Академический Документы

Профессиональный Документы

Культура Документы

Air Admission To Turbine Runners

Загружено:

octatheweelОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Air Admission To Turbine Runners

Загружено:

octatheweelАвторское право:

Доступные форматы

N

\

I

Qs

N

\)'-

,\s

s\

Nn

N

POWER

.

September L942

We operate a hydroelectric plant

in parallel with our steam plant, but

during about two-thirds of each year we

experience a water shortage for the

hydro plant. This piant has one 800 hp

Franci s wheel di rect -connect ed t o a 625

kva 0.80-pf ac generator, which

connects with the local utility company

at our switchboard. The turbine

operates under a 27 ft, head on water

suppl i ed t hrough a 1300 f t , penst ock.

A float-actuated selsyn motor at the

dam actuates the turbine gates so as to

utilize the flow of the river continuously

dunng dry peri ods.

To start the wheel and bring it

up to synchronizing speed required 75

cfs of water, Having read at one time

sometiring about increasing the power

of a waterwheel by admitting air to it

during part-gate operation, I decided to

see what could be done with our wheel,

The problem was to apply the air where

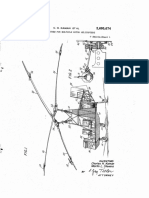

it would do the most good. Looking at a

blueprint of the wheel I found that the

shaft was drilled from the lower end up

to near the top of the hub as at

' C'

in

the figure.

In my way of reasoning to a

sol ut i on of t he probi em I deci ded t hat

the best place to admit the air would be

into the center of the dra-ft tube, Doing

this at 1ow flows wouid tend to keep the

wat er t o out er penphery of t he wheel

where it would have the greatest

turning effect and therefore develop the

most power. So worhng on this theory

we bored and t apped t wo 1 7z" ho1es i n

the turbine cover plate as at

' A' .

We

a-lso drilled two I Yz" dtagonal holes B'

through the runner hub and shaft to

,at'

\

THE JAIIES IEFFEI & CO.

Irrildrt C IIIDRAUUC TUR 8l N Es

1978 ootltERcE clRcLE

sPRtNGFlELD,

0H 45504-20 12

ysv

73e 6/gs

Repri nt I O

126 199

connect with the center hole. A pipe

with a va-lve was threaded into the hoies

in the covei plate to control airflow to

the turbine.

After some experimenting we

found oniy one of the air connections

was required, so removed the other and

plugged the hole in the cover plate. We

have found on our unit that admission

of air begins to increase the power of

the turbine at 35o/o gate opening with

the greatest increase occurring at

17,5o/o gate opening. This is the

opening required to bring the wheel up

to slmchronizing speed without alr,

But with air admission to the draft tube

the unit will generate B0 kw. Without

air the unit requires 75 cfs to bring it

up t o speed but wi t h ai r 25 cf s i s

sufficient.

There was only one day last

summer when the flow was down to 25

cfs at which point we were unabie to

operate the wheei, Most of the time we

were operating at about TOoh gate

opening and carr5.ing about 50 krv load.

Without the air we would have been

unable to generate any power a good

part of the time in the summer months.

This gives an idea what can be done by

admitting air to a hydro turbine

operated at small gate openings.

Вам также может понравиться

- Cross Section Retaining Wall 2 PDFДокумент1 страницаCross Section Retaining Wall 2 PDFoctatheweelОценок пока нет

- Table A8-7. Free-Flow Discharge Through 1-Inch Parshall MeasuringДокумент1 страницаTable A8-7. Free-Flow Discharge Through 1-Inch Parshall MeasuringoctatheweelОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- 64 839Документ6 страниц64 839octatheweelОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Basic Hydroponic Systems and How They Work PDFДокумент4 страницыBasic Hydroponic Systems and How They Work PDFIndo Biotech Agro100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A7 5 PDFДокумент5 страницA7 5 PDFoctatheweelОценок пока нет

- Table A9-4. Discharge of Constant-Head Orifice (CHO) Turnout in FTДокумент1 страницаTable A9-4. Discharge of Constant-Head Orifice (CHO) Turnout in FToctatheweelОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Mou Pt. TekДокумент2 страницыMou Pt. TekoctatheweelОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Cross Section Retaining Wall 1lДокумент1 страницаCross Section Retaining Wall 1loctatheweelОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Cross Section Retaining Wall 1lДокумент1 страницаCross Section Retaining Wall 1loctatheweelОценок пока нет

