Академический Документы

Профессиональный Документы

Культура Документы

E193.1207474-1 Norma Astm Micropipetas

Загружено:

Ana Chiaradia100%(1)100% нашли этот документ полезным (1 голос)

120 просмотров6 страницThis standard covers several micropipets useful in measuring microlitre quantities of liquids. The values stated in SI units are to be regarded as standard. This standard has been approved for use by agencies of the department of defense.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis standard covers several micropipets useful in measuring microlitre quantities of liquids. The values stated in SI units are to be regarded as standard. This standard has been approved for use by agencies of the department of defense.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

120 просмотров6 страницE193.1207474-1 Norma Astm Micropipetas

Загружено:

Ana ChiaradiaThis standard covers several micropipets useful in measuring microlitre quantities of liquids. The values stated in SI units are to be regarded as standard. This standard has been approved for use by agencies of the department of defense.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

Designation: E193 94 (Reapproved 2010)

Standard Specication for

Laboratory Glass Micropipets

1

This standard is issued under the xed designation E193; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specication covers several micropipets useful in

measuring microlitre quantities of liquids.

NOTE 1This specication was originally developed by the Committee

on Microchemical Apparatus, Division of Analytical Chemistry, American

Chemical Society.

2,3, 4

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

standard.

2. Referenced Documents

2.1 ASTM Standards:

5

E920 Specication for Commercially Packaged Laboratory

Apparatus

E921 Specication for Export Packaged Laboratory Appa-

ratus

E1133 Practice for Performance Testing of Packaged Labo-

ratory Apparatus for United States Government Procure-

ments

E1157 Specication for Sampling and Testing of Reusable

Laboratory Glassware

3. Nomenclature

3.1 The pipets specied in Figs. 1-3, and Fig. 4 are classied

as micropipets, whereas those in Figs. 5 and 6 are classied as

microlitre pipets in order to differentiate among the various

pipets, not on a technical basis, but rather on the basis of usage.

This is done to prevent confusion that might result from the

fact that the pipets shown in Figs. 1 and 2, and Fig. 3 are listed

in trade catalogs as micropipets designed especially for use in

the elds of biological and clinical chemistry, and the pipets

shown in Fig. 4 are listed as micropipets, density-type, de-

signed for use as microweighing pipets, or pycnometers.

4. Micropipets, Measuring-Type (to deliver)

4.1 The measuring-type micropipets

2,6

are specied in ve

capacities and shall conform to the requirements shown in Fig.

1. The narrow, elongated delivery stem of the pipets can reach

to the bottom of microvolumetric asks,

2,5

permitting almost

complete withdrawal of the contents of the ask. Quantitative

delivery of the entire volume of the pipets is obtained by

touching off the last drop.

5. Micropipets, Folin-Type (to contain)

5.1 The Folin-type

4,6,7

micropipets are specied in two

capacities and shall conform to the requirements shown in Fig.

2. Complete delivery of the volume indicated by the graduation

mark on these pipets is ensured by washing out several times

any solution adhering to the inner surface with wash liquid

drawn up from the tip.

6. Micro Washout Pipets, Pregl-Type (to contain)

6.1 The micro washout pipets, Pregl-type

4,6,8

are specied

in four capacities and shall conform to the requirements shown

in Fig. 3. Quantitative delivery of the volume indicated by the

graduation mark on the pipets is obtained by rinsing out the

contents with wash liquid added from the top of the pipet.

1

This specication is under the jurisdiction of ASTM Committee E41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

Apparatus.

Current edition approved July 1, 2010. Published July 2010. Originally approved

in 1962. Last previous edition approved in 2005 as E193 94 (2005). DOI:

10.1520/E0193-94R10.

2

Committee on Microchemical Apparatus, Division of Analytical Chemistry,

American Chemical Society. Report on Recommended Specications for Micro-

chemical Apparatus, Volumetric Glassware, Flasks, Pipets, and Centrifuge Tubes,

Analytical Chemistry, Vol 28, 1956, p. 1993.

3

Committee on Microchemical Apparatus, Division of Analytical Chemistry,

American Chemical Society. Report on Recommended Specications for Micro-

chemical Apparatus, Volumetric Glassware, Microlitre Pipets, Analytical

Chemistry, Vol 30, 1958, p. 1702.

