Академический Документы

Профессиональный Документы

Культура Документы

Report Dts I

Загружено:

eravisrОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Report Dts I

Загружено:

eravisrАвторское право:

Доступные форматы

1

TABLE OF CONTENTS

NO. TITLE PAGE NO.

ABSTRACT iii

LIST OF FIGURES.....................................................................................iv

1.INTRODUCTION

1.1 GENERAL...............2

1.2 MAIN CHARACTERISTICS..................................5

2.CONSTRUCTION

2.1 ENGINE CONSTRUCTION....................................................................7

2.2 CONSTRUCTIONAL DETAILS.............................................................7

2.3 VALVE DESIGN......................................................................................8

2.4 FUEL FEED.............................................................................................11

3.WORKING

3.1 PROBLEM WITH HIGH CAPACITY BIKES.......................................13

3.2 COMBUSTION BEFORE DTS-I TECHNOLOGY................................14

3.3 HOW DTS-I SOLVES THE PROBLEM................................................14

3.3.1 TRICS III..................................................................................16

3.3.2 C.D.I..........................................................................................17

3.3.3 BASIC PRINCIPLES................................................................18

3.3.4 IGNITION.................................................................................20

3.4 MATHEMATICAL MODEL.................................................................23

4. ADVANCEMENTS

2

4.1 TECHNICAL IMPROVISATIONS......................................................26

4.1.1 DTS-SI TECHNOLOGY...............................................................27

4.1.2 DTS-FI TECHNOLOGY...............................................................29

4.2 STATISTICS...........................................................................................32

4.3 ADVANTAGES &DISADVANTAGES................................................33

5. CONCLUSION

REFERENCES

3

CHAPTER:1

INTRODUCTION

1.1 GENERAL

A conventional 4 Stroke engine has a Single Spark Plug located at

one end of the combustion chamber and hence the combustion is

inefficient leading to sub optimal mileage and sub optimal performance

& can even have problems with oil flow. Hence forth there was a

requirement

to change engines' design, fuelling, ignition, production and quality to

achieve the following objectives. Uniform power delivery in all

operating conditions:-

A high degree of drivability

First rate standards of reliability

Long service life.

With a view to overcome the above limitations a new patent was

introduced that is known as DTS-I technology & its use is increasing

day by days. DIGITAL TWIN SPARK ignition engine has two Spark

plugs located at opposite ends of the combustion chamber and

hence fast and efficient combustion is obtained. The benefits of this

efficient combustion process can be felt in terms of better fuel efficiency

4

and lower emissions. The ignition system on the Twin spark is a digital

system with static spark advance and no moving parts subject to wear. It

is mapped by the integrated digital electronic control box which also

handles fuel injection and valve timing. It features two plugs per

cylinder

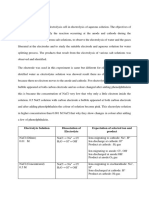

DIFFERENCE BETWEEN CONVENTIONAL 4-STROKE AND DTS-i

ENGINE

This innovative solution, also entailing a special configuration of the

5

hemispherical combustion chambers and piston heads, ensures a fast,

wide flame front when the air-fuel mixture is ignited, and therefore less

ignition advance, enabling, moreover, relatively lean mixtures to be

used. This technology provides a combination of the light weight and

twice the power offered by two-stroke engines with a significant power

boost, i.e. a considerable "power-to-weight ratio" compared to quite a

few four-stroke engines. The actual picture of Bajaj Pulsar Bike is

Moreover, such a system can adjust idling speed & even cuts off fuel

feed when the accelerator pedal is released, and meters the enrichment of

6

the air-fuel mixture for cold starting and accelerating purposes; if

necessary, it also prevents the upper rev limit from being exceeded. At

low revs, the over boost is mostly used when overtaking, and this is why

it cuts out automatically. At higher speeds the over boost will enhance

full power delivery and will stay on as long as the driver exercises

maximum pressure on the accelerator.

