Академический Документы

Профессиональный Документы

Культура Документы

Smart Solutions - Helping Mechanical Contractors

Загружено:

Donnie GilmoreОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Smart Solutions - Helping Mechanical Contractors

Загружено:

Donnie GilmoreАвторское право:

Доступные форматы

14

To keep pace with fierce competi-

tion, Boston-based J .C. Cannistraro

has found creative ways to lever-

age building information modeling

(BIM) solutions from Technical Sales

International (TSI) to the fullest poten-

tial and, in turn, push savings and

productivity to new levels. The com-

bination of CAD-Mech and J OB-Site

Solutions software with the Trimble

Total Station from TSI produces con-

struction-ready models that enable

W H A T S I N S I D E

11

J.C. Cannistraro

Improves Jobsite

Productivity Using TSI

BIM Solutions

SMART SOLUTIONS

H e l p i n g c o n t r a c t o r s s a v e mo n e y a n d e n h a n c e p r o d u c t i v i t y

S

U

M

M

E

R

2

0

1

1

Victaulic Helps 4 Js Plumbing, Fresh Meadow

Mechanical, and KSW Complete the 9/11 Memorial

for 10-Year Anniversary Opening

To keep the National September 11

Memorial on track to open on the 10th

anniversary of the 2001 terrorist attacks,

contractors 4 Js Plumbing & Heating

Corp., Fresh Meadow Mechanical Corp.,

and KSW, Inc., turned to Victaulic. For

two enormous reflecting pools with

waterfalls of an unprecedented sizeand

an incredibly tight timeframe4 Js

Plumbing and Fresh Meadow Mechanical

needed a reliable piping solution they

could install quickly. KSW not only faced

time constraints but also space constraints

that prohibited them from using a welded

solution for a heating and cooling system

to keep the bronze name plaques at mod-

erate temperature year-round.

Victaulic was the piping system of choice

to meet the compressed construction

schedule, reduce total installation costs,

accommodate expansion and contrac-

tion, ease future system maintenance, and

New York-based contractors 4 Js Plumbing, Fresh Meadow Mechanical, and KSW did their part to keep the

National September 11 Memorial project on track by using Victaulic piping and couplings to meet the com-

pressed construction schedule and reduce total installation costs.

Cannistraro crews use data from the TSI CAD-

Mech software to identify each hanger, then

rolling racks with several hundred hangers are

sent out to the field and rolled to the appropri-

ate section of the building. Cannistraro saves

time and money by installing entire floors

of hangers before a piece of pre-fab pipe is

brought on the job.

3

North, Anvil Score Big Savings on Super Bowl Project .............. 3

D.V. Brown Teams with Johnson Controls to Cut Energy Costs ...... 8

Shinn Increases Productivity with Miller Electric, Get the Point ... 10

Kirk Williams and Grinnell Cut Costs on Air Force Base ............ 14

TJ Dyer Cuts Labor Costs by 20 Percent with Aquatherm ......... 15

continued on page 6

Small Effort in the Office

Translates to Big Savings Onsite

continued on page 4

Time-Saving Tools Are In Demand

This issue of Smart Solutions demonstrates the continuing

demand for products and services that save time and trimlabor

costs to meet ever-tightening deadlines.

Time is Money

High-profile projects can have especially demanding schedules.

In this issue, see how Kirk Williams Company relied on

Grinnell to complete the new Wright-Patterson Air Force Base

Human Performance Wing. New York-based 4 Js Plumbing,

Fresh Meadow Mechanical, and KSW kept the National

September 11 Memorial project on track by using Victaulic

products, while Anvils Gruvlok products allowed North Mechanical to keep the new

Indianapolis JW Marriott on schedulein time for the 2012 Super Bowl.

Read why Smith & Oby and Coleman Spohn prefer Viegas time-saving products and how

the easy-to-install Quad Close Trap Seal device by Jay R. Smith Mfg. Co. helped Olson

Plumbing keep its Colorado College renovation project on schedule. By choosing Metraflex

Metraloop expansion joints, Edwards Engineering estimates saving over 1,200 man-hours in

renovating Chicagos Kluczynski Federal Building. Learn why Mesa Mechanical picked the

JosamPush-Fit Stainless Steel Drainage Systemfor a project at Las Vegas Bellagio.

Find out how TJ Dyer kept costs down by using Aquatherms Climatherm

piping for a

Cincinnati senior living communitys heating system. And, learn how Shinn Mechanical

saves significant labor hours with the Miller Electric Mfg. Co.s PipeWorx Welding System.

