ERMA EBA - Reading Material Module 2 - Introduction To ISO 31000Документ19 страницERMA EBA - Reading Material Module 2 - Introduction To ISO 31000Bagas NurfazarОценок пока нет

- Basic Problem Solving (BPS) Template - RevisedДокумент38 страницBasic Problem Solving (BPS) Template - RevisedgcldesignОценок пока нет

- CRAFTSMAN AUTOMATION Repeatability and Reproducibility Study R&R AnalysisДокумент4 страницыCRAFTSMAN AUTOMATION Repeatability and Reproducibility Study R&R Analysissivaseeni100% (1)

- Measurement System AnalysisДокумент2 страницыMeasurement System AnalysispsathishthevanОценок пока нет

- Session 11. Defining Quality To Apply To Everyone, Everywhere (Watson, 2020)Документ49 страницSession 11. Defining Quality To Apply To Everyone, Everywhere (Watson, 2020)taghavi1347Оценок пока нет

- Leanmap FREE Six Sigma Project CharterДокумент1 страницаLeanmap FREE Six Sigma Project CharterWixi MundoОценок пока нет

- By: M. Asjad Aamir (2016-ME-10) Umar Imtiaz (2016-ME-11) Naeemullah (2016-ME-12)Документ20 страницBy: M. Asjad Aamir (2016-ME-10) Umar Imtiaz (2016-ME-11) Naeemullah (2016-ME-12)MUHAMMAD ASJAD AAMIR AAMIR AMINОценок пока нет

- Session 03. Designing Quality As An Inclusive Business System (Watson, 2020)Документ66 страницSession 03. Designing Quality As An Inclusive Business System (Watson, 2020)taghavi1347Оценок пока нет

- DMAIC: The Complete Guide To Lean Six Sigma in 5 Key Steps: We're HiringДокумент24 страницыDMAIC: The Complete Guide To Lean Six Sigma in 5 Key Steps: We're Hiringlipsy25Оценок пока нет

- Peration Anagement: Concept of Quality Juran's PrincipleДокумент24 страницыPeration Anagement: Concept of Quality Juran's PrincipleAyushi BisenОценок пока нет

- 09 Process Capability PDFДокумент41 страница09 Process Capability PDFMukesh Krishna RОценок пока нет

- Sunflag Crack IssueДокумент7 страницSunflag Crack IssueKumaravelОценок пока нет

- LSSGB (Simplilearn, 2014) - Lesson - 3. MeasureДокумент121 страницаLSSGB (Simplilearn, 2014) - Lesson - 3. Measuretaghavi1347Оценок пока нет

- Automotive Quality Management Systems A Complete Guide - 2020 EditionОт EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionОценок пока нет

- Statistical Process Control TrainingДокумент117 страницStatistical Process Control TrainingS M Jagadish JagadishОценок пока нет

- TheHinduBookofAstrology 10001042Документ105 страницTheHinduBookofAstrology 10001042Purushothama Nanje Gowda100% (1)

- V4precision Company Profile - 2019Документ15 страницV4precision Company Profile - 2019Purushothama Nanje GowdaОценок пока нет

- Success Sply CatalougeДокумент4 страницыSuccess Sply CatalougePurushothama Nanje GowdaОценок пока нет

- Internal Dimensions of Hexalobular Screws (DIN en ISO 10664)Документ1 страницаInternal Dimensions of Hexalobular Screws (DIN en ISO 10664)Purushothama Nanje GowdaОценок пока нет

- Thread Locking and Sealing enДокумент8 страницThread Locking and Sealing enPurushothama Nanje GowdaОценок пока нет

- The Nakshatra of Vedic AstrologyДокумент9 страницThe Nakshatra of Vedic Astrologyashishbhagoria100% (1)

- Nakshatras 27Документ2 страницыNakshatras 27Ramanasarma100% (2)

- 202-Fms Timing Belts Calc Methods enДокумент28 страниц202-Fms Timing Belts Calc Methods enYesenia AquilinaОценок пока нет

- qs006 13000006 1Документ11 страницqs006 13000006 1Purushothama Nanje GowdaОценок пока нет

- Process AuditДокумент15 страницProcess Auditdesurkarb100% (2)

- Audit - Visio-Template Process MapДокумент1 страницаAudit - Visio-Template Process MapPurushothama Nanje GowdaОценок пока нет

- ASTM F1470.zcvg5907Документ5 страницASTM F1470.zcvg5907Purushothama Nanje Gowda100% (1)

- Appendix A - Supplier ISO-TS16949 Checklist-Rev.1 PDFДокумент45 страницAppendix A - Supplier ISO-TS16949 Checklist-Rev.1 PDFPurushothama Nanje GowdaОценок пока нет

- Kapitel 05 DINO Techn TeilДокумент10 страницKapitel 05 DINO Techn TeilPurushothama Nanje GowdaОценок пока нет

- IMDS Instructions - CTT v3Документ21 страницаIMDS Instructions - CTT v3Purushothama Nanje GowdaОценок пока нет

- Qq181en 3Документ1 страницаQq181en 3Purushothama Nanje GowdaОценок пока нет

- qs011 13000002 1Документ11 страницqs011 13000002 1Purushothama Nanje GowdaОценок пока нет

- Lead Time - 001Документ18 страницLead Time - 001Purushothama Nanje GowdaОценок пока нет

- HT Process Run SheetДокумент1 страницаHT Process Run SheetPurushothama Nanje GowdaОценок пока нет

- BOSCH Specification For Chemistry and MetallurgicalДокумент2 страницыBOSCH Specification For Chemistry and MetallurgicalPurushothama Nanje GowdaОценок пока нет

- APQP Manual VolvoДокумент30 страницAPQP Manual VolvoVictor Hugo50% (2)

