Академический Документы

Профессиональный Документы

Культура Документы

Revised BOQ

Загружено:

Kishore KrishnaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Revised BOQ

Загружено:

Kishore KrishnaАвторское право:

Доступные форматы

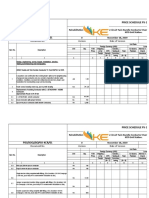

Rev.

01

S.No. Description Unit Quantity Rate Amount

MAIN EQUIPMENT

1

Transformer /Reactor

1.1

125 MVA, 400/132/33kV, Auto Transformer, 3 Phase, complete with terminal

connectors, all auxiliaries, MK and internal cabling and termination complete

including oil filtration/filling etc

no. 1.00 -

1.2

80MVAR, 400kV, bus Shunt Reactor , 3 Phase, complete with terminal

connectors, all auxiliaries, MK and internal cabling and termination complete

including oil filtration/filling etc

no. 1.00 -

1.3

63MVAR, 400kV, line Shunt Reactor along with NGR , 3 Phase, complete

with terminal connectors, all auxiliaries, MK and internal cabling and

termination complete including oil filtration/filling etc

nos. 2.00 -

1.4

400kVA , 6.6/0.433KV, LT Station Transformer, 3 Phase, complete with

terminal connectors & all auxiliaries and internal cabling and termination

complete including oil filtration/filling etc

nos. 2.00 -

2 Circuit Breaker

2.1

400 kV SF6 spring operated Circuit Breakers, 3 Ph., 2000A, 40 KA, with

closing resistor suitable for single and three phase operation alongwith

Support Structure, terminal connectors , Breaker Control Cabinets and

interpole cabling

nos. 6.00 -

2.2

400 kV SF6 spring operated Circuit Breakers, 3 Ph., 2000A, 40 KA, without

closing resistor suitable for single and three phase operation alongwith

Support Structure, terminal connectors , Breaker Control Cabinets and

interpole cabling

nos. 9.00 -

2.3

132 kV SF6 spring operated Circuit Breakers, 3 Ph., 1600A, 31.5 KA,

suitable for single and three phase operation alongwith Support Structure,

terminal connectors , Breaker Control Cabinets and interpole cabling

nos. 3.00 -

2.4

132 kV SF6 spring operated Circuit Breakers, 3 Ph., 1600A, 31.5 KA,

suitable for three phase operation alongwith Support Structure, terminal

connectors , Breaker Control Cabinets and interpole cabling

nos. 3.00 -

3 Current Transformer

3.1

400KV, 2000A ,40kA, 5 core Current Transformer, 1 Phase, complete with

terminal connectors

nos. 27.00 -

3.2

400KV, 2000A ,40kA, 6 core Current Transformer, 1 Phase, complete with

terminal connectors

nos. 12.00 -

3.3

132KV, 1600A ,31.5kA, Current Transformer, 1 Phase, complete with

terminal connectors

nos. 18.00 -

4 Capacitor Voltage Transformer / EMVT

4.1 400KV , 4400pF CVT, 1 Phase, complete with Line terminal connector nos. 36.00 -

4.2 132KV , 13200pF CVT, 1 Phase, complete with Line terminal connector nos. 15.00 -

4.3 132KV , EMVT, 1 Phase, complete with Line terminal connector nos. 6.00 -

5 Isolator

5.1

420 kV, 2000A, 3 phase Horizontal double break Isolator ( electrically

ganged motor operated ) with two earth switch ( manually opearted)

complete with 9 Nos. support insulators per 3 phase Isolator, terminal

connectors

nos. 9.00 -

5.2

420 kV, 2000A, 3 phase Horizontal double break Isolator ( electrically

ganged motor operated ) with one earth switch ( manually opearted)

complete with 9 Nos. support insulators per 3 phase Isolator, terminal

connectors

nos. 31.00 -

5.3

132 kV, 1600A, 3 phase Horizontal double break Isolator ( mechanically

ganged motor operated ) with two earth switch ( manually opearted)

complete with 9 Nos. support insulators per 3 phase Isolator, terminal

connectors

no. 1.00 -

5.4

132 kV, 1600A, 3 phase Horizontal double break Isolator ( mechanically

ganged motor operated ) with one earth switch ( manually opearted)

complete with 9 Nos. support insulators per 3 phase Isolator, terminal

connectors

nos. 15.00 -

5.5

132 kV, 1600A, 3 phase Horizontal double break tandem Isolator (

mechanically ganged motor operated ) without earth switch complete with 9

Nos. support insulators per 3 phase Isolator, terminal connectors

nos. 5.00 -

5.6

132 kV, 1600A, 3 phase Horizontal double break Under hung Isolator (

mechanically ganged motor operated ) without earth switch complete with 9

Nos. support insulators per 3 phase Isolator, terminal connectors

nos. 5.00 -

Project : 726.6MW combined cycle power project Pallatana Tripura -400/132kV Substation at ONGC Tripura

Customer :ONGC-Tripura Power Company Ltd.

Bill of Quantities for ETC Works

Page 1 of 6

Rev.01

S.No. Description Unit Quantity Rate Amount

MAIN EQUIPMENT

Project : 726.6MW combined cycle power project Pallatana Tripura -400/132kV Substation at ONGC Tripura

Customer :ONGC-Tripura Power Company Ltd.

