Академический Документы

Профессиональный Документы

Культура Документы

Evaluation Studies of Expansive Soil Treated With Electrolytes

Загружено:

Saparya Varma0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров9 страницiijest

Оригинальное название

IJEST11-03-12-123

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документiijest

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров9 страницEvaluation Studies of Expansive Soil Treated With Electrolytes

Загружено:

Saparya Varmaiijest

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 9

EVALUATION STUDIES OF

EXPANSIVE SOIL TREATED WITH

ELECTROLYTES

KESAVA N K CHAITANYA G Dr. G. V .R. PRASADA RAJ U

P.G Student Professor

Department of Civil Engineering Dr. K. RAMU

University College of Engineering Associate Professor

KAKINADA-533003::INDIA.

ABSTRACT

Expansive soils, such as black cotton soils, are basically susceptible to detrimental volumetric changes,

with changes in moisture. This behavior of soil is attributed to the presence of mineral montmorillonite,

which has an expanding lattice. In the present work, experimentation is carried-out to investigate the

influence of strong electrolyte viz. potassium chloride, calcium chloride and ferric chloride on the

properties of expansive soil. A methodical process, involving experimentation in the laboratory under

controlled conditions is done. It is observed form the laboratory studies that maximum improvement in

the properties of Expansive soil is for Ferric Chloride treatment compared to other electrolytes tried in

this investigation.

KEY WORDS: Expansive soils; Calcium Chloride; Potassium Chloride; Ferric Chloride

1.1 1NTRODUCTION

Expansive soil cover large tracts of several world nations and in India; these deposits are known by the name,

black cotton soils which occupy about 20% of its surface area. In India, these soils are predominant in the

states of Gujarat, Maharashtra, Madhya Pradesh, Andhra Pradesh, Karnataka and Tamilnadu. After recognizing

the problems posed by these soils to civil engineering structures, Engineers from all parts of the world have been

trying to find solutions. Among several techniques adopted to overcome the problems posed by expansive soils,

lime stabilization gained prominence during the past few decades due to its abundance and adaptability (Snethan

et al, 1979). However, it is reported (Chen, 1988) that lime stabilization suffers from the major drawback of

difficulty in soil pulverization and mixing of with it. Recent studies (Ramana Murthy, 1998; Srinivas,(2008), D.

Koteswararao, (2011)). indicated that CaCl

2

could be an effective alternative to conventional lime used due to its

ready dissolvability in water and to supply adequate calcium ions for exchange reactions. Katti et al (1966)

made an attempt to stabilize the in-situ soil using KOH solution and they revealed that it is possible to alter the

properties of black cotton soils in place by treating them with aqueous solution of KOH. Frydman et al (1977)

studied the use of KCl to modify heavy clay in the laboratory and revealed that from engineering point of view,

the use of KCl as a stabilizer appears potentially promising in locations where it is readily and cheaply available.

In the present work, the efficiency of Potassium Chloride (KCl), Calcium Chloride (CaCl

2

) and Ferric Chloride

(FeCl

3

)

,

as stabilizing

agents, was extensively studied in the laboratory for improving the properties of

expansive soil.

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8298

1.2 OBJECTIV E

The objective of the present work is to study the impact of the electrolytes like KCl,

CaCl

2

and FeCl

3

on the properties of expansive soil with laboratory.

1.3 MATERIALS USED

The details of the various materials and chemicals used in the laboratory experimentation are reported in

the following sections.

1.3.1 Soil

The black cotton soil collected from Kothapeta near Amalapuram, in East Godavari District, Andhra

Pradesh State, India. The properties of soil are presented in the table. All the tests carried on the soil are as per

IS specifications.

Table.1. Properties of Expansive soil

1.3.2 Chemicals Used

Commercial grade KCl, CaCl

2

and FeCl

3

was used in this study. The quantity of Chemicals was varied from 0

to 1.5% by dry weight of soil.

1.4 LABORATORY EXPERIMENTATION

1.4.1 Index Properties

S.No Property Value

1. Grain size distribution

Sand (%)

Silt (%)

Clay (%)

2

20

78

2. Atterberg limits

Liquid limit (%)

Plastic limit (%)

Plasticity index (%)

Shrinkage limit (%)

77

37

40

13

3. Compaction

properties

Optimum Moisture

Content, O.M.C. (%)

Maximum Dry Density,

M.D.D (g/cc)

28.2

1.48

4. Specific Gravity (G) 2.7

5. IS Classification CH

6. Soaked C.B.R (%) 2

7. Differential free swell

(%)

110

8 Permeability (cm/sec) 1.4710

9 Shear Strength

Parameters

Cohesion (C) (Kg/cm)

Angle of internal

friction ()

0.46

2

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8299

Different percentages of chemicals (ranging from 0-1.5% by weight) were mixed with soil (for all the

combinations as listed in the table) and the liquid limit, plastic limit and shrinkage limit were determined as per

IS:2720 (part-5)-1985; IS:2720 (part-6)-1972.

