Академический Документы

Профессиональный Документы

Культура Документы

Dynamic Thermal Modelling and CFD Simulation Tecniques Used

Загружено:

akhilesh120Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dynamic Thermal Modelling and CFD Simulation Tecniques Used

Загружено:

akhilesh120Авторское право:

Доступные форматы

DYNAMIC THERMAL MODELLING AND CFD SIMULATION TECNIQUES USED

TO INFLUENCE THE DESIGN PROCESS IN BUILDINGS

Roberto Padovani

1

Dominique Hes

2

Finbar MacLaughlin

3

1,3

Medland Metropolis, Melbourne Australia

2

Faculty of Architecture, Building and Planning, University of Melbourne, Australia

ABSTRACT

This application paper outlines some innovative

building simulation methodologies used to predict

thermal performance of complex energy efficient

systems using commercially available softwares.

Industry case studies are presented to demonstrate

how simulation can influence the design process with

requirements varying from zero carbon emissions to

optimum thermal comfort.

Simplifications used to reduce computational time

and handle software limitations are assessed in

regards to model accuracy and the ability to influence

the design decision process. Building simulation

models are presented with a fit for purpose approach

from simpler models to detailed HVAC models used

for system performance and thermal comfort

assessments.

Keywords: thermal simulation, CFD, IES VE,

HVAC, Desiccant, Solar, In-slab cooling.

INTRODUCTION

Computer modelling has been extensively used in the

green building industry to predict energy

consumption, thermal comfort and to size HVAC

equipment. The integrated modelling of innovative

green building elements and HVAC systems can

reduce risks, validate and optimise design and predict

thermal performance required for green building and

energy efficiency benchmark for certification such as

Green Star (NZGBC,2011) and NABERS

(NABERS,2011) (National Australian Built

Environment Rating System).

The industry-oriented approach of the case studies

presented in the paper show the ability to model

systems appropriately despite software limitations.

Simulation models are presented using a fit-for-

purpose approach; for example, where

simplifications are applied to keep computational

time and costs low or accuracy levels are set

depending on design stage. Thus, a simpler and faster

model is used when testing concepts while a more

detailed model is used for sizing equipment.

The IES Virtual Environment (VE) software is used

for the building simulation analysis coupled with

solar energy simulations performed in the TRNSYS

software for Photo Voltaic (PV) panels and CPC

solar evacuated collectors sizing and performance

assessment. Some of the software limitations and

their solutions presented in this paper are outlined in

Table 1.

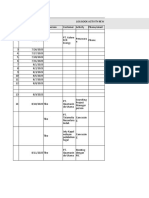

Table 1

Limitations of the software used and approach

applied to minimise their impact

SOFTWARE LIMITATION APPROACH

TAKEN

IES VE

Apache

HVAC

No component

that simulates

desiccant wheels

Multiplex looping

system to simulate

performance data

CFD

module of

IES VE

(Microflo)

Cartesian Grid

mesh, steady-

state,

Segment curves, use

dynamic simulation

for boundary

conditions

IES VE - In-

slab cooling

Adjusted U-value

of concrete slab

cannot be

calculated directly

calculated

separately in the

LBNL software

THERM 6.3

Case studies to illustrate success of approaches to

software limitations

1 Coleman St London

The first case study consists of a server room located

in the commercial building at 1 Coleman St, London,

UK. The objective of this assessment was to

determine the cooling capacity and layout of back-up

DX units serving the Comms Room, through the use

of CFD and dynamic thermal simulation. The CFD

simulation software used for this assessment was the

Microflo module of the IES VE software and the

dynamic thermal simulation was carried out on

Apache Sim module of IES VE software.

The primary Comms Room Air- Conditioning

(CRAC) system serving the room consists of 6 DX

units and one spare DX unit supplying conditioned

air at a total flow rate of 19.8m

3

/s. The conditioned

air is supplied to a sub-floor void that delivers air via

multiple floor grilles located between server cabinet

rows. In the event of the primary system breakdown,

the system will continue to operate in order to

circulate air via floor grilles. The secondary backup

system is then enabled to maintain the server room

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 231 -

temperature below 30

o

C for a minimum of 4hrs to

allow for repairs of the main system to be completed.

The layout of the primary and secondary cooling

system is shown in Figures 1 and 2.

The total maximum server load is 116 kW and

lighting load of 12W/m

2

with a layout as shown in

the CFD model (Figure 3): The total conditioned area

of the room is 667 m

2

and total volume is 635m

3

.