Bill of Quantities for ETC Works

6 Surge Arrester

6.1

360KV, 1 Phase, 20kA , class -4 Gapless Metal Oxide Surge Arrester

complete with surge counter , insulating base, connecting cable between

insulating base and surge counter, Line terminal connector

nos. 30.00 -

6.2

120KV, 1 Phase, 10kA , class -3 Gapless Metal Oxide Surge Arrester

complete with surge counter , insulating base, connecting cable between

insulating base and surge counter, Line terminal connector

nos. 18.00 -

7 Wave Trap

7.1

420kV, 2000A, 0.5mH, 1 -PH Wave Trap with 3 nos support insulator

complete with , terminal connector

nos. 4.00 -

7.2

132kV,1600A, 0.5mH, 1 -PH Wave Trap with 3 nos support insulator complete

with , terminal connector

nos. 4.00 -

8 Bus Post Insulator

8.1 420kV Post Insulators for Bus support complete with , terminal connector nos. 30.00 -

8.2 132kV Post Insulators for Bus support complete with , terminal connector nos. 25.00 -

BUS BAR MATERIALS

9 String Insulator and Hardware

9.1

400 kV Double Tension String insulator with double anchoring point(anchor

spacing 450mm), string comprising 2x25 Nos. 120KN anti fog type disc with

hardware set with all hardware accessories including tension clamp and Turn

Buckle set suitable for Quad ACSR Moose Conductor (sub conductor

spacing 450mm).

nos. 18.00 -

9.2

400 kV Double Tension String insulator with double anchoring point(anchor

spacing 450mm), string comprising 2x25 Nos. 120KN anti fog type disc with

hardware set with all hardware accessories including tension clamp but

without Turn Buckle set suitable for Quad ACSR Moose Conductor (sub

conductor spacing 450mm).

nos. 18.00 -

9.3

400 kV Double Tension String insulator with double anchoring point(anchor

spacing 450mm), string comprising 2x25 Nos. 120KN anti fog type disc with

hardware set with all hardware accessories including tension clamp and Turn

Buckle set suitable for twin ACSR Moose Conductor (sub conductor spacing

450mm).

nos. 54.00 -

9.4

400 kV Double Tension String insulator with double anchoring point(anchor

spacing 450mm), string comprising 2x25 Nos. 120KN anti fog type disc with

hardware set with all hardware accessories including tension clamp but

without Turn Buckle set suitable for twin Moose Conductor (sub conductor

spacing 450mm).

nos. 54.00 -

9.5

420 kV Single Suspension String insulator, each string comprising 25 No.

120KN anti fog type disc with hardware set with all hardware accessories

including drop type suspension clamp suitable for Twin ACSR Moose

Conductor (sub conductor spacing 450mm).

nos. 30.00 -

9.6

420 kV Single Suspension String insulator, each string comprising 25 No.

120KN anti fog type disc with hardware set with all hardware accessories

including through type suspension clamp suitable for Twin ACSR Moose

Conductor (sub conductor spacing 450mm).

nos. 15.00 -

9.7

145 kV single Tension String insulator, each string comprising 10 No. 120KN

anti fog type disc with hardware set with all hardware accessories including

tension clamp and Turn Buckle set suitable for Twin ACSR Moose Conductor

(sub conductor spacing 250mm).

nos. 27.00 -

9.8

145 kV single Tension String insulator, each string comprising 10 No. 120KN

anti fog type disc with hardware set with all hardware accessories including

tension clamp but without Turn Buckle set suitable for Twin ACSR Moose

Conductor(sub conductor spacing 250mm).

nos. 27.00 -

9.9

145 kV single Tension String insulator, each string comprising 10 No. 120KN

anti fog type disc with hardware set with all hardware accessories including

tension clamp and Turn Buckle set suitable for single ACSR Moose

Conductor.

nos. 30.00 -

9.10

145 kV single Tension String insulator, each string comprising 10 No. 120KN

anti fog type disc with hardware set with all hardware accessories including

tension clamp but without Turn Buckle set suitable for single ACSR Moose

Conductor.

nos. 30.00 -

9.11

145 kV Single Suspension String insulator, each string comprising 10 No.

120KN anti fog type disc with hardware set with all hardware accessories

including drop type suspension clamp suitable for single ACSR Moose

Conductor .

nos. 12.00 -

Page 2 of 6

Rev.01

S.No. Description Unit Quantity Rate Amount

MAIN EQUIPMENT

Project : 726.6MW combined cycle power project Pallatana Tripura -400/132kV Substation at ONGC Tripura

Customer :ONGC-Tripura Power Company Ltd.

Bill of Quantities for ETC Works

9.12.

145 kV Single Suspension String insulator, each string comprising 10 No.

120KN anti fog type disc with hardware set with all hardware accessories

including through type suspension clamp suitable for single ACSR Moose

Conductor .

nos. 6.00 -

9.13

145 kV Single Suspension String insulator, each string comprising 10 No.

120KN anti fog type disc with hardware set with all hardware accessories

including drop type suspension clamp suitable for twin ACSR Moose

Conductor (sub conductor spacing 250mm).

nos. 3.00 -

9.14

145 kV Single Suspension String insulator, each string comprising 10 No.

120KN anti fog type disc with hardware set with all hardware accessories

including through type suspension clamp suitable for twin ACSR Moose

Conductor (sub conductor spacing 250mm).

nos. 12.00 -

10 Conductor /Aluminium Tube/shield wire

10.1

ACSR Moose conductor for bus /jack bus connection , droppers ,

equipment connection , busbar jumpering along with spacers, Tee

connectors, PG Clamps etc.

kM 20.50 -

10.2 4" IPS Al Tube

Meter 965.00 -

Note-ETC of Aluminium tube includes Aluminium Welding and bending.