1.4.2 Compaction Properties

Optimum moisture content and maximum dry density of the black cotton soil were determined according to

the IS Heavy weight compaction test (IS:2720 part-8,1983).

1.4.3 Differential Free Swell (DFS)

The DFS values for all the combinations listed in table and also of the untreated soil, were determined as

per IS:2720-part XL-1977.

1.4.4 Strength Tests

Tri-axial test, California bearing ratio and Unconfined compressive strength were found for all the soil

combinations, as presented.

1.5 LABORATORY TEST RESULTS ON CHEMICAL STABILIZATION

In the laboratory, index tests and strength tests were conducted by using different percentages of

chemicals with a view to determine the optimum percentage of chemical.

The effect of addition of different chemicals to the expansive soil on the Atterberg limits, differential

free swell and strength properties are discussed in detail in the following sections.

.

Table.2. Effect of strong electrolytes on Index Properties of expansive soil

Chemical

Percentages

of chemical

Index properties

WL

(%)

P.L.

(%)

I

P

(%)

S.L

(%)

KCl

0 77 37 40 13.0

0.5 69 37 32 13.4

1 63 37 26 14.7

1.5 59 38 21 16.0

CaCl

2

0 77 37 40 13.0

0.5 65 38 27 13.7

1 59 38 21 15.4

1.5 56 39 17 16.2

FeCl

3

0 77 37 40 13.0

0.5 58 38 20 14.1

1 52 39 13 15.9

1.5 50 40 10 16.8

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8300

Fig.1.Effect of chemicals on liquid limit

Fig.2.Variation of Plastic limit

Fig.3.Variation of plasticity Index

0

20

40

60

80

100

0 0.5 1 1.5 2

L

i

q

u

i

d

L

i

m

i

t

(

%

)

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

36.5

37

37.5

38

38.5

39

39.5

40

40.5

0 0.5 1 1.5 2

P

l

a

s

t

i

c

L

i

m

i

t

(

%

)

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

0

5

10

15

20

25

30

35

40

45

0 0.5 1 1.5 2

P

l

a

s

t

i

c

i

t

y

I

n

d

e

x

(

%

)

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8301

Fig.4.Variation of Shrinkage Limit

1.5.1 Effect of Additives on Atterberg Limits

The decrease in the liquid limit values for different percentages of chemicals added to the expansive

soil is presented in the Table.2. The decrease in the values of liquid limit upto 1% of chemical is significant for

all the chemicals, as shown in Fig.1. Beyond 1% there is a nominal decrease in the liquid limit values, for all the

chemicals, tried in this investigation. For FeCl

3

treatment there is maximum decrease in the values of the liquid

limit when compared with other two chemicals viz. KCl and CaCl

2

. There is a nominal increase in the values of

the plastic limit with the increase in the percentage of the chemical.

The increase in the plastic limit values and the reduction in the liquid limit values cause a net reduction

in the values of plasticity index. For 1% chemical, it is observed that, the reduction in plasticity index values are

of the order of 35%, 45% and 68% for KCl, CaCl

2

and FeCl

3

treatment respectively with respect to the

untreated soil. The effect of KCl, CaCl

2

and FeCl

3

treatments on plasticity index of expansive clay as observed

in the laboratory testing are shown in Tables.2. and Fig 3. It can be seen from the figure that, the FeCl

3

treatment has effectively controlled the plasticity index compared to other additives. The shrinkage limit values

are increased by 13%, 18% & 22% respectively for 1% KCl, CaCl

2

and FeCl

3

treatments.

The reduction in plasticity index, with FeCl

3

treatment could be attributed to the depressed double layer

thickness due to cation exchange by trivalent Ferric ions and increased electrolyte concentration, as the chemical

is completely soluble in water

Table 3: Effect of Chemical on DFS

0

5

10

15

20

0 0.5 1 1.5 2

S

h

r

i

n

k

a

g

e

L

i

m

i

t

(

%

)

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

chemical

% chemical

D F S (%)

KCl 0 110

0.5 90

1 75

1.5 70

0 110

CaCl 0.5 80

1 70

1.5 65

0 110

FeCl 0.5 70

1 55

1.5 50

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8302

Fig 5. Variation of DFS

1.5.2 Effect of Additives on DFS

The variation of D.F.S. for different percentages of the chemicals is shown in the Table.3& Fig 5.