- Table A9-5. Discharge of Constant-Head Orifice (CHO) Turnout in FTДокумент1 страницаTable A9-5. Discharge of Constant-Head Orifice (CHO) Turnout in FToctatheweelОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 15 Chapter13 PDFДокумент4 страницы15 Chapter13 PDFoctatheweelОценок пока нет

- Table A7-3. Discharge of Standard Suppressed Rectangular WeirsДокумент2 страницыTable A7-3. Discharge of Standard Suppressed Rectangular WeirsoctatheweelОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- DDD Channels PDFДокумент2 страницыDDD Channels PDFoctatheweelОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Discharge rates of submerged rectangular orificesДокумент2 страницыDischarge rates of submerged rectangular orificesoctatheweelОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Discharge rates of submerged rectangular orificesДокумент2 страницыDischarge rates of submerged rectangular orificesoctatheweelОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Table A8-12 (Continued) - Free-Flow Discharges in FTДокумент6 страницTable A8-12 (Continued) - Free-Flow Discharges in FToctatheweelОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- All Model Toyotas Engine Wiring DiagramsДокумент25 страницAll Model Toyotas Engine Wiring DiagramsHilton Karstum Tri67% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Table A8-10. Free-Flow Discharge Through 6-Inch Parshall MeasuringДокумент1 страницаTable A8-10. Free-Flow Discharge Through 6-Inch Parshall MeasuringoctatheweelОценок пока нет

- Partial Differential Equations: Analytical and Numerical MethodsДокумент136 страницPartial Differential Equations: Analytical and Numerical MethodsMohamed Mounir FekriОценок пока нет

- Supplementary Service Manual For 4Wd ModelДокумент1 страницаSupplementary Service Manual For 4Wd ModelrevealedОценок пока нет

- Sae-Mechanical Engineering - Vehicle DesignДокумент39 страницSae-Mechanical Engineering - Vehicle Designapi-3712636Оценок пока нет

- Sachio Pneumatic PDFДокумент4 страницыSachio Pneumatic PDFoctatheweelОценок пока нет

- Hamdbuch Für Verkabelung Manual Des Schemas de Cablage Manual de Diagrama de Conexiones Wiring Diagram ManualДокумент1 страницаHamdbuch Für Verkabelung Manual Des Schemas de Cablage Manual de Diagrama de Conexiones Wiring Diagram ManualoctatheweelОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Engineer WebДокумент35 страницEngineer Webpedrocaels989Оценок пока нет

- Layout Retaing Wall PDFДокумент1 страницаLayout Retaing Wall PDFoctatheweelОценок пока нет

- Civil Penstocks Tunnels Best PracticeДокумент19 страницCivil Penstocks Tunnels Best PracticeJenny Cecilia Ureña ZuriОценок пока нет

- Is.4410.16.2.1981 Gates and Valves, Valves PDFДокумент21 страницаIs.4410.16.2.1981 Gates and Valves, Valves PDFoctatheweelОценок пока нет

- E 13-07 Module 2a Axial Exp Joints General BOA AG 14 PDFДокумент16 страницE 13-07 Module 2a Axial Exp Joints General BOA AG 14 PDFoctatheweelОценок пока нет

- Engineering Design Basis GAДокумент67 страницEngineering Design Basis GAswabrightОценок пока нет

- 10.ieee 2014 Mechanical Automobile Design and Fabrication Ofpneumatic Clamping DeviceДокумент59 страниц10.ieee 2014 Mechanical Automobile Design and Fabrication Ofpneumatic Clamping DeviceoctatheweelОценок пока нет

- Caterpillar Cat 320 GC Excavator (Prefix KTN) Service Repair Manual (KTN00001 and Up)Документ21 страницаCaterpillar Cat 320 GC Excavator (Prefix KTN) Service Repair Manual (KTN00001 and Up)kfmuseddk75% (8)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- VRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonДокумент55 страницVRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonFred BensimonОценок пока нет

- Manual de Overhaul Io-520Документ133 страницыManual de Overhaul Io-520Alfredo Ergueta CorilaОценок пока нет

- Repair WeldingДокумент33 страницыRepair WeldingAkhilesh Kumar100% (1)

- Thermography ReportДокумент9 страницThermography ReportsandrositohangОценок пока нет

- Stone Crusher Spare Parts Manufacturer and Supplier - VK Metal Cast & Engineering BrochureДокумент6 страницStone Crusher Spare Parts Manufacturer and Supplier - VK Metal Cast & Engineering BrochureVK Metal Cast & Engineering100% (1)