Welding Sleeve and tube will be supplied by BHEL. Electrodes, Welding

machines, bending machines and any other equipment will be in ETC

Contractor scope.The scope also includes erection of end clamps/corona bells

etc.

10.3

Overhead 10.98 dia. shield wire

Meter 4,100.00 -

Note:Erection of shield wire includes tension clamps , PG clamps etc for

Peak tower . Tension clamps and PG clamps shall be supplied by BHEL.

YARD WORK INCLUDING CABLING, TRENCH & EARTHING.

11

Cabling including laying, dressing , glanding and termination of cables - laying

can be either on , supports, underground, over ground etc.All other erection

materials viz.cables glands, ferrules, lugs, cable ties / straps, markers etc. to

be included in the quoted rates. Refer enclosed Annexure-B regarding

specification and quantities of cable glands.Trefoil clamps shall be supplied

by BHEL.Cable tags at 30 M intervals and at turning points, cable route

markers for burried cables etc. to be included in the quoted rates.

11.1 1.1kV XLPE Power cables

11.1.1 1C X 630 sq. mm(In Trench) kM 1.80 -

11.1.2 3.5 C X 300 sq. mm(In Trench) kM 1.25 -

11.2 1.1kV PVC /Al Power cable

11.2.1 1C X 150 sq. mm( Trench) kM 3.00 -

11.2.2 3.5CX 70 sq.mm( In Trench) kM 2.00 -

11.2.3 3.5CX 70 sq.mm( buried ) kM 1.00 -

11.2.4 3 CX 35 sq.mm( In Trench) kM 5.00 -

11.2.5 4 CX 6 sq.mm( In Trench) kM 5.00 -

11.2.6 2CX 6sq.mm( In Trench) kM 5.50 -

11.2.7 4CX1 6sq.mm( in trench ) kM 1.50 -

11.2.8 4CX1 6sq.mm( Buried) kM 2.50 -

11.3 1.1kV PVC Control cable

11.3.1 2 C X 2.5 sq.mm( In Trench) kM 2.00 -

11.3.2 2 C X 2.5 sq.mm( buried) kM 1.00 -

11.3.3 5 C X 2.5 sq.mm( In Trench) kM 49.00 -

11.3.4 7 C X 2.5 sq.mm( In Trench) kM 3.00 -

11.3.5 10 C X 2.5 sq.mm( In Trench) kM 110.00 -

11.3.6 14 C X 2.5 sq.mm( In Trench) kM 38.00 -

11.3.7 19 C X 2.5 sq.mm( In Trench) kM 23.00 -

12 MK/JB

12.1 CVT Junction Box (JB-45N) nos. 19.00 -

12.2 CT Junction Box (JB-130D) nos. 19.00 -

12.3 Bay Mashalling Kiosk (MK-300P) nos. 21.00 -

Page 3 of 6

Rev.01

S.No. Description Unit Quantity Rate Amount

MAIN EQUIPMENT

Project : 726.6MW combined cycle power project Pallatana Tripura -400/132kV Substation at ONGC Tripura

Customer :ONGC-Tripura Power Company Ltd.

Bill of Quantities for ETC Works

13

Cable trench( for 1.1kV cable) material shall be supplied by BHEL. Cable

rack assembly shall be erected/fabricated at every 1500 mm interval . Refer

enclosed Annexure-C for details of figure 1 to 7 , section 1-1 to 6-6 and

ladder tray .The sizes of below cable tray are indicative & can vary upto

150mm.

13.1 4-tier cable rack assembly as per Fig. 1 for trench Section 1-1 Nos. 310.00 -

13.2

3-tier cable rack assembly as per Fig. 2 for trench Section 2-2

Nos. 155.00 -

13.3 3-tier cable rack assembly as per Fig. 3 for trench Section 3-3 and 4-4 Nos. 440.00 -

13.4 2-tier cable rack assembly as per Fig. 4 for trench Section 5-5 Nos. 255.00 -

13.5 2-tier cable rack assembly as per Fig. 5 for trench Section 6-6 Nos. 165.00 -

13.6

3 tier under hung ( both side) cable rack assembly as per fig. 6

Nos. 65.00 -

13.7

3 tier under hung ( one side) cable rack assembly as per fig. 7

Nos. 28.00 -

13.8

700mm wide,100mm high, 2 mm tk.(min.) galvanised iron slotted rung type ladder

cable trays each 2.5 m long with 2 Nos. Side plate, along with 8 mm dia bolts with

nuts and washers for each number of cable tray

Nos. 1,280.00 -

13.9

600mm wide, 100mm high,2 mm tk.(min.) galvanised iron slotted rung type ladder

cable trays each 2.5 m long with 2 Nos. Side plate, along with 8 mm dia bolts with

nuts and washers for each number of cable tray

Nos. 940.00 -

13.10

350mm wide,100mm high, 2 mm tk.(min.) galvanised iron slotted rung type ladder

cable trays each 2.5 m long with 2 Nos. Side plate, along with 8 mm dia bolts with

nuts and washers for each number of cable tray

Nos. 155.00 -

13.11

300mm wide,100mm high,2 mm tk.(min.) galvanised iron slotted rung type ladder

cable trays each 2.5 m long with 2 Nos. Side plate, along with 8 mm dia bolts with

nuts and washers for each number of cable tray

Nos. 100.00 -

13.12

200mm wide,100mm high,2 mm tk.(min.) galvanised iron slotted rung type ladder

cable trays each 2.5 m long with 2 Nos. Side plate, along with 8 mm dia bolts with

nuts and washers for each number of cable tray

Nos. 100.00 -

14

EARTHING MATERIAL -The earthing includes earthing of all 400/132 kV

switchyard equipment, towers , pipe structures, cable trenches, fence,

electronic earthing and Control room equipments using necessary

Connectors for earthing flats. Earthing clamping ( refer enclosed annexure-E

for typical cases) shall be carried by ETC contractor.