There is a significant decrease in D.F.S. values upto 1% of the chemical, after that the change is marginal. The

reduction in the values of D.F.S. at 1% chemical are at the order of 32%, 37% and 50% for KCl, CaCl

2

and

FeCl

3

treatments respectively in comparison with untreated soil.

The reduction in DFS values could be supported by the fact that the double layer thickness is

suppressed by cation exchange with trivalent ferric ions and increased electrolyte concentration. .

Table 4: Effect of Chemical on CBR

Fig 6. Variation of CBR

0

20

40

60

80

100

120

0 0.5 1 1.5 2

D

F

S

(

%

)

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

0

1

2

3

4

5

6

0 0.5 1 1.5 2

C

B

R

(

%

)

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

chemical

% chemical

CBR(soaked)

KCl

0 2.00

0.5 2.66

1 3.96

1.5 4.22

CaCl

0.5 2.82

1 4.50

1.5 4.75

FeCl

0.5 3.06

1 5.00

1.5 5.30

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8303

1.5.3 Effect of Additives on CBR

The CBR values are increased by 98%, 125% , 150% when treated with 1% KCl, 1%CaCl

2

&1%

FeCl

3

as shown in Table 4 & Fig .6. The increase in the strength with addition of chemicals may be attributed to

the cation exchange of KCl, CaCl

2

& FeCl

3

between mineral layers and due to the formation of silicate gel. The

reduction in strength beyond 1% each of KCl, CaCl

2

& FeCl

3

may be due to the absorbtion of more moisture at

higher KCl, CaCl

2

& FeCl

3

contents.

Table 5: Effect of Chemical on shear strength parameters

1.5.4 Effect of Additives on Shear Parameters

The significant improvement of shear parameters was observed, when treated with 1%KCl, 1%CaCl

2

,

and 1% FeCl

3

respectively as shown in Table 5.

Table 6: Effect of Chemical on UCS

chemical

(%)

chemical

Shear strength

Parameters

(c, ) in Kg/cm & degrees

KCl

1 day 7 days 14days

0 0.46,2

0

----- ----

0.5 0.51,6

0

1.02,5

0

1.12,3

0

1.0 0.57,4

0

1.12,5

0

1.24,3

0

1.5 0.53,7

0

1.08,4

0

1.19,5

0

CaCl

0 0.46,2

0

------ -----

0.5 0.58,5

0

1.05,4

0

1.16,3

0

1.0 0.63,3

0

1.22,4

0

1.28,3

0

1.5 0.60,2

0

1.13,3

0

1.26,4

0

FeCl

0 0.46,2

0

------- -----

0.5 0.64,4

0

1.11,4

0

1.20,3

0

1.0 0.81,3

0

1.26,4

0

1.36,5

0

1.5 0.74,4

0

1.19,3

0

1.29,4

0

chemical

(%)

chemical

Unconfined Compressive

Strength(KPa)

KCl

1 day 7 days 14days

0 84 ---- -----

0.5 123 168 180

1.0 161 179 208

1.5 116 152 176

CaCl

0 84 ------ -------

0.5 129 195 209

1.0 167 209 243

1.5 120 176 201

FeCl

0 84 ------ ------

0.5 134 238 251

1.0 174 260 296

1.5 127 217 243

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8304

Fig 7. Variation of UCS in 14 days curing Period

1.5.5 Effect of Additives on UCS

The UCS values are increased by 147%, 189% and 252% when treated with KCl, CaCl

2

and FeCl

3

. The

increase in the strength with addition of chemicals may be attributed to the cation exchange of KCl, CaCl

2

and

FeCl

3

between mineral layers and due to the formation of silicate gel. The reduction in strength beyond 1% each

of KCl, CaCl

2

and FeCl

3

, may be due to the absorbtion of more moisture at higher KCl, CaCl

2

& FeCl

3

contents.

The optimum percentage of different additives observed during the laboratory experimentation are

summarized and presented in the following Table.

1.6 CONCLUSIONS

The following conclusions are made based on the laboratory experiments carried out in this investigation.

1. From the laboratory studies, it is observed that the liquid limit values are decreased by 18%, 23% and

33% respectively for 1% of KCl, CaCl

2

and FeCl

3

. There is a decrease in the values of plasticity index

with respective chemical treatment because of the decrease in liquid limit and increase in the plastic

limit values. Plasticity index is decreased by 35%, 48% and 68% respectively for 1% of KCl, CaCl

2

,

FeCl

3

.