Figure 1 Up flow DX Units configuration

Figure 1 Down flow DX Units configuration

Figure 3 Microflo CFD model of the server room

Main approach, lessons and outputs of the modelling

The limitations of the meshing geometry simulation

in IES VE Microflo drove some simplifications of

the model to allow for convergence of residual values

within a reduced timeframe:

Cartesian grid meshing: Sloping walls of server

room were designed with a stepped geometry to

maintain grid cell aspect ratio under 10:1

CFD Microflo module can only run steady state

analysis which required dynamic thermal

simulation done on a simpler Apache model

Floor grille geometry was not feasible to be

executed in Microflo with an integrated subfloor

void space and air recirculation through chiller

DX units. The limitation faced in the creation of

this CFD geometry was the impossibility of

having multiple floor holes that were required to

add fans as boundary conditions. It was

imperative that entire geometry was congruent

and aligned with grid meshing.

The simplified geometry was developed with larger

floor holes between server cabinet rows and a series

of fans added as boundary conditions. Fans were

added in the same location as the floor grilles and

with a supply air flow rate of 0.47m3/s which is

equivalent to the total air flow rate of 19.7m3/s

divided by the total number of floor grilles. The

cubic equation for the fan performance curve was

simplified with all coefficients set to zero to create a

constant velocity profile independent of pressure.

The areas within the holes created on the floor

partitions where there are no fans have been filled by

highly dense porous baffle boundary condition to

simulate a solid floor surface. The pressure drop

equation used for the porous baffle in the model

followed the Darcys Law (IESVE,2011):

Ap ! -o [

u

"

1

2

Cp#0# 0 (1)

where a is the baffle thickness, C is the pressure jump

coefficient and o is the permeability. The fluids

viscosity, density and velocity are given by p, p and

0 respectively. The above equation is defined in IES

VE Microflo in the following form:

Ap ! %C

1

"C

2

#0#&0 (2)

The equation used in this model had the following

coefficients to maintain a high-pressure drop in any

condition in order to simulate a solid barrier:

C

1

! '(( Po -

s

m

) C

1

! -'Po -

s

2

m

2

(3)

Air recirculation set-up via sub-floor void connected

to adjacent room where CRAC units are located. All

room are joined in IES VE Microflo using create

multi-partition function with air supply and extract

grilles are modelled as openings on surfaces.

The objective of this assessment was to evaluate two

configurations of conditioned air flow supply: an

upflow direction where air is supplied at ceiling level

and down flow where conditioned air is supplied at

above floor level. In addition to that, an optimisation

of the air flow rate was required to be determined in

order to maintain a maximum average air

temperature of 30

o

C for a minimum of 4 hours. Due

to the impossibility of simulating dynamical thermal

behaviour in the Microflo module, it was necessary

to run the dynamic thermal simulation in the Apache

Sim module prior to the CFD simulation to determine

critical room hourly temperature profile and

associated boundary conditions. The below diagrams

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 232 -

shows the server room layout with primary and back

up cooling units location (Figures 4,5 and 6).

Figure 4 Primary and secondary cooling layout

Figure 5 Floor grille diffusers configuration

Figure 6 Fan and Porous baffle setup

The CFD analysis had a high level of complexity due

to the configuration of two cooling systems with air

recirculation provided by primary system at floor

level through multiple floor diffusers and cool air

supplied by secondary system. The grid meshing had

to be set up very fine with minimum cell size of

0.07m to be able to detail air flow passing between

server cabinets and through floor diffusers. The

model had also to be simplified with a stepped

approximation of the north sloping wall. The total

number of iterations to achieve acceptable levels of

numerical convergence was 6,000 iterations.

The CFD results indicated that the layout of the DX

cooling system was not initially efficiently designed

to deliver cool air in a balanced way to the comms

room space. The reason behind the poor air flow

distribution is the close proximity between the supply

and return air grilles that leads to short circuiting the

air flow of cool air. However, this system can be

acceptable if requirement is only to operate

secondary cooling system for a minimum number of

hours to allow for repair of the primary chiller

system. The CFD plots indicated that the upflow DX

unit configuration is the most efficient to cool the

room when back-up system is required. The total

supply air flow of the secondary back-up system was

optimized to 9,600L/s with a total cooling capacity of

111.9kW and supply air temperature of 15

o

C.

Figure 7 and 8 below demonstrates the output

presented to the client in the final report of this

particular project, illustrating the secondary cooling

units operation during a primary cooling system

breakdown.

Figure 7 Temperature plot at z plane 1.5m above

finished floor: upflow configuration

Figure 8 Air velocity contour plot at z plane 1.5m

above finished floor: upflow configuration

This case study demonstrated that a simplified CFD

model using the limited software resources available

for this application could be sufficient to influence

design decision significantly. The sizing of the

secondary back-up DX units, air flow rates and

location were optimized and design validated to

operate according to client specifications.