1.2 MAIN CHARACTERISTICS

Digital electronic ignition with two plugs per cylinder and two

ignition distributors;

Twin overhead cams with camshaft timing variation;

Injection fuel feed with integrated electronic twin spark ignition;

A high specific power;

Compact design and Superior balance;

This power unit, equipping the naturally aspirated 2-litre used on the

Alfa 164, is a direct dilative of the engine fitted on the 2.0 Twin Spark

version of the Alfa 75, a recent addition to the Alfa car range. It includes

a number of exclusive engineering solutions resulting in superior power

output and exceptional peak torque for this cylinder capacity. Its main

characteristics are:

7

Digital electronic ignition with two plugs per cylinder and two

ignition distributors

Twin overhead cams with camshaft timing variation

Injection fuel feed with integrated electronic twin spark ignition

Cylinder capacity amounts to 1,962 cc thanks to an 84 mm bore and 88.5

mm stroke with the Compression ratio 10: 1.

Maximum power output at 5,800 rpm is a remarkable 148 BHP DIN,

while maximum torque, of 19 mkg DIN, is reached at 4,000 rpm. The

shape of the torque curve has been perfected to make available fully 16

mkg when revving speed reaches 2,000 rpm and 18 mkg as early as

3,000 rpm, thus making the engine's performance much more

responsive.

8

CHAPTER:2

CONSTRUCTION

2.1ENGINE CONSTRUCTION

The engine used on the Alfa 164 T. Spark is a four-in-line

cylinder unit whose weight has been considerably reduced with all

aluminium-alloy engine block, cylinder head, oil sump and tappet

covers. Eight counterweights ensure optimal balancing of the high

strength nitride steel crankshaft. The pressed-in cast iron cylinder liners

feature wet mounting for more effective heat dissipation.

2.2 CONSTRUTIONAL DETAILS

9

The construction of DTS-i engine is same as that of the conventional 4-

Stroke engine. It consists of following parts:

Piston

Cylinder

Crankshaft

Connecting rod

Fly wheel

Carburettor

2-sparkplug

2-ports

2-valves

Here the only change made is that the 2 sparkplug placed at the two

opposite end of the combustion chamber At 90 degree to each other.

2.3 VALVE DRIVE

The twin overhead cams, driven by a double chain, act directly on

theValves set in a tight Vee configuration (46o). The timing of the valve

10

TIGHT VEE CONFIGURATION OF VALVES

train is not fixed as in most present day engines, but can be adjusted by a

patented device conceived and produced by Alfa Romeo,the timing

variation. This is an electro-hydraulic actuator keyed onto the gear that

drives the camshaft acting on the intake valves. This actuator enables the

camshaft to be shifted into two different angular positions and to modify

the intake valve opening durations. Its operation is controlled by the

11

electronic control box of the integrated ignition and fuel injection

system.

Valve timing actuator logic is predetermined so that overlap - i.e. that

fraction of the engines operating cycle when both the exhaust and the

intake valves are open simultaneously is shorter at low revs and with

lighter loads and longer at higher engine speeds when extra power is

required

At high and medium-high engine speeds or whenever additional

power has to be provided (normal timing) cylinder filling is

optimal, maximizing power output and torque

At low and medium-low revs and lighter loads (delayed timing),

fluctuation-free operation is ensured combined with a reduction in

specific consumption

At all engine speeds, noxious emissions are minimized.

12

PICTURE SHOWING INTAKE AND EXHAUST VALVES

2.4 FUEL FEED

The Alfa 164 T. Spark power plant is equipped with the ML 4.1

Bosch Motronic multi-point injection system, controlled by the same

microprocessor which governs the twin spark ignition and variable valve

timing Systems.

13

The excellent volumetric efficiency of the Twin Spark engine is also

enhanced by the special straight section individual intake man folding

that cuts down losses and fully exploits intake resonance for better mid-

range torque.