14.1

65x8 mm galvanised MS Flat (riser)

Meter 7,000.00 -

14.2

50x6 mm galvanised MS Flat( in trenches and riser)

Meter 6,000.00 -

15

GI Pipes -Laying of GI Conduits including excavation, backfilling, making of

holes in trench walls and wherever required and its repairing , cutting, fixing

of sockets/ bends where required etc. complete (payment will be made for the

as erected pipe length).

15.1

GI pipe, 50 NB

Meter 3,500.00 -

15.2 GI pipe,100 NB Meter 4,200.00 -

16

Control and relay Panels - Supervision of testing and commissioning of

numerical relays are in scope of panel supplier. All the other works in ETC

contractor's scope.Refer enclosed single line diagram drawing no. TB-3-321-

510-001 rev-03 for details of bay nos.

16.1 400kV One & A Half CB Diameter Cicruit Control Panel (Bay-1,2,3) No 1.00 -

16.2

400kV One & A Half CB Diameter Cicruit Control Panel (Bay-4,5,6) No 1.00 -

16.3 400kV One & A Half CB Diameter Cicruit Control Panel (Bay-7,8,9) No 1.00 -

16.4

400kV Bus Reactor Diameter Control Panel (Bay-10,12) No 1.00 -

16.5 400kV One & A Half CB Diameter Cicruit Control Panel(Bay-13,14,15) No 1.00 -

16.6 132kV ST-1 Control Panel (Bay-2) No 1.00 -

16.7 132kV Line-1 Control Panel (Bay-3) No 1.00 -

16.8 132kV ST-2 Control Panel (Bay-4) No 1.00 -

16.9 132kV Line-2 Control Panel (Bay-5) No 1.00 -

16.10 132kV Bus Coupler Control Panel (Bay-6) No 1.00 -

16.11 132kV ICT Control Panel (Bay-7) No 1.00 -

16.12 RTCC PANEL FOR 400/132/33kV ICT No 1.00 -

16.13 400KV STG-GT1 CB Relay Panel (Bay-1) No 1.00 -

16.14 400KV Tie CB Relay Panel (Bay-2) No 1.00 -

16.15 400KV ICT Protection Panel (Bay-3) (1 set comprising of 2 Panels) Set 1.00 -

16.16 400KV GTG-GT1 CB Relay Panel (Bay-4) No 1.00 -

16.17 400KV Tie CB Relay Panel (Bay-5) No 1.00 -

16.18 400KV Line-1 Protection Panel (Bay-6) (1 set comprising of 2 Panels) Set 1.00 -

Page 4 of 6

Rev.01

S.No. Description Unit Quantity Rate Amount

MAIN EQUIPMENT

Project : 726.6MW combined cycle power project Pallatana Tripura -400/132kV Substation at ONGC Tripura

Customer :ONGC-Tripura Power Company Ltd.

Bill of Quantities for ETC Works

16.19 400KV Line Reactor-1 Protection Panel (Bay-6) No 1.00 -

16.20 400KV STG-GT2 CB Relay Panel (Bay-7) No 1.00 -

16.21 400KV Tie CB Relay Panel (Bay-8) No 1.00 -

16.22 400KV Line-2 Protection Panel (Bay-9) (1 set comprising of 2 Panels) Set 1.00 -

16.23 400KV Line Reactor-2 Protection Panel (Bay-9) No 1.00 -

16.24 400KV Bus Reactor Protection Panel (Bay-10 & 12) (1 set comprising of 3 Panels) Set 1.00 -

16.25 400KV GTG-GT2 CB Relay Panel (Bay-13) No 1.00 -

16.26 400KV Tie CB Relay Panel (Bay-14) No 1.00 -

16.27 400kV BUSBAR PROTECTION (1 set comprising of 4 Panels) Set 1.00 -

16.28 132kV ST-1 Protection Panel (1 set comprising of 2 Panels) Set 1.00 -

16.29 132kV Line-1 Protection Panel (1 set comprising of 2 Panels) Set 1.00 -

16.30 132kV ST-2 Protection Panel (1 set comprising of 2 Panels) Set 1.00 -

16.31 132kV Line-2 Protection Panel (1 set comprising of 2 Panels) Set 1.00 -

16.32 132kV Bus Coupler Protection Panel No 1.00 -

16.33 132kV ICT Protection Panel No 1.00 -

16.34 132kV BUSBAR PROTECTION (1 set comprising of 2 Panels) Set 1.00 -

16.35 SCADA Panels No 12.00 -

16.36 400kV ENERGY METERING PANEL No 1.00 -

16.37 132kV ENERGY METERING PANEL No 1.00 -

16.38 EVENT RECORDER PANEL Set 1.00 -

16.39 Synchronising Trolley No 1.00 -

16.40

PC, Printer with their furniture(Includes HMI system consist of 1 no operator

wotk station , 1 no. engineering work station , 1 no historian located in

switcjyard control room , 1 no of color laser printer ( A4) , 1 no of Dot matrix

printer( A4) , Desktop type tables( 3 nos) for above workstations, 2 nos. of

printers table, 3 nos of chairs, FO cable network for communication between

switchyard control building and unit control room( distance 400m).Laying of

FO cable will be in contractor scope.