Meanwhile, our partners at CNA remind us that an ounce of prevention is worth a pound of

cure. They provide 10 simple tips to prevent equipment theft.

Taking Advantage of Tech

Cost-conscious contractors are also seeking ways to leverage new technology to stay com-

petitive. In this issue, get tips fromJ.C. Cannistraro on using building information modeling

solutions fromTechnical Sales International to push savings and productivity to new levels.

Learn how Shinn Mechanical uses Get The Points Total Station Solution software and

equipment to transmit accurate layout information rapidly to field crews. Read about Action

Electrical & Mechanical Contractors success in streamlining accounting processes and more

with the Digio document management solution by Jonas Software.

Performance Pays Off

Energy efficiency is no longer a bonus in building constructionits the new norm. Learn

how J.E. Shekell is using AirAdvice/BuildingAdvice Energy Audits to identify areas for

improvements and help clients make the case for undertaking energy-efficient renovations.

Also read how D.V. Brown & Associates not only kept installation costs down for a school

renovation project but also helped the school meet energy-efficiency requirements by using

Johnson Controls products.

Planning for Success

For more smart solutions, join us for the 2011 Mid-Year ConferenceNavigating the

Recovery: Strategies for Successin Indianapolis September 1214. The educational ses-

sions will help you transition your company fromsurvival mode to success. For more infor-

mation, visit www.mcaa.org/education.

Bill Bartley

Chairman

SMART SOLUTIONS

Helping contractors save money

and enhance productivity

Smart Solutions showcases new tech-

nologies and promotes cost-saving and

productivity-enhancing applications

available from members of MCAAs

Manufacturer/Supplier Council. Smart

Solutions is published biannually for

contractor members of MCAA and its

subsidiaries.

All information in this newsletter was

supplied by members of MCAAs

Manufacturer/Supplier Council. MCAA

is not responsible for any claims made

regarding products or services mentioned.

Cynthia Buffington

Senior Executive Director

Jan Letow

Director, Membership

Adrienne Breedlove

Director, Publications

Dana Trevas

Consultant

1385 Piccard Drive

Rockville, MD 20850-4340

301-869-5800

Fax 301-869-3520

e-mail cbuffington@mcaa.org

www. mcaa. org

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

3

To complete a new J W Marriott hotel

in Indianapolis, North Mechanical

Contracting chose Anvils Gruvlok

product to provide the kind of perfor-

mance and value required to keep the

project on time and within budget.

The $450-million hotel and conven-

tion center project was smack in the

center of Indianapolis crowded down-

town area and had to be completed

a full year ahead of the 2012 Super

Bowl there. Complicating matters

further, North also had to

provide services to other

Marriott hotels within the

same complex that would

open a year before the mar-

quee J W Marriott property,

compressing Norths time-

frame considerably.

We have a 30-plus-year

track record installing

grooved piping systems,

said Rod Foley, proj-

ect manager for North

Mechanical. We knew

that grooved would save us

time and labor costs, two

things very important on

this job, so North selected

Anvils Gruvlok products.

2012 Super Bowl Brings

Need for New Lodgings

When Indianapolis won

the bid for the 2012 Super

Bowl, the city realized it

likely didnt have enough

hotel rooms to accommo-

date the more than 100,000

people expected to come

to town for the big game.

The city selected Marriott

Corporation to build a

1,005-room, luxury J W

Marriott property near

Lucas Oil Field, home

of the Indianapolis Colts

and site of the 2012 Super Bowl.

The glass curtain wall project broke

ground in May 2008.

North provided plumbing and

mechanical systems for the conven-

tion center, as well as full infra-

structure HVAC and plumbing for

the existing buildings and the new

hotel in the complex. While weld

pipe was included in the original

bid, North wanted to use as much

time- and labor-saving grooved

piping as possible to help meet the

tight timeframe. Everything North

needed was available in the Gruvlok

line, said Kyle Crawford, Anvil

Mechanical Specialist. Gruvlok

products used by North Mechanical

in the Marriott project included 3

12 couplings and fittings and Anvil

pipe supports, both clevis-type and

roller hangers.

Ready for Some

Football!

The project was com-

pleted in December 2010.

Anvil kept everything

moving, said Foley.

They provided a value

product that worked as

promised and was deliv-

ered to meet our product

schedule. We plan on

using Anvil products on

our upcoming Indianapolis

Veterans Administration

hospital chiller replace-

ment project.

Now, Indianapolis has

another luxury hotel prop-

erty to welcome guests for

the Super Bowl in 2012.