Having all thermodynamic cycle components under the wings of a single

electronic control unit means that the power plant used on the Alfa 1 64

T. Spark can guarantee-in addition to outstanding torque and power

figures-regular, smooth running at all speeds regardless of load.

Moreover, this engine features particularly attractive specific fuel

economy compared with rival naturally aspirated units in the same

displacement class (with savings of up to 20- 25%).

14

CHAPTER:3

WORKING

3.1THE ACTUAL PROBLEM WITH HIGHER CAPACITY

BIKES:

The central problem in the higher capacity bikes is its higher

capacity(i.e. larger bore) it self. As the capacity is higher its intake of

fresh charge (air fuel mixture) will usually gets increases which in turn

increases the fuel consumption. And also the complete combustion of

the fresh charge that entered the combustion chamber is not assured,

because initially the capacity is higher, therefore the flame front of the

spark ignited by the spark plug has to travel the additional distance of

increased bore in order to fire the charge at the farthest corners of the

cylinder thereby slackening the combustion process. There must be some

15

modifications in the engine design to eliminate these problems in higher

capacity bikes. The application of Digital twin spark ignition technology

can eliminate this problem up to maximum extent

3.2 COMBUSTION PROCESS BEFORE USING DTS-I

TECHNOLOGY

The orthodox single cylinder, four-stroke, spark ignition engine is

generally equipped with a single spark plug. The fresh charge (air fuel

mixture) that entered the cylinder during the suction stroke is

compressed during the compression stroke resulting the increase of

pressure and temperature of the charge. The spark plug, usually situated

at one end of the combustion chamber, ignites the air-fuel mixture and

the ensuing flame spreads like a slowly inflating balloon. There is an

inevitable delay for this inflating balloon to reach the furthest part of the

combustion chamber. So there are pockets of poor combustion within

the chamber and, overall, the combustion is slow and inefficient.

When it comes to higher capacity engines the distance to be travelled by

the flame front is further increased resulting the still slower combustion.

3.3 HOW DTS-i ENGINE SOLVES THE PROBLEM?

16

The Digital Twin Spark Ignition technology takes care of this slower

combustion problem in a simple but a novel way. The cylinder head is

equipped with two spark plugs, instead of the usual one. By generating

two sparks at either ends of the combustion chamber, (approximately

90 to the valve axis) the air-fuel mixture gets ignited in a way that

creates two flame fronts and, therefore, a reduction in flame travel of the

order of 40 per cent is achieved. A fast rate of combustion is achieved

leading to faster rise in pressure. The obvious outcome of this is more

torque, better fuel efficiency and lower emissions. An electronic device

(microprocessor) controls the firing order of these twin spark plugs.

The fresh charge that entered the cylinder during the suction stroke is

compressed during the compression stroke. Then a spark will be ignited

by one of the twin spark plugs and the flame front begins to expand like

an inflating balloon. In the mean while another spark will be ignited by

another spark plug as per controls of the microprocessor. The flame front

also begins to expand like an inflating balloon. Therefore the areas that

are not covered by the first flame front will be covered by second flame

front resulting in the complete & rapid combustion of the fuel.

However, this technology even though proved as a successful one all

bike-manufacturing companies are not incorporating this technology in

their models. Their idea is this faster rate of combustion can be achieved

by employing a single spark plug with differential sparking cycles.

There are some advance technology used in DTS-i engine which makes

it more powerful than the conventional single sparkplug 4-stroke engine

like

17

1. Tricks III technology

2. CDI technology

3.3.1 TRICS III

Throttle Responsive Ignition Control System 3rd generation. It is a

means of controlling the Ignition by operating the Throttle. Depending

on the needs of the Rider whether it be cruising, acceleration or max

speed, the ignition requirements constantly change. Based on a particular

amount of Throttle opening, the Magnetic field generated by the Magnet

opens or closes the Reed switch. The Reed switch is connected to the

Digital CDI, which signals the CDI to change/switch, the desired

Ignition Advance Timing Maps. This helps in achieving a good balance

between driveability and Optimum Ignition Spark advance, resulting in

an almost perfect Ignition Spark advance for every Throttle opening and

Engine rpm.