2 University of Queensland Global Change

Institute

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 233 -

The Global Change Institute building is located in the

University of Queensland campus and has been

designed with several solar passive and renewable

energy solutions to achieve a zero or possibly a

negative carbon operational capability by exporting

electricity back to the grid.

The key features of this landmark project are:

Thermal labyrinth to pre-cool outside air;

An air-handling unit with integrated latent

and sensible heat recovery wheels and a

desiccant wheel for cooling of the process

air. Desiccant wheel heat supplied by hot

water delivered by Evacuated Compound

Parabolic Collectors (CPC) solar collectors;

Cooled air delivered at subfloor level via

floor grilles;

In-slab cooling and passive chilled beams

with chillers energy supplied by solar PV

panels located on rooftop;

Natural ventilation and wide temperature

band.

Main approach, lessons and outputs of the modelling

The University of Queensland Global Change

Institute presented challenges to model and integrate

all the HVAC elements due to the complexity of the

systems and the unavailability of a solar hot water

collector and desiccant wheel model in IES VE

Apache HVAC module, which limited a full dynamic

simulation.

The air handling unit in this building consists of a

latent and sensible heat recovery wheel, followed by

a desiccant wheel and a sensible heat recovery wheel.

Fresh intake air is pre-cooled by an underground

labyrinth and further cooled by air handling unit

before being delivered to conditioned spaces at

subfloor level via floor grilles. Desiccant wheel heat

is supplied by hot water from roof top CPC

evacuated solar collectors with an array of

305m2.The diagram of the entire system is shown on

the image below. The air temperature and moisture

content shown on the diagram and points (a) to (m) is

only one point of the performance curves of this

system.

The proposed CPC (compound parabolic collector)

evacuated collectors with a total array of 412m2 and

a supply return water flow rate of 1.6L/s were

modelled in TRNSYS 16 to size stratified hot water

storage tank , optimise solar collector area and solar

collector installation angle. The objective of this

solar energy model was to ensure supply of water at

90

o

C to the desiccant wheel in order to provide

maximum cooling during peak summer loads. Based

on the solar collector simulation results, a simplified

annual profile was created in IES VE to simulate the

input water temperature into the desiccant wheel. The

annual hot water temperature profile was based

around discretized temperatures of 60

o

C, 70

o

C, 80

o

C

and 90

o

C to reduce the number of points generated

for the desiccant wheels performance curve.

Figure 9 below shows the detailed diagram of the

complete air-handling system:

(1) Energy recovery wheel (1) with a sensible

effectiveness of 86.2% and latent

effectiveness of 82.6%;

(2) Desiccant wheel (2) with a sensible

effectiveness of 65.2% and a latent

effectiveness of 0% (moisture added by

cooling coil/ heating coil combination

instead);

(3) Sensible heat recovery wheel (3) with a

sensible effectiveness of 82% and a latent

effectiveness of 0%;

(4) Humidifiers and heating coils from CPC

evacuated solar collectors hot water system.

Figure 9 Air Handling system schematics

The desiccant wheel was modelled with a sensible

heat recovery component and a cooling and heating

coil to dehumidify the air. Manufacturing

performance test data for 140 points were supplied

by Seibu Giken (2011) with varying conditions of

process air inlet temperature and moisture content

and solar collector hot water temperature. Seibu

Giken (2011) performance data was based on

manufacturing testing and simulation results.

The desiccant wheel performance data was entered in

Apache HVAC with a Multiplex loop of 140

adiabatic rooms. A controller measuring inlet process

air temperature and moisture content, and hot water

temperature diverts the air flow in the correct air

stream of the Multiplex desiccant wheel loop. Two

dummy rooms had to be added to the geometry of the

model to allow for temperature and moisture content

readings in different points of the system. The

temperature and moisture content of the process air

outlet immediately after the desiccant wheel cooling

were specified based on manufacturers performance

data and calculated using a weekly profile and a

formula derived from a linear regression of combined

points with same process air inlet temperature.

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 234 -

Additional cooling is provided by in-slab cooling

coils and passive chilled beams with cold water

supplied by chillers powered by PV panels. The

undulated variable thickness of the slabs required a

finite element calculation of the equivalent

conductivity of the material, using THERM 6.3 from

the Lawrence Berkeley National Laboratory (LBNL)

(shown in Figure 10). The chilled slabs were

modelled as individual thermal zones with a

maximum height of 1mm to minimise the effect of

air volume. Chilled Ceiling components from Apache

HVAC were used to simulate the water cooling effect

by setting the hydronic cooling component to 100%

convective. This methodology for in-slab cooling

was developed from the report of Moore (2008).

