Академический Документы

Профессиональный Документы

Культура Документы

Fabric Inspection Procedure

Загружено:

GarmentLearnerАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fabric Inspection Procedure

Загружено:

GarmentLearnerАвторское право:

Доступные форматы

SECTION 9

QUALITY STANDARDS

Section 9 Quality.doc, Page 2

FABRIC INSPECTION PROCEDURE

The request or decision to inspect a particular lot of fabric will be generated from the Fabric Purchasing

Department. It will be based on the following criteria:

First time Resource

Prior history of deficient fabric quality from the supplier

Anticipation of possible fabric quality problems

This procedure will be used for all Destination Maternity Piece Goods received. Responsibility for the

process will come from the Raw Materials area. The system that will be used is the Four-point system.

1. Amount to inspect: inspect at least ten percent of the yardage per shipment.

2. Selection of rolls: randomly select the rolls to be inspected after the initial receiving

procedure has been satisfied.

3. Defect classification: The four-point system will classify as follows:

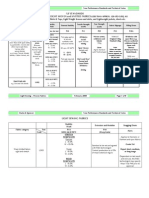

Size of Defect Penalty

3 inches or less 1 point

Over 3 but less than 6 inches 2 points

Over 6 but less than 9 inches 3 points

Over 9 inches 4 points

The length of the defect is used to determine the penalty point. Only major defects are

considered (a major defect would be any and all defects that, if found in a finished garment,

would classify it as a second). No penalty points are recorded or assigned for minor defects.

4. Acceptance Point Count: For all Divisions except Pea in the Pod Collection and Pea in the

Pod. 30 Points per hundred yards will be deemed as an acceptable defect rate. For Pea in the

Pod Collection and Pea in the Pod piece goods that acceptable point level will be 20.

5. Acceptance Criteria: This will be established by projecting the total defects from the data

found during the inspection process. This is equal to the total penalty point, divided by the

number of yards inspected & multiplied by one hundred. The projected point value must be

below the Acceptance Point Count for each Division if the lot of fabric is to be accepted.

6. Reject Fabric Lots: If the shipment fails the initial inspection, a second ten percent inspection

will take place. The Fabric Purchasing Department must be notified of the failed inspection.

They will then contact the vendor prior to this second inspection. This will allow the vendor

to be present for the second inspection.

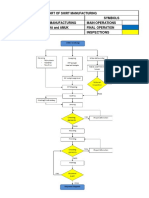

Inspection Procedure: This procedure indicates the steps required for the inspector.

1. Fabric Purchasing must identify the face

2. Select the rolls

3. Place the fabric on the inspection machine

4. Cut a swatch at least 6 inches across the length of the fabric

5. Determine the amount of rolls to inspect

6. Fabric Purchasing must identify the face

7. Use this swatch during the inspection process to check for shading (either side to side or end

to end)

8. Begin the inspection process of the roll at a speed slow enough that the inspector can find any

and all major defects

9. Verify yardage against what is stated on the roll

10. Mark all defects on the selvage with a swift tack gun and record the data

Section 9 Quality.doc, Page 3

RECOMMENDED GARMENT LABELING AND PACKAGING PROCEDURES

All labels and price tickets should be checked as part of the incoming trim Quality Control system when

they arrive into the factory. A random sampling of all SKUs of bar coded labels and tickets should be

scanned.

Main and care labels should be counted out and placed in a small poly bag and attached to the individual

bundles as the cut pieces are sent to the line. Operators attaching labels should not have boxes of labels at

their work-stations, as it is easy to mix them up resulting in the wrong label in the garment. If a size label

has to be hung from the main label, it should be prepped prior to the garments being separated in bundles.

Washed garments may require a temporary label to identify the garment until after washing.

When the garments get to the end of line QC station, where the garments are checked 100% for open

seams etc, the inspector must check the care label of every garment to the main label to make sure the

sizes match. At this point, since every garment is checked, there is no reason any garment should get out

of the line with the main and care labels not matching 100% correctly. DMC care labels indicate the size,

style number, and the color code. In addition to maintaining style and size integrity, the color code must

also match.

After all manufacturing processes, including pressing and washing, the garments should be separated by

size for all remaining work. When the garments get to packing, they should be separated by size and kept

separated. People, who tag, fold and place the garments in poly bags should only work on one size at a

time so there is not chance for the garments to get mixed up. The person adding the price ticket should

check the main label for the size on every garment. No person should have more than one size garment or

more than one size of price ticket available to that person. After the garment is bagged, the sizes should

be kept in separate bins or baskets with the size clearly marked.

The carton packer should pack from the marked bins directly to the export carton. The cartons of

available units for one size should be completed before another size is started. The size does not have to

be complete for the order, but that is preferable. The packer counts the units placed in each carton.

Another person should check the count, spot check the sizes of a few pieces and seal the carton. This

should be done promptly. Packed cartons should not be left on the floor for more than a few minutes

before being sealed. The person checking the count and sealing the carton should initial the inside flap of

the carton. The size and count should be noted on the carton if the carton labels are to be added later. If

the labels are available, they should be added when the carton is sealed.

An auditor should open randomly selected cartons according to the AQL chart. A percentage of the

garments should be checked for quality and every unit should be checked for labeling. The carton count

should be checked. The auditor should initial the carton on the inside flap.

If any count or label errors are found, the shipment should be checked. Whenever an auditor finds an

error, a record should be kept of the person sealing the carton. The auditor should not be part of the

Packing Department. Auditors should report to upper management.

If Destination Maternity finds a count or labeling discrepancy, DMC will process the chargeback and

provide notice of issue. This will help determine if additional training is needed in the packing area.

Please note an approval from the Technical Designer on the T.O.P care label, is only a VISUAL approval.

We strongly suggest a corrective action as chargeback will escalate to non-compliance charge. The

vendor is responsible for scanning the label and price ticket for accuracy of info.

Any foreign objects found in a carton will result in a $1000.00 Charge Back, this includes but not limited

to garbage or waste, rolls of tape food, cell phones, etc. In the case of a sharp or dangerous item found

within the carton, the vendor will be responsible for all medical costs incurred as well as lost wages and

possible disability of the DMC employee.