18

3.3.2 C.D.I

Capacitor discharge ignition (CDI) or thyristor ignition is a type of

automotive electronic ignition system which is widely used in outboard

motors, motorcycles, lawn mowers, chainsaws, small engines, turbine-

powered aircraft, and some cars. It was originally developed to

overcome the long charging times associated with high inductance coils

used in inductive discharge ignition (IDI) systems, making the ignition

system more suitable for high engine speeds (for small engines, racing

engines and rotary engines). The capacitive-discharge ignition uses

capacitor discharge current output to fire the spark plugs.

Capacitor discharge ignition

19

3.3.3 BASIC PRINCIPLES

Most ignition systems used in cars are inductive discharge ignition (IDI)

systems, which are solely relying on the electric inductance at the coil to

produce high-voltage electricity to the spark plugs as the magnetic field

collapses when the current to the primary coil winding is disconnected

(disruptive discharge). In a CDI system, a charging circuit charges a

high voltage capacitor, and at the instant of ignition the system stops

charging the capacitor, allowing the capacitor to discharge its output to

the ignition coil before reaching the spark plug.

A typical CDI module consists of a small transformer, a charging circuit,

a triggering circuit and a main capacitor. First, the system voltage is

raised up to 250 to 600 volts by a power supply inside the CDI module.

Then, the electric current flows to the charging circuit and charges the

capacitor. The rectifier inside the charging circuit prevents capacitor

discharge before the moment of ignition. When the triggering circuit

receives triggering signals, the triggering circuit stops the operation of

the charging circuit, allowing the capacitor to discharge its output

rapidly to the low inductance ignition coil. In a CD ignition, the ignition

coil acts as a pulse transformer rather than an energy storage medium as

it does in an inductive system. The voltage output to the spark plugs is

purely dependent on the design of the CD ignition. Voltages exceeding

the insulation capabilities of existing ignition components can lead to

early failure of those components. Most CD ignitions are made to give

very high output voltages, but this is not always beneficial. When there's

no triggering signal, the charging circuit is re-connected to charge the

capacitor.

20

The amount of energy the CDI system can store for the generation of a

spark is dependent on the voltage and capacitance of the capacitors used,

but usually it's around 50 mJ, or more. The standard

points/coil/distributor ignition, more properly called the inductive

discharge ignition system or Kettering ignition system, produces 25mJ at

low speed and drops off quickly as speed increases.

Most CDI modules are generally of two types:

AC-CDI - The AC-CDI module obtains its electricity source solely from

the alternating current produced by the alternator. The AC-CDI system

is the most basic CDI system which is widely used in small engines.

Note that not all small engine ignition systems are CDI. Some older

engines, and engines like older Briggs and Stratton use magneto ignition.

The entire ignition system, coil and points, are under the magnetized

flywheel.

Another sort of ignition system commonly used on small off-road

motorcycles in the 1960s and 1970s was called Energy Transfer. A coil

under the flywheel generated a strong DC current pulse as the flywheel

magnet moved over it. This DC current flowed through a wire to an

ignition coil mounted outside of the engine. The points sometimes were

under the flywheel for two-stroke engines, and commonly on the

camshaft for four-stroke engines. This system worked like all Kettering

(points/coil) ignition systems... the opening points trigger the collapse of

the magnetic field in the ignition coil, producing a high voltage pulse

which flows through the spark plug wire to the spark plug.

21

If the engine was rotated while examining the wave-form output of the

coil with an oscilloscope, it would appear to be AC. Since the charge-

time of the coil corresponds to much less than a full revolution of the

crank, the coil really 'sees' only DC current for charging the external

ignition coil.

Some electronic ignition systems exist that are not CDI. These systems

use a transistor to switch the charging current to the coil off and on at the

appropriate times. This eliminated the problem of burned and worn

points, and provided a hotter spark because of the faster voltage rise and

collapse time in the ignition coil.