2. The Shrinkage Limit values are increased by 13%, 18% & 22% respectively for 1% KCl, CaCl

2

and

FeCl

3

treatments.

3. The Differential free swell values are decreased by 32%, 37% and 50% for 1% KCl, 1% CaCl

2

, 1%

FeCl

3

respectively with respect to the untreated soil.

4. There is a significant improvement in plasticity and DFS upto 1% chemical, after that the change is

marginal.

5. The CBR values are increased by 98%, 125% & 150% respectively for 1% KCl, CaCl

2

and FeCl

3

treatments.

6. The significant improvement of shear parameters was observed, when treated with 1%KCl, 1%CaCl

2

,

and 1% FeCl

3

respectively

7. The UCS values, are increased by 147%, 189% and 252% respectively for 1% KCl, CaCl

2

and FeCl

3

treatments, for a curing period of 14 days.

0

50

100

150

200

250

300

350

0 0.5 1 1.5 2

U

C

S

K

P

a

(%) Chemical

Potassium Chloride

Calcium Chloride

Ferric Chloride

Additives Optimum

percentage

KCl

CaCl

2

FeCl

3

1

1

1

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8305

8. It is observed that, the UCS values are increased for all the three chemicals up to 1% and later the

strength decrease in trend is observed.

REFERENCES

[1] Snethen, D.R. et al. (1979), An evaluation methodology for prediction and minimization of detrimental volume change of

expansive soils in highway subgrades, research report, Vol. 1, prepared for federal highway administration, Washington.

[2] Sivanna,G.S. et al. (1976). Strength and consolidation characteristics of black cotton soil with chemical additives CaCl

2

&

KOH, report prepared by Karnataka Engg. Research station, Krsihnarajasagar,India. .

[3] Katti, R.K., Kulkarni, K.R. and Radhakrishnan, N. (1966), Research on Black Cotton Soils without and with Inorganic

Additives, IRC, Road Research Bulletin, No. 10, pp. 1-97.

[4] Holtz, W.G. (1959). Expansive Clays Properties and Problems, First Annual Soil Mechanics Conf., Colorado School of

Mines, Colorado, pp. 1-26.

[5] Frydman, S., Ravins, L and Ehrenreich, T. (1997), Stabilization of Heavy Clay with PotassiumChloride, J ournal of Geo

technical Engg., Southeast Asian Society of Soil Engg., Vol 8, pp. 95-108.

[6] Chandrasekhar, B.P., Prasad Raju, G.V.R., Ramana Murthy, V. and Hari Krishna, P. (1999). Relative Performance of Lime and

CalciumChloride on properties of Expansive soil for pavement subgrades, Proc. Of IGC-99, Calcutta, pp 279-282.

[7] Koteswara Rao.D(2011), Laboratory investigations on GBFS- CH soil mixes for the utilization of foundation beds, CONCEPTS-

2011, J NT university college of engineering, Kakinada.

[8] M. Srinivas(2008), Test track studies on chemically stabilized expansive soil subgrades, a Ph.D. thesis, J NT University college of

engineering, Kakinada, J une 2008.

Kesava N K Chaitanya G et al. / International Journal of Engineering Science and Technology (IJEST)

ISSN : 0975-5462 Vol. 3 No.12 December 2011 8306

Вам также может понравиться

- Stabilisation of Silty Clay Soil Using Chloride CompoundsДокумент9 страницStabilisation of Silty Clay Soil Using Chloride CompoundsShivendra SinghОценок пока нет

- AP Building Rules-2017Документ12 страницAP Building Rules-2017Somesh KurellaОценок пока нет

- S P C S E S: Tudy On Erformance of Hemically Tabilized Xpansive OILДокумент10 страницS P C S E S: Tudy On Erformance of Hemically Tabilized Xpansive OILbakhtiar Al-BarzinjiОценок пока нет

- Chapter-1: 1.1.GENERALДокумент37 страницChapter-1: 1.1.GENERALعقيل باسم عبد فرحانОценок пока нет

- Stabilization of Black Cotton Soil Using Alkali Activated Fly AshДокумент6 страницStabilization of Black Cotton Soil Using Alkali Activated Fly AshIJIRSTОценок пока нет

- Durability Study of Low Calcium Fly Ash Geopolymer ConcreteДокумент7 страницDurability Study of Low Calcium Fly Ash Geopolymer Concretethisisatest402003Оценок пока нет