4

Committee on Microchemical Apparatus, Division of Analytical Chemistry,

American Chemical Society. Report on Recommended Specications for Micro-

chemical Apparatus, Volumetric Glassware, Micropipets, Analytical Chemistry,

Vol 32, 1960, p. 1045.

5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

6

Steyermark, A., Quantitative Organic Microanalysis, 2nd Ed., Academic Press,

New York, NY, 1961.

7

Folin, O., Journal of Biological Chemistry, Vol 77, 1928, p. 421.

8

Grant, J., Quantitative Organic Microanalysis Based on Methods of Fritz Pregl,

5th Ed., Blakiston Co., Philadelphia, PA 1951, p. 34.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

Copyright by ASTM Int'l (all rights reserved); Tue Jul 29 14:19:25 EDT 2014

Downloaded/printed by

Universidade Federal do Espirto Santo pursuant to License Agreement. No further reproductions authorized.

7. Micro Weighing Pipets, Density-Type (Pycnometers)

(to contain)

7.1 The micro weighing pipets, density-type (pycnometers),

4,6,9

with ground-glass caps, are specied in three capacities

and shall conform to the requirements shown in Fig. 4. These

pipets are designed for density determinations on small

amounts of volatile, viscous or hygroscopic liquids. The

decigram size has a capacity of 100 L and is especially

suitable for highly viscous liquids. The centigram size has a

capacity of 40 to 80 L and the milligram size has a capacity

of 10 to 30 L. The centigram and milligram sizes are

graduated in 1-mm divisions, and can be used even when the

total amount of sample available is less than the maximum

9

Alber, H. K., Industrial and Engineering Chemistry, Analytical Edition, Vol 12,

1940, p. 764.

Lining

Capacity, mL

Subdivision,

mL

Interval Graduated,

mL

Ring at Each,

mL

Half Ring

at Each, mL

Number at 0

and Each mL

Tolerance, ,

mL

0.2 0.01 0 to 0.18 0.02 0.01 0.02 0.005

0.5 0.01 0 to 0.45 0.05 0.01 0.1 0.01

1 0.02 0 to 0.90 0.1 0.02 0.1 0.02

2 0.05 0 to 1.75 0.25 0.05 0.5 0.04

3 0.05 0 to 2.70 0.25 0.05 0.5 0.06

Notes:

1. No graduations shall appear in tapered portion.

2. Tip may be tapered at junction with body, but outside diameter at this point may not exceed 4.5 mm.

3. Tip outlet shall be glazed, with least possible constriction.

4. Calibrated to deliver at 20C, touching off last drop.

FIG. 1 Micropipets with Cylindrical Tip

E193 94 (2010)

2

Copyright by ASTM Int'l (all rights reserved); Tue Jul 29 14:19:25 EDT 2014

Downloaded/printed by

Universidade Federal do Espirto Santo pursuant to License Agreement. No further reproductions authorized.

capacity of the micropipet. The sample may occupy any

portion of the graduated stem, thereby eliminating the neces-

sity of making a precise adjustment to a xed calibration mark.

8. Microlitre Pipets (to contain)

8.1 The microlitre pipets

3, 6

are specied in 25 capacities

and shall conform to the requirements shown in Fig. 5 (1 to

5-L capacities) and Fig. 6 (5 to 1000-L capacities). The

dimensions of these pipets are such that they may be used with

micro volumetric asks.

2,5

Complete delivery of the volume

indicated by the graduation mark on the pipets is obtained by

rinsing out several times any solution adhering to the inner

surface with wash liquid drawn up from the tip.

9. Sampling and Testing

9.1 Refer to Specication E1157.

10. Packaging

10.1 Select from Specication E920, E921, or E1133.

11. Keywords

11.1 glass; micropipets

FIG. 2 Micropipets, Folin-Type

E193 94 (2010)

3

Copyright by ASTM Int'l (all rights reserved); Tue Jul 29 14:19:25 EDT 2014

Downloaded/printed by

Universidade Federal do Espirto Santo pursuant to License Agreement. No further reproductions authorized.

FIG. 3 Micro Washout Pipets, Pregl-Type

E193 94 (2010)

4

Copyright by ASTM Int'l (all rights reserved); Tue Jul 29 14:19:25 EDT 2014

Downloaded/printed by

Universidade Federal do Espirto Santo pursuant to License Agreement. No further reproductions authorized.