DC-CDI - The DC-CDI module is powered by the battery, and therefore

an additional DC/AC inverter circuit is included in the CDI module to

raise the 12 V DC to 400-600 V DC, making the CDI module slightly

larger. However, vehicles that use DC-CDI systems have more precise

ignition timing and the engine can be started more easily when cold.

3.3.4 IGNITION WITH C.D.I

A Digital CDI with an 8 bit microprocessor chip handles the spark

delivery. The programmed chips memory contains an optimum Ignition

timing for any given engine rpm, thereby obtaining the best performance

characteristics from the combustion chamber. Working together with the

TRICSIII system, it delivers Optimum Ignition Timing for varying load

conditions. The ignition system on the Twin spark is a digital system

with static spark advance and no moving parts subject to wear. It is

22

mapped by the integrated digital electronic control box which also

handles fuel injection and valve timing. It features two plugs per

cylinder.

This innovative solution, also entailing a special configuration of the

hemispherical combustion chambers and piston heads, ensures a fast,

wide flame front when the air-fuel mixture is ignited, and therefore less

ignition advance, enabling, moreover, relatively lean mixtures to be

used. As a result, the adoption of twin spark ignition yields:

A remarkable improvement in thermodynamic efficiency and

hence a considerable increase in the amount of power

available;

more effective combustion at low load and at idling speed;

A sizeable reduction in specific fuel consumption;

A reduced exhaust emission;

Less chance of ignition system failure...

(Failure of either circuit will not stop the engine, which can still work

with single spark ignition).

23

STARTING OF PULSAR DTS-i ENGINE

24

3.4 MATHEMATICAL MODEL

Governing equations of the cycle model:

The energy equation in crank angle basis is written as:

==/+/=//

To determine instantaneous cylinder volume, pressure, and

burned and unburned gas temperatures, the following

governing equations have been used

()={+/[+[(-r

2

crsin

2

).]]

}

Equations to determine the burnt mass fraction

25

26

CHAPTER:4

ADVANCEMENTS IN DTS-i TECHNOLOGY

4.1 TWO NEW TECHNICAL IMPROVISATIONS

DTS-i.e. Engine can be further tuned to deliver exhilarating

performance or exceptional mileage. The further advances of DTS-I

technology are:

Digital Twin Spark Swirl Induction (DTS - Si)

Digital Twin Spark Fuel Injection (DTS - Fi)

4.1.1 DIGITAL TWIN SPARK SWIRL INDUCTION

Need for Swirl Induction:

The DTS-I technology is the parent technology for this latest DTS-Si

technology. Even though a faster rate of combustion is achieved by

27

incorporating the DTS-I technology, there is a chance for further of

improvement of rapid combustion process at lighter loads. When there is

a sufficient or heavy load on the engine, the 4 stroke cycle completes

at a faster rate resulting in the faster combustion because of the twin

sparks produced by the twin plugs. But when there exists a lighter load

on the engine, the 4 stroke cycle will not complete at a faster rate.

Therefore even the incorporation of twin spark plugs cannot aid the

faster combustion i.e. still a better rate of combustion can be achieved

at lighter loads.

Combustion efficiency in lean Air-Fuel mixture conditions can be

further improved by generating high turbulence in the combustion

chamber. Combustion chambers having low turbulence give rise to

propagation of a flame front, which is akin to that of a gradually

expanding balloon. This results in a slower rate of combustion and thus

slower rate of pressure rise.

End result is lower efficiency. When high turbulence is generated and

combustion takes place, the surface of the ballooning flame front

fragments itself, with projection like fingers, which increases its surface

area, thereby improving combustion further.

Here comes the Swirl Induction concept, which is meant for producing

higher turbulence in the combustion chamber. Swirl Induction is nothing

but imparting a swirling motion to the fresh charge that enters the

combustion chamber. This can be done by making slight modifications

in the ports positioning of engine.