Figure 10 U-value calculation of chilled slab

The results of the Global Change Institute HVAC

model were assessed with regards to the simulation

accuracy of the desiccant wheel model to the

manufacturers performance curve data. The

simulation results of the in-slab cooling radiant

output into conditioned zones were also used to

calculate thermal comfort indicators required for

Green Star submission (ASHRAE 55-2004 thermal

comfort criteria for naturally ventilated spaces)

(ASHRAE,2004).

Graph 1 below shows the operation of the desiccant

wheel on a typical summer day with delta

temperature of air inlet and outlet to desiccant wheel

system.

Graph 1 Plot of supply and ambient air temperature

The IES VE HVAC model of the University of

Queensland Global Change Institute was a crucial

part of the system design and sizing due to little

industry experience with the integration of the solar

thermal collectors with the desiccant wheel system

(which does not have constant latent heat transfer

effectiveness). Therefore the energy model has

influenced the design greatly and gave great

confidence to the design team that the thermal

comfort levels of a proposed naturally ventilated

Zero Carbon building, without an active air

conditioning system, would be acceptable for an

educational institution. The desiccant wheel model

in itself dealt with the software limitation of constant

latent heat effectiveness by mapping the performance

curve of 140 points in a multiplex loop with cooling

and heating coils to dehumidify the air. The deviation

of the modelled desiccant wheel system to the

manufacturers testing data was 3.7% for the air

temperature leaving the desiccant wheel and 12% for

the relative humidity at the same point.

The solar thermal collectors (CPC evacuated tubes)

simulation has also influenced the sizing of the

system and validated the requirements of hot water

supply to the desiccant wheel. An annual temperature

plot of the hot water temperature simulated in the

TRNSYS 16 model is shown below, in Graph 2, with

clear indication that water temperature would be

peaking above 90

o

C from December to February

(summer months in the Southern Hemisphere).

Graph 2 TRNSYS hot water temperature to

desiccant wheel

5.1137 Bottom Thermal transmittance or U-value of slab and tubes at 10 K delta-T, W/m

2

-K

0.1956 Overall resistance, including water film, tubing, and air film at exposed surface, m

2

-K/W

0.1067 Air film resistance on exposed cooling surface, m

2

-K/W

0.0003 Water-film resistance at tubing inside surface (forced convection, 1.8 m/s flow), m

2

-K/W

0.0886 Resistance for slab plus Polybutylene tubing without air or water films, m

2

-K/W

3.3166 Top Thermal transmittance or U-value of slab and tubes at 10 K delta-T, W/m

2

-K

0.3015 Overall resistance, including water film, tubing, and air film at exposed surface, m

2

-K/W

0.1067 Air film resistance on exposed cooling surface, m

2

-K/W

0.0003 Water-film resistance at tubing inside surface (forced convection, 1.8 m/s flow), m

2

-K/W

0.1945 Resistance for slab plus Polybutylene tubing without air or water films, m

2

-K/W

Adjusted conductivity using THERM 2-D heat transfer model GCI

12.0 Hydronic tubing inside diameter, mm

2.5 Hydronic tubing wall thickness, mm

0.134 Hydronic tubing spacing in the slab, m

0.384 Hydronic tubing conductivity (Polybutylene tubing), W/m-k

1.40 Slab conductivity, W/m-K

2.0118 Total Thermal transmittance or U-value of slab and tubes at 10 K delta-T, W/m

2

-K

0.4971 Overall resistance, including water film, tubing, and air film at exposed surface, m

2

-K/W

0.2135 Air film resistance on exposed cooling surface, m

2

-K/W

0.0006 Water-film resistance at tubing inside surface (forced convection, 1.8 m/s flow), m

2

-K/W

0.2830 Resistance for slab plus Polybutylene tubing without air or water films, m

2

-K/W

3.533 Conductance for slab plus Polybutylene tubing without air or water films, W/m

2

-K

0.295 Slab thickness at perpendicular heat transfer path (center of tubes to cooling surface), m

1.042 Adjusted conductivity for chilled slab material in VE model, W/m-K

89% Faction of adjusted conductivity value obtained using simple spreadsheet model

00:00 06:00 12:00 18:00 00:

35

30

25

20

15

10

5

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Date:Thu14/Jan

Air temperature: node15/0(gci vav140611complete.aps) Air temperature: node4/0(gci vav140611complete.aps)

Desiccant Wheel

Air Intake

Supply air

temperature

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 235 -

The U value adjustment of the chilled concrete slabs

had also to be simplified due to the sloping cross

section. The U-value adjustment calculated by

THERM 6 via finite element analysis was used to

calculate the conductivity value (k) of the pre-cast

concrete material dividing the overall cross section

area by its length to obtain an average height.

c) Quad5 - Auckland International Airport

The Quad5 Auckland International Airport building

is a landmark green building project aiming for a 5

star Green Star New Zealand Office 2009

(NZGBC,2011) certification in 2011. This 5 storey

building has a total Green Star assessable area of

4024 m2 consisting of office spaces in the upper

floors, cyclist facilities and change rooms in the

basement level and a caf/reception in the first level.