Section 9 Quality.doc, Page 4

If bugs, insects, or any other type of foreign matter is found in shipment the shipment could be cancelled

at DMC discretion or sent for cleaning if deemed to be repaired. All charges will be at the responsibility

of vendor.

Due to our automated Distribution Center, the accuracy of the labeling and carton integrity is very

important. There will be a chargeback for every incorrectly marked garment we find and a 100%

inspection may be performed if errors are found. The requirement for accuracy is clearly stated.

This system is being successfully utilized in factories all over the world with excellent results. Every step

in this process is already being done to some degree in every factory. We have found this process to be

effective. Individual circumstance may dictate slight modifications without negating the benefits.

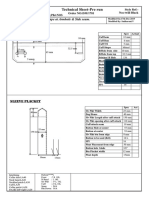

NECK SHAPER POLICY

Section 9 Quality.doc, Page 5

NECK SHAPERS

NECK SHAPERS eliminate quality issues of misshapen and inconsistent

neck shapes on our knit tee styles. They are used as a tool to control how neck

shapes are pressed in production, and provide both vendors and in-house teams

with a clear example of the correct neck shapes to be achieved in the

production process.

NOTE: Previously, neck shapers were provided by DMC to the vendors.

Effective immediately, vendors will now be responsible for creating neck

shapers, and submitting a hard copy of the neck shaper in size Medium, along

with the TOP sample, to DMC for tech review and approval.

Section 9 Quality.doc, Page 6

Section 9 Quality.doc, Page 7

AVOIDING NEEDLE HOLES IN MATERNITY BELLIES

Spandex quality sewing check: Upon receipt of spandex, check the quality. Cut a piece from the roll

five to ten yards into it. Sew the fabric to a piece of denim on the same machine to be used in

production. Remove the chain stitch and check for needle cuts. Old or poorly stored cotton spandex

will become brittle and will needle cut easily. If the fabric is brittle, needle cuts will be obvious.

Spandex spreading: Spread a maximum of 75 ply, fabric must be spread tension free. After

spreading, cut the spread into smaller sections for relaxing. Fabric must sit for 24 hours before

cutting. Check parts for spring back. Fabric can be pre-relaxed prior to spreading.

Spandex cutting: Make sure all knives are sharp, if you use a dull blade it could cause pulls in the

fabric.

Making the Belly: Close the belly seam with a safety stitch. Use ball point needles when sewing this

fabric. A chisel point needle will cut the yarn. Ball point needles should push the yarn aside and not

cause cuts. Use the smallest needle size possible. You must also check and change the needle

regularly to make sure they do not have any burs. Do NOT sharpen or buff the needle used in this

operation. If you sharpen the needle, use it on another operation not sewing cotton spandex.

SEWING MATERNITY BANDS

Body Sewing: Sew the garment body and serge the seam to which the belly will be set to prevent

fraying of the raw edge in the wash. The garment bodies must have size / lot identification in them

before sending them out to wash. Attach the belly after wash, then attach main and care labels.

Setting the belly: After wash, attach the belly to the garment body. You must use ball point needles

when sewing this fabric. A chisel point needle will cut the yarn. Ball point needles should push the

yarn aside and not cause cuts. Use the smallest needle size possible. You must also check and change

the needle regularly to make sure they do not have any burs. Do NOT sharpen or buff the needle used

in this operation. If you sharpen the needle, use it on another operation not sewing cotton spandex.

The belly must be sewn separately from the garment body and not attached to it until after the wash

Section 9 Quality.doc, Page 8

cycle. The belly can be set in one of two methods. Preset the belly using a chain stitch and close the

seam with a serge stitch, or set the belly in one operation with a safety stitch machine.

NEEDLE CUTS

Quality control: The operator should also be checking every seventh piece for needle cuts. In-line

QC personnel should be checking the operation every hour. End of line QC should be checking at

least 25% of the garments as well for this operation.

The Q/C check should be the point at which needle cuts are found. If the sewing operation does not

cut the fabric, then the inspector pulling on the belly seam to look for needle cuts will not cause holes

to appear. If the belly setting operation is cutting the yarn, then the holes will be obvious when the

garment is checked.

Final audit should be checking for needle cuts as well. Do not be afraid to pull the seam to look

for cuts. If the yarn is not broken, checking the seam will not cause a cut to appear.

ELASTIC STORAGE AND USEAGE

Each lot of elastic should be tested to ensure that the elastics used are to the approved standard. In

storing elastic we suggest:

Maintaining low temperatures and maintaining low humidity

Prevent excessive lighting

Reduce contact with air

Exclude exhaust fumes from the storage area

Eliminate wood and particle board shelving which are a common source of phenolic compounds

which cause yellowing of elastic

When manufacturing with elastic we suggest:

Finishing the products with the pH on the acidic side (pH 5.5-6.5)

Avoiding highly alkaline detergents

Using BHT-free poly bags for packaging

Using BHT-free lubricants for machines

Using non-yellowing softeners and anti-yellowing softeners

GARMENT QUALITY STANDARDS

Measurements

All quality inspections and audits must include measurements against specifications. In any case where

acceptable tolerances versus specifications are not given, the maximum allowance is one half the grade,

but never greater than .

Example: If the waist grade between medium and large is 2, one half the grade is 1, but the tolerance is

.

Example: If the sleeve length grade between medium and large is , one half the grade is 1/8 so the

tolerance is 1/8.

Measurement Sampling Inspection: DMC, reserves the right to add a measurement sampling inspection

charge if a garment fails the initial measurement sampling (size M or 1X) and needs to have a full size

measurement sampling performed.

Section 9 Quality.doc, Page 9

Defects

These quality standards are to evaluate finished garments during the audit process. Any other defect that

the auditors find that would affect the sale or hinder the use of the product is considered a major defect.

Labels, Hangtags, Emblems & Embroidery

1. Hangtags omitted

2. Hangtags insecurely attached or misplaced

3. Hangtags insecurely attached or misplaced, requiring re-handling

4. Wrong hangtag used (style number, group and size)

5. Wrong Label attached (size)

6. Label attached more than beyond specified location

7. Label sewn with mono filament yarn

8. Label sewing thread does not match color

9. Label sewing seam uneven, puckered and 1/8 or more away from label edge

10. Harsh and stiff label compared to approved sample

11. Labels omitted or insecurely attached

12. Emblems attached to wrong place

13. Emblems attached with a cam, not following the contour of emblem

14. Emblems attached crooked

15. Label sewing not reinforced or sewn beyond label edge

16. Bobbin & needle thread color not matching fabric and label or emblem color respectively.

17. Labels that do not meet legal requirements. Note: legal requirements will be issued as a separate

requirement.