FIG. 4 Micro Weighing Pipets, Density-Type (Pycnometers)

Capacity, L

A

Over-all Length, mm ID Tubing, mm B D at End, mm C

Min Capacity

Safety Bulb, L

Volume Tol-

erance,

B

%

1 140 5 0.12 to 0.16 0.10 to 0.20 50 1

2 140 5 0.16 to 0.25 0.15 to 0.25 50 1

3 140 5 0.20 to 0.28 0.15 to 0.25 50 1

4 140 5 0.24 to 0.32 0.15 to 0.25 50 1

A

Calibrated to contain.

B

Closer volumetric standardization shall be carried out by the operator with substances under actual conditions of use.

FIG. 5 Microlitre Pipets (1 to 4-L Capacities)

E193 94 (2010)

5

Copyright by ASTM Int'l (all rights reserved); Tue Jul 29 14:19:25 EDT 2014

Downloaded/printed by

Universidade Federal do Espirto Santo pursuant to License Agreement. No further reproductions authorized.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

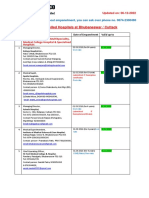

Delivery System

Capacity,

L

A

Over-all

Length,

mm

OD Tubing,

mm A

ID Tubing,

mm B

ID at End,

mm C

Approximate

Length,

mm D

Max OD,

mm E

Min

Length,

mm F

Wall at

End,

mm G

Min

Capacity

Safety

Bulb, L

Volume

Toler-

ance,

B

%

5 140 5 5 to 6 0.18 to 0.25 0.15 to 0.25 6 4 55 0.5 to 0.7 50 0.5

6 140 5 5 to 6 0.18 to 0.25 0.15 to 0.25 65 4 55 0.5 to 0.7 50 0.5

7 140 5 5 to 6 0.18 to 0.25 0.15 to 0.25 65 4 55 0.5 to 0.7 50 0.5

8 140 5 5 to 6 0.18 to 0.25 0.15 to 0.25 65 4 55 0.5 to 0.7 50 0.5

9 140 5 5 to 6 0.18 to 0.25 0.15 to 0.25 65 4 55 0.5 to 0.7 50 0.5

10 140 5 5 to 6 0.20 to 0.35 0.15 to 0.25 65 4 55 0.5 to 0.7 50 0.5

15 140 5 5 to 6 0.25 to 0.40 0.15 to 0.25 65 4 55 0.5 to 0.7 50 0.5

20 140 5 5 to 6 0.35 to 0.50 0.25 to 0.50 65 4 55 0.5 to 0.7 50 0.5

25 140 5 5 to 6 0.35 to 0.50 0.25 to 0.50 65 4 55 0.5 to 0.7 50 0.5

35 140 5 5 to 6 0.35 to 0.50 0.25 to 0.50 65 4 55 0.5 to 0.7 50 0.3

50 140 5 5 to 6 0.35 to 0.50 0.25 to 0.50 65 4 55 0.5 to 0.7 50 0.3

60 140 5 5 to 6 0.40 to 0.55 0.30 to 0.50 65 4 55 0.5 to 0.7 50 0.3

75 140 5 5 to 6 0.40 to 0.60 0.30 to 0.50 65 4 55 0.5 to 0.7 75 0.3

100 140 5 5 to 6 0.50 to 0.75 0.30 to 0.50 65 4 55 0.5 to 0.7 75 0.3

150 140 5 5 to 6 0.75 to 1.00 0.40 to 0.60 65 4 55 0.5 to 0.7 100 0.3

200 145 10 5 to 6 0.75 to 1.00 0.40 to 0.60 65 4 55 0.6 to 0.8 100 0.2

250 145 10 5 to 6 0.75 to 1.00 0.40 to 0.60 65 4 55 0.6 to 0.8 100 0.2

300 145 10 5 to 6 0.75 to 1.00 0.40 to 0.70 65 4 55 0.6 to 0.8 200 0.2

400 150 10 6 to 7 1.00 to 1.25 0.40 to 0.70 70 6 60 0.6 to 0.8 200 0.2

500 160 10 6 to 7 1.25 to 1.50 0.40 to 0.70 70 6 60 0.6 to 0.8 200 0.2

1000 170 10 7 to 8 2.00 to 2.25 0.40 to 0.70 80 7 60 0.6 to 0.8 300 0.2

A

Calibrated to contain.

B

Closer volumetric standardization shall be carried out by the operator with substances under actual conditions of use.