- Lime Pile Technique For The Improvement of Properties of Clay SoilДокумент7 страницLime Pile Technique For The Improvement of Properties of Clay SoilSirimilla MeharОценок пока нет

- Batch A-7Документ15 страницBatch A-7Gajangi ShireeshaОценок пока нет

- Yusoff2017 PDFДокумент8 страницYusoff2017 PDFoussamaОценок пока нет

- Yusoff 2017Документ8 страницYusoff 2017oussamaОценок пока нет

- The Effects of Different Compaction Energy On Geotechnical Properties of Kaolin and LateriteДокумент8 страницThe Effects of Different Compaction Energy On Geotechnical Properties of Kaolin and Lateritenoorul hadiОценок пока нет

- Electrokinetic Remediation of Cadmium-Contaminated Soil Using Zero-Valent Iron ParticlesДокумент11 страницElectrokinetic Remediation of Cadmium-Contaminated Soil Using Zero-Valent Iron ParticlespriyakumaranОценок пока нет

- Study of Black Cotton Soil Characteristics With Cement Waste Dust and LimeДокумент9 страницStudy of Black Cotton Soil Characteristics With Cement Waste Dust and LimedhwaniОценок пока нет

- 2020serie de Conferencias IOP Ciencia e Ingeniera de MaterialesДокумент7 страниц2020serie de Conferencias IOP Ciencia e Ingeniera de MaterialesSebastian CorzoОценок пока нет

- 216906-Article Text-534037-1-10-20211103Документ4 страницы216906-Article Text-534037-1-10-20211103sajahan aliОценок пока нет

- Lab Scale Experiments For Permeable Reactive Barriers Against Contaminated Groundwater With Ammonium and Heavy Metals Using Clinoptilolite (01-29B)Документ15 страницLab Scale Experiments For Permeable Reactive Barriers Against Contaminated Groundwater With Ammonium and Heavy Metals Using Clinoptilolite (01-29B)Desanka DasicОценок пока нет

- Trengthening Silty Soil Using Electrokinetic GroutingДокумент4 страницыTrengthening Silty Soil Using Electrokinetic GroutingLalit ThakurОценок пока нет

- Stabilization of Expansive Soil by Using Jute Fiber2020IOP Conference Series Materials Science and EngineeringДокумент7 страницStabilization of Expansive Soil by Using Jute Fiber2020IOP Conference Series Materials Science and EngineeringRithYОценок пока нет

- Experimental Study On Stabilization of Black Cotton Soil With Stone Dust and FibersДокумент5 страницExperimental Study On Stabilization of Black Cotton Soil With Stone Dust and Fiberslakshmana sureshОценок пока нет

- Kolkata Organic SoilДокумент9 страницKolkata Organic SoilPalak ShivhareОценок пока нет

- Waste Management: Krishna R. Reddy, Hiroshan Hettiarachchi, Janardhanan Gangathulasi, Jean E. BognerДокумент12 страницWaste Management: Krishna R. Reddy, Hiroshan Hettiarachchi, Janardhanan Gangathulasi, Jean E. Bognershrakesh22922212Оценок пока нет

- Sunil2006 PDFДокумент7 страницSunil2006 PDFGadige ChandraОценок пока нет

- Agrieletric RHAДокумент9 страницAgrieletric RHAAINA SAMОценок пока нет

- Ze34245250 PDFДокумент6 страницZe34245250 PDFAnirban DeyОценок пока нет

- Journal of Rock Mechanics and Geotechnical Engineering:, Lingwei Kong, Aiguo GuoДокумент6 страницJournal of Rock Mechanics and Geotechnical Engineering:, Lingwei Kong, Aiguo GuoFranko AlgarinОценок пока нет

- Jurnal Internasional 2Документ16 страницJurnal Internasional 2Alexander TandilayukОценок пока нет

- Effect of Electric Fertilizer On Soil PropertiesДокумент2 страницыEffect of Electric Fertilizer On Soil PropertiesIvan FadhillahОценок пока нет

- Carbonated Concrete StrengthДокумент7 страницCarbonated Concrete StrengthDianna LambertОценок пока нет

- Stabilization of Problematic Soil Using Pond Ash and Mosaic DustДокумент3 страницыStabilization of Problematic Soil Using Pond Ash and Mosaic DustIJORATОценок пока нет

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityОт EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleОценок пока нет