Set 1.00 -

17.0 PLCC Panels -Supervision of testing and commissioning in scope of panel

supplier. All the other works in ETC contractor's scope.

17.1 40 Watt PLC Terminal with 4-command protection coupler for Speech and Protection No 8.00 -

17.2 40 Watt PLC Terminal without protection coupler for Speech and Data No 8.00 -

17.3 VFT Modem No 1.00 -

17.4 Phase to Phase Coupling Device Sets 4.00 -

17.5 HF Cable (75 Ohms Unbalanced)* m 2,000.00 -

17.6 Telephane Exchange No 1.00 -

17.7 4 wire Telephone Sets with connecting cables No 4.00 -

17.8 2 wire Telephone Sets with connecting cables No 24.00 -

17.9 Single Pair Telephone Cable* m 500.00 -

( * ) Cabling to be done in line with details given in Sl NO 11.0 above)

18 Auxiliary supply- (Battery /Charger /Distribution Board)

18.1 415V AC Distribution board Set 1.00 -

18.2 415V Main lighting Distribution board Set 1.00 -

18.3 415V emergency lighting Distribution board Set 1.00 -

18.4 220V DC Distribution board - (1 & 2) Set 1.00 -

18.5 48V DC Distribution baord - (1 & 2) Set 1.00 -

18.6 220V, 300AH Ni-Cd Battery high discharge type complete with Accessories.

Set 2.00 -

18.7 48V, 120AH Ni-Cd Battery high discharge type complete with Accessories.

Set 2.00 -

18.8 Common discharge resistor for above 220V and 48V battery

no. 1.00 -

18.9 220V, 70A Float cum Boost Charger Complete in all respects for

efficient and trouble free operation for Nickel Cadmium battery with high

discharge type with Accessories.

nos. 4.00 -

18.10 48V, 70A Float cum Boost Charger Complete in all respects for efficient

and trouble free operation for Nickel Cadmium battery with high

discharge type with Accessories.

nos. 4.00 -

19.0 Illmination

19.1

Illumination Package( Includes ETC of Illumination system as per

enclosed BOQ Annexure-A, Scope also includes cutting, making holes in

RCC/BM, finishing with CC/platering etc. wherever required to complete the

Illumination system ) .

Lot 1.00 -

19.2

Point Wiring for Light points, Fans power points 5/15 amps with 2.5 sqmm/4

sqmm copper for circuit wiring and 1.5 sqmm copper earth wire PVC insulated

in green colour including wiring for submains i.e. wiring from Lighting Panel to

switchboards.

Page 5 of 6

Rev.01

S.No. Description Unit Quantity Rate Amount

MAIN EQUIPMENT

Project : 726.6MW combined cycle power project Pallatana Tripura -400/132kV Substation at ONGC Tripura

Customer :ONGC-Tripura Power Company Ltd.

Bill of Quantities for ETC Works

19.2.1 For 2.5 sq. mm wire

Nos. in

points

50.00 -

19.2.1 For 4 sq. mm wire

Nos. in

points

25.00 -

19.3

Wiring from lighting panel to switch boards, from switchboards to junction

boxes for Light Points, Submain, Power and Fan points with 2.5/4.0 sqmm

Copper wire , complete in all respects. 1.5 sqmm copper wire (Green) will be

used for earthing inside conduits.

19.3.1 For 2.5 sq. mm wire

Nos. in

points

40.00 -

19.3.2 For 4 sq. mm wire

Nos. in

points

20.00 -

20 STEEL STRUCTURES FOR

20.1 Lattice Structure( excluding CB structure) MT 488.00 -

20.2 Pipe Structure MT 331.00 -

20.3 Structure Hardwares MT 25.00 -

21 Supply of channels /angles /steel for mounting the panels/MK & misc

structural work

MT 2.00 -

22 Mandatory Spare /Commissioning Spares /Special Equipmentas per

Annexure -D

Lot 1.00 -

Total Amount

-

1

2

3

4

5

6

7

8

Loading / Unloading, verification, handling, shifting to & from stores, proper storage, assembly, installation, pre-commissioning test and

commissioning tests are included in the scope for the quantities mentioned.

All paint , welding electrodes & other consumable by contract supplies shall be part of ETC works. Paint /welding electrode make etc. is subject

to BHEL/CUSTOMER site incharge approval.

The quantities given above may changes to any extent.

Notes for ETC works:-

MS welding - apply 2 coats of red lead paint then two coats of aluminium paint / bitumen paint after welding.

Refer enlosed annexure-F regarding guidelines for electrical installation.

Equipment and tower erection would includes supply and erection of miscellanneous items , viz Phase colour discs , labels painting of

equipments , phase colour painting , phase marking , bay identification board , danger plates , rubber mats , device number marking on the

equipment, keyboard etc as per site requirements .

Quoted rates are deemed to be inclusive of miscellaneous works viz erection of clamps and connectors.

Any other items not listed above , but required as per specification shall be deemed to be included in Bidder's scope and extra price shall be

paid for the same.