Greg Fuller, president of

North Mechanical and an

MCAA Board Member, will

discuss how his company

successfully uses integrated

project deliverya collabor-

ative process involving all the

participants early in devel-

opmenton September 13

at MCAAs 2011 Mid-Year

Conference in Indianapolis,

IN (visit www.mcaa.org/

education for more details).

For more information about

Anvil, visit www.anvilintl.com.

North Mechanical and Anvil Score Big in Super Bowl Project Kickoff

Partners Tackle Space, Time Constraints Together with Grooved Piping Solution

North Mechanical Contracting chose Anvils Gruvlok product to stay on time and within

budget for a new luxury JW Marriott hotel and convention center in Indianapolis (shown

here under construction)which is now ready to welcome more than 100,000 people

when Super Bowl 2012 kicks off.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

4

eliminate confined space safety con-

cerns. Victaulic was definitely a prob-

lem solver, said KSW Chief Executive

Officer Floyd Warkol. This was an

absolute perfect application.

A Memorial for America

The National September 11 Memorial

& Museum will honor the nearly 3,000

people who lost their lives in the ter-

rorist attacks of September 11, 2001,

and the World Trade Center bombing

on February 26, 1993. The memorial

consists of two reflecting pools, each

approximately one acre in size, sunken

30 feet into the footprints of the north

and south towers of the World Trade

Center. Featuring the largest manmade

waterfalls in the country, each pool

contains about 560,000 gallons of

water, and every minute, 24,000 gal-

lons of water ringlets cascade over the

edges of each fountain. The pools are

set within an eight-acre plaza studded

with oak trees. The mechanical rooms

housing the pumps for the waterfalls

are located directly beneath the pools,

approximately 50 feet below plaza level.

The name plaques are bronze parapets

surrounding the twin pools that are

inscribed with the names of the victims.

The memorial will open in a dedica-

tion ceremony for victims families on

September 11, 2011the 10-year anni-

versary of the attacks. It opens to the

general public by reservation a day later

on September 12. (Online reservations

for free visitor passes can be made at

www.911memorial.org.)

Tight Deadline Gets Tighter

4 Js Associates, LLC, a joint venture

of 4 Js Plumbing and Fresh Meadow

Mechanical, both based in New York,

began the piping and equipment instal-

lation for the fountains in March 2010.

In June, the target completion date for

the north pool was moved to ensure that

the pool would be filled and the pumps

operating in time for a November 2010

demonstration. The team of contractors

faced a tight schedule, one in which

everything had to be done right the first

time. Meanwhile, New-York based

KSW handled the installation of a heat-

ing and cooling system for the name

plaques, as well as the chiller plant.

Victaulic grooved mechanical piping

solutions were selected to join much of

the piping for the seven different types

of mechanical systems on each pool,

including the stainless steel waterfall

systems and filtration systems, stainless

steel sump and galvanized ejector lines,

and ductile iron plaza drainage system,

as well as the name plaque heating and

cooling system.

Faster and Easier Installations

Completing the project on time was a

primary concern of the Port Authority.

I assured them it wouldnt be a prob-

lem, Daniel Justus, president of 4 Js

Plumbing, recalled. They asked if weve

ever done a fountain project this large,

and I said I dont think anyone has done

a fountain project this large. But its a

doable project for us, just larger pumps

and bigger pipe and fittings.

Victaulic grooved mechanical piping

is faster and easier to install than other

pipe-joining methods because the gasket

and coupling housing are simply posi-

tioned on the grooved pipe ends and the

bolts and nuts tightened with standard

hand tools.

For the 24 and 16 waterfall piping,

Victaulic Advanced Groove System

(AGS) couplings were selected. AGS

couplings feature enhanced pressure

ratings and are the only couplings on

the market that feature a two-piece

housing design up to 60 in diameter

for increased installation speed and

ease of assembly.

On the memorial project, Victaulic

QuickVic

installation-ready cou-

plings further reduced installation

time. The couplings do not require

disassembly prior to installation, so

plumbers could simply stab the cou-

plings onto the grooved pipe ends and

tighten the bolts. Victaulic couplings

featuring installation-ready technology

are up to 10 times faster than welding

and six times faster than flanging to

install.

VICTAULIC

continued from page 1

4 Js Plumbing and Fresh Meadow Mechanical chose easy-to-install Victaulic couplings to meet the tight

deadline for the National September 11 Memorial reflecting pools, which are approximately one acre in size

and sunken 30 feet into the footprints of the north and south towers of the World Trade Center.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

5

The use of Victaulic couplings and

fittings accelerated the installation

process tremendously, said Michael

Russo, chief operating officer of Fresh

Meadow Mechanical. Its a much

easier system to install.