- An Initial Study On The Effect of Nano Zirconium On The - 2023 - Construction AnДокумент10 страницAn Initial Study On The Effect of Nano Zirconium On The - 2023 - Construction AnGabriela DraghiciОценок пока нет

- Applsci 09 05487Документ17 страницApplsci 09 05487Ricardo CamposОценок пока нет

- Cobre 20011 KaufholdДокумент10 страницCobre 20011 KaufholdMelba Johanna Sanchez SoledadОценок пока нет

- Final Experimental SetupДокумент18 страницFinal Experimental SetupDevinder SokhiОценок пока нет

- Stabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Документ18 страницStabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Shaker QaidiОценок пока нет

- (Strength Development Cement Hidrasi)Документ8 страниц(Strength Development Cement Hidrasi)doni erlanggaОценок пока нет

- Optimization Using Box-Behnken For Enhancement of Electrokinetic Remediation For PB and Cu Removal From Contaminated SoilДокумент15 страницOptimization Using Box-Behnken For Enhancement of Electrokinetic Remediation For PB and Cu Removal From Contaminated SoilZainab SattarОценок пока нет

- Effect of PH Variation of Pore Fluid On The Geotechnical Properties of Fly Ash Stabilized ClayДокумент6 страницEffect of PH Variation of Pore Fluid On The Geotechnical Properties of Fly Ash Stabilized ClayGadige ChandraОценок пока нет

- PRAKASH - e - ARUMAIRAJ - Effects of Acid and Base Contamination On Geotechnical Porperties of ClayДокумент5 страницPRAKASH - e - ARUMAIRAJ - Effects of Acid and Base Contamination On Geotechnical Porperties of ClayEcomaster Engenharia AmbientalОценок пока нет

- Expansive Soil Stabilization Using Industrial Solid Wastes A ReviewДокумент11 страницExpansive Soil Stabilization Using Industrial Solid Wastes A ReviewTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.100% (1)

- Fly Ash Amended Soils As Highway Base MaterialsДокумент10 страницFly Ash Amended Soils As Highway Base MaterialsSalman HaiderОценок пока нет

- 29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354Документ8 страниц29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354helpdesk9532Оценок пока нет

- Review Ejemplo 5Документ23 страницыReview Ejemplo 5Bladimir charcaОценок пока нет

- A Study On Stabilization of Black Cotton Soil by Use of Fly Ash, Ferric Chloride and Stone DustДокумент6 страницA Study On Stabilization of Black Cotton Soil by Use of Fly Ash, Ferric Chloride and Stone DustinventyОценок пока нет

- (2007) Examination of Chlorides in MSW To EnergyДокумент37 страниц(2007) Examination of Chlorides in MSW To EnergyNakao SakurabaОценок пока нет

- Jalal 2020Документ23 страницыJalal 2020henryОценок пока нет

- IGC-2015 Submission 69Документ10 страницIGC-2015 Submission 69Dr. Chayan GuptaОценок пока нет

- Study of The Effect of Cement Kiln Dust On The Mechanical, Thermal and Durability Properties of Compressed Earth BlocksДокумент14 страницStudy of The Effect of Cement Kiln Dust On The Mechanical, Thermal and Durability Properties of Compressed Earth BlocksKraft DinnerОценок пока нет

- Research ArticleДокумент8 страницResearch ArticleJorge SHОценок пока нет

- The Effects of Different Compaction Energy On Geotechnical Properties of Kaolin and LateriteДокумент8 страницThe Effects of Different Compaction Energy On Geotechnical Properties of Kaolin and LateriteTita Kartika DewiОценок пока нет

- Electrokinetic Remediation of Copper Contaminated Expansive Soil by Surfactant & Chelating AgentsДокумент4 страницыElectrokinetic Remediation of Copper Contaminated Expansive Soil by Surfactant & Chelating Agentsseif17Оценок пока нет

- Red Mud ConcreteДокумент5 страницRed Mud ConcretepraneethaОценок пока нет

- Nanotechnology Applied To Chemical Soil Stabilization: Procedia EngineeringДокумент8 страницNanotechnology Applied To Chemical Soil Stabilization: Procedia EngineeringAravindОценок пока нет

- Elements Volume 2 Issue 6 2006 (Doi 10.2113/gselements.2.6.365) Lumpkin, G. R. - Ceramic Waste Forms For ActinidesДокумент8 страницElements Volume 2 Issue 6 2006 (Doi 10.2113/gselements.2.6.365) Lumpkin, G. R. - Ceramic Waste Forms For ActinidesRaluca RainОценок пока нет

- Study On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesДокумент7 страницStudy On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesRVNLPKG6B VBL-GTLMОценок пока нет