18. Defective zipper stops on open front jackets

19. Tight clearance between the slider and the seam edge causing slider to operate with difficulty.

20. Rivets not properly fastened

21. Rivets with rough edges

22. Buttons cracked or damaged affecting function or appearance.

Cleanliness

1. Oil spots, stains and soils 1/8 or larger in diameter

2. Fly (foreign yarn)

3. Multiple thread ends not trimmed flush with garment or trim

4. Excessive contamination in the garment

Material Defects and Damages

1. Rips, holes or cuts on any part of the product

2. Drops and tuck stitches

3. Snags, pulls and knots

4. Slubs more than 1/8 (Use judgment based on location on garment)

5. Slubs less than 1/8 in any obvious location

6. Needle Lines

7. Permanent creases on the fabric

8. Bowing/Torque on fabrics & stripes more than 1

9. Bowing/Torque on fabrics & stripes less than 1

10. Barre marks due to fabric manufacturing (thick and thin yarn)

11. Nap and/or pile deformation

12. Undesirable odor

Necklines

1. No puckering on neckline seams

2. Balanced from right to left sides

3. Center neck miters and seams should be balanced

4. Neck curves on knit should follow approved sloper shape

Section 9 Quality.doc, Page 10

5. Neck Shapers if advised by tech designer

Collars and Cuffs

1. Fullness or puckers at collar attachment

2. Collar points not uniform and balanced, shapers must be used to sew out collars

3. Serious puckers on collar joining

4. Misaligned, crooked collar setting more than 3/16

5. Misaligned, crooked collar setting less than 3/16

6. Puckered and/or crooked top stitching

7. Fullness or twist of cuff affecting appearance

8. Misaligned cuffs at bottom

Seams and Stitching

1. Open seam

2. Double stitching gap from 1/16 up to 1/8

3. Double stitching gap 1/8 or over

4. Needle holes or cuts

5. Part of garment caught in unrelated seam or operation, distorting fit/appearance

6. Seams twisted, puckered or pleated, affecting appearance

7. Improper stitch tension (too loose or tight) that affects appearance or stitch breaking

8. Ends of stitching not backstitched, tied in, or securely caught in other seams or stitching

9. Raw edges (other than specified)

10. Gauge of edge stitching irregular, i.e., unevenly gauged affecting appearance

11. Repairs where original seam still shows

12. Piecing/joining of binding and/or trims on critical zone of garments

13. Mono filament yarn being used as a sewing thread in any type of stitching

14. Seam irritation when in contact with bare skin

15. Wrong color sewing thread

16. Stitches per inch not as specified. Pearl edge stitching with gaps or poor density.

17. Top stitching tie-in that is sloppy, overlaps more than 3 stitches or that has thread ends visible

from the right side of garment

INSPECTION FOR WORKMANSHIP

The most important part of statistical sampling is a thorough visual inspection on every garment in the

sample. Do not assume that after inspecting a few units that the lot is good as it could be a rejected lot.

The reverse is also true. If the first few garments are defective, do not assume that the lot is bad. The

following procedure will ensure that the auditor will inspect the garment thoroughly.

Lay the garment on the inspection table in good light (150 candle is the standard).

Inspect the front side for soil and fabric defects. Then inspect every operation on the garment

individually.

Inspect all seams by grasping the fabric on each side of the seam and apply slight pressure to see into the

seam. This method enables the auditor to see needle cuts, open seams and skip stitches.

Below is an example of inspecting a tee shirt. The inspection process starts at the top of the garment and

works its way down to the hem.

Inspect the main label, care label and hangtag

Inspect the collar operation

Inspect the right shoulder seam

Inspect the right armhole

Inspect the right sleeve under arm seam

Inspect the right sleeve hem

Inspect the left shoulder seam

Section 9 Quality.doc, Page 11

Inspect the left armhole

Inspect the left sleeve under arm seam

Inspect the left sleeve hem

Inspect the bottom hem

Turn the garment over and check the back side in the same manner

SEWING NEEDLE CONTROL SYSTEM

Sewing needles are very fragile and can be broken easily. They are also very sharp and jagged needle

parts can be very dangerous.

All sewing lines producing DMC product must have a needle control system. No needle should ever be

issued to an operator without surrendering an intact needle. Any broken needle needing replacement must

be recorded in a needle log. The format of the log can be left to the factory or buying representative, but

must include the following information at minimum:

o Date

o Operator

o Bundle / piece # of garment under the needle

o The recovered pieces of the needle (taped to the sheet)

o Signature of QA or responsible party

*See below for format log example.

All parts of all broken needles must be found and reconstructed. If the broken needle cannot be totally

reconstructed, the entire bundle at the operators station should be placed through a needle detector. If a

needle detector is not available, the bundle should not be shipped.

ALL NURSING TOPS MUST BE PASSED A NEEDLE DETECTOR.

ALL DMC FACTORIES PRODUCING NURSING TOPS MUST BE EQUIPPED WITH A NEEDLE

DETECTOR.

Failure to comply with this system or failure to administer to it completely will result in termination of

production for DMC. The costs and losses in any claim or litigation arising out of or resulting from

injury caused by needle parts found in a DMC garment will be passed entirely to the factory and/or

buying representative involved.

Factory Name

date operator bundle / piece # needle reconstruction supervisor

Section 9 Quality.doc, Page 12

PRODUCT QUALITY AND PACKAGING QUALITY

All incoming shipments undergo a random inspection. From the electronic packing list, the computer

selects a cross section of cartons representing all SKUs for audit. These cartons are inspected for:

AQL audit for measurements and defects

Zero defect inspection for adherence to packing requirements

Failure of either of these criteria will trigger a 100% inspection of the entire shipment. This inspection

charge will be billed to the vendor at $25.00 US$ per hour to cover the cost of inspection. The charges

will be based on an average garment-processing rate of 45 units per hour or 60 units per hour based on a

re-sort.