28

The picture on this page shows how swirl induction works:-

Actual DTS-i ENGINE

The DTS-Si engine will have two spark plugs but it differs from the

parent DTS-I engine in the design of position of the ports. The straight

29

ports used in conventional engines have limitations in generating high

swirl values due to their geometry. One of the ways to generate more

swirl is to have a port configuration that promotes this phenomena. An

offset port configuration was arrived upon and optimized to generate the

required swirl numbers. Incorporated in the new engine, this results in a

swirling motion of the incoming charge, which decays itself into

turbulence as the piston moves in the Induction and Compression

strokes.

This results in the Air-Fuel mixture being more thoroughly mixed and

spread around the combustion chamber. Sparks provided by the twin

spark plugs ignite this highly turbulent and compressed Air-Fuel

mixture, leading to a flame front with high surface area, resulting in a

rapid rise of pressure due to rapid combustion. The values of turbulence

achieved now, are substantially higher than that of a straight port

cylinder head, such as in DTS-i. A combination of DTS-i and Swirl

induction thus provides extremely rapid combustion, resulting in high

efficiency.

This technology is applied by Bajaj Auto Ltd in its latest model XCD-

125 that delivers an outstanding mileage of 109 kmpl under ideal

conditions, which is the best of Indian motorbikes. The DTS-Si engine is

far superior to the conventional 4-stroke engines, which dominate the

100cc segment at present. With the new DTS-Si engine the consumer

now would not have to compromise between power and mileage - he

gets the best of both.

30

4.1.2DIGITAL TWIN SPARK FUEL INJECTION (DTS - Fi):

DTS Fi is another advancement of the parent DTS i technology. This

technology is the combination of both DTS i and fuel injection. This

technology is meant for increasing the fuel efficiency in power bikes.

Generally in conventional 4-stroke engines, which uses petrol as fuel,

makes use of carburettor , which mixes the fuel and fresh air in required

ratio and supplies the same to the combustion chamber. The process is

similar for all loads. But the fuel consumption will be more when there

is a heavy load on the engine and it is less when there is a light load on

the engine. It is impossible for a conventional carburettor to take care of

the fuel supply for these varying loads. Therefore there is a need for

some intelligent device that controls the fuel supply according to the

varying loads.

That so wanted intelligent device is nothing but the Electronic Control

Unit (ECU). The Electronic Control Unit is a microprocessor based

system and can be regarded as the brain of the fuel injection system.

Fig. showing sectional view of DTS-Fi engine

31

4.1.3 WORKING OF ECU

Control of Air/Fuel ratio

For an engine with fuel injection, an engine control unit (ECU) will

determine the quantity of fuel to inject based on a number of parameters.

If the throttle position sensor is showing the throttle pedal is pressed

further down, the mass flow sensor will measure the amount of

additional air being sucked into the engine and the ECU will inject fixed

quantity of fuel into the engine ( most of the engine fuel inlet quantity is

fixed). If the engine coolant temperature sensor is showing the engine

has not warmed up yet, more fuel will be injected (causing the engine to

run slightly 'rich' until the engine warms up). Mixture control on

computer controlled carburettors works similarly but with a mixture

control solenoid or stepper motor incorporated in the float bowl of the

carburettor.

32

Control of ignition timing

A spark ignition engine requires a spark to initiate combustion in the

combustion chamber. An ECU can adjust the exact timing of the spark

(called ignition timing) to provide better power and economy. If the

ECU detects knock, a condition which is potentially destructive to

engines, and determines it to be the result of the ignition timing

occurring too early in the compression stroke, it will delay (retard) the

timing of the spark to prevent this. Since knock tends to occur more

easily at lower rpm, the ECU may send a signal for the automatic

transmission to downshift as a first attempt to alleviate knock.

A full authority throttle control system may be used to control idle

speed, provide cruise control functions and top speed limitation.

Control of variable valve timing

Some engines have Variable Valve Timing. In such an engine, the ECU

controls the time in the engine cycle at which the valves open. The

valves are usually opened sooner at higher speed than at lower speed.