In addition to speeding the construc-

tion, J ustus and Russo credit the

couplings with reducing costs. Its

definitely going to cost more money

to weld a pipe than to groove it and

use the couplings, J ustus said. Not

only would welding have been more

expensive, it also would have been

extremely difficult given the time and

space constraints. Welding all the

pipe onsite would have been impos-

sible, Russo stated. Theres between

3,000 and 4,000 couplings. If all those

connections had been welded, wed

still be welding.

To further reduce installation time, as

well as organize and coordinate deliv-

ery of the piping, a majority of the

larger pipe was fabricated offsite and

delivered to the jobsite for connection.

This approach allowed for relocation

of some labor to a controlled envi-

ronment, minimizing the amount of

material handling onsite while also

saving space. In the cramped quarters

of the pump roomsparticularly the

south pump room, which is about half

the size of the norththere wasnt

much room in which to work. KSWs

Warkol explained, The mechanical

rooms are shared space. There were

different companies working under

different contracts for different enti-

ties all at the same time. The orches-

tration of the various contracts and the

various trades by the Port Authority is

an unbelievable feat.

Couplings Accommodate

Last-Minute Changes, System

Maintenance

The speed of installation also proved

to be advantageous when last-minute

design changes were handed down.

We had several design changes

throughout the job, some small, some

large, J ustus explained. Victaulic

grooved piping systems provide easy

access for system alteration, as well as

maintenance and expansion, because

a coupling creates a union at every

joint. To access the system, a worker

unscrews two bolts and removes the

coupling housing and gasketno

torch, saw, or welding machine is nec-

essary.

With grooved pipe, if you have to

take something apart, you take off the

coupling and you extend it or alter

it; its easy to work with. If you have

welded pipe, you have to cut into the

pipe and you have to weld another fit-

ting. Doing that in the field versus the

grooved systemits night and day,

J ustus said.

The serviceability of the Victaulic

grooved system also simplifies system

maintenance. Given the nature of the

application and the chemical treatment

of the water, periodic inspections will

be conducted to detect microbiologi-

cal growth within the piping. The

access capabilities of the Victaulic

connections [allows maintenance per-

sonnel to] take systems out of service,

open up the piping, and do a visual

internal inspection very easily, Russo

explained.

Accommodation of thermal movement

was also a requirement. The design

of a Victaulic flexible grooved pip-

ing system accommodates expansion

and contraction by permitting linear

movement and deflection of the pipe

within the coupling, thus minimizing

the need for costly expansion joints or

large expansion loops, which would

have been nearly impossible given the

space constraints.

Safe Installation in a Confined

Space

While 4 J s Plumbing and Fresh

Meadow Mechanical installed piping

for the reflecting pools, KSW was

installing piping for the bronze name

plaques, which required a heating and

cooling system to keep the plaques

cool in the summer and warm in the

winter. The system, including 4 steel

mains and

3

/4 copper branches, was

to be installed in a 4-foot-tall crawl

space below the parapets. Because

welding in such a location would have

introduced confined space concerns,

Victaulic couplings were selected to

join the mains.

Proud To Be Part of History

The speed of installation of the

Victaulic grooved piping system was

a considerable factor in complet-

ing the project on time. The 4 J s

Associates team was able to turn over

the north pool to the Port Authority

on November 3, 2010, and installation

of the piping systems for the south

pool was substantially completed by

J anuary 2011, more than three months

ahead of schedule. Victaulic was a

key player in being able to meet the

required timelines for the project,

Russo stated.

The Port Authority and the founda-

tion were really happy with what

we did, J ustus said proudly. They

praised us for our workmanship and

for completing the job in the time-

frame we did.

As proud as each of the firms were to

finish ahead of schedule, the symbolic

nature of the project resonated even

more. Being a part of the rebirth of

the World Trade Center area was a

remarkable experience. It meant a lot

to us as a contractor in the New York

metropolitan area and our employees

to be involved in the project, Russo

reflected.

Warkol added, Its exciting to be

a part of whats taking place down

there. Its a major piece of American

history.

For more information about Victaulic

products, visit www.victaulic.com. To

learn more about the 9/11 Memorial,

visit www.911memorial.org.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

6

off-site pre-fabrication and efficient

installation processes.

As J oe Mierzejewski, Cannistraros

project manager and coordination

department manager, commented, We

are always attempting to find ways to

become more efficient and save labor

costs, and the CAD-Mech and J OB-

Site Solutions software and Trimble

hardware from TSI is the perfect ave-

nue for that.

