Академический Документы

Профессиональный Документы

Культура Документы

United States Patent (10) Patent No.: US 7,497,097 B2

Загружено:

Kasra Golban0 оценок0% нашли этот документ полезным (0 голосов)

83 просмотров9 страницPaper

Оригинальное название

Us 7497097

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPaper

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

83 просмотров9 страницUnited States Patent (10) Patent No.: US 7,497,097 B2

Загружено:

Kasra GolbanPaper

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 9

US007497097B2

( 1 2) United States Patent ( 1 0) Patent N o . : US 7, 497, 097 B2

Herr ( 45 ) Date o f Patent: Mar. 3 , 2009

( 5 4) SWEAT BLOCKIN G AN D VEN TILATIN G 6, 779, 3 69 B2 * 8/2004 Shepherd . . . . . . . . . . . . . . . . . . . . . 66/1 96

SWEATBAN D FOR HEADWEAR 6, 893 , 695 B2 * 5 /2005 Baychar . . 428/3 61

7, 043 , 767 B2 * 5 /2006 Jaeger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2/87

( 75 ) Inv ento r: Paul Hen. 1 4 E_ Genev a Cir Madiso n, 7, 276, 275 B2 * 1 0/2007 Schindz ielo rz et a1 . . . . . . . . . 428/86

WI ( Us) 5 3 71 7 7, 3 1 4, 840 B2 * 1 /2008 Baychar . . . . . . . . . . . . . . . . . . . . . 442/3 70

FOREIGN PATEN T DOCUMEN TS

( 73 ) Assignee: Paul Herr, Madiso n, WI ( U S)

EP 0988804 A2 3 /2000

( * ) N o tice: Sub j ect to any disclaim er, the term o f this GB 23 41 784 A 3 /2000

patent is ex tended o r adj usted under 3 5 * Cited b y ex am iner

U. S. C. 1 5 4( b ) b y 5 69 days.

Prim ary Ex am ineriDanny Wo rrell

( 21 ) App1 _ N O; 1 1 /1 47, 297 ( 74) Atto rney, Agent, o r Firm 4Galv in & Palm er; Sheldo n

Palm er

( 22) Filed: Jun. 8, 2005

( 5 7) ABSTRACT

( 65 ) Prio r Pub licatio n Data _ _ _

A spacer- f ab r1 c sWeatb and, f o r, and inco rpo rated into head

US 2006/027795 1 A1 1 3 3 6- 1 4, 2006 Wear Which has an inner, sk in- co ntact f ab ric layer, and an

o uter, headWear- f acing f ab ric layer co nnected b y a m ultiplic

( 5 1 ) Int- Cl- ity o f hydro pho b ic m o no ? lam ent- pile spacing elem ents. The

D04B 1 /24 ( 2006- 01 ) pile spacing elem ents f unctio n lik e tho usands o f m iniature

US. Cl- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Springs to m aintain the f ab ric layers in Spaced par

( 5 8) Field o f Classi? catio n Search . . . . . . . . . . . . . . . 66/ 1 69 R, allel relatio n While creating sub stantial, pile- suppo rted air

66/1 70, 1 71 , 1 72 R, 1 95 , 1 96; 2/1 81 , 1 82. 1 , space b etw een the f ab ric layers to f acilitate the m o v em ent o f

2/1 82. 3 , 1 82. 8 v entilating air? o W. The headWear- f acing f ab ric layer is m esh

See applicatio n ? le f o r co m plete search histo ry. lik e f o r enhanced air circulatio n. The sk in- co ntact layer is

( 5 6) Ref erences Cited co m po sed o f so lid sk in- f riendly f ab ric.

U. S. PATEN T DOCUMEN TS

4, 024, 5 86 A * 5 /1 977 Lam b . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2/41 4

4, 274, 1 5 7 A 6/1 981 Bo den

4, 292, 689 A 1 0/1 981 To w nsend, Jr.

5 , 1 01 , 5 1 6 A 4/1 992 Scarnato

5 , 1 5 7, 788 A 1 0/1 992 Schultz

5 , 625 , 901 A 5 /1 997 Healy

5 , 63 0, 23 0 A 5 /1 997 Fuj ino et a1 .

5 , 887, 276 A 3 /1 999 Lee

6, 1 3 8, 280 A 1 0/2000 Bae

The pile segm ents b lo ck sWeat f ro m m igrating f ro m the inner

to the o uter f ab ric layers b y v irtue o f their hydro pho b ic co m

po sitio n. This sWeat- b lo ck ing f unctio n m inim iz es the o ccur

rence o f sWeat stains o n the b o dy o f the headWear and co n

centrates sWeat Within the sk in- co ntact f ab ric layer, f ro m

Which it is sub seq uently sub j ect to ev apo ratio n and co nco m i

tant co o ling b y air ? o Wing thro ugh the pile- suppo rted air

space.

1 8 Claim s, 3 Draw ing Sheets

US. Patent Mar. 3 2009 Sheet 1 o f 3

US. Patent Mar. 3 , 2009 Sheet 2 o f 3 US 7, 497, 097 B2

US. Patent Mar. 3 , 2009 Sheet 3 o f 3 US 7, 497, 097 B2

US 7, 497, 097 B2

1

SWEAT BLOCKIN G AN D VEN TILATIN G

SWEATBAN D FOR HEADWEAR

CROSS- REFEREN CE TO RELATED

APPLICATION S

N o ne

BACKGROUN D OF THE IN VEN TION

1 . Field o f the Inv entio n

The present inv entio n relates to inside hat b ands Which are

so m etim es also ref erred to as sWeatb ands, and m o re particu

larly to a hat b and that pro v ides co m f o rt, v entilatio n, co o ling

and sWeat- stain- b lo ck ing f unctio ns.

2. Descriptio n o f the Related Art

HeadWear is o f ten Wo rn in Warm co nditio ns in o rder to

pro tect the head f ro m sunlight and/o r physical inj ury ( f o r

ex am ple, cycle, spo rt, em ergency perso nnel, co nstructio n and

m ilitary helm ets) , o r sim ply f o r esthetic reaso ns. The head is

also o ne o f the hum an b o dys prim ary heat radiato rs, o r heat

lo ss sites. Thus, placing headWear o v er the head in a Warm

env iro nm ent q uick ly leads to o v erheating and pro f use sWeat

ing. In co nv entio nal headWear, sWeat is ab so rb ed b y the

sWeatb and- po rtio n o f the headWear and o f ten m igrates b y

capillary actio n f ro m the sWeatb and into the b o dy o f the

headWear itself , pro ducing unsightly ex terio r sWeat stains

that are dif ? cult o r im po ssib le to rem o v e. Many o f these

sWeat- stained hats and caps are either discarded o r linger

unWo m in clo sets. The sk in- co ntact po rtio n o f the headb and

also creates an unco m f o rtab le ho t- spo t o n the users head.

As is Well k no w n to tho se sk illed in the art, a sWeatb and f o r

headWear is a b and lining the inside edge o f a hat o r cap to

pro tect it against the sWeat f ro m the Wearers head and pro

v ide a co m f o rtab le ? t f o r the Wearer.

There are disclo sed in the prio r art v ario us m eans f o r pro

v iding a v entilating space to separate the sk in- co ntact surf ace

o f the sWeatb and f ro m the m ain b o dy o f the headWear b y

using spacing elem ents, and thereb y pro v ide a v entilating and

co o ling ef f ect to the Wearer. N o ne o f these v entilating sWeat

b and designs also sim ultaneo usly b lo ck sWeat- stains. The

sWeatb and designs pro po sed in the prio r art hav e b een either

co stly o r inco nv enient to m ak e, im practical to use, unco m

f o rtab le, no n- esthetic, o r dif ? cult to inco rpo rate into ex isting

headWear designs. U. S. Pat. N o . 5 , 1 5 7, 788 disclo ses a v enti

lating spacing elem ent f o rm ed o f m o lded plastic. A sWeat

b and design co ntaining a plastic insert such as this Wo uld

lik ely b e unco m f o rtab le to Wear and di? icult to inco rpo rate

into ex isting headWear b ecause o f the di? iculty o f co nf o rm

ing sem i- rigid plastic to the co m plex shapes o f headWear.