- PPAP Readiness AuditДокумент4 страницыPPAP Readiness AuditPurushothama Nanje GowdaОценок пока нет

- Evaporator WBSP02 TurningДокумент2 страницыEvaporator WBSP02 TurningPurushothama Nanje GowdaОценок пока нет

- Run at Rate AuditДокумент12 страницRun at Rate AuditPurushothama Nanje GowdaОценок пока нет

- Esic Udc Mts Question Paper 2012Документ9 страницEsic Udc Mts Question Paper 2012Purushothama Nanje GowdaОценок пока нет

- qs006 13000006 1Документ11 страницqs006 13000006 1Purushothama Nanje GowdaОценок пока нет

- Strategic Supply AgreementДокумент12 страницStrategic Supply AgreementPurushothama Nanje GowdaОценок пока нет

- A UDC-Paper IДокумент7 страницA UDC-Paper IPurushothama Nanje GowdaОценок пока нет

- qs036 13000005 1Документ10 страницqs036 13000005 1Purushothama Nanje GowdaОценок пока нет

- Final Slip2Документ30 страницFinal Slip2rohan pawarОценок пока нет

- Theory of Elinor OstromДокумент5 страницTheory of Elinor OstromSanjana KrishnakumarОценок пока нет

- 12V Laptop ChargerДокумент12 страниц12V Laptop ChargerSharon Babu0% (1)

- Abm Trial Balance ActivityДокумент3 страницыAbm Trial Balance ActivityRoxanne RoldanОценок пока нет

- Keltbray Crude Oil and Gas LTDДокумент2 страницыKeltbray Crude Oil and Gas LTDIana LeynoОценок пока нет

- GT2-71D Amplifier Unit Data SheetДокумент3 страницыGT2-71D Amplifier Unit Data SheetKenan HebibovicОценок пока нет

- DesertationДокумент145 страницDesertationhishamromi760% (1)

- Agency Certificate of Compliance: IGHRS Update As of June 30, 2022Документ2 страницыAgency Certificate of Compliance: IGHRS Update As of June 30, 2022Dacanay RexОценок пока нет

- Revision Question 2023.11.21Документ5 страницRevision Question 2023.11.21rbaambaОценок пока нет

- Ecovadis Survey Full 3 07 2019Документ31 страницаEcovadis Survey Full 3 07 2019ruthvikОценок пока нет

- Product Bulletin VHP7104GSI S5Документ2 страницыProduct Bulletin VHP7104GSI S5Wiliam SeguraОценок пока нет

- Mining Operational ExcellenceДокумент12 страницMining Operational ExcellencegarozoОценок пока нет

- M100 PD ENДокумент2 страницыM100 PD EN윤병택Оценок пока нет

- Micom P139: Feeder Management and Bay ControlДокумент376 страницMicom P139: Feeder Management and Bay ControljjcanoolivaresОценок пока нет

- Lesson 2 Empowerment MidtermДокумент5 страницLesson 2 Empowerment Midtermaronfranco223Оценок пока нет

- A Review of Bharat Nirman ProgrammeДокумент3 страницыA Review of Bharat Nirman Programmevivek559Оценок пока нет

- Ds Gigavue FM Fabric ManagerДокумент9 страницDs Gigavue FM Fabric ManagerMARCELOTRIVELATTOОценок пока нет

- Solaris 10 Service - (Management Facility (SMF: Oz Melamed E&M Computing Nov 2007Документ18 страницSolaris 10 Service - (Management Facility (SMF: Oz Melamed E&M Computing Nov 2007Anonymous 4eoWsk3100% (3)

- Delivering Large-Scale IT Projects On Time, On Budget, and On ValueДокумент5 страницDelivering Large-Scale IT Projects On Time, On Budget, and On ValueMirel IonutОценок пока нет

- Jmeter Performance Testing Your Webapp 1203622239433273 3Документ12 страницJmeter Performance Testing Your Webapp 1203622239433273 3pallavi91Оценок пока нет

- TopGearДокумент188 страницTopGearbarborina10% (1)

- TOTO Indonesia Sanitary CatalogДокумент40 страницTOTO Indonesia Sanitary CatalogiaqistiОценок пока нет

- E No Ad Release NotesДокумент6 страницE No Ad Release NotesKostyantinBondarenkoОценок пока нет

- A Case Study On Design of Ring Footing For Oil Storage Steel TankДокумент6 страницA Case Study On Design of Ring Footing For Oil Storage Steel Tankknight1729Оценок пока нет

- This Study Resource Was: Artur Vartanyan Supply Chain and Operations Management MGMT25000D Tesla Motors, IncДокумент9 страницThis Study Resource Was: Artur Vartanyan Supply Chain and Operations Management MGMT25000D Tesla Motors, IncNguyễn Như QuỳnhОценок пока нет

- Factors for Marketing Success in Housing SectorДокумент56 страницFactors for Marketing Success in Housing SectorNhyiraba Okodie AdamsОценок пока нет

- Techniques For Optimal Placement of Electric Vehicle Charging Stations A ReviewДокумент5 страницTechniques For Optimal Placement of Electric Vehicle Charging Stations A Reviewkumar_ranjit6555Оценок пока нет

- Francisco v. Boiser PDFДокумент12 страницFrancisco v. Boiser PDFPia Christine BungubungОценок пока нет

- Acetanilide C H Nhcoch: Aniline Acetic Acid Reactor Filter Crystallizer Centrifuge DryerДокумент4 страницыAcetanilide C H Nhcoch: Aniline Acetic Acid Reactor Filter Crystallizer Centrifuge DryerAnonymous 4hx84J3Оценок пока нет

- Science Room Rules Teaching PlanДокумент1 страницаScience Room Rules Teaching PlanraqibsheenaОценок пока нет