This can optimize the flow of air into the cylinder, increasing power and

economy.

4.2 STATISTICS

33

The following are the various statistics showing the advantages of

application of DTS i & its derived technologies:

4.3 ADVANTAGES AND DISADVANTAGES

4.3.1 ADVANTAGES

Less vibrations and noise

0

10

20

30

40

50

60

CBZ-Xtreme Unicorn pulsar

power

Torque

Mileage

34

Long life of the engine parts such as piston rings and

valve stem.

Decrease in the specific fuel consumption

No over heating

Increase the Thermal Efficiency of the Engine & even

bear high loads on it.

Better starting of engine even in winter season & cold

climatic conditions or at very low temperatures because

of increased Compression ratio.

Because of twin Sparks the diameter of the flame

increases rapidly that would result in instantaneous

burning of fuels. Thus force exerted on the piston would

increase leading to better work output.

4.3.2 DISADVANTAGES

There is high NOx emission

If one spark plug get damaged then we have to replace

both

The cost is relatively more

You spend double the amount on spark plugs when it is

time to replace them.

35

The engine tends to overheat and loose power at higher

speeds as compared to a single plug engine.

In case the Engine is kept unused for a long time soiling

of spark plugs occur. Twin Spark system helps to reduce

this problem.

36

CHAPTER:5

CONCLUSION

Hence it can be concluded that the application of these

technologies the present day automobiles will give the present

generation what they want i.e. power bikes with fuel efficiency. Since

these technologies also minimize the fuel consumption and harmful

emission levels, they can also be considered as one of the solutions for

increasing fuel costs and increasing effect of global warming.

From this paper I have concluded that perfect Combustion in Internal

Combustion engine is not possible. So for the instantaneous burning of

fuels in I.C. engine twin spark system can be used which producing twin

sparks at regular interval can help to complete the combustion.

37

REFERENCES

1. Alabastri E., L. Magni, S. Ozioso, R. Scattolini, C. Siviero, and A.

Zambelli. Modeling, analysis and simulation of a digital twin

spark injection system. In Proceedings of the IFirst IFAC

Symposium on Advances in Automotive Control, 2004.

2. Baker P. and Watson H. Mpi air/fuel mixing gaseous and liquid

plg. SAE Technical Papers, 01(246), 2005.

3. Bajaj Auto.com

4. Kouremenos D. A. and Hountalas D. T. Development and

validation of a detailed fuel injection system simulation model for

dtsi engines. SAE Technical Papers, 01(0527), 1999.

5. Official Journal L 044, 16/02/2000. Directive 1999/96/EC of the

European Parliament and of the Council.

6. Wikipedia.org

Вам также может понравиться

- Turbo Charging - Introduction and HistoryДокумент39 страницTurbo Charging - Introduction and HistoryeravisrОценок пока нет

- Format of The Report For StudentsДокумент18 страницFormat of The Report For StudentsNamit GuptaОценок пока нет

- Indutrial Training Report Format Tybtech MechДокумент4 страницыIndutrial Training Report Format Tybtech MecheravisrОценок пока нет

- Annual Report 2013Документ106 страницAnnual Report 2013eravisrОценок пока нет

- Erection Manual for 500 MW Steam Turbine (KWU DesignДокумент127 страницErection Manual for 500 MW Steam Turbine (KWU DesigneravisrОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- POWER Nav1 - MIDTERM - Topic 1 & 2Документ31 страницаPOWER Nav1 - MIDTERM - Topic 1 & 2CLIJOHN PABLO FORD100% (1)

- TOS in PRE-CALCULUSДокумент2 страницыTOS in PRE-CALCULUSSerjohnRapsingОценок пока нет

- Aditya Rahul Final Report PDFДокумент110 страницAditya Rahul Final Report PDFarchitectfemil6663Оценок пока нет

- PDF Ecs h81h3 Ad DDДокумент37 страницPDF Ecs h81h3 Ad DDsanak tiuhОценок пока нет