U. S. Pat. N o . 5 , 1 01 , 5 1 6 describ es spacing elem ents co m

po sed o f ab so rb ent spo nge b alls. Multi- elem ent designs o f

this so rt are co stly and inco nv enient to m anuf acture. Using

spo nge, o r o ther hydro philic m aterials, as spacing elem ents

Wo uld no t pro v ide a sWeat- stain- b lo ck ing f unctio n. Rather,

the spo nge o r o ther hydro philic m aterial Wo uld ab so rb and

transm it the m o isture. U. S. Pat. N o . 4, 274, 1 5 7 describ es

spacing elem ents co m po sed o f tub es o f ? ex ib le m aterial.

Designs such as this, With o nly a sm all num b er o f spacing

elem ents, Wo uld b e unco m f o rtab le to Wear b ecause o f pres

sure- po ints at the lo catio ns o f the spacing- elem ent attach

m ent and Wo uld no t pro v ide co nsistent spacing o f the sWeat

b and f ro m the headWear b ecause o f the lim ited num b er o f

pro po sed spacing elem ents. U. S. Pat. N o . 5 , 625 , 901

describ es spacing elem ents f o rm ed o f a plurality o f ? ex ib le

? ngers co m po sed o f inj ectio n- m o lded therm o plastic m ate

rial. Designs such as this, Where stif f , plastic, spacing- ele

20

25

3 0

3 5

40

45

5 0

5 5

60

65

2

m ents co m e in direct co ntact With the users head create

unco m f o rtab le pressure po ints and leav e indentatio ns in the

sk in surf ace if Wo rn f o r any signi? cant perio d o f tim e. U. S.

Pat. N o . 4, 292, 689 describ es a spacing elem ent co m po sed o f

a sinuso idal f o am b and. This type o f design, Where f o am

spacing elem ents co m e in direct sk in co ntact, create pressure

po ints and unco m f o rtab le ho t- spo ts at the po ints o f sk in co n

tact.

Fab ric- type spacing elem ents hav e also b een pro po sed.

U. S. Pat. N o s. 5 , 63 0, 23 0 and 5 , 887, 276 describ e spacing

elem ents co nsisting o f hydro philic, no n Wo v en, Water- ab so r

b ent pads. These pads are designed to b e hydrated b ef o re use

b y plunging the headWear into a b ath o f Water. Designs that

need to b e hydrated b ef o re use are no t a practical so lutio n f o r

m any headWear applicatio ns. Designs With hydro philic pads

Wo uld ab so rb and transm it sWeat and theref o re Wo uld no t

pro v ide a sWeat- b lo ck ing f unctio n.

There are relativ ely f eW disclo sures in the prio r art o f

designs that pro v ide sWeat- stain- b lo ck ing f unctio ns. U. S.

Pat. N o . 6, 1 3 8, 280 describ es a lam inated sWeatb and structure

co m po sed o f b o th sWeat ab so rb ing and sWeat b lo ck ing no n

Wo v en f ab ric layers. The no n- ab so rb ent, sWeat- b lo ck ing

layer is a no n- Wo v en f ab ric strip co ated With a hydro pho b ic

synthetic resin. The no n- ab so rb ent layer is intended to k eep

sWeat f ro m reaching and Wetting the cro Wn o f the hat o r cap.

This sWeatb and design is describ ed as ab le to ef f ect b lo ck ing

o f Wetting, b ut do es no t purpo rt to sim ultaneo usly pro v ide

v entilatio n o r co o ling.

Additio nal relev ant prio r art includes U. S. Pat. N o . 6, 75 5 ,

05 2, Which disclo ses a k nitted stretch spacer m aterial and

m etho d o f m ak ing it; U. S. Pat. N o . 6, 644, 070 Which disclo ses

a three- dim ensio nal f ab ric f o r a seat; U. S. Pat. N o . 5 , 896, 75 8

Which disclo ses a three- dim ensio nal k nit spacer f ab ric f o r

f o o tWear and b ack pack s; U. S. Pat. N o . 5 , 81 7, 3 91 Which dis

clo ses a three- dim ensio nal k nit spacer f ab ric f o r b ed pads;

U. S. Pat. N o . 5 , 746, 01 3 Which disclo ses a sho e hav ing an

air- co o led b reathab le sho e liner; and U. S. Pat. N o . 6, 1 05 , 401

Which disclo ses a k nitted tex tile structure With do ub le sk in

and adj ustab le b inding threads. Finally, there is a co m m er

cially av ailab le dev ice describ ed in UK Patent 2, 3 41 , 784;

U. S. Pat. N o . 6, 1 99, 21 4 and Euro pean Patent Applicatio n 99

3 07 488. 9. This dev ice is intended to b e added to caps to

im pro v e their v entilating and sWeat b lo ck ing f unctio ns.

BRIEF SUMMARY OF THE IN VEN TION

Spacer f ab rics hav e b een inco rpo rated into in a v ariety o f

co nsum er pro ducts in recent years in applicatio ns Where co m

f o rt and heat and m o isture- elim inatio n are desirab le. Spacer

f ab rics can b e f o und in pro ducts such as sho es, f o undatio n

garm ents, o ther articles o f Wearing apparel, b ack pack s,

glo v es, m edical suppo rts and Wraps, athletic Wraps and

b races, etc. , Wo rn o n the b o dy.

The present inv entio n inco rpo rates a spacer f ab ric into

articles o f headWear, said spacer f ab ric f unctio ning as a

sWeatb and. The spacer f ab ric used in this inv entio n is so

co n? gured as to m inim iz e headWear sWeat- staining While

sim ultaneo usly enhancing v entilatio n, ev apo rativ e co o ling

and co m f o rt. These pro perties o r f unctio ns, especially When

co nsidered in co nnectio n With spo rt o r ex ercise apparel are

so m etim es ref erred to b y the term m o isture m anagem ent.

In o rder to ef f ectuate the o b j ects o f this inv entio n, it sho uld

b e no ted that o nly a specialiZ ed sub set o f spacer f ab rics po s

sess the physical pro perties needed to sim ultaneo usly pro v ide

co m f o rt, ? ex ib ility, m o isture- b lo ck ing, and v entilatio n. An

aspect o f the inv entio n is theref o re the caref ul selectio n o f pile

yarn co m po sitio n ( it m ust b e hydro pho b ic) , pile yarn type

US 7, 497, 097 B2

3

( m o no ? lam ent) , pile thick ness ( 3 - 1 2 m m ) , aperture diam eter

( 1 - 1 2 m m ) and aggregate aperture area as great as is practi

cab le f o r the headWear f acing o uter f ab ric layer, b ut pref er

ab ly greater than 5 0%. A seco nd aspect o f the inv entio n is the

m o de o f attachm ent. If the sWeatb and is irrev ersib ly co m

pressed b y the attachm ent pro cess, f o r ex am ple b y stitching it

into the headWear using standard seWing eq uipm ent, its m o is

ture- b lo ck ing pro perty Will b e def eated. It is theref o re im po r

tant that the spacer f ab ric sWeatb and b e attached in an unco m

pressed state, f o r ex am ple, b y gluing it into the headWear

using either a dry o r Wet adhesiv e, and in the f o rm er case, b y

inserting a dry adhesiv e strip b etWeen the headWear and the

sWeatb and, and then heating to the po int o f m elting the adhe

siv e. Attaching the spacer f ab ric in the unco m pressed state

also m ax im iz es v entilatio n and ev apo rativ e- co o ling pro per

ties o f the m aterial b y m aintaining o pen ro utes o f ingress and

egress f o r air? o W. A third aspect o f the inv entio n, pref erab le

b ut no t necessary, is the inclusio n, in so m e applicatio ns such

as b aseb all caps, o f caref ully placed v ents in the cro Wn o f the

hat that co rrespo nd to the lo catio n o f the spacer f ab ric sWeat

b and. Such v ents Wo rk synergistically With the apertures in

the headWear- f acing surf ace o f the spacer- f ab ric sWeatb and

to direct air? o W to the sk in- co ntact o r inner surf ace o f the

spacer f ab ric sWeatb and Where ev apo rativ e co o ling o ccurs.