An e-mail notice is sent to the vendor or buying representative with digital photos and an explanation of

the problem found. DMC will provide samples of defective merchandise as needed. The LDP cost and

freight charges for returning defect samples will be charged to the vendor. Packing errors cannot be

demonstrated, these will be rectified at the time of receiving. Packing error cannot be rectified on the

receiving line, the vendors may be given the opportunity to rectify at their own expense. All repairs

undertaken by the vendor will be considered as late and a penalty equal to the late to in-warehouse date

will be applied for every day the merchandise is unshipped.

The following zero defect violations will automatically trigger a 100% inspection and an automatic

charge-back for inspection and rework costs to rectify:

packing list error

mixed sizes in one carton

mixed colors in one carton

incorrect or missing price ticket (price ticket error and/or price ticket not matching garment)

bar code on price ticket incorrect, mutilated or unable to be scanned

incorrect information on care label: size, style, number, color code or care instructions (do not

whiteout or correct care label)

invalid, missing or mutilated bar code on the care label

multiple piece sets with mismatched components (small top with medium bottom)

Inaccurate, missing or non-active carton license plates

In the event that DMC has an account payable to a vendor for whom a chargeback or discount is

pending collection, DMC will use the payable to offset the amount owed.

REPAIRS AND REWORKS

DMC reserves the right to decide whether repairs should be undertaken immediately. DMC will not hold

merchandise un-repaired and un-shipped. DMC reserves the right to repair the goods ourselves if we feel

that time to do otherwise will reduce the value of the merchandise. This decision will be made based on

the requirement to prevent loss of sales and to mitigate our damages. Where time allows, repair costs will

be estimated and advised to the vendor or vendors agent and a course of action determined. Repair or

rework may require use of outside party, or return to vendor, depending upon the nature of the problem.

DMC also reserves the right to charge back vendor for loss sales due to time lost during inspection and/or

repairing.

REJECTED PRODUCT

If DMC rejects non-conforming product, the merchandise may be returned to the vendor and all costs

associated with the delivery of the product will be recovered from the vendor. No additional chargebacks

Section 9 Quality.doc, Page 13

will apply. If the merchandise can be sold at a reduced price, DMC will offer the vendor a price reflective

of a discount. If the vendor does not agree to the discount offered, the product will be returned with the

vendor responsible for absorbing all incoming and outbound charges associated with moving the product,

as well as any other damages that DMC may have incurred. DMC may choose to remove all trademarked

material and bill vendor for cost. If returned to vendor without removal, the vendor must remove any

trademarked material prior to disposal. In the event that any material is distributed with DMC

trademarks, DMC will pursue all available remedies to protect its rights. Please refer to the Resale

Requirements for more information.

Once it is determined that goods will be returned, vendor will be allowed 5 business days to advise a

RA# (return authorization). If vendor does not advise and RA# within 5 business days then DMC reserves

the right to arrange for the return at the vendors expense.

Once an RA# is given, the vendor is allowed 5 business days to arrange for goods to be picked up, after

the 5th business day DMC reserves the right to arrange for return at the vendors expense.

RTV PROCESS

In the event of Quality Hold, some vendors prefer for DMC to return the damages found to their

establishment. This is known as RTV.

1. A final count is emailed to the vendor

2. The vendor will reply with an RTV or RA (Return authorization) number. If the vendor does not agree

to a forced RTV (which DMC can decide to return the defects without permission from the vendor), DMC

can use any combination of numbers and letters. This RTV or RA number is used to keep record in our

systems

3. Once an RTV or RA number has been issued, the damages are then taken out of our inventory using the

RTV code. When removing items from inventory, DMC has different codes to use so that we can keep

record of why the item has been removed

4. The damages are moved onto the loading dock and then returned to the vendor

AGENCY RESPONSIBILITIES REGARDING CHARGEBACKS

Buying Representatives have the obligation to fully explain the failure to perform chargeback

policies of DMC to their vendors prior to the placement of any orders. The Buying

Representative, through the execution of its duties as a buyers representative, must monitor all

factors that lead to performance against the Purchase Order and violation of DMC failure to

perform chargeback policies. Buying Representatives have the obligation to communicate to all

vendors any chargebacks issued by DMC IMMEDIATELY. It is the Buying Representatives

responsibility to have chargeback documents signed by the factory to acknowledge receipt and

the Buying Representative must keep these records for a minimum period of 3 years. The

Buying Representative should discuss with the vendor any justification the vendor may request

and/or any options they have in regards to opportunities to reduce any charges.

Section 9 Quality.doc, Page 14

CHARGEBACK SCEHDULE

Inspection Labor rate: If an initial audit reveals packing, labeling or quality issues, a 100%

inspection is done. The 100% audit rate is calculated at 45 units per hour X $25 per hour.

Replacing hangers: If hanger is required and the hanger is not the specified DMC hanger, it

will be replaced. The replacement cost is calculated at $0.25 each plus the cost of the hanger.

Incorrect bag or missing bags: Calculated at $0.10 each. Additional labor cost may apply if

cartons need to be replaced.

Missing or bad price tickets: Replacement cost is $0.25 each. Labor and/or inspection fees

are also associated with this type of debit.

Foreign Object in Cartons: Any foreign object found in a carton other than what DMC as

ordered will result in a $1000.00 Charge Back.

Invoice/Packing List Quantity: If there is a discrepancy in quantity, a debit is issued for the

value of each garment not included in the shipment.

DMC Administrative Fee: $100 is added to each purchase order for internal processing and

handling costs for handling shipments defects.

Incorrect packing slip: Mixed sizes in cartons generate a debit for $100. 100% inspection

debit is associated with this.

Sewing Repairs in-house: Charged at a rate of $25 per hour. There may be additional cost

added depending on the nature of the repair; i.e. materials.

Outside Labor/Repairs: If an outside contractor is needed, chargeback will be the rate

negotiated with the contractor. Additional freight and handling costs will apply.

Damaged items: Garments that cannot be repaired but can be sold in DMC Outlets are

"seconds". Chargeback is 50% of the LDP cost and follows a 100% inspection debit and

additional material costs such as but not limited to poly bags, price tickets, cartons, labels,

documentation, etc.