The base building HVAC model presented in this

paper is a VRF system with sensible heat recovery

integrated to outdoor air handling units. The VRF

condenser heat recovery and part load performance

model was entirely modelled in the Apache HVAC

module of IES VE. A detailed HVAC model was

required to maximise the number of credit points

achieved under Energy and GHG emissions by

reducing the margin of error in the HVAC system

model.

Figure 11 - IES VE model geometry of Quad5 -

Auckland International Airport

Main approach, lessons and outputs of the modelling

This case study shows an example of the

simplification of the architecture geometry created in

REVIT with core and perimeter zones, as shown on

Figures 13, 14, 15 and 16. The HVAC model has a

fresh air intake tampered with return air via a

sensible heat recovery element. The HVAC system

comprises of a Variable Refrigerant Flow (VRF)

system with condenser heat recovery loops. The part-

load performance of the VRF outdoor units were

entered in the IES VE Apache HVAC model as a DX

cooling component and heat pump connected to

cooling and heating coils respectively.

The interior spaces of this building presented a high

level of complexity with spiral staircases, enclosed

offices throughout and a high degree of complexity

of the exterior shading devices. As an example, the

detailed architecture level 2 floor plan, shown on

Figure 12 below, was changed to a much more

simplified energy model with core, north and south

perimeter zones. Exterior shading devices on the

other hand have been drawn as per Revit architecture

model to minimise uncertainties in the solar gains

and shading calculations.

Figure 12 - Quad5 Level 2 Floor Plan

Figure 13 - Quad5 Level 1 - Green Star assessed

area: 435m2

Figure 14 - Quad5 Level 2 - Green Star

assessed area: 1748m

2

Figure 15 - Quad5 Level 3 - Green Star assessed

area: 1374m

2

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 236 -

Figure 16- Quad5 Level 4 - Green Star assessed area:

1250m

2

The Apache HVAC model shown below (Figure 17)

has a series of 5 outdoor heat pumps used for the

heating side of the VRF system and air handling units

and are connected to the heating coils elements. The

cooling side of the VRF system and air handling

units comprises of DX components connected to the

cooling coils. The air-conditioned zones are

multiplexed around the supply and recirculation air

loop with air return from conditioned zones directed

to ceiling void spaces. A series of controllers are

used to specify air flow rates and required

temperature after coils and heat recovery temperature

targets.

Figure 17-IES VE Apache HVAC model of VRF

system with condenser heat recovery, outside air

sensible heat recovery and economy cycle

The energy report of this project was a requirement

for the Green Star New Zealand 2009

(NZGBC,2011) submission and therefore the VRF

system was modelled as per manufacturers part-load

performance testing data. The results were

significantly important to the client as it indicated the

VRF system was not shifting heat from cooling zones

to heating zones due to overlapping with sensible

heat recovery in early mornings and late afternoons.

There was not sufficient overlapping of heating and

cooling requirements to justify a VRF condenser heat

recovery strategy.

PMV analysis was also carried out to assess thermal

comfort credit. Based on IES VE model, changes to

the original HVAC layout were introduced to

improve PMV levels from within range of -1 and 1

to -0.75 and 0.75.The design was fully validated final

energy model result predicted a 5 star Green Star

rating.

Graph 3 shows a typical winter day with results

showing a small VRF heat recovery of 0.23kW at

2.30pm and a much greater sensible heat recovery

from heat recovery wheel that peaked at 5.6kW at

10am.

Graph 3 Sensible and condenser heat recovery plot

Graph 4 below shows the dry resultant temperature

of the two perimeter zones and the core zone on level

3 for a typical summer day. The perimeter zone

facing the northeast direction has a higher predicted

temperature during the day due to higher solar gains

through windows. This is the reason the model was

simplified and divided in core and perimeter zones to

avoid averaging of higher temperatures near

windows and lower temperatures away from

windows.