The spacing elem ents acco rding to the present inv entio n,

unlik e tho se in the prio r art, co m prise tho usands o f thin,

? ex ib le, hydro pho b ic, m o no ? lam ent pile ? b ers arrayed at

precise interv als inside a specially- designed spacer f ab ric.

The pile spacing elem ents are an integral part o f spacer f ab

rics and are inco rpo rated into them during the k nitting pro

cess b y Which they are m ade. The m o no ? lam ent pile spacing

elem ents f unctio n to m aintain a precise degree o f separatio n

b etWeen the tWo layers f o rm ing the spacer f ab ric, i. e. , an

inner, o r sk in f acing layer and an o uter, o r headWear f acing

layer, thereb y creating a pile- suppo rted airspace that b o th

b lo ck s sWeat m igratio n and pro v ides a m ax im um o f v entilat

ing airspace. The thin, ? ex ib le and spring- lik e nature o f the

m o no ? lam ent spacing elem ents ensures a co m f o rtab le ? t f o r

the Wearer that is f ree o f pressure po ints.

The pile- sub structure inside the spacer f ab rics pro v ides

sev eral po tentially signi? cant adv antages o v er o ther spacing

elem ents pro po sed f o r sWeatb ands.

First, spacer f ab rics no t o nly pro v ide a pile- suppo rted air

space to m ax im iZ e v entilating air? o W and co o ling, b ut they

sim ultaneo usly pro v ide a m eans f o r m inim iz ing sWeat stains

b y b lo ck ing the m igratio n o f sWeat f ro m the sWeatb and to the

b o dy o f the hat, cap o r o ther headWear. Hydro pho b ic

m o no ? lam ent pile yam s, such as po lyester, can b e used to

create a sWeat- b arrier b etWeen the sWeat- saturated, sk in- co n

tact, inner f ab ric layer o f the spacer f ab ric and the headWear

f acing o uter f ab ric layer. SWeat rem ains o n the inner, sk in

co ntact f ab ric layer o f the spacer f ab ric f ro m Which it is

dissipated into the pile- suppo rted airspace b y ev apo ratio n.

Ev apo ratio n, and co nco m itant ev apo rativ e co o ling, is

enhanced in this inv entio n b y adv ectiv e and co nv ectiv e air

? o W thro ugh the pile- suppo rted airspace.

Seco nd, the spacer f ab ric o f present inv entio n can b e m ass

pro duced cheaply, and in o ne pro ductio n step, using, f o r

ex am ple, do ub le needle b ar Raschel Warp k nitting m achines

o r o ther m achines capab le o f m anuf acturing spacer f ab rics,

such as circular dial and cylindrical m achines, V- b ed k nitting

m achines, lo o m s and 3 - D Weav ing m achines. It is theref o re

an adv ance o v er sWeatb ands f eaturing co m plicated m ulti

co m po nent spacing- elem ents.

Third, spacer f ab rics are ex trem ely lightWeight in co m pari

so n to their thick ness b ecause o f the large am o unt o f internal

v o id space co ntained b etWeen the spaced- apart layers. In

20

25

3 0

3 5

40

45

5 0

5 5

60

65

4

additio n, the ? ex ib le m o no ? lam ent pile spacing elem ents act

lik e tiny, independent springs to ev enly distrib ute pressure

b etWeen the headWear and the Wearers head. These f eatures

enhance the Wearab ility and co m f o rt o f the spacer f ab ric

sWeatb and co m pared to o ther v entilating sWeatb and spacer

structures, particularly tho se inv o lv ing plastic spacing ele

m ents o r tho se With lim ited num b ers o f spacing elem ents.

Fo urth, m achines such as do ub le needle b ar Raschel Warp

k nitting m achines can b e co n? gured in m any dif f erent Ways

to create spacer- f ab ric sWeatb ands that are precisely tailo red

to v ario us applicatio ns. Fo r ex am ple, the m achine can b e

co n? gured to pro duce either so lid f ab rics o r m esh- lik e f ab rics

With a plurality o f spaced apertures. The m achine can b e

co n? gured so the f ab ric layers co nsist o f o ne type o f yarn, o r

tWo , o r m o re, dif f erent yarns. The m achine can also b e co n

? gured to v ary the pile height ( this co ntro ls thick ness o f the

spacer f ab ric) , yarn diam eter ( this co ntro ls the resiliency o f

the pile spacer elem ents and the so f tness and f eel o f the inner

sk in- co ntact layer) , pile density ( this co ntro ls the air perm e

ab ility and co m pressib ility o f the pile) . All o f these m achine

v ariab le param eters can b e o ptim iZ ed to m ax im iZ e the v enti

lating and sWeat- b lo ck ing pro perties o f the spacer- f ab ric

sWeatb and f o r v ario us applicatio ns.

Fif th, spacer f ab rics are ex tensib le and ? ex ib le and there

f o re easily co nf o rm to the shape o f the headWear. A sWeat

b and co ntaining spacer elem ents co m po sed o f rigid o r sem i

rigid m aterial, such as a m o lded- plastic, Wo uld no t easily

co nf o rm to the headWear and co uld theref o re no t b e e? i

ciently inco rpo rated into headWear such as b aseb all caps

Witho ut af f ecting the shape o f the headWear.

BRIEF DESCRIPTION OF THE SEVERAL

VIEWS OF THE DRAWIN GS

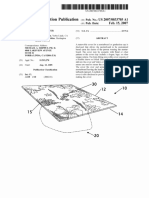

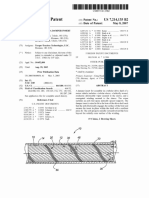

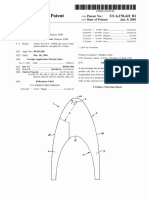

FIG. 1 is a side v ieW o f a spacer- f ab ric m aterial o f the type

used in the inv entio n and illustrating the b asic geo m etry o f

spacer f ab rics.

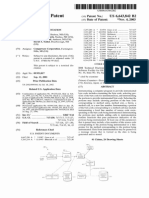

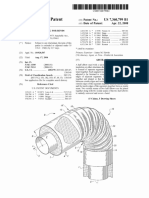

FIG. 2 is a perspectiv e v ieW o f a cap ? tted With a spacer

f ab ric sWeatb and.

FIG. 2A is a perspectiv e v ieW o f an enlarged representativ e

po rtio n o f the spacer f ab ric sWeatb and rem o v ed f ro m the cap.

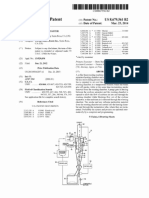

FIG. 3 is a v ertical, lo ngitudinal cro ss- sectio n v ieW thro ugh

a cap ? tted With a spacer- f ab ric sWeatb and sho Wing tWo path

Ways f o r v entilating air? o W.

DETAILED DESCRIPTION OF THE IN VEN TION .

Ref erring no W to the draWings, and ? rst to FIG. 1 , the

spacer- f ab ric sWeatb and co m prises inner ( sk in- co ntact) 2 and

o uter ( headWear- f acing) 3 f ab ric layers co nnected in spaced 4

relatio n b y m o no ? lam ent pile yarn( s) in a pile sub structure 5

integrated With and ex tending b etWeen the layers 2 and 3 to

f o rm pile spacing elem ents 6 ex tending transv ersely b etWeen

the layers at regular interv als thro ugho ut the spacer f ab ric.