Page 6 of 6

Вам также может понравиться

- BOQ Electrical TrackingДокумент40 страницBOQ Electrical Trackingfadli.lpgОценок пока нет

- Main Substation Earthing Layout R0-Layout1Документ1 страницаMain Substation Earthing Layout R0-Layout1zabiruddin786Оценок пока нет

- Cost Data 132 KVДокумент14 страницCost Data 132 KVJojolasОценок пока нет

- Masterlist - SubstationДокумент16 страницMasterlist - SubstationIzwan ShihabuddinОценок пока нет

- Portable Appliance Testing (Pat) Report/Certificate: Copy Certificate Certificate Reference NumberДокумент3 страницыPortable Appliance Testing (Pat) Report/Certificate: Copy Certificate Certificate Reference NumberPete KomorОценок пока нет

- Quotation CT PT VCB SF6 HT Panel Isolator DO Fuse Set AB Switch Horn Gap Transmission LineДокумент11 страницQuotation CT PT VCB SF6 HT Panel Isolator DO Fuse Set AB Switch Horn Gap Transmission LineShokautОценок пока нет

- Huzurnagar 220kV line-BOQДокумент22 страницыHuzurnagar 220kV line-BOQzakir242Оценок пока нет

- Boq 132 - 33kv GssДокумент14 страницBoq 132 - 33kv GssMathur DineshОценок пока нет

- Substation Equipment ListДокумент68 страницSubstation Equipment ListVimal SinghОценок пока нет

- Tender BOQ Surajbare 2x50 MVAДокумент18 страницTender BOQ Surajbare 2x50 MVAapi-25885200Оценок пока нет

- Quotation 11KV 33KV Electrical Equipment NESCL NTPC CS DA 628 DarlipaliДокумент17 страницQuotation 11KV 33KV Electrical Equipment NESCL NTPC CS DA 628 DarlipaliSharafat AliОценок пока нет

- BOQ Cum Price Scedule - Package A - BudhapalДокумент34 страницыBOQ Cum Price Scedule - Package A - BudhapalSanjay GulatiОценок пока нет

- Handbook-GRID CODEДокумент123 страницыHandbook-GRID CODEabhijitОценок пока нет

- 199-GST-0101-RevA - Electrical MV LV Transformers SpecificationДокумент14 страниц199-GST-0101-RevA - Electrical MV LV Transformers Specificationdhanny ma100% (1)

- Quotation Electrical Items HVPNL ProjectДокумент4 страницыQuotation Electrical Items HVPNL ProjectSharafat AliОценок пока нет

- 33KV LineДокумент138 страниц33KV LineSekharmantri SitapatiОценок пока нет

- UPPTCL - PDF - Electrical Substation - Switch - Free 30-Day Trial - ScribdДокумент954 страницыUPPTCL - PDF - Electrical Substation - Switch - Free 30-Day Trial - ScribdSwatiОценок пока нет

- Bhatinda R 2 SLDДокумент1 страницаBhatinda R 2 SLDvineets058Оценок пока нет

- BOQ-HT Sub-Stn. at Market Complex at Baruipur (22 7 11)Документ6 страницBOQ-HT Sub-Stn. at Market Complex at Baruipur (22 7 11)Ramesh AnanthanarayananОценок пока нет

- 5 Section V SJVN Technical Specification Rev 1 PDFДокумент195 страниц5 Section V SJVN Technical Specification Rev 1 PDFbacuoc.nguyen356Оценок пока нет

- O2001 DC SCF 001 SCF Cal With 32mtr SpanДокумент5 страницO2001 DC SCF 001 SCF Cal With 32mtr SpanGanesh SantoshОценок пока нет

- 66 KV Bay End Boq - EnquiryДокумент3 страницы66 KV Bay End Boq - EnquiryUmamaheshwarrao VarmaОценок пока нет

- SR Book 1Документ83 страницыSR Book 1Shiva Krishna100% (1)

- Lighting BOQ Offer 14.11.19Документ3 страницыLighting BOQ Offer 14.11.19Akd Deshmukh100% (1)

- 220kV Lines at Rajokheri Technical Specifications PDFДокумент421 страница220kV Lines at Rajokheri Technical Specifications PDFrahulОценок пока нет

- 014 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 13.04.2021Документ4 страницы014 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 13.04.2021Ajay MedikondaОценок пока нет

- Offer For Electrical Installation WorkДокумент6 страницOffer For Electrical Installation Workparveen kumarОценок пока нет

- BOQДокумент2 страницыBOQVasu BagganОценок пока нет

- Training 400 KV SubstaionДокумент69 страницTraining 400 KV SubstaionDeepak Yadav100% (1)

- Schedule of Quantities GISДокумент6 страницSchedule of Quantities GISBalkishan AgrawalОценок пока нет

- Schedule of Prices For 220 KV Double CKT Twin Bundle BQPS - KCR (OH & UGTL) & Grid WorksДокумент143 страницыSchedule of Prices For 220 KV Double CKT Twin Bundle BQPS - KCR (OH & UGTL) & Grid WorksShan UL Haq RehmaniОценок пока нет

- BOQ 400 & 132 KV Lattice TowerДокумент6 страницBOQ 400 & 132 KV Lattice TowerSourav SatapathyОценок пока нет

- 31 STДокумент60 страниц31 STRajeshYadavОценок пока нет

- Description Unit Rate Rate Amount ED: Price List For LT WorksДокумент16 страницDescription Unit Rate Rate Amount ED: Price List For LT Worksapi-25885200100% (2)

- Porumamilla 220kV SS & Line-Reach II-BOQДокумент58 страницPorumamilla 220kV SS & Line-Reach II-BOQzakir242100% (1)

- 2 - Earthing Calculation No.1Документ2 страницы2 - Earthing Calculation No.1Sharik KhanОценок пока нет

- MDL Number ListДокумент3 страницыMDL Number ListanjaneyulubhelОценок пока нет

- 33 KV Pooling Station & Metering YardДокумент12 страниц33 KV Pooling Station & Metering YardMadhukar PadipallyОценок пока нет