Damaged items (100% LDP): Garments that cannot be repaired or sold in our outlets are

defective garments and vendor is charged the full LDP value. Accompanies a 100%

inspection debit.

Freight Charge: When garments are sent for a repair, freight is assessed at actual rate

garment shipped.

Handling Fee: Additional $100 charge is added whenever garments are sent back to vendor.

This fee is in addition to the 100% inspection fee and the FOB/LDP value of the garment.

Substandard Sewing Deduction: This is a discount taken that both the vendor and buyer

agree on a percentage when the garments are not at acceptable quality levels.

Defective Samples: When defective samples are sent to vendor, the full LDP price is

charged, 100% inspection debit is also applied.

Quality Defect on a Shipment Level: When a shipment is deemed not saleable, all units

will be charged at 100% of the LDP value (FOB + Duty + Transportation Cost). Duty and

Freight cost will not be refunded to the agent/vendor.

Sample freight charge: The courier cost for returning defective samples to supplier.

Defective sample charge is associated with this. Cost includes duty and shipping supplies.

Offsite Inspection fees: Orders inspected or processed by a third party are charged as the

actual cost of the service. Handling and freight fees may also apply and additional costs such

as but not limited to poly bags, price tickets, cartons, labels, documentation, etc.

Travel Reimbursement: When it is determined that DMC QA needs to assist factory with

quality issues, a chargeback for transportation and incidentals may occur.

License Plate Sticker/File Non Compliance: Carton File transmitted incorrectly or not at all

generates a $1000.00 chargeback per purchase order. If the shipment is more than 500

cartons a chargeback for $1500.00 will be generated. This chargeback includes electronic

packing list that do not have the correct information or quantity transmitted prior to receipt of

Section 9 Quality.doc, Page 15

goods in DMCs Distribution Center. Additional material costs could apply such as but not

limited to poly bags, price tickets, cartons, labels, documentation, etc.

Incorrect WAG: incorrect Wearing Apparel Guide $250.00

SIL fee: supplemental information letter needed to change a U.S. Customs entry against

vendor information provided $100

Carton Labeling Non Compliance: Missing or incorrect carton license plate label generates

a $1000.00 charge.

Invoice Pricing Variance: Generated if there is a difference between the billed price and the

price paid. A chargeback is issued for the actual cost difference.

Non Compliance FTC Regulation: Garments missing Country of Origin labels generate a

$1000.00 debit. Accompanies inspection, handling and return fees. Material costs are extra

such as but not limited to poly bags, price tickets, cartons, labels, documentation, etc.

Additional Labor Charge: Extra processing/labor is used when preparing and counting

garments to an outside repair source. This debit is issued at $0.25 each garment.

Demurrage Charges: Actual amount incurred for storage is charged to factory. These accrue

when freight is waiting to be released.

Prepaid Freight: Actual amount charged if there is a freight variance.

DMC Admin Fee: $100 added to each chargeback issued.

Late Document fee: $1000 per day for delay of freight arriving late in house.

Bad Document fee: $1000 per day for delay of freight arriving in house due to a wrong or

incorrect document. Fee may be applied in addition to late document fee.

Storage Charges: Actual fee assessed for storing freight for an unspecified period of time

due to an error.

Brokerage Fee Charges: Actual brokerage fee when shipment is returned to vendor. Also

used when a separate customs entry is made due to incorrect documents.

Pre Paid Embargo Stock: Fee issued if a shipment should embargo. This fee is in addition

to other fees that are assessed as a result of the embargo.

Freight Forwarder Charge: If an incorrect freight forwarder/service provider is used, a

$500 fee will be assessed.

Offsite Inspection Fees: Actual charges when a shipment moves off site due to suspicious

cargo or activity. If DMC dispatches an inspection team, a $500 fee will be assessed.

Cartage: Actual amount charged for moving freight from one location to another.

Fuel Surcharge: Charge is the actual fuel surcharged from moving freight from one location

to another location.

Warehouse Fee: Actual amount charged for any warehousing that needs to take place

because of vendor problems or delay to shipment.

Warehouse Storage: Actual amount charged for warehouse storage that is needed due to

vendor problems or delay to shipment.

Outlay Fee: Actual amount charged. If Destination Maternity or a service provider has to

outlay money in order to facilitate a shipment, then the vendor is charged actual amount.

Missing, incorrect or late ACI (automated Commercial Invoice): If a vendor is late or has

not supplied an ACI, a $500 fee is assessed per invoice. Other late fees may apply.

Vendor Management Violation: If document procedures are not as required by the DMC

vendor manual, $500 is charged for each purchase order. This includes but is not limited to

country of origin changes, Resale/Global Labor/Security Violations, etc.

Factory Re-Audit Fee: DMC reserves the right to audit any factory in which are goods are

made. The initial audit fee will be covered by DMC. Any subsequent re-audit fees and fees

associated with the re-audit(s) will be charged to the factory.

Document Discrepancy: $1000 fee for remitting reduced invoice to DMC with no

corresponding reduction in bank draft request.

Section 9 Quality.doc, Page 16

Shipment Transmission Charge (ASN): $1000 fee will be incurred for failure to transmit

shipment information prior to the receipt of goods to DMCs distribution center.

Re-Pack, Re-Sort, Re-Configure Charge: If a quality defect is detected in a pre-pack order,

shipment will have an additional charge above the inspection charge to re-pack the purchase

order back to the correct pre-pack formation prior to shipping. Cost will be charged at actual

cost.

Documentation Filing: If Destination Maternity receives a financial penalty as a result of

freight being delivered late, not delivered as specified, or wrong freight delivered, or

quantity/data discrepancy, DMC reserves the right to pass through the fines and penalties

received as a result of the delay, lateness or erroneous information.

Example, if we incorrect information is provided for a Importer Security Filing (ISF) and

as a result the filing is not transmitted or transmitted incorrectly, Customs and Border

Protection reserves the right to impose an $8,000 fine. DMC reserves the right to pass this

fine through to the vendor.

If a shipment has a significant violation that causes a delay in being processed and could

or does require a correction, DMC reserves the right to assess a non-compliance fee of

$1000.00 over and above any specified charges listed above.