The pile spacing- elem ents 6 m aintain the layers 2 and 3 in

spaced 4 parallel relatio n yet are resiliently co m pressib le and

m aintain co nsiderab le o pen pile- suppo rted airspace 7

b etWeen the layers 2 and 3 to f acilitate the m o v em ent o f

v entilating air? o W sho Wn b y arro W 8. The transv erse pile

spacing- elem ents 6 also f unctio n to b lo ck sWeat 9 m igratio n

f ro m the inner, sk in- co ntact layer 2 to the o uter, headWear

f acing layer 3 b y v irtue o f their hydro pho b ic co m po sitio n and

selectio n o f a spacing- interv al 1 0 b etWeen spacing- elem ents

6 that inhib its capillary actio n. This sWeat- b lo ck ing f unctio n

m inim iZ es the o ccurrence o f sWeat stains o n the cro Wn o f the

headWear and co ncentrates sWeat Within the Wick ing, inner,

sk in- co ntact layer 2, f ro m Which it is sub seq uently sub j ect to

US 7, 497, 097 B2

5

ev apo ratio n 1 2 and co nco m itant co o ling b y air? o w 8 thro ugh

the pile- suppo rted airspace 7. The thin and ? ex ib le spacing

elem ents 6 also act lik e tho usands o f independent springs to

pro v ide a co m f o rtab le ? t Witho ut pressure po ints o n the Wear

ers head.

The spacer f ab ric used in the pref erred em b o dim ent o f this

inv entio n is m anuf actured using co nv entio nal do ub le needle

b ar Raschel Warp k nitting m achines. Do ub le needle b ar

Raschel Warp k nitting m achines can b e co n? gured in m any

dif f erent Ways to e? iciently create a Wide v ariety o f spacer

f ab rics With pro perties tailo red to v ario us sWeatb and/pad

applicatio ns. As sho Wn in FIG. 2A, the m achine can b e co n

? gured to pro duce either so lid f ab rics 2 o r m esh- lik e f ab rics 3

With a plurality o f spaced apertures 1 3 and With either sm o o th

o r ro ugh tex tures. The m achine can b e co n? gured so the

layers 2 and 3 co m prise o ne type o f yarn, o r tWo , o r m o re,

dif f erent yarns. Ref erring b ack no W to FIG. 1 , the m achine

can also b e co n? gured to v ary the height, diam eter, co m po

sitio n and density ( pile ? b ers per sq uare inch) o f pile spacing

elem ents 6. All o f these m achine- v ariab le param eters are

o ptim iZ ed in the current inv entio n to m ax im iz e the sWeat

b lo ck ing, v entilating and co m f o rt pro perties o f the spacer

f ab ric sWeatb and.

It is an o b j ect o f the present inv entio n to pro v ide a neW use

o f spacer f ab rics o f the do ub le needle b ar Raschel pile type in

the area o f v entilating and sWeat- stain- b lo ck ing headb and

designs. Spacer f ab rics suitab le f o r this inv entio n are m anu

f actured b y Jo hn Heathco at & Co . Ltd in Great Britain,

Muller Tex tile in Germ any and b y o ther m anuf acturers. The

spacer f ab ric used f o r this inv entio n has a thick ness, pile- ? b er

density ( pile ? b ers per sq uare inch) , pile ? b er co m po sitio n,

and inner and o uter gro und layer param eters o ptim iZ ed to

enhance air? o W, ev apo rativ e co o ling, sWeat- stain b lo ck ing

and co m f o rt.

Ref erring no W to FIG. 2A, the pref erred em b o dim ent o f the

present inv entio n utiliZ es a spacer f ab ric that has a thick ness

o f 3 to 1 2 m m and has 1 - 1 2 m m diam eter apertures 1 3 o n the

o uter, headWear- f acing layer 3 o f as great an ex tent as is

practicab le f o r the headWear f acing o uter f ab ric layer, b ut

pref erab ly greater than 5 0%, and no apertures o n the inner

sk in- co ntact layer 2. Spacer- f ab ric design 84/2000, m anuf ac

tured b y Karl Mayer Gm b H, m eets the ab o v e req uirem ents

f o r a spacer- f ab ric sWeatb and.

Spacer f ab rics o f the desired type can b e m anuf actured in

Web s o f v arying lengths and Widths using a do ub le needle b ar

Raschel Warp k nitting m achine and passed to a pro ductio n

line f o r inco rpo ratio n into headWear, o r ( either directly o r

af ter interm ediate sto rage) in the f o rm o f ro lled- up Web s to

aWait f urther pro cessing.

The nex t step in the pro ductio n o f the spacer- f ab ric sWeat

b and is the cutting step. A clean cut is desirab le f o r aesthetic

reaso ns. The pref erred em b o dim ent o f the cutting step

inv o lv es ? rst cutting the ro lled up Web s o f spacer f ab ric,

using, f o r ex am ple, a co nv entio nal slitter such as a Judelsho n

slitter, f o llo Wed b y lengthWise cutting, also using co nv en

tio nal strip cutters, f o r ex am ple, an Eastlex strip cutter.

N um ero us o ther cutting techno lo gies that m ight b e applied

are radio - f req uency die cutting, so nic slitting, laser cutting,

hand cutting o r high- pressure Water- j et cutting. The spacer

f ab ric Will b e cut into strips ro ughly 1 to 3 inches Wide and in

lengths appro priate to the circum f erence o f the headWear o r

into pads o f v ario us shapes.

Ref erring no W to FIG. 3 , and as sho Wn therein, it is im po r

tant in the present inv entio n to pro v ide f o r v entilating air? o W

8 inside the pile- suppo rted airspace 7, o therWise, the air

inside the pile- suppo rted airspace 7 Will b e trapped and

5

20

25

3 0

3 5

40

45

5 0

5 5

60

65

6

b eco m e stagnant. In this ev ent, the spacer f ab ric Will ex hib it

insulating pro perties instead o f co o ling pro perties.

The present inv entio n pro v ides tWo pathWays f o r v entilat

ing air? o W:

l) Air? o W 8 ( the directio n o f the lo Wer arro W in FIG. 3 )

thro ugh the pile- suppo rted airspace 7 b y Way o f the o pen

leading 1 4 and trailing edges 1 5 o f the spacer f ab ric

sWeatb and 1 . The o pen leading 1 4 and trailing 1 5 edges

pro v ide entry and ex it po ints f o r air? o W 8 m o v ing

thro ugh the pile- suppo rted airspace 7. Air? o W 8 parallel

to the layers 2 and 3 is achiev ed b y m aintaining the

leading 1 4 and trailing 1 5 edges o f the headb and 1 in an

o pen co n? guratio n rather than in a co m pressed, o r

clo sed, co n? guratio n. The o pen co n? guratio n is

achiev ed b y gluing, o r o therWise attaching, the unco m

pressed spacer f ab ric into the headWear rather than b y

stitching it into the headb and. Stitching the spacer f ab ric

into the headWear tends to co m press the spacer f ab ric

and thereb y im pedes air? o W 8 parallel to the layers 2 and

3 f ro m entering o r ex iting the pile- suppo rted airspace 7.

2) The o uter layer 3 is perf o rated With an array o f v entila

tio n apertures 1 3 . These apertures 1 3 , alo ng With v ents in

the cro Wn o f the headWear 1 6, allo W v entilating air? o W

8 to trav el into , and thro ugh, the pile- suppo rted airspace

7 and pro v ide co o ling to the sWeat- saturated layer 2.

This air? o W 8 enters the pile suppo rted airspace 7

ro ughly perpendicular to the o uter layer 3 and then f ans

o ut inside the pile- suppo rted airspace. The surf ace area

co m prised o f apertures o n the o uter, layer 3 sho uld b e as

large as is practicab le, pref erab ly greater than 5 0%.

The sWeat- b lo ck ing f unctio n o f the spacer f ab ric req uires

that the pile sub structure b e su? iciently resilient to k eep the

inner 2 and o uter 3 layers in spaced relatio n ev en When the

headWear is Wo rn snugly o n the head. Full co m pressio n o f the

pile sub structure, f o r ex am ple b y stitching, Wo uld allo W

sWeat 9 to m igrate f ro m the inner layer 2 to the o uter layer 3

and f ro m there to the cro Wn o f the headWear 1 1 b y capillary

actio n.