- Acme-kr1-01-Ee-224-Ts-001 - r0 Bay End Etc - Technical SpecificationДокумент74 страницыAcme-kr1-01-Ee-224-Ts-001 - r0 Bay End Etc - Technical SpecificationUmamaheshwarrao VarmaОценок пока нет

- 6.6kV CABLE SIZINGДокумент2 страницы6.6kV CABLE SIZINGmahesh_sali2003Оценок пока нет

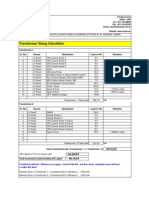

- Transformer Sizing 1W09 FEWA EEMS E 2106 00Документ1 страницаTransformer Sizing 1W09 FEWA EEMS E 2106 00shaikhsajid242Оценок пока нет

- Cable Schedule For Shahzada Bagh Bay Extension WorkДокумент8 страницCable Schedule For Shahzada Bagh Bay Extension WorkAnkur SangwanОценок пока нет

- GA LayoutДокумент34 страницыGA LayoutPRASOON100% (1)

- Fatehabad 765/400KV Substation SLDДокумент1 страницаFatehabad 765/400KV Substation SLDसन्दीप कुमार सरल100% (1)

- 33kv Switchyard Details JatniДокумент138 страниц33kv Switchyard Details JatniDeptiranjan MohapatraОценок пока нет

- Technical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableДокумент13 страницTechnical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableGokul VenugopalОценок пока нет

- Typical Details of Switchyard RequirementДокумент364 страницыTypical Details of Switchyard RequirementEspro100% (1)

- List Drawing - Uip ViiДокумент47 страницList Drawing - Uip Viizainalabidin3388Оценок пока нет

- 3.1 Selection of Cross Section of Grid Conductor (A) : 3.0 CalculationДокумент5 страниц3.1 Selection of Cross Section of Grid Conductor (A) : 3.0 CalculationPrasadОценок пока нет

- HT SWGR Test SCHДокумент24 страницыHT SWGR Test SCHsantoshkumarОценок пока нет

- 220-132kV Power and Control Cable Schedule - Dhalkebar With CommentДокумент53 страницы220-132kV Power and Control Cable Schedule - Dhalkebar With CommentmanishОценок пока нет

- Cable Sizing DetailsДокумент5 страницCable Sizing DetailsKalam NagappanОценок пока нет

- HT CABLE SCHEDULE With Actual Load DsДокумент19 страницHT CABLE SCHEDULE With Actual Load Dsvinod_eicsОценок пока нет

- Schedule of Charges and Procedure PDFДокумент58 страницSchedule of Charges and Procedure PDFabhi...Оценок пока нет

- 110 - Technical REC - 112Документ199 страниц110 - Technical REC - 112umamaheshwarraoОценок пока нет

- Power Cable ScheduleДокумент40 страницPower Cable ScheduleAnupam0103Оценок пока нет

- LIST OF DRAWING REQUIRED For SubstationДокумент2 страницыLIST OF DRAWING REQUIRED For SubstationDhurba KafleОценок пока нет

- RSC SLDДокумент1 страницаRSC SLDMichael Parohinog Gregas0% (1)

- Technical Specification 1432036065 PDFДокумент172 страницыTechnical Specification 1432036065 PDFPandiyanОценок пока нет

- Stage 2 PDFДокумент8 страницStage 2 PDFAmol NimaseОценок пока нет

- Materials Rate 2022-23Документ14 страницMaterials Rate 2022-23JaslinrajsrОценок пока нет

- Solar Inverters: MODELS: PM-1500SL-12 PM-1500SL-24 Specifications: MODELS: PM-3000SL-12 PM-3000SL-24 SpecificationsДокумент1 страницаSolar Inverters: MODELS: PM-1500SL-12 PM-1500SL-24 Specifications: MODELS: PM-3000SL-12 PM-3000SL-24 SpecificationsKishore Krishna100% (1)

- Street & Area Lighting Deemed Calculation Method: Metal Halide Low Pressure SodiumДокумент4 страницыStreet & Area Lighting Deemed Calculation Method: Metal Halide Low Pressure SodiumKishore KrishnaОценок пока нет

- KEMA Certificate - 7SR11 and 7SR12 IEC 61850Документ2 страницыKEMA Certificate - 7SR11 and 7SR12 IEC 61850Kishore KrishnaОценок пока нет

- Electrical BOS Solutions For UK Grid-Connected PV Systems: Richard Molloy Segment Sales - Renewable Energy 25 June 2014Документ15 страницElectrical BOS Solutions For UK Grid-Connected PV Systems: Richard Molloy Segment Sales - Renewable Energy 25 June 2014Kishore KrishnaОценок пока нет

- Hydraulic Actuators SpecsДокумент8 страницHydraulic Actuators SpecsKishore KrishnaОценок пока нет

- 505 - Site Assessment Checklist Rev2010!04!12Документ21 страница505 - Site Assessment Checklist Rev2010!04!12Kishore KrishnaОценок пока нет

- E Strive To Provide Our Clients The Very Best Technical Expertise and E-Business SolutionsДокумент12 страницE Strive To Provide Our Clients The Very Best Technical Expertise and E-Business SolutionsKishore KrishnaОценок пока нет

- Costing CGDPДокумент20 страницCosting CGDPKishore KrishnaОценок пока нет

- Vendor Evaluation Matrix Tool v1.0Документ10 страницVendor Evaluation Matrix Tool v1.0Kishore KrishnaОценок пока нет