ANY DISPUTES REGARDING CHARGEBACKS SHOULD BE ADDRESSED TO

chargebacks@DestinationMaternity.com

EXAMPLES OF DEFECTS

Needle Hole

Section 9 Quality.doc, Page 17

Embroidery / Decoration coming off

Untrimmed Threads

Mismatched Care label and Price tickets

Section 9 Quality.doc, Page 18

Open Seams

Shading

Bug Contamination

Section 9 Quality.doc, Page 19

Destination Maternity Corporation has a ZERO TOLERANCE on Tag to Ticket Accuracy.

Inspection Levels & AQL Updated 7/24/2009

A PEA IN THE POD COLLECTION

GENERAL INSPECTION LEVEL II 2.5 AQL NORMAL

Lot Size Units to Inspect Accept Reject

16-25 5 0 1

26-50 8 0 1

51-90 13 1 2

91-150 20 1 2

151-280 32 2 3

281-500 50 3 4

NOTE: All Defects Considered Major Defects. Minor Defects Are Not Permitted.

PEA IN THE POD

GENERAL INSPECTION LEVEL II AQL 2.5 NORMAL

Lot Size Units to Inspect Accept Reject

51-90 13 1 2

91-150 20 1 2

151-280 32 2 3

281-500 50 3 4

501-1200 80 5 6

1201-3200 125 7 8

Section 9 Quality.doc, Page 20

MOTHERHOOD & OH BABY

GENERAL INSPECTION LEVEL II AQL 4.0 NORMAL

Lot Size Units to Inspect Accept Reject

151-280 32 3 4

281-500 50 5 6

501-1200 80 7 8

1201-3200 125 10 11

3201-10000 200 14 15

WAREHOUSE QUALITY ASSURANCE DEPARTMENT

When a debit memo is issued for Quality Assurance issues, samples are sent to the agent within a week. If

there are any concerns regarding the debit memo and samples, e-mail should be sent to discuss concerns.

DMC must quickly issue debits and process out defects. We do not save or have extra samples in our

facility to send. If you have any questions or concerns with any debit memo that is issued, please contact

us within 10 days of the debit being issued. After the 10 days, we will consider the issue closed.

Вам также может понравиться

- Garment InspectionДокумент12 страницGarment Inspectionmohan smrОценок пока нет

- Fabric Inspection Under 4Документ5 страницFabric Inspection Under 4texcons677150% (2)

- Processed Fabric InspectionДокумент5 страницProcessed Fabric InspectionTamrat TesfayeОценок пока нет

- 4 Point SystemДокумент6 страниц4 Point Systemapi-2649455589% (9)

- Fabric Inspection SystemДокумент14 страницFabric Inspection SystemVrinda GuptaОценок пока нет

- An Overview of Quality and Quality Control in Textile IndustryДокумент12 страницAn Overview of Quality and Quality Control in Textile IndustryTasnif Mahmud100% (1)

- Fabric Inspection ProcedureДокумент6 страницFabric Inspection ProcedureMayan DynastyОценок пока нет

- 2 - Garment InspectionДокумент23 страницы2 - Garment Inspectionhridi147Оценок пока нет

- Garment Production for Fashion Start-ups: Overseas Apparel Production Series, #1От EverandGarment Production for Fashion Start-ups: Overseas Apparel Production Series, #1Оценок пока нет

- 59 Fabric Quality ManualДокумент17 страниц59 Fabric Quality Manualbeeyesyem100% (3)

- H&M QSR Part 01 - IntroductionДокумент7 страницH&M QSR Part 01 - IntroductionRashedul AlamОценок пока нет

- Fabrics Faults or DefectsДокумент13 страницFabrics Faults or DefectsGopal KrishnanОценок пока нет

- Assignment On Fabric Quality Control and TestingДокумент57 страницAssignment On Fabric Quality Control and TestingBayazid Bustami Shaun100% (2)

- Fabric and Apparel Performance Testing ProtocolДокумент20 страницFabric and Apparel Performance Testing Protocolbeeyesyem100% (1)

- Fabric InspectionДокумент20 страницFabric InspectionHarrison Kan100% (1)

- Flow Process in Garment IndustryДокумент5 страницFlow Process in Garment IndustryMeeta AroraОценок пока нет

- Process Flow Chart of Banswara Garment Kadaiya Unit AvinashДокумент23 страницыProcess Flow Chart of Banswara Garment Kadaiya Unit AvinashakashОценок пока нет

- Catalogue of Visual Textile Defects Aasim AhmedДокумент20 страницCatalogue of Visual Textile Defects Aasim AhmedAdi TtaОценок пока нет

- H&M Fabric Inspection Guideline English 2014Документ12 страницH&M Fabric Inspection Guideline English 2014Rashedul Alam100% (1)

- Fabric DefectsДокумент27 страницFabric Defectsniftchennai9067% (3)

- Traffic Light System in Garment IndustryДокумент11 страницTraffic Light System in Garment IndustryGopal Dixit0% (1)

- F-02 Fabric Inspection ManualДокумент13 страницF-02 Fabric Inspection Manualzoomerfins22100% (1)

- 10 Apparel QamanualДокумент44 страницы10 Apparel QamanualRanjeetKamatОценок пока нет

- WASH & GARMENT DYE SOP Denim & CasualДокумент17 страницWASH & GARMENT DYE SOP Denim & CasualTwaha M&S100% (1)

- NPG Fabric InspectionДокумент4 страницыNPG Fabric InspectionDivya SinghОценок пока нет

- Defect Classification Zones - Garment InspectionДокумент11 страницDefect Classification Zones - Garment InspectionGarmentLearner92% (13)

- STDS'M&SДокумент8 страницSTDS'M&SSazid Rahman100% (1)

- Global URBN Fabric and Apparel Testing Manual 2.25.2019Документ81 страницаGlobal URBN Fabric and Apparel Testing Manual 2.25.2019THYAGUОценок пока нет

- Fabric Defect Reading MaterialДокумент6 страницFabric Defect Reading MaterialAnoop Singh100% (1)

- Quality Control Systems Used in Apparel IndustryДокумент61 страницаQuality Control Systems Used in Apparel IndustryKhuram Shah Engr100% (1)

- Grey Fabric InspectionДокумент7 страницGrey Fabric InspectionMuhammad KamranОценок пока нет