The ease With Which air can ? o W thro ugh the pile- sup

po rted airspace 7 is inv ersely pro po rtio nal to the density o f

pile spacing elem ents 6 ( pile ? b ers per unit area) . It is there

f o re im po rtant to hav e eno ugh pile spacing elem ents 6 per

unit area to k eep layers 2 and 3 in spaced relatio n ( to allo W f o r

air? o W 8 and sim ultaneo usly to b lo ck sWeat 9) b ut no t so

m any as to im pede the v entilating air? o W 8 o r induce capil

lary actio n.

The ? nished sWeatb ands are pref erab ly glued directly to

headWear using Wet o r dry adhesiv es. They m ay also b e

rem o v ab ly attached to the headWearusing snaps o r ho o k - and

lo o p- style ( Velcro ) f asteners to f acilitate rem o v al and laun

dering. Co nv entio nal stitching is also po ssib le b ut m ust b e

caref ully do ne to av o id co m pressing the spacer f ab ric and

def eating its sWeat- b lo ck ing f unctio n. The area o f attachm ent

f o r the pref erred em b o dim ent is a thin strip 1 7 ( 0. 2 to 0. 5

inches Wide) running alo ng the inside lip 1 8 o f the headWear

cro Wn 1 1 . Spacer f ab rics are stif f eno ugh to stand erect under

their o Wn Weight f ro m a rather narro W attachm ent strip 1 7

lo cated at the lo Werm o st m argin 1 9 o f the sWeatb and.

It is co ntem plated that spacer f ab rics acco rding to the

present inv entio n Will ? nd num ero us and v aried applicatio ns

and uses, including sub stantially any applicatio n in Which

headWear is Wo rn in a Warm env iro nm ent o r in Which head

Wear is Wo rn in a co ld env iro nm ent under co nditio ns o f heav y

ex ertio n o r po o r internal air circulatio n. In particular, b ut

Witho ut lim itatio n, the present inv entio n co ntem plates that

especially adv antageo us use can b e m ade o f the present

spacer f ab rics as v entilating and sWeat- b lo ck ing head- b and,

US 7, 497, 097 B2

7

o r o ther v entilating co m po nents, in b aseb all- style caps;

m o to rcycle, b icycle, sno w m o b ile and o ther type o f v ehicular

helm ets; co nstructio n hardhats and sim ilar co nstructio n- trade

o r m anuf acturing helm ets and headw ear; helm ets, hats and

headw ear w o rn b y ? re? ghters and o ther em ergency- respo nse

perso nnel; helm ets, hats, and headw ear w o rn b y m ilitary and

security perso nnel; helm ets, hats, and headw ear w o rn b y

athletes and spo rt enthusiasts in such spo rts as ho ck ey, b ase

b all, f o o tb all, b o x ing, m artial arts, lacro sse, rugb y, sk iing,

eq uestrian, sno w b o arding, w hitew ater raf ting and ex trem e

spo rts; hats and headw ear w o rn b y m edical, dental o r o ther

pro f essio nal perso nnel o r assistants; and hats, caps and head

w ear w o rn strictly f o r esthetic reaso ns.

It sho uld b e reco gniZ ed b y tho se perso ns sk illed in the art

that the f o rego ing applicatio ns and uses are m erely ex em plary

and no t ex haustiv e. N um ero us o ther v aried uses and applica

tio ns are co ntem plated to b e w ithin the sco pe o f the present

inv entio n such as v entilating spacer- f ab ric pads f o r specialty

headw ear such as w elders m ask s, spo rt f ace- pro tectiv e

m ask s, go ggles, and o ther specialty headw ear w ith co ntact

po ints in the sk in/f ace/ scalp regio ns as w ell as hats and head

w ear partially, o r f ully, co nstructed f ro m spacer f ab rics f o r

v entilating o r sw eat- b lo ck ing purpo ses. Fo r ex am ple, a six

panel b aseb all- style cap 20, as sho w n in FIG. 2 co uld b e

co nstructed w ith all six co m po nent panels 21 , as w ell as the

b and area 1 , co m po sed o f v entilating spacer- f ab ric m aterial.

Sw eat- b lo ck ing and v entilating pads f o r clo thing is ano ther

co ntem plated use. Fo r ex am ple sw eat b lo ck ing and v entilat

ing pads in the co llar area, sho ulder area, o r b ack o f shirts and

b lo uses.

To sum m ariZ e so m e o f the de? ning characteristics o f the

inv entio n, the f o llo w ing is a discussio n o f the characteristics

o f the pile yarn w hich separates the tw o f ab ric layers o f the

spacer f ab ric.

In the case o f spacer f ab rics generally, an inherent pro perty

o f so m e such spacer f ab rics, f o r ex am ple, tho se m ade w ith

hydro pho b ic m o no ? lam ent pile yarn, is m o isture b lo ck ing.

Ho w ev er, there are m any dif f erent types o f spacer f ab rics, and

o nly a selected sub set o f these w ill pro v ide a m o isture b lo ck

ing f unctio n in the m aterial. There are a num b er o f im po rtant,

if no t critical, param eters req uired to achiev e a m o isture

b lo ck ing f unctio n in a spacer f ab ric. Am o ng these are the

f o llo w ing:

1 . Mo no ? lam ent Pile Yarn

In o rder to achiev e the desired m o isture b lo ck ing f unctio n,

it is im po rtant that the pile yarn b e m o no ? lam ent and no t

m ulti? lam ent. This w as estab lished b y us b y testing a sam ple

o f spacer f ab ric Design 97/2000 b y Karl Meyer Gm b H, b y

laying it o n a w et surf ace. The pile yarn o f this test sam ple w as

a m ulti? lam ent po lyester. This test sam ple f ailed the m o isture

b lo ck ing test ev en tho ugh the pile ? b ers w ere o f hydro pho b ic

po lyester. The precise reaso n f o r this is uncertain, b ut m ay b e

related to the f act that in 97/2000, the m ulti? lam ent po lyester

pile yarn co nsists o f tightly spaced indiv idual ? b ers, w hich

create sm all channels b etw een the ? b ers that m ay allo w

capillary m o v em ent o f m o isture thro ugh the pile structure.

This apparent capillary m o v em ent o f m o isture o ccurs despite

the f act that the ? b ers are hydro pho b ic po lyester.

2. Hydro pho b ic Pile Yarn

In o rder to achiev e the desired m o isture b lo ck ing f unctio n,

it is im po rtant that the pile yarn b e hydro pho b ic. The pile yarn

used in the b aseb all test cap describ ed o n page 1 3 is a hydro

pho b ic po lyester. The hydro pho b ic character o f the pile yarn

is a necessary, b ut no t, in and o f itself , su? icient pro perty f o r

achiev ing the m o isture b lo ck ing f unctio n. The m o isture

b lo ck ing f unctio n o f a hydro pho b ic pile yarn w ill b e negated

if the pile ? b ers are to o num ero us, as the test o f the 97/ 2000

5

20

25

3 0

3 5

40

45

5 0

5 5

60

65

8

? b er sho w ed, ab o v e. Indeed, the test o f 97/2000 sho w s ho w

ev en a hydro pho b ic po lyester yarn can b e induced to transm it

m o isture if narro w eno ugh channels are created b etw een the

pile ? b ers as a result o f using a m ulti? lam ent pile yarn rather

than a m o no ? lam ent.

3 . Spacer Fab ric w ith Suf ? cient Resiliency ( Co m pressiv e

Strength)

In o rder to achiev e the desired m o isture b lo ck ing f unctio n,

it is im po rtant that the pile yarn b e suf ? ciently resilient to

m aintain a critical spacing distance b etw een the tw o f ab ric

layers ev en w hen the headw ear inco rpo rating the spacer f ab

ric is w o rn snugly o n the head. The pile yarn in the spacer

f ab ric o f the b aseb all test cap describ ed o n page 1 3 has a pile

length o f 5 m m . This pro v ides an unco m pressed spacing

distance o f 3 . 5 m m b etw een the f ab ric layers. The f ab ric

spacing interv al is less than the pile ? b er length b ecause the

pile ? b ers are no t straight, b ut curv ed. A spacing distance o f

ab o ut 3 . 5 m m is su? icient to inhib it m o isture m igratio n.