- Ipc Autosaw en Web 0115Документ2 страницыIpc Autosaw en Web 0115Jose Miguel Gonzalez VirviescasОценок пока нет

- Solar Water Heaters Guidelines V1 Aug 2019Документ49 страницSolar Water Heaters Guidelines V1 Aug 2019Mile DjordjevicОценок пока нет

- ITP For Nuts & Bolts - R22Документ7 страницITP For Nuts & Bolts - R22Hamid Taghipour ArmakiОценок пока нет

- Calculation of Gear Dimensions - KHK Gears PDFДокумент25 страницCalculation of Gear Dimensions - KHK Gears PDFlawlawОценок пока нет

- Low Pressure Pumps: Installation and Start-Up InstructionДокумент12 страницLow Pressure Pumps: Installation and Start-Up InstructionsmithworkОценок пока нет

- Maintain Anesthesia Machine Performance with Maintenance KitsДокумент2 страницыMaintain Anesthesia Machine Performance with Maintenance KitsRoberto SierraОценок пока нет

- Gallic 16 Engels Hld23 TornoДокумент47 страницGallic 16 Engels Hld23 TornoAdrian Macaya100% (1)

- B8 PPT Composites MT14 20nov14Документ86 страницB8 PPT Composites MT14 20nov14Rasagya MishraОценок пока нет

- ERP Regulation 2281-2016Документ50 страницERP Regulation 2281-2016Bianca-Elena LupuОценок пока нет

- EPS TestДокумент8 страницEPS TestGhilea GeorgeОценок пока нет

- Chapter 2 Rankine Cycle in EnglishДокумент26 страницChapter 2 Rankine Cycle in EnglishRahmandan HafidОценок пока нет

- 793F, 793F, WTR, Oem PDFДокумент18 страниц793F, 793F, WTR, Oem PDFDennis OlayaОценок пока нет

- Kic API X70Документ8 страницKic API X70Ivan SilveiraОценок пока нет

- Steel and Cast Iron Bar Compression ProblemДокумент26 страницSteel and Cast Iron Bar Compression ProblemLarete PaoloОценок пока нет

- Caja Transferencia Jeep Grand Cherokee Laredo 1993 4.0LДокумент120 страницCaja Transferencia Jeep Grand Cherokee Laredo 1993 4.0LGermán BustamanteОценок пока нет

- CompAir LeROI CL20-25-30SS,CUB Parts ListДокумент59 страницCompAir LeROI CL20-25-30SS,CUB Parts ListDiana Zar100% (1)

- 1.C.1 Limitations On The Work That Can Be Supplied by A Heat EngineДокумент30 страниц1.C.1 Limitations On The Work That Can Be Supplied by A Heat EnginekamsОценок пока нет

- 1950 Kaman Servoflap US2695674Документ23 страницы1950 Kaman Servoflap US2695674jorge paezОценок пока нет

- Design and Fabrication of Scotch Yoke Mechanism - Main PpiДокумент24 страницыDesign and Fabrication of Scotch Yoke Mechanism - Main PpiMusic LoverОценок пока нет

- Chapter 3. Part 2Документ49 страницChapter 3. Part 2yohannes lemiОценок пока нет

- CDM816DⅢ配件图册 (2015第1版第1次)Документ188 страницCDM816DⅢ配件图册 (2015第1版第1次)Mohammadazmy Sobursyakur0% (1)

- Interlock, Protection & Permissive of BFPДокумент15 страницInterlock, Protection & Permissive of BFPShweta Srivastava100% (2)

- Selection of MotorsДокумент16 страницSelection of Motorsmithun46Оценок пока нет

- SA - Super Inverter - Original File PDFДокумент32 страницыSA - Super Inverter - Original File PDFJojit Cantillep MagbutayОценок пока нет

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveОт EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveОценок пока нет

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldОт EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldРейтинг: 4.5 из 5 звезд4.5/5 (107)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityОт EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityРейтинг: 5 из 5 звезд5/5 (1)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyОт EverandChip War: The Quest to Dominate the World's Most Critical TechnologyРейтинг: 4.5 из 5 звезд4.5/5 (227)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumОт EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumРейтинг: 3 из 5 звезд3/5 (12)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldОт EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldРейтинг: 4.5 из 5 звезд4.5/5 (54)

- Algorithms to Live By: The Computer Science of Human DecisionsОт EverandAlgorithms to Live By: The Computer Science of Human DecisionsРейтинг: 4.5 из 5 звезд4.5/5 (722)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyОт EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyРейтинг: 4 из 5 звезд4/5 (51)