- Major Defects: Dye Spots HoleДокумент35 страницMajor Defects: Dye Spots Holebeeyesyem100% (4)

- Garment Defect AnalysisДокумент21 страницаGarment Defect AnalysisIndranil Saha100% (10)

- Carr and Latham's Technology of Clothing ManufactureОт EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerРейтинг: 4 из 5 звезд4/5 (1)

- Garment Defects - Root Cause AnalysisДокумент6 страницGarment Defects - Root Cause AnalysisMd Majharul Islam100% (1)

- Fabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessДокумент2 страницыFabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessSubrata Mahapatra100% (2)

- QMS - F.02 Fabric Inspection Training ModuleДокумент22 страницыQMS - F.02 Fabric Inspection Training ModuleDebashishDolonОценок пока нет

- TrainingДокумент29 страницTrainingNavodita Singh100% (1)

- Training Module For Finishing Checkers in A Garment FactoryДокумент26 страницTraining Module For Finishing Checkers in A Garment FactoryVachan Abhilekh Thakur100% (3)

- Factory QC Manual - 高端服装品牌QC验货标准 (英文版)Документ103 страницыFactory QC Manual - 高端服装品牌QC验货标准 (英文版)beeyesyem50% (4)

- SOP On Sewn Button & Snap Fastener Safety PDFДокумент58 страницSOP On Sewn Button & Snap Fastener Safety PDFJuwel Rana85% (13)

- Fabric RelaxationДокумент2 страницыFabric RelaxationNahid67% (3)

- Garment InspectionДокумент10 страницGarment Inspectionsyed asim najam100% (7)

- SPREADING, Cutting & FusingДокумент17 страницSPREADING, Cutting & FusingVishwanath KrОценок пока нет

- KQATEX1 Apparel Textile Requirements 150310Документ17 страницKQATEX1 Apparel Textile Requirements 150310Ammar Maqsood100% (1)

- Cutting SOPДокумент8 страницCutting SOParvindtiwari21Оценок пока нет

- SM QA ChildrenswearДокумент58 страницSM QA Childrenswearnaveenerotex100% (1)

- Fabric DefectsДокумент30 страницFabric Defectsaparna_ftОценок пока нет

- Quality ManualДокумент18 страницQuality ManualSandesh SharmaОценок пока нет

- Quality Manual MaduraДокумент22 страницыQuality Manual MaduraAbhishek Yadav100% (1)

- Apparel Quality ManagementДокумент32 страницыApparel Quality Managementshawar6967% (3)

- Naina ApparelsДокумент11 страницNaina ApparelsAman DeepОценок пока нет

- Quality Check Points in Garment ProductionДокумент5 страницQuality Check Points in Garment ProductionumairvmdОценок пока нет

- Garment InspectionДокумент9 страницGarment InspectionJames_45Оценок пока нет

- Fabric InspectionДокумент6 страницFabric InspectionJothi Vel Murugan100% (7)

- Quality Control in Garments ProductionДокумент22 страницыQuality Control in Garments Productioni_sonetОценок пока нет

- Garments Manufacturing Process: Stepwise Garments ManufacturingДокумент24 страницыGarments Manufacturing Process: Stepwise Garments ManufacturingAnamika Priyadarshini100% (1)

- 5.1 Introduction To ProductionДокумент3 страницы5.1 Introduction To ProductionukeypravinОценок пока нет

- Fabric Check ProcedureДокумент7 страницFabric Check ProcedureEleni LanaraОценок пока нет

- Fabric Inspection GuidelinesДокумент10 страницFabric Inspection GuidelinesSohel AhmedОценок пока нет

- Denim Finishing With EnzymesДокумент3 страницыDenim Finishing With Enzymesapi-26494555Оценок пока нет

- Clothing Materials and ClassificationsДокумент4 страницыClothing Materials and ClassificationsGarmentLearnerОценок пока нет

- Efficient Water Utilisation in Textile Wet ProcessingДокумент4 страницыEfficient Water Utilisation in Textile Wet ProcessingGarmentLearnerОценок пока нет

- Facts About Fabric FlammabilityДокумент7 страницFacts About Fabric Flammabilityapi-26494555Оценок пока нет

- Denim Seam Quality DefectsДокумент6 страницDenim Seam Quality Defectsapi-26494555Оценок пока нет

- What Is Letter of Credit? ExplainedДокумент4 страницыWhat Is Letter of Credit? ExplainedGarmentLearnerОценок пока нет

- Simulating Knitted Cloth at The Yarn LevelДокумент9 страницSimulating Knitted Cloth at The Yarn LevelGarmentLearnerОценок пока нет

- Washing Principle Denim DystarДокумент80 страницWashing Principle Denim DystarLieven Verraest100% (4)

- A Thread OF TruthДокумент17 страницA Thread OF Truthapi-26494555100% (1)

- Manufacturing Process of Denim FabricДокумент22 страницыManufacturing Process of Denim FabricGarmentLearner100% (3)

- TRI 3005 Garment Washing Techniques For Cotton ApparelДокумент13 страницTRI 3005 Garment Washing Techniques For Cotton Apparelapi-26494555Оценок пока нет

- Apparel Packing Method Manual of Target AustraliaДокумент21 страницаApparel Packing Method Manual of Target AustraliaGarmentLearner100% (2)

- 5 - Functional Finishes For Cotton ProductsДокумент10 страниц5 - Functional Finishes For Cotton ProductsVasluianuОценок пока нет

- Bangladesh Is Going To Be The Largest Apparel Exporter in The WorldДокумент3 страницыBangladesh Is Going To Be The Largest Apparel Exporter in The WorldGarmentLearner0% (1)

- International Packaging Guidelines Fold Method Codes and DiagramsДокумент40 страницInternational Packaging Guidelines Fold Method Codes and DiagramsGarmentLearnerОценок пока нет

- Effect of Machine Parameters On Knit Fabric SpecificationsДокумент5 страницEffect of Machine Parameters On Knit Fabric SpecificationsGarmentLearnerОценок пока нет

- Fundamentals of Knitting ExplainedДокумент15 страницFundamentals of Knitting ExplainedGarmentLearnerОценок пока нет