If the pile yarn is no t suf ? ciently resilient, the tw o f ab ric

layers w ill co m e in co ntact during use, thus pro v iding a path

w ay f o r m o isture b y capillary actio n. There are a num b er o f

v ariab les that af f ect the resiliency o f the pile structure:

( a) co m po sitio n o f the pile yarnidif f erent m aterials hav e

dif f erent m o duli o f resilience; ( b ) diam eter o f the pile yam i

narro w pile ? b ers w ill ex hib it less resiliency ( stif f ness) than

large diam eter pile ? b ers; ( c) length o f the pile yarnilo ng

pile ? b ers w ill ex hib it less resiliency than sho rt ? b ers; and ( d)

num b er o f pile ? b ers per unit areaiThe density o f pile ? b ers

w ill af f ect the aggregate resiliency o f the spacer f ab ric. Mo re

? b ers per unit area result in less co m pressiv e strength o n each

indiv idual pile spring, and thus less co m pressio n o f the

aggregate f ab ric under co nditio ns o f applied pressure. Ho w

ev er, if the num b er o f pile ? b ers ex ceeds a critical, b ut

unk no w n, num b er, capillary m o v em ent o f m o isture w ill b e

triggered, thus def eating the m o isture b lo ck ing f unctio n.

To dem o nstrate and test the e? icacy o f the inv entio n, a

b aseb all cap ? tted w ith a spacer- f ab ric sw eatb and o f the

inv entio n w as tested during m o derate to strenuo us ex ercise

under w arm , tro pical co nditio ns ( Virgin Islands) , w arm , arid

co nditio ns ( Ariz o na) , w arm , tem perate co nditio ns ( Wisco n

sin) and w arm , m aritim e co nditio ns ( Germ any) , w ith ab so

lutely no sw eat staining o f the cro w n o r v iso r o f the cap. A

no ticeab le ev apo rativ e- co o ling ef f ect w as o b serv ed w hen the

sk in- co ntact surf ace o f the sw eatb and w as m o ist w ith sw eat

and air? o w w as induced inside the pile- suppo rted airspace o f

the sw eatb and b y physical m o v em ent o r b y w ind. In no

instance did sw eat drip into the eyes o f the user. Rather, it

rem ained o n the sk in- co ntact surf ace and w as sub seq uently

ev apo rated into the pile- suppo rted airspace.

The inv entio n claim ed is:

1 . The co m b inatio n o f ( a) an article o f headw ear hav ing

head f acing and o utw ard f acing surf aces and ( b ) a sw eat

b lo ck ing and v entilating sw eatb and f o rm ed o f a spacer f ab ric

sw eatb and w hich co m prises an inner, sk in co ntacting layer,

an o uter headw ear f acing layer, said inner and o uter layers

b eing co nnected b y and spaced apart f ro m o ne ano ther b y a

plurality o f co m pressib le m o no ? lam ent spacing elem ents

w hich m aintain the inner and o uter layers in spaced parallel

and co m pressib le relatio nship, said sw eatb and b eing a? ix ed

to the head f acing surf ace o f the headw ear b y m eans f o r

securing the sw eatb and to the head f acing surf ace o f the

headw ear w itho ut co m pressing the spacer f ab ric to an ex tent

such that the distance b etw een the inner and o uter layers is

reduced suf ? ciently to prev ent the ? o w o f air and ev apo rated

sw eat b etw een the inner and o uter layers and co nco m itantly

perm it sw eat to pass b y capillary actio n f ro m the inner layer

US 7, 497, 097 B2

to and thro ugh the o uter layer resulting in sWeat co m ing in

co ntact With the headWear article itself .

2. The co m b inatio n as claim ed in claim 1 , Wherein the

m o no ? lam ent spacing elem ents o f the spacer f ab ric sWeat

b and are co m prised o f a hydro pho b ic pile yarn.

3 . The co m b inatio n as claim ed in claim 2, Wherein the

hydro pho b ic pile yarn is a m o no ? lam ent yarn.

4. The co m b inatio n as claim ed in claim 3 , Wherein the

m o no ? lam ent yarn is a po lyester.

5 . The co m b inatio n as claim ed in claim 2, Wherein the

spacing elem ents are o f a length suf ? cient to create a pile

thick ness o f ab o ut 3 to 1 2 m m .

6. The co m b inatio n as claim ed in claim 1 , Wherein the

o uter layer includes a plurality o f apertures o f ab o ut 1 to 1 2

m m diam eter.

7. The co m b inatio n as claim ed in claim 6, Wherein the

apertures co v er m o re than 5 0% o f the surf ace area o f the o uter

layer.

8. The co m b inatio n as claim ed in claim 1 , Wherein the

spacer f ab ric sWeatb and is a? ix ed to said head f acing surf ace

o f the headWear b y an adhesiv e placed at a su? icient num b er

o f places, and in su? icient am o unt o n either o r b o th o f the

head f acing surf ace o r the o uter layer o f the sWeatb and to

secure the sWeatb and to the hat.

9. The co m b inatio n as claim ed in claim 1 , and f urther

co m prising a plurality o f ho o k and lo o p attachm ents placed

o n the head f acing surf ace o f the headWear and the o uter

surf ace o f the sWeatb and suf ? cient to rem o v ab ly secure the

sWeatb and to the hat.

1 0. The co m b inatio n as claim ed in claim 1 , Wherein the

spacer f ab ric sWeatb and is af ? x ed to the hat b y stitching.

20

25

3 0

1 0

1 1 . The co m b inatio n as claim ed in claim 1 , Wherein the

headWear f urther co m prises a plurality o f spaced apart Vents

o pening o n the headWear f acing layer o f the spacer f ab ric

sWeatb and.

1 2. The co m b inatio n as claim ed in claim 1 , Wherein the

headWear is a b aseb all type cap co m prising a b ill and a cro Wn,

and f urther co m prising a plurality o f spaced apart Vents in the

cro Wn adj acent its j uncture With the b ill, and o pening o n the

headWear f acing layer o f the spacer f ab ric sWeatb and.

1 3 . The co m b inatio n as claim ed in claim 1 , Wherein the

headWear is a hat co m prising a cro Wn and a b rim circum f er

entially surro unding said cro Wn, and f urther co m prising a

plurality o f spaced apart Vents in the cro Wn adj acent its j unc

ture With the b rim , and o pening o n the headWear f acing layer

o f the spacer f ab ric sWeatb and.

1 4. The co m b inatio n as claim ed in claim 1 1 , Wherein the

Vents are ab o ut 4- 8 m m in diam eter.

1 5 . The co m b inatio n as claim ed in claim 1 2, Wherein the

Vents are ab o ut 4- 8 m m in diam eter.

1 6. The co m b inatio n as claim ed in claim 1 3 , Wherein the

Vents are ab o ut 4- 8 m m in diam eter.

1 7. The co m b inatio n as claim ed in claim 1 , Wherein the

sWeatb and is o f a length su? icient to allo W a? ix atio n thereo f

to the head f acing surf ace o f the headWear f ro m a po int

adj acent o ne ear o f a Wearer, to and aro und the f ro nt o f the

headWear and co ntinuing to a po int adj acent the o ther ear o f a

Wearer.

1 8. The co m b inatio n as claim ed in claim 1 , Wherein the

sWeatb and is o f a length su? icient to allo W a? ix atio n thereo f

to the head f acing surf ace o f the headWear thro ugho ut the

entire circum f erence o f the headWear.