- xúc tác quang ZnO xử lý chất thải hữuДокумент13 страницxúc tác quang ZnO xử lý chất thải hữucuc12cptОценок пока нет

- Permeability and Compression Characteristics of Clay Contaminated With Kerosene and GasoilДокумент10 страницPermeability and Compression Characteristics of Clay Contaminated With Kerosene and GasoilSupritha KОценок пока нет

- Evaluation of The Properties of Red Mud ConcreteДокумент4 страницыEvaluation of The Properties of Red Mud ConcreteAndre GugunОценок пока нет

- Soil Improvement With Lime: Parampreet Kaur, Gurdeep SinghДокумент3 страницыSoil Improvement With Lime: Parampreet Kaur, Gurdeep Singhtyas_pramesthiОценок пока нет

- Heritage Pasts PDFДокумент16 страницHeritage Pasts PDFEmina SafaricОценок пока нет

- Value Obligation and Cultural HeritageДокумент65 страницValue Obligation and Cultural HeritageSaparya VarmaОценок пока нет

- Lewis PatilДокумент20 страницLewis PatilSaparya VarmaОценок пока нет

- Cant - Practising Aesthetics PDFДокумент363 страницыCant - Practising Aesthetics PDFSaparya VarmaОценок пока нет

- Gillespie 2000 Beyond Kinship Introduction-LibreДокумент11 страницGillespie 2000 Beyond Kinship Introduction-LibreSaparya VarmaОценок пока нет

- Mega Jordan Cot ArticleДокумент26 страницMega Jordan Cot ArticleSaparya VarmaОценок пока нет

- 14.2e Spr03marchand SMLДокумент18 страниц14.2e Spr03marchand SMLSaparya VarmaОценок пока нет

- Language Sciences - Landscape Terms and Place Names in The Trobriand Islands - 2008Документ22 страницыLanguage Sciences - Landscape Terms and Place Names in The Trobriand Islands - 2008Saparya VarmaОценок пока нет

- 1938 Himalayan Village - Account of Lepchas of Sikkim by Gorer SДокумент573 страницы1938 Himalayan Village - Account of Lepchas of Sikkim by Gorer SSaparya VarmaОценок пока нет

- Knowledge in Hand: Explorations of Brain, Hand and Tool: Trevor H. J. MarchandДокумент11 страницKnowledge in Hand: Explorations of Brain, Hand and Tool: Trevor H. J. MarchandSaparya VarmaОценок пока нет

- Knowledge in Hand: Explorations of Brain, Hand and Tool: Trevor H. J. MarchandДокумент11 страницKnowledge in Hand: Explorations of Brain, Hand and Tool: Trevor H. J. MarchandSaparya VarmaОценок пока нет

- Meraz-Architecture and Temporality in Conservation PhilosophyДокумент364 страницыMeraz-Architecture and Temporality in Conservation PhilosophyCorina MariaОценок пока нет

- Spiritual Landscapes (LSERO)Документ27 страницSpiritual Landscapes (LSERO)Saparya VarmaОценок пока нет

- Continuity, Cult & ContestДокумент23 страницыContinuity, Cult & ContestSaparya VarmaОценок пока нет

- Byrne Herzfeld Interview JSA June 2011Документ14 страницByrne Herzfeld Interview JSA June 2011Saparya VarmaОценок пока нет

- Cohen CommandofLanguageДокумент26 страницCohen CommandofLanguageSaparya VarmaОценок пока нет

- 12053-Preparation & Application of PuttyДокумент9 страниц12053-Preparation & Application of PuttyMihir GhadiaОценок пока нет

- q4m3 Perf SummДокумент2 страницыq4m3 Perf SummAlbert FragaОценок пока нет

- Ciclo de Produccion Semana 48.3Документ5 страницCiclo de Produccion Semana 48.3Raul BazanОценок пока нет

- For The Following Reactions: A) N (G) + 3H (G) 2NH (G) : Example: Write The Appropriate Equilibrium ExpressionДокумент67 страницFor The Following Reactions: A) N (G) + 3H (G) 2NH (G) : Example: Write The Appropriate Equilibrium ExpressionjillОценок пока нет

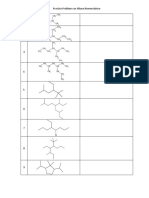

- Practice Problems On Alkane Nomenclature: CH CHДокумент2 страницыPractice Problems On Alkane Nomenclature: CH CHRishav Sasmal100% (2)