Graph 4 Plot of core and perimeter zones

temperature for a typical summer day

SUMMARY OF MAIN POINTS OF

INTEREST

CS1 CS2 CS3

CuLllne 1 Coleman sL uC - CCl Auckland

AlrporL

Alm slze sysLem slze sysLem/

Lhermal

comforL

Creen

SLar

reporL

LlmlLaLlons CarLeslan

grld,sLeady-

sLaLe

PvAC

model

llmlLaLlons

Complex

archlLecL's

model

SoluLlons

applled

SegmenL

curves, use

dynamlc

slmulaLlon for

boundary

condlLlons

MulLlplex

looplng

sysLem Lo

slmulaLe

LesLlng daLa

Slmpllfled

Lhermal

zones Lo

core and

perlmeLer

00:00 06:00 12:00 18:00 00:00

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

T

e

m

p

e

r

a

t

u

r

e

(

C

)

16

14

12

10

8

6

4

2

0

S

y

s

l

o

a

d

(

k

W

)

Date:Thu24/Jun

Dry-bulbtemperature: (AucklandIWEC.fwt)

ApHVACrecoveredsensibleheat: (quad5_110211final complete.aps)

ApHVACrecoveredchiller heat: (quad5_110211final complete.aps)

00:00 06:00 12:00 18:00

26

24

22

20

18

16

14

12

10

8

6

4

2

0

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Date:Thu25/Feb

Dryresultant temperature: Level 3OpenPlanPerimeter SW(quad5_110211final complete.aps)

Dryresultant temperature: Level 3OpenPlanPerimeter SE(quad5_110211final complete.aps)

Dryresultant temperature: Level 3OpenPlanCentreSouth(quad5_110211final complete.aps)

Dry-bulbtemperature: (AucklandIWEC.fwt)

Recovered

sensible heat

peaks at 5.6kW

Ambient

temperature

Condenser heat

recovery peaks

at 0.3 kW

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 237 -

Maln

lesson

CongruenL

geomeLry

use of

mulLlplex

for mulLlple

efflclency

paLhs

Model

acLual

Lhermal

zones

CONCLUSION

This industry application paper demonstrated the

successful development of innovative models using a

combination of different simulation software

algorithms and outputs to work around software

limitations. A case study of a desiccant wheel

system, using existing components in IES VE and

detailed performance data from manufacturer,

illustrated how results could validate system design

and influence the design process. The maximum

deviation of 12% for the relative humidity of the air

leaving the desiccant wheel was due to the

approximation of the dehumidification process with

cooling and heating coils in series. Further

development to the methodology developed by

Moore (2008) with regards to in-slab cooling and

adjusted concrete U value was also achieved. A

complete integration with the solar collectors

performance was achieved by exporting results from

TRNSYS into IES VE.

Simplifications of the CFD and HVAC models were

necessary to achieve reliable results within a reduced

timeframe, which is imperative from a business case

and productivity standpoint. The industry-driven

approach of the case studies presented in this paper

demonstrated the ability to model systems and

solutions despite software limitations. Building

simulation models are presented with a fit for

purpose approach where simplifications are essential

to keep computational and development costs low

and model accuracy specific for each application. It

is demonstrated that a simpler CFD model with

Cartesian grid coupled with dynamic thermal models

are sufficient to test conceptual solutions

performance. On the other far more complex HVAC

models that incorporate heat recovery processes,

part-load VRF performance, airflow balance to

conditioned zones, dehumidification process and

control systems are required to predict annual energy

consumption for Green Star NZ (NZGBC,2011) and

NABERS (NABERS,2011) certification or system

sizing.

In all case studies, the approach for modelling was

customised to achieve the right outcome with regards

to influencing the design decision. The simulations

detailed in this paper are industry case studies using

commercial softwares and do not have an academic

nature in terms of modelling the governing equations

of dehumidification, adsorption and heat transfer

processes. Future work can be developed to identify

errors and risks associated with simplification of

models when compared with actual post-occupancy

data of thermal and system performance. IES VE

simplified CFD and HVAC models could be

compared to far more sophisticated simulation tools

such as ANSYS FLUENT and Matlab/Simulink for

validity of results and accuracy.

REFERENCES

ASHRAE (2004) Thermal Environmental Conditions

for Human Occupancy, American Society of

Heating, Refrigerating and Air-Conditioning

Engineers Atlanta, USA.

IESVE (2011) Microflo Users manual.

MOORE, T. (2008) Simulation of Radiant Cooling

Performance with Evaporative Cooling Sources.

http://www.cbe.berkeley.edu/research/pdf_files/

Moore2008-RadCool Simulations.pdf accessed

23rd May 2011.

NABERS (2011) National Australian Built

Environment Rating System. IN

GOVERNMENT, N. (Ed.). Sydney, Australia.

NZGBC (2011) New Zealand Green Star Office

2009. IN COUNCIL, T. N. Z. G. B. (Ed.).

Auckland, New Zealand.