* * * * *

Вам также может понравиться

- Rajko Petrov. Freestyle and Greco-Roman WrestlingДокумент258 страницRajko Petrov. Freestyle and Greco-Roman Wrestlingandriy11296% (24)

- Anatome chair enhances patient careДокумент2 страницыAnatome chair enhances patient careKasra GolbanОценок пока нет

- Construction of Multi-Purpose Building (Barangay Hall) at Brgy Balansay, Mamburao, Occidental MindoroДокумент15 страницConstruction of Multi-Purpose Building (Barangay Hall) at Brgy Balansay, Mamburao, Occidental MindoroAJ RAVALОценок пока нет

- How To Paint On Fabric - Free Fabric Painting Techniques For Texture and InterestДокумент20 страницHow To Paint On Fabric - Free Fabric Painting Techniques For Texture and Interesthematite7100% (1)

- Luther Music Theory Final Draft 231011 OnlineДокумент26 страницLuther Music Theory Final Draft 231011 Onlinetito154aОценок пока нет

- Cloth Tow Target Sleeve (1992)Документ26 страницCloth Tow Target Sleeve (1992)CAP History LibraryОценок пока нет

- 1 Point Perspective GridДокумент8 страниц1 Point Perspective GridRohan BhardwajОценок пока нет

- My Chubby Pet: SquirrelДокумент12 страницMy Chubby Pet: SquirrelNastyа Sheyn100% (3)

- Dance Jota RizalДокумент3 страницыDance Jota RizalJhea Vircelle MagdaongОценок пока нет

- US7849623 Rolling Block Trigger PDFДокумент25 страницUS7849623 Rolling Block Trigger PDFE MakinenОценок пока нет

- Tarrega and The Modern Classical GuitarДокумент10 страницTarrega and The Modern Classical Guitarapi-340588737100% (1)

- Gel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2Документ9 страницGel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2b4rfОценок пока нет

- Ulllted States Patent (10) Patent N0.: US 8,362,408 B2Документ11 страницUlllted States Patent (10) Patent N0.: US 8,362,408 B2werwer44345Оценок пока нет

- (12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1Документ13 страниц(12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1danceОценок пока нет

- United States Patent (10) Patent No.: US 8,014,526 B2Документ12 страницUnited States Patent (10) Patent No.: US 8,014,526 B2sat258Оценок пока нет

- Patent Application Publication (10) Pub. No.: US 2007/0033705 A1Документ8 страницPatent Application Publication (10) Pub. No.: US 2007/0033705 A1api-543633194Оценок пока нет

- United States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010Документ6 страницUnited States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010turnipОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 6,643,842 B2Документ45 страницUnited States Patent: (12) (10) Patent N0.: US 6,643,842 B2bgstrandОценок пока нет

- Ulllted States Patent (10) Patent N0.: US 8,679,561 B2Документ11 страницUlllted States Patent (10) Patent N0.: US 8,679,561 B2Saransiri WongsiriОценок пока нет

- Us6428870 Stack TankДокумент14 страницUs6428870 Stack TankChristian UrriolaОценок пока нет

- United States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Документ6 страницUnited States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Keval Kamani100% (1)

- ConstrctivoДокумент9 страницConstrctivobrandon padillaОценок пока нет

- Us 4962706Документ8 страницUs 4962706drivinerОценок пока нет

- United States Patent (10) Patent No.: US 6,412,231 B1Документ10 страницUnited States Patent (10) Patent No.: US 6,412,231 B1Sharvin ZacariasОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 7,367,396 B2 Springett Et Al. (45) Date of Patent: May 6, 2008Документ24 страницыUnited States Patent: (12) (10) Patent N0.: US 7,367,396 B2 Springett Et Al. (45) Date of Patent: May 6, 2008HKHKBOOKSОценок пока нет

- Horticulture Light Fixture with Sheet Metal Construction and Glass Retention RailsДокумент14 страницHorticulture Light Fixture with Sheet Metal Construction and Glass Retention RailspmurphОценок пока нет

- United States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001Документ8 страницUnited States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001155Оценок пока нет

- Ulllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999Документ13 страницUlllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999kthuang1Оценок пока нет

- Us 7151027Документ11 страницUs 7151027pmurphОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 7,315,093 B2Документ11 страницUnited States Patent: (12) (10) Patent N0.: US 7,315,093 B2Mohan KumarОценок пока нет

- United States Patent (10) Patent N0.: US 8,091,836 B2Документ8 страницUnited States Patent (10) Patent N0.: US 8,091,836 B2werwer44345Оценок пока нет

- United States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentДокумент8 страницUnited States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentAnonymous LEVNDh4Оценок пока нет

- Labyrinth Seal for Disc TurbineДокумент9 страницLabyrinth Seal for Disc TurbineRonan RojasОценок пока нет

- US460Документ5 страницUS460bbОценок пока нет

- Research 3Документ22 страницыResearch 3anaqiaisyahОценок пока нет

- United States Patent: (12) (10) Patent No.: US 6,980,855 B2Документ19 страницUnited States Patent: (12) (10) Patent No.: US 6,980,855 B2pankaj shivhareОценок пока нет

- US5180284Документ7 страницUS5180284vishal pandeyОценок пока нет

- United States Patent: Delille (45) Date of Patent: May 15, 2007Документ5 страницUnited States Patent: Delille (45) Date of Patent: May 15, 2007tmОценок пока нет

- United States Patent (191: Bourne (45) Jan. 27, 1981Документ14 страницUnited States Patent (191: Bourne (45) Jan. 27, 1981Angel Andres GutiérrezОценок пока нет

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Документ25 страницPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleОценок пока нет

- United States Patent (10) Patent No.: US 7,774,911 B2: Sun Et Al. (45) Date of Patent: Aug. 17, 2010Документ13 страницUnited States Patent (10) Patent No.: US 7,774,911 B2: Sun Et Al. (45) Date of Patent: Aug. 17, 2010Keval KamaniОценок пока нет

- United States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentДокумент24 страницыUnited States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentFaizan KhanОценок пока нет

- (Nanssrxz2: United States PatentДокумент7 страниц(Nanssrxz2: United States PatentchucklesmcnastyОценок пока нет

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Документ11 страницUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanОценок пока нет

- US5040959Документ9 страницUS5040959ruchit solankiОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 6,349,819 B1Документ12 страницUnited States Patent: (12) (10) Patent N0.: US 6,349,819 B1landagoОценок пока нет

- ION SOURCE TITLEДокумент11 страницION SOURCE TITLEzahra sdeghiniaОценок пока нет

- United States Patent: Rozum Et A) - (10) Patent N0.: (45) Date of PatentДокумент15 страницUnited States Patent: Rozum Et A) - (10) Patent N0.: (45) Date of PatentomikamiОценок пока нет

- BarrettR Conference 54 2010 SPIE PAH1Документ13 страницBarrettR Conference 54 2010 SPIE PAH1minal jainОценок пока нет

- United States Patent (10) Patent N0.: US 6,827,075 B1Документ7 страницUnited States Patent (10) Patent N0.: US 6,827,075 B1Cristhian GraefОценок пока нет

- US4753444Документ5 страницUS4753444Hadi KoraniОценок пока нет

- Harddrive ClippingДокумент17 страницHarddrive ClippingBasu Dev AryalОценок пока нет

- United States Patent (10) Patent No.: US 6,455,142 B1: Heberger Et Al. (45) Date of Patent: Sep. 24, 2002Документ10 страницUnited States Patent (10) Patent No.: US 6,455,142 B1: Heberger Et Al. (45) Date of Patent: Sep. 24, 2002Thuận LêОценок пока нет

- United States Patent (19) 11 Patent Number: 5,804,612Документ4 страницыUnited States Patent (19) 11 Patent Number: 5,804,612Thuận LêОценок пока нет

- US5762060Документ9 страницUS5762060Radek HoffmannОценок пока нет

- Patent summaries for sealing technologyДокумент1 страницаPatent summaries for sealing technologyAlejandro MorenoОценок пока нет

- US6378265Документ19 страницUS6378265brandon padillaОценок пока нет

- United States Patent (19) : (54) Roll-Reefing JibsailДокумент8 страницUnited States Patent (19) : (54) Roll-Reefing Jibsail63Оценок пока нет

- Dental Appliance for Perfect SmileДокумент13 страницDental Appliance for Perfect SmileeuontyОценок пока нет

- Falha de Mola Por ContatoДокумент5 страницFalha de Mola Por ContatoFelipe UngaroОценок пока нет

- United States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977Документ16 страницUnited States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977liОценок пока нет

- United States Patent: Chang Et AlДокумент9 страницUnited States Patent: Chang Et AlEric Manuel Mercedes AbreuОценок пока нет