- Lecture 2 - Kinematics Fundamentals - Part AДокумент30 страницLecture 2 - Kinematics Fundamentals - Part ASuaid Tariq BalghariОценок пока нет

- Peabody y Movent ABCДокумент11 страницPeabody y Movent ABCIngrid BarkoОценок пока нет

- Sandvik DL311Документ4 страницыSandvik DL311Anonymous Dm7iMmtОценок пока нет

- Chapter 4 Worksheets Algebra 1Документ110 страницChapter 4 Worksheets Algebra 1Amanda GeorginoОценок пока нет

- NX Advanced Simulation坐标系Документ12 страницNX Advanced Simulation坐标系jingyong123Оценок пока нет

- Discussion Exp 2 Chm674Документ4 страницыDiscussion Exp 2 Chm674Eva Lizwina MatinОценок пока нет

- Vitamins With Minerals Oral PowderДокумент8 страницVitamins With Minerals Oral PowderWH PANDWОценок пока нет

- Novel Proteinaceous Infectious Particles Cause ScrapieДокумент10 страницNovel Proteinaceous Infectious Particles Cause ScrapieMikey HaveyОценок пока нет

- Ellipse Properties and GraphingДокумент24 страницыEllipse Properties and GraphingREBY ARANZOОценок пока нет

- Lesson Statement Sheet.Документ2 страницыLesson Statement Sheet.Anya AshuОценок пока нет

- Peak Performance 4.3-Inch GPS ManualДокумент16 страницPeak Performance 4.3-Inch GPS ManualmcneelydОценок пока нет

- SQL Injection Attack Detection and Preve PDFДокумент12 страницSQL Injection Attack Detection and Preve PDFPramono PramonoОценок пока нет

- Geometri Ruang File 1Документ4 страницыGeometri Ruang File 1Muhammad Isna SumaatmajaОценок пока нет

- SSC JE Mechanical Study Material Strength of Materials PDFДокумент13 страницSSC JE Mechanical Study Material Strength of Materials PDFSameer ShahОценок пока нет

- Biophoton Light TherapyДокумент1 страницаBiophoton Light TherapyVíctor ValdezОценок пока нет

- SKM and OKM User ManualДокумент36 страницSKM and OKM User ManualOutlawRОценок пока нет

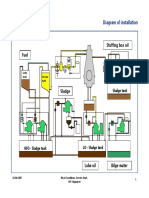

- Westfalia Separator Installation DiagramДокумент68 страницWestfalia Separator Installation DiagramOno Jr Araza100% (3)

- Experiment03 PCM-DecodingДокумент10 страницExperiment03 PCM-DecodingMary Rose P Delos SantosОценок пока нет

- Foundations On Friction Creep Piles in Soft ClaysДокумент11 страницFoundations On Friction Creep Piles in Soft ClaysGhaith M. SalihОценок пока нет

- Kotlin Programs - StudentsДокумент74 страницыKotlin Programs - Studentsgandem gowhithОценок пока нет

- Eaton 290376 NZMH4 VE800 S1 en - GBДокумент10 страницEaton 290376 NZMH4 VE800 S1 en - GBkarthik01heroОценок пока нет

- Shipboard: Micrpoclimate' Coolin SysemsДокумент47 страницShipboard: Micrpoclimate' Coolin Sysemsjakalae5263Оценок пока нет

- Grundfosliterature 5439390Документ108 страницGrundfosliterature 5439390ptlОценок пока нет

- Uptime Awards: Recognizing The Best of The Best!Документ40 страницUptime Awards: Recognizing The Best of The Best!Eric Sonny García AngelesОценок пока нет

- Manage expenses and group contributions with Expense ManagerДокумент29 страницManage expenses and group contributions with Expense ManagerPt Kamal SharmaОценок пока нет

- Exp 5-SteamPowerPlantДокумент11 страницExp 5-SteamPowerPlantFirst LastОценок пока нет