- Flat Knitted 3d Spacer Fabrics For High PerformanceДокумент198 страницFlat Knitted 3d Spacer Fabrics For High PerformanceGarmentLearner100% (3)

- A Handbook of WeavesДокумент84 страницыA Handbook of Weaves장지용Оценок пока нет

- Sewing With Knit FabricДокумент8 страницSewing With Knit FabricGarmentLearnerОценок пока нет

- Merchandise Floor Ready Standards - Supplier InformationДокумент46 страницMerchandise Floor Ready Standards - Supplier InformationGarmentLearner100% (1)

- Merchandise Packaging & Presentation Standards For StoresДокумент27 страницMerchandise Packaging & Presentation Standards For StoresGarmentLearnerОценок пока нет

- Container Packing Hapag-LloydДокумент48 страницContainer Packing Hapag-LloydGarmentLearner50% (2)

- Production of Cotton-Knit Fabrics Starfish TechnologyДокумент15 страницProduction of Cotton-Knit Fabrics Starfish TechnologyGarmentLearnerОценок пока нет

- Lace Making Book of PatternsДокумент24 страницыLace Making Book of PatternsGarmentLearner67% (3)

- Handbook of Ergonomic For The Clothing IndustryДокумент69 страницHandbook of Ergonomic For The Clothing IndustryGarmentLearner100% (1)

- How Clothing Is Made - Learning SeedДокумент17 страницHow Clothing Is Made - Learning SeedGarmentLearner33% (6)

- Company Profile TGLДокумент10 страницCompany Profile TGLYasir AlamОценок пока нет

- Handbook On Clothing - 2nd EdДокумент321 страницаHandbook On Clothing - 2nd Edcharliethwaites100% (1)

- Doel Group - Doel Apparels LimitedДокумент9 страницDoel Group - Doel Apparels LimitedGarmentLearnerОценок пока нет

- Fancy Pillowcase TutorialДокумент5 страницFancy Pillowcase TutorialElizabethОценок пока нет

- Process Flow Chart of Shirt ManufacturingДокумент8 страницProcess Flow Chart of Shirt ManufacturingAASTHA KUMARIОценок пока нет

- 0022500-00001-02 Sunrise Cushion Punch Needle Sara MooreДокумент6 страниц0022500-00001-02 Sunrise Cushion Punch Needle Sara MooreÁngela BurbanoОценок пока нет

- Defects in Garment IndustryДокумент14 страницDefects in Garment IndustryKarthik BalaОценок пока нет

- Tle Dressmaking Learning GuideДокумент19 страницTle Dressmaking Learning GuideMaxicris SlowerОценок пока нет

- Hems For GarmentsДокумент9 страницHems For Garmentsvivek jangra100% (1)

- Singer Tradition 2259 ManualДокумент58 страницSinger Tradition 2259 ManualGeorgeCR100% (1)

- LM Tle 6 HeДокумент55 страницLM Tle 6 HeShenSy86% (56)

- Pe 400 Dom 01 enДокумент112 страницPe 400 Dom 01 enDani Perry (Dinara)Оценок пока нет

- Singer Model 66 18 Sewing Machine ManualДокумент64 страницыSinger Model 66 18 Sewing Machine ManualPrasert BoontharaksaОценок пока нет

- DressmannДокумент3 страницыDressmannMahuri KesharwaniОценок пока нет

- Instruction Manual: HD 6600C - HD 6605CДокумент38 страницInstruction Manual: HD 6600C - HD 6605CfatagiuОценок пока нет

- E988 DL Mod 11 ENДокумент3 страницыE988 DL Mod 11 ENmalektrojetОценок пока нет

- Apparel Analysis For Layout Planning in Sewing SectionДокумент8 страницApparel Analysis For Layout Planning in Sewing SectionNadarajОценок пока нет

- 5523 Instruction ManualДокумент72 страницы5523 Instruction ManualBitstream SurferОценок пока нет

- Standard: Aerodynamic Decelerator and Parachute DrawingsДокумент58 страницStandard: Aerodynamic Decelerator and Parachute DrawingsFlorin NiteОценок пока нет

- Fursova E F Traditional Tailoring TechnoДокумент11 страницFursova E F Traditional Tailoring TechnoRocio Valeria BritoОценок пока нет

- Lesson 6 TLEДокумент2 страницыLesson 6 TLELee DokyeomОценок пока нет

- Sewing Tools and EquipmentДокумент8 страницSewing Tools and EquipmentChareLyn CaronggayОценок пока нет

- Motifs Templates: Print OUT & KeepДокумент29 страницMotifs Templates: Print OUT & KeepYessenia GОценок пока нет

- Folders FinalДокумент16 страницFolders FinalAkhil TyagiОценок пока нет

- New DressmakerДокумент176 страницNew Dressmakerjayrock57476593% (14)

- Minnesota (Davis) Model C Sewing Machine Instruction ManualДокумент20 страницMinnesota (Davis) Model C Sewing Machine Instruction ManualiliiexpugnansОценок пока нет

- How To Use Your Multi Size Pattern Cutting Layouts Sewing DirectionsДокумент4 страницыHow To Use Your Multi Size Pattern Cutting Layouts Sewing DirectionsLinh Kurt100% (1)

- Fitting Problems & Garments AlterationДокумент33 страницыFitting Problems & Garments AlterationMaria Elizabeth Tabelisma100% (1)

- Pfaff 6110,6120,6122,6150,6230 Tiptronic A PDFДокумент89 страницPfaff 6110,6120,6122,6150,6230 Tiptronic A PDFdsosicОценок пока нет

- Pfaff Tiptronic 2030/2040 Sewing Machine Instruction ManualДокумент138 страницPfaff Tiptronic 2030/2040 Sewing Machine Instruction ManualiliiexpugnansОценок пока нет

- Basic Sewing Stitches For BeginnersДокумент8 страницBasic Sewing Stitches For BeginnersJasmin JoОценок пока нет

- Hanbok Wrap Skirt Instruction - ENДокумент8 страницHanbok Wrap Skirt Instruction - ENtatjana.mirolubovaОценок пока нет

- Alfa 472 Sewing Machine ManualДокумент44 страницыAlfa 472 Sewing Machine ManualFrancis Gladstone-Quintuplet100% (1)