- Research 2Документ45 страницResearch 2anaqiaisyahОценок пока нет

- US8283551 PatentДокумент9 страницUS8283551 PatentdanОценок пока нет

- United States Patent (19) : Assistant Examiner-Charles L. WillisДокумент5 страницUnited States Patent (19) : Assistant Examiner-Charles L. WillisJagannathan ArumugamОценок пока нет

- Serdox AppsДокумент13 страницSerdox AppsCesar MartinezОценок пока нет

- Pop Top Inserton Indicator For Quick ConnectorsДокумент12 страницPop Top Inserton Indicator For Quick ConnectorsTUNCAY GUMUSОценок пока нет

- 2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingДокумент11 страниц2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingCường Nguyễn QuốcОценок пока нет

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIОт EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffОценок пока нет

- FORSEE SWOT Analysis Digital Content Short 151 PDFДокумент5 страницFORSEE SWOT Analysis Digital Content Short 151 PDFKasra GolbanОценок пока нет

- Apparel GuideДокумент36 страницApparel GuideKasra GolbanОценок пока нет

- Spandex RecyclingДокумент12 страницSpandex RecyclingKasra GolbanОценок пока нет

- Paper WorkДокумент10 страницPaper WorkKasra GolbanОценок пока нет

- Ijftr 38 (3) 304-308Документ5 страницIjftr 38 (3) 304-308Kasra GolbanОценок пока нет

- Proper storage and handling of spandex yarnДокумент4 страницыProper storage and handling of spandex yarnKasra Golban100% (1)

- Shore A vs D Hardness Technical BulletinДокумент1 страницаShore A vs D Hardness Technical BulletinKasra GolbanОценок пока нет

- Finish Fabrics: ShirtingДокумент3 страницыFinish Fabrics: ShirtingKasra GolbanОценок пока нет

- Johnson Controls SeatДокумент3 страницыJohnson Controls SeatKasra GolbanОценок пока нет

- 32 36Документ4 страницы32 36Kasra GolbanОценок пока нет

- 408ao 7619Документ2 страницы408ao 7619Kasra GolbanОценок пока нет

- US Legally Binding Document Establishes Water Vapor Transmission Test MethodsДокумент10 страницUS Legally Binding Document Establishes Water Vapor Transmission Test MethodsKasra GolbanОценок пока нет

- 1165Документ5 страниц1165Kasra GolbanОценок пока нет

- Synthetic Fibers PDFДокумент22 страницыSynthetic Fibers PDFFERNANDO JOSE NOVAES0% (1)

- Manufacturing End Uses: Riaz-Ul-Haq 060820-054Документ12 страницManufacturing End Uses: Riaz-Ul-Haq 060820-054Kasra GolbanОценок пока нет

- Measure Air Flow Through Textiles with ASTM D737Документ2 страницыMeasure Air Flow Through Textiles with ASTM D737jyoti1234321Оценок пока нет

- Journal of Applied Polymer Science Volume 80 Issue 10 2001 (Doi 10.1002 - App.1262) T. Haga T. Takagishi - Structural Change in Mercerized Cotton Fibers On Cellulase TreatmentДокумент6 страницJournal of Applied Polymer Science Volume 80 Issue 10 2001 (Doi 10.1002 - App.1262) T. Haga T. Takagishi - Structural Change in Mercerized Cotton Fibers On Cellulase TreatmentKasra GolbanОценок пока нет

- Mechanisms of Degradation of Cotton and Effects of MerceriДокумент16 страницMechanisms of Degradation of Cotton and Effects of MerceriKasra GolbanОценок пока нет

- Polymer Volume 19 Issue 2 1978 (Doi 10.1016 - 0032-3861 (78) 90027-7) Francis J Kolpak Mark Weih John Blackwell - Mercerization of Cellulose - 1. Determination of The Structure of Mercerized CottonДокумент9 страницPolymer Volume 19 Issue 2 1978 (Doi 10.1016 - 0032-3861 (78) 90027-7) Francis J Kolpak Mark Weih John Blackwell - Mercerization of Cellulose - 1. Determination of The Structure of Mercerized CottonKasra GolbanОценок пока нет

- Knitted FabДокумент2 страницыKnitted FabKasra GolbanОценок пока нет

- Measure Air Flow Through Textiles with ASTM D737Документ2 страницыMeasure Air Flow Through Textiles with ASTM D737jyoti1234321Оценок пока нет

- Technical Report #17: Recycling and Reuse of Mixed-Fiber Fabric RemnantsДокумент39 страницTechnical Report #17: Recycling and Reuse of Mixed-Fiber Fabric Remnantscham_matahariОценок пока нет

- Dimensional Properties of Cellulosic FibersДокумент10 страницDimensional Properties of Cellulosic FiberschocklingamОценок пока нет

- Colour Index LeafletДокумент4 страницыColour Index LeafletKasra GolbanОценок пока нет

- Continuous Modification of Polyester Fabric by Dielectric DischargeДокумент5 страницContinuous Modification of Polyester Fabric by Dielectric DischargeKasra GolbanОценок пока нет

- FREQUENTLY USED ADVERBSДокумент5 страницFREQUENTLY USED ADVERBSHugo LacerddaОценок пока нет

- M.C. Escher biography highlights graphic artist's impossible structuresДокумент3 страницыM.C. Escher biography highlights graphic artist's impossible structuresLauren KelliherОценок пока нет

- Digital Vs OffsetДокумент9 страницDigital Vs OffsetJohn Ronald SantosОценок пока нет

- Expert Report - Vanessa FuscoДокумент254 страницыExpert Report - Vanessa FuscoWDET 101.9 FMОценок пока нет

- Confix HVДокумент1 страницаConfix HVGian ArevaloОценок пока нет

- QSN Paper XI Fine Arts-2Документ2 страницыQSN Paper XI Fine Arts-2architthakur1508Оценок пока нет

- GE 6 Lesson 2Документ4 страницыGE 6 Lesson 2Ellano MenendezОценок пока нет

- Z Thesis SynopsisДокумент22 страницыZ Thesis SynopsisAfsheen NaazОценок пока нет

- Introduction To 20TH Century Music 2Документ73 страницыIntroduction To 20TH Century Music 2John Andre MagoОценок пока нет

- Preschool Arabic WorksheetДокумент12 страницPreschool Arabic WorksheetJo HarahОценок пока нет

- CubismДокумент4 страницыCubismCassie CutieОценок пока нет

- 6 Elevation Day Spa-Finish Floor PlanДокумент1 страница6 Elevation Day Spa-Finish Floor Planapi-290046801Оценок пока нет

- Poem Interpretation: I wandered Lonely as a CloudДокумент8 страницPoem Interpretation: I wandered Lonely as a CloudBianca Victoria Uy CorralОценок пока нет

- Scheme Art Grade 1 Term 2Документ3 страницыScheme Art Grade 1 Term 2libertyОценок пока нет

- Pamplet Menara Condong EngДокумент2 страницыPamplet Menara Condong EngEr Chun Ren100% (1)

- CNU II 12 Piano and Organ Works PDFДокумент352 страницыCNU II 12 Piano and Organ Works PDFWUОценок пока нет

- Esther and The King Color by NumberДокумент2 страницыEsther and The King Color by Numbermarilyn micosaОценок пока нет

- 6 8 Year Old Lesson PlanДокумент4 страницы6 8 Year Old Lesson Planapi-234949588Оценок пока нет

- D& D5e - (Midnight Tower) - A Most Unexpected Zombie InvasionДокумент13 страницD& D5e - (Midnight Tower) - A Most Unexpected Zombie InvasionDizetSmaОценок пока нет

- Elvis PresleyДокумент5 страницElvis PresleyKath Magbag-RivalesОценок пока нет

- Music MKMNNMBJBJN BNBДокумент33 страницыMusic MKMNNMBJBJN BNBVignesh KumarОценок пока нет

- Representation of Beauty Standards in Films Imperfect: Career, Love & ScalesДокумент7 страницRepresentation of Beauty Standards in Films Imperfect: Career, Love & ScalesKylei EraОценок пока нет