- Expt. 3 Qualitative Test of Proteins and Amino AcidsДокумент8 страницExpt. 3 Qualitative Test of Proteins and Amino AcidsMary Ella Mae PilaОценок пока нет

- Ac and WD Pom, Micp, MictДокумент32 страницыAc and WD Pom, Micp, MictLicardo, Marc PauloОценок пока нет

- Act 6 Benzene PDFДокумент5 страницAct 6 Benzene PDFDulce Wendolyn BollásОценок пока нет

- Beaconhouse School System, Mandi Bahauddin Work Sheet of Chemistry Topic: Organic Chemistry - Alcohols Class: XI-Cambridge Name: - Date: - Q1Документ4 страницыBeaconhouse School System, Mandi Bahauddin Work Sheet of Chemistry Topic: Organic Chemistry - Alcohols Class: XI-Cambridge Name: - Date: - Q1Qurrat Ul AinОценок пока нет

- Questions About DensityДокумент8 страницQuestions About DensityJohn OsborneОценок пока нет

- Expt On Solubility of Organic CompoundsДокумент4 страницыExpt On Solubility of Organic CompoundsJasmine Juit100% (1)

- Preparation of Domestically Useful Chemical ProductsДокумент7 страницPreparation of Domestically Useful Chemical ProductsPackianathan SarathОценок пока нет

- Melaleuca CatalogueДокумент95 страницMelaleuca CatalogueNatasha LimОценок пока нет

- AP Chemistry Study Guide: Chapter 14: Acids and Bases and Chapter 15, 16.1 and 21.3: Aqueous and Acid-Base EquilibriaДокумент8 страницAP Chemistry Study Guide: Chapter 14: Acids and Bases and Chapter 15, 16.1 and 21.3: Aqueous and Acid-Base Equilibrialorraine_cuaОценок пока нет

- 12 Chemistry Haloalkanes and Haloarenes Test 05 Answer s2l6 PDFДокумент2 страницы12 Chemistry Haloalkanes and Haloarenes Test 05 Answer s2l6 PDFShreyash KolekarОценок пока нет

- Investigation of Straight-Run Diesel Oil Fractions With Sulphur High Content Oxidative DesulphurizationДокумент8 страницInvestigation of Straight-Run Diesel Oil Fractions With Sulphur High Content Oxidative DesulphurizationPhuc NguyenОценок пока нет

- Full Length Article: J. Greco-Duarte, E.D. Cavalcanti-Oliveira, J.A.C. Da Silva, R. Fernandez-Lafuente, D.M.G. FreireДокумент10 страницFull Length Article: J. Greco-Duarte, E.D. Cavalcanti-Oliveira, J.A.C. Da Silva, R. Fernandez-Lafuente, D.M.G. FreireAna Cristina CollaçoОценок пока нет

- Study Material For Practical - RVCEДокумент25 страницStudy Material For Practical - RVCEMalavika UnnikrishnanОценок пока нет

- Production of Detergent From Castor OilДокумент8 страницProduction of Detergent From Castor OilLenh DavidleОценок пока нет

- Organic Chemistry 9th Edition Wade Test BankДокумент46 страницOrganic Chemistry 9th Edition Wade Test Bankjavierwarrenqswgiefjyn100% (26)

- Tiamina, IPДокумент4 страницыTiamina, IPmagicianchemistОценок пока нет

- Sample: Acidic Exposure - H2SO4 - TM 004Документ5 страницSample: Acidic Exposure - H2SO4 - TM 004G.W.S.S.B SUB DVISION2 MORBIОценок пока нет

- Chem ch10Документ16 страницChem ch10ChandlerОценок пока нет

- Acid Value 1Документ7 страницAcid Value 1Mujtaba AbbasОценок пока нет

- Basic ShampooДокумент9 страницBasic Shampoosukriti biswas100% (1)

- Electrolyte Methodology Lecture GuideДокумент13 страницElectrolyte Methodology Lecture Guidejuris surgeonОценок пока нет

- Factors Affecting SolubilityДокумент3 страницыFactors Affecting SolubilityJason Raquin RoqueОценок пока нет

- Chemistry Investigatory Project by Ritik Patel Class 12Документ10 страницChemistry Investigatory Project by Ritik Patel Class 12Ashlesha ShahareОценок пока нет

- Assignment: Organic ChemistryДокумент6 страницAssignment: Organic ChemistryWalid EbaiedОценок пока нет

- 12 Chemistry Exemplar Chapter 11Документ11 страниц12 Chemistry Exemplar Chapter 11Priya dharshiniОценок пока нет