SEIBU-GIKEN (2011) Seibu Giken http://seibu-

giken.com/eg/index.php accessed 23rd May 2011.

Proceedings of Building Simulation 2011:

12th Conference of International Building Performance Simulation Association, Sydney, 14-16 November.

- 238 -

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- MhamotdesДокумент30 страницMhamotdesakhilesh120Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Ape030 Bennion 2011 oДокумент28 страницApe030 Bennion 2011 oakhilesh120Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- PSB Series - Lit - V1.2.1 UpdatedДокумент2 страницыPSB Series - Lit - V1.2.1 Updatedakhilesh120Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Mi 150084Документ11 страницMi 150084akhilesh120Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- EGU21 668 PrintДокумент1 страницаEGU21 668 Printakhilesh120Оценок пока нет

- Design and Construction of An Evaporative Cooling System For The Storage of Fresh TomatoДокумент10 страницDesign and Construction of An Evaporative Cooling System For The Storage of Fresh Tomatoakhilesh120Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Designs 07 00007 v2Документ22 страницыDesigns 07 00007 v2akhilesh120100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- 24 Sample ChapterДокумент14 страниц24 Sample ChapterRomyMohanОценок пока нет

- Notes MechV PDFДокумент21 страницаNotes MechV PDFzamburittiОценок пока нет

- Vibration Analysis in Reciprocating CompressorsДокумент11 страницVibration Analysis in Reciprocating Compressorsakamalapuri388Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- PDS STAAD Advanced Concrete Design LTR EN LR PDFДокумент2 страницыPDS STAAD Advanced Concrete Design LTR EN LR PDFSYED FAROOQUDDINОценок пока нет

- Outokumpu Steel Grades Properties Global StandardsДокумент20 страницOutokumpu Steel Grades Properties Global StandardsLance BlackstarОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 7 Introduce Tekla Open API PDFДокумент34 страницы7 Introduce Tekla Open API PDFakhilesh120Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- ReinforcedConcreteBuildingModelingbyStaad ProExample 1Документ7 страницReinforcedConcreteBuildingModelingbyStaad ProExample 1akhilesh120Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- 06 Eurocodes Steel Workshop WALDДокумент136 страниц06 Eurocodes Steel Workshop WALDIonut SavaОценок пока нет

- Vibration Analysis in Reciprocating CompressorsДокумент11 страницVibration Analysis in Reciprocating Compressorsakamalapuri388Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Acoustic Applications in Mechanical Engineering:: Structure-Borne Sound Versus Air-Borne SoundДокумент0 страницAcoustic Applications in Mechanical Engineering:: Structure-Borne Sound Versus Air-Borne SoundArturas TadzОценок пока нет

- 14 S06-016Документ9 страниц14 S06-016akhilesh120Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 7-75-0027 Rev 5 PDFДокумент1 страница7-75-0027 Rev 5 PDFakhilesh120Оценок пока нет

- Excel Detail DesignДокумент7 страницExcel Detail DesignKishore KrishnanОценок пока нет

- Mechanical Vibrations Lecture NotesДокумент133 страницыMechanical Vibrations Lecture NotesHarrison AdemuОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Vibration Analysis in Reciprocating CompressorsДокумент11 страницVibration Analysis in Reciprocating Compressorsakamalapuri388Оценок пока нет

- Automation of Design Process Using Etabs, Microsoft Excel and AutoCADДокумент13 страницAutomation of Design Process Using Etabs, Microsoft Excel and AutoCADakhilesh120Оценок пока нет

- Declare OpenSTAADДокумент34 страницыDeclare OpenSTAADAnonymous JZFSB3DОценок пока нет

- Analysis and Design of RC BeamДокумент6 страницAnalysis and Design of RC Beamakhilesh120Оценок пока нет

- Analysis and Design of Reinforced Concrete Beams and Columns Using Open STAADДокумент6 страницAnalysis and Design of Reinforced Concrete Beams and Columns Using Open STAADAnuj ChaudharyОценок пока нет

- Force and Bending MomentДокумент115 страницForce and Bending MomentMani KrishnaОценок пока нет

- A Decision Support Tool For Predicting The Impact of Development Process ImprovementsДокумент25 страницA Decision Support Tool For Predicting The Impact of Development Process Improvementsakhilesh120Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Get Max Bending MomentДокумент1 страницаGet Max Bending Momentakhilesh120Оценок пока нет

- Pds Staadpro LTR 0617 HR FДокумент2 страницыPds Staadpro LTR 0617 HR FMassa SebatianОценок пока нет

- I-V Characterization of Tunnel Diodes and Multojunction Solar CellsДокумент7 страницI-V Characterization of Tunnel Diodes and Multojunction Solar CellsMaura MusioОценок пока нет