- Guide To Help You Buy The Car of Your Choice Select by ManufacturerДокумент62 страницыGuide To Help You Buy The Car of Your Choice Select by ManufacturerKishore KrishnaОценок пока нет

- Electrical Engineering Portal - Com Transformer Connection StarStarДокумент7 страницElectrical Engineering Portal - Com Transformer Connection StarStarraul_bsuОценок пока нет

- The Andhra Pradesh Agricultural LandДокумент10 страницThe Andhra Pradesh Agricultural LandKishore KrishnaОценок пока нет

- Fault Ride ThroughДокумент9 страницFault Ride ThroughKishore KrishnaОценок пока нет

- Straight Cale TrayДокумент2 страницыStraight Cale TrayKishore KrishnaОценок пока нет

- Cable Trunking For PrefabricatedДокумент1 страницаCable Trunking For PrefabricatedKishore KrishnaОценок пока нет

- Trunking CatlougeДокумент306 страницTrunking CatlougeKishore KrishnaОценок пока нет

- Woodward SEG MaualДокумент16 страницWoodward SEG MaualKishore KrishnaОценок пока нет

- Calibrated Balance Valve Performance CurvesДокумент20 страницCalibrated Balance Valve Performance CurvesDiana Andreina Linarez ContrerasОценок пока нет

- A Power Tool Is A Tool That Is Actuated by An Additional Power Source and Mechanism Other Than The Solely Manual Labour Used With Hand ToolsДокумент15 страницA Power Tool Is A Tool That Is Actuated by An Additional Power Source and Mechanism Other Than The Solely Manual Labour Used With Hand ToolsAnanya ChitranshОценок пока нет

- Trafoindo Catalogue Instrument TransformersДокумент6 страницTrafoindo Catalogue Instrument TransformersFaisal Irsan PasaribuОценок пока нет

- (Estimation and Costing)Документ26 страниц(Estimation and Costing)Diksha GuptaОценок пока нет

- OEC 9900 Room Interface ConnectorДокумент1 страницаOEC 9900 Room Interface ConnectorCamilo RodríguezОценок пока нет

- Hilight V5+-Wux918433Документ62 страницыHilight V5+-Wux918433Factoria Santa IsolinaОценок пока нет

- Electric Diagram 80 - 6 - 243364EN - 1 0 0Документ14 страницElectric Diagram 80 - 6 - 243364EN - 1 0 0andraОценок пока нет

- PRO-680DN Box CCTV Camera: With Inter-Changeable Vari-Focal Lens, IR CUT FILTER & Outdoor Housings OptionsДокумент2 страницыPRO-680DN Box CCTV Camera: With Inter-Changeable Vari-Focal Lens, IR CUT FILTER & Outdoor Housings OptionshendraОценок пока нет

- RGP Lens MeasurementДокумент5 страницRGP Lens MeasurementSumon SarkarОценок пока нет

- Tutorial QuestionsДокумент2 страницыTutorial QuestionsAmber MomentОценок пока нет

- Biomedical Instrumentation: COURSE CODE: 15EC1148Документ2 страницыBiomedical Instrumentation: COURSE CODE: 15EC1148hema maliniОценок пока нет

- EODS 65 3 Red OcrДокумент92 страницыEODS 65 3 Red OcrNa ACME67% (3)

- Catalogo Stanley 2016 3Документ8 страницCatalogo Stanley 2016 3Kenki HuemuraОценок пока нет

- Types of SwitchesДокумент5 страницTypes of Switchesameyd2Оценок пока нет

- Din 965Документ10 страницDin 965PacoОценок пока нет

- Lab ReportДокумент7 страницLab ReportRehanNasirОценок пока нет

- Rasb10n3kv2 Series PDFДокумент10 страницRasb10n3kv2 Series PDFSomadbsiОценок пока нет

- JUS Pulling Tool: PurposeДокумент2 страницыJUS Pulling Tool: PurposebenaoudaОценок пока нет

- Multifunctional Digital Heat Press Machine: User GuideДокумент9 страницMultifunctional Digital Heat Press Machine: User GuideREBECCA JOHNSONОценок пока нет

- SP Awb Amaris V1Документ1 страницаSP Awb Amaris V1maunОценок пока нет

- Smart Watch ManualДокумент9 страницSmart Watch ManualMURALEE VEERAMALAIОценок пока нет

- 2012 GEM New Manlift ManualДокумент110 страниц2012 GEM New Manlift Manualoro plataОценок пока нет

- Response House Alarm SA3 ManualДокумент32 страницыResponse House Alarm SA3 ManualCarlos VieitesОценок пока нет

- Digital User ManualДокумент23 страницыDigital User ManualkahandawalaОценок пока нет

- C8 - MillingДокумент16 страницC8 - MillingHans PinonОценок пока нет

- Power Cord With Locking System For Inlet Filters IL 13, IL 13 P, IL 19Документ6 страницPower Cord With Locking System For Inlet Filters IL 13, IL 13 P, IL 19Akash RajanОценок пока нет

- GST Fire Alarm PanelДокумент1 страницаGST Fire Alarm PanelMohammed HaroonОценок пока нет

- Micro BioДокумент6 страницMicro Biobhobot riveraОценок пока нет

- Luk Repair Solution For Clutch Modules: Technology Special Tool / Removal and InstallationДокумент40 страницLuk Repair Solution For Clutch Modules: Technology Special Tool / Removal and InstallationDan MurgoviciОценок пока нет