FIG. 6 Microlitre Pipets (5 to 1000-L Capacities)

E193 94 (2010)

6

Copyright by ASTM Int'l (all rights reserved); Tue Jul 29 14:19:25 EDT 2014

Downloaded/printed by

Universidade Federal do Espirto Santo pursuant to License Agreement. No further reproductions authorized.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Anthony Robbins - Time of Your Life - Summary CardsДокумент23 страницыAnthony Robbins - Time of Your Life - Summary CardsWineZen97% (58)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Big Bang Theory EpisodesДокумент24 страницыBig Bang Theory EpisodesBroly dbzОценок пока нет

- Uh 60 ManualДокумент241 страницаUh 60 ManualAnonymous ddjwf1dqpОценок пока нет

- P66 M10 CAT B Forms and Docs 04 10Документ68 страницP66 M10 CAT B Forms and Docs 04 10VinayОценок пока нет

- List of Modern Equipment and Farm ToolsДокумент15 страницList of Modern Equipment and Farm ToolsCarl Johnrich Quitain100% (2)

- India Biotech Handbook 2023Документ52 страницыIndia Biotech Handbook 2023yaduraj TambeОценок пока нет

- Ethiopian Airlines-ResultsДокумент1 страницаEthiopian Airlines-Resultsabdirahmanguray46Оценок пока нет

- Remedy MidTier Guide 7-5Документ170 страницRemedy MidTier Guide 7-5martin_wiedmeyerОценок пока нет

- ProbДокумент10 страницProbKashif JawaidОценок пока нет

- Jurnal 1 Ieevee LPF PDFДокумент4 страницыJurnal 1 Ieevee LPF PDFNanda SalsabilaОценок пока нет

- Bathinda - Wikipedia, The Free EncyclopediaДокумент4 страницыBathinda - Wikipedia, The Free EncyclopediaBhuwan GargОценок пока нет

- Mobile Services: Your Account Summary This Month'S ChargesДокумент3 страницыMobile Services: Your Account Summary This Month'S Chargeskumarvaibhav301745Оценок пока нет

- Lakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoДокумент2 страницыLakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoShivam MishraОценок пока нет

- MQXUSBDEVAPIДокумент32 страницыMQXUSBDEVAPIwonderxОценок пока нет

- Contigency Plan On Class SuspensionДокумент4 страницыContigency Plan On Class SuspensionAnjaneth Balingit-PerezОценок пока нет

- Auto Turn-Off For Water Pump With Four Different Time SlotsДокумент3 страницыAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K100% (1)

- BluePrint & High Pressure Pascalization (HPP)Документ3 страницыBluePrint & High Pressure Pascalization (HPP)Prof C.S.PurushothamanОценок пока нет

- Module 2 TechnologyДокумент20 страницModule 2 Technologybenitez1Оценок пока нет

- What Are Some of The Best Books On Computer ScienceДокумент9 страницWhat Are Some of The Best Books On Computer ScienceSarthak ShahОценок пока нет

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Документ19 страницEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uОценок пока нет

- Bustax Midtem Quiz 1 Answer Key Problem SolvingДокумент2 страницыBustax Midtem Quiz 1 Answer Key Problem Solvingralph anthony macahiligОценок пока нет

- Steel Price Index PresentationДокумент12 страницSteel Price Index PresentationAnuj SinghОценок пока нет

- Controlled DemolitionДокумент3 страницыControlled DemolitionJim FrancoОценок пока нет

- Process Description of Function For Every Unit OperationДокумент3 страницыProcess Description of Function For Every Unit OperationMauliduni M. AuniОценок пока нет

- Effect of Plant Growth RegulatorsДокумент17 страницEffect of Plant Growth RegulatorsSharmilla AshokhanОценок пока нет

- IbmautomtiveДокумент38 страницIbmautomtiveMeltz NjorogeОценок пока нет

- Dash 3000/4000 Patient Monitor: Service ManualДокумент292 страницыDash 3000/4000 Patient Monitor: Service ManualYair CarreraОценок пока нет

- Qualitrol 900 910Документ6 страницQualitrol 900 910chennupati999Оценок пока нет

- Waswere Going To Waswere Supposed ToДокумент2 страницыWaswere Going To Waswere Supposed ToMilena MilacicОценок пока нет

- Shaqlawa Technical College: IT DepartmentДокумент20 страницShaqlawa Technical College: IT Departmentbilind_mustafaОценок пока нет