- User Manual: Where Sun Shined Power Always OnДокумент20 страницUser Manual: Where Sun Shined Power Always OnАнатолий ЯновскийОценок пока нет

- Power System AnalysisДокумент3 страницыPower System AnalysisbeshoyabdouОценок пока нет

- Electromagnetism Session 2 QuestionsДокумент80 страницElectromagnetism Session 2 QuestionsJohn English100% (1)

- Cannot Be Located Taxpayers Master List 12152016 PDFДокумент78 страницCannot Be Located Taxpayers Master List 12152016 PDFHanabishi Rekka100% (1)

- Prepared by Ray Delaforce For Internal Use OnlyДокумент20 страницPrepared by Ray Delaforce For Internal Use OnlyEdwin MariacaОценок пока нет

- Q1 - LESSON 5 Student's NameДокумент3 страницыQ1 - LESSON 5 Student's NameNGUYỄN THẾ VIỆT QUANGОценок пока нет

- Operating Procedure ERLDCДокумент154 страницыOperating Procedure ERLDCbramhanand vermaОценок пока нет

- Omid Beik PHD ThesisДокумент333 страницыOmid Beik PHD ThesisMuhammad Sohaib ShahidОценок пока нет

- CURICULUM VITAE - Koko SantanaДокумент2 страницыCURICULUM VITAE - Koko SantanaRiesky FirdyanОценок пока нет

- Tariff Order 2019-20Документ398 страницTariff Order 2019-20Raghu VallabhuОценок пока нет

- Building Utilities Mock Test QuestionnairesДокумент22 страницыBuilding Utilities Mock Test QuestionnairesJames AsasОценок пока нет

- CG Industrial Product OverviewДокумент12 страницCG Industrial Product Overviewvanessa quispeОценок пока нет

- Log Book ActivityДокумент15 страницLog Book ActivityGus BisantikoОценок пока нет

- Spring Summer 2023 Technical Exams ListДокумент10 страницSpring Summer 2023 Technical Exams ListAshraf BadrОценок пока нет

- Eutectic System - WikipediaДокумент10 страницEutectic System - Wikipediasterling goinОценок пока нет

- Reprocessing of Aluminum Chips by Hot Backward Extrusion Seminar Report 2016Документ15 страницReprocessing of Aluminum Chips by Hot Backward Extrusion Seminar Report 2016HARI KRISHNAN GОценок пока нет

- Electrical Submersible Pumps DesigningДокумент17 страницElectrical Submersible Pumps Designingdhulfikarfadhil100% (1)

- Chemical BondingДокумент6 страницChemical BondingNoongju AbdullahОценок пока нет

- Powerplant SyllabusДокумент2 страницыPowerplant SyllabusATHARV BANSALОценок пока нет

- SME Management - MGT601 Spring 2009 Assignment 03Документ3 страницыSME Management - MGT601 Spring 2009 Assignment 03Rana Muhammad Arif KhanОценок пока нет

- Monthly Equ. Report (21-05-11 To 20-06-11) 1Документ103 страницыMonthly Equ. Report (21-05-11 To 20-06-11) 1sivathegrateОценок пока нет

- Exchanger Inspection 101Документ19 страницExchanger Inspection 101se1007100% (3)

- Coal Pulverising in Boilers 1Документ96 страницCoal Pulverising in Boilers 1Babu AravindОценок пока нет

- Phys 1111 SygsuДокумент4 страницыPhys 1111 SygsuLeporeОценок пока нет

- Hsslive Xi Chem Prvs QN 6. ThermodynamicsДокумент5 страницHsslive Xi Chem Prvs QN 6. ThermodynamicsmazinhussainkОценок пока нет

- Lightning Protection CalculationДокумент14 страницLightning Protection Calculationgepewin2009100% (1)

- Labphys 6Документ4 страницыLabphys 6Edyson CitraОценок пока нет

- Physics Class Xii Sample Paper Test 01 For Board Exam 2023 AnswersДокумент18 страницPhysics Class Xii Sample Paper Test 01 For Board Exam 2023 AnswersGyan BardeОценок пока нет

- The lEE Regulations, BS 7671 and This Guide PDFДокумент259 страницThe lEE Regulations, BS 7671 and This Guide PDFatramanathanОценок пока нет

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetОт EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetРейтинг: 4.5 из 5 звезд4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОценок пока нет

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОт EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОценок пока нет

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Geotechnical Engineering Calculations and Rules of ThumbОт EverandGeotechnical Engineering Calculations and Rules of ThumbРейтинг: 4 из 5 звезд4/5 (17)