Pre-Fabrication Ensures

Quality, Productivity

Bringing the bulk of the work to

Cannistraros pre-fabrication facility

ensures that every component is pre-

engineered, thereby improving mate-

rials management and overall project

flow. Cannistraros Fab Lab has

the capacity to design and pre-fabri-

cate piping components for the most

complicated mechanical systems.

The company has pre-fabrication and

storage facilities for the plumbing

and fire protection trades, as well as

a 40,000-square-foot HVAC shop

complete with overhead cranes, a

plasma cutter, and automatic welding

machines.

We can take months off of a schedule

because we do three or four months of

work upfront, before were on the job,

said Mierzejewski.

Without pre-fab capabilities, contrac-

tors deliver piping pieces to jobsites

which then remain in a pile, taking up

precious floor space. The subsequent,

on-site, stick-built method results

in lower productivity, longer installa-

tion schedules, and greater waste and

debris. Weather, too, becomes a for-

midable factorshutting down work-

sites, damaging materials, and making

work uncomfortably cold, hot, or wet

for construction workers. Measuring,

cutting, fitting, and assembling in the

field is tiresome, time-consuming,

wasteful, and potentially

dangerousand those fac-

tors all drive up costs.

Minimizing Layout Labor

Cannistraro has also found

opportunities for savings and

efficiency in the installation

of hangers and sleeves. Once

the components are assem-

bled, time and labor costs

can accrue during on-site

installation of sleeves and

hangers. The Boston mar-

ket and job conditions dont

always allow us to sleeve

ahead of time. Coring after

a deck has been poured has

become the common practice in this

area, said Mierzejewski. Through the

use of TSI J OB-Site Solutions software

and Trimble Total Station, the labor

required to layout points is signifi-

cantly reduced. Typically, the employ-

ees doing the layout have to attach the

wireless controller (the Nomad) to a

rod with a 360-degree prism mounted

on top and walk around the site to

shoot the points.

Making More Intelligent Models

To solve the problem of uncon-

structable 3D models received from

designers, Cannistraro now uses TSIs

CAD-Mech software for creating intel-

ligent models for fabrication. Using

TSIs BIM software, our foremen work

directly with our modelers to produce

pre-fabrication documents known as

spool sheets. These documents are

downloaded to the shop floor, where

our licensed mechanics create piping

assemblies that are ready for delivery

and installation, said Mierzejewski.

The entire process is driven by geom-

etry in the model provided by TSIs

CAD-Mech software.

Furthermore, the model allows

Cannistraro to produce stock lists auto-

matically for estimating and change

management. CAD-Mech generates

detailed reports for shipping, purchas-

ing, and fabrication; with the auto-

spooling feature, detailers can create

fabrication drawings with an automatic

bill of material generation for each ISO

drawing. Building owners and con-

struction managers can then view cost

implications for project planning and

make decisions within the context of

the model.

Additionally, by using TSIs BIM soft-

ware, Cannistraro can take advantage

of barcoding to track equipment and

piping assemblies from pre-fabrication

to installation.

From Fabrication to Installation

Bang It and Hang It

Before we purchased the CAD-Mech

and J OB-Site Solutions software

and Trimble hardware from TSI, the

installer would be armed with a coor-

dinated 2D drawing, a tape measure,

a hammer drill, inserts, a lift, band

saw, cords, and the associated hanger

stock, said Mierzejewski. Using the

Trimble Total Station in conjunction

with TSIs CAD-Mech and J OB-Site

Solutions BIM software makes sleeves,

coring, and hanger layout safer, more

efficient, and less expensive.

With the ability to extrapolate intel-

ligence out of the CAD-Mech soft-

ware, the Cannistraro crews can now

individually number each hanger and

run a report showing the rod size,

TSI

continued from page 1

Extrapolating information from TSIs CAD-Mech software, the

Cannistraro crews can individually number each hanger, then send

it to the appropriate section of the building, saving labor time onsite.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

7

length, and various other pieces of

information. That number corre-

sponds to the concrete inserts and the

physical drawing. Rolling racks with

several hundred hangers are sent out

to the field and rolled to the appro-

priate section of the building. Entire

floors of hangers are installed before

a piece of pre-fab pipe is brought on

the job.

Before this innovation, the installer

would lay out hangers off a 2D draw-

ing and control lines. If not done

perfectly, pre-fab may be slightly

off and need to be altered, or some

hangers might need to be moved.

With the combination of TSIs

CAD-Mech software producing the

pre-fabbed hangers and piping, the

J OB-Site Solutions software extract-

ing accurate hanger locations, and

the Trimble hardwares offering

overwhelming accuracy and ease of

use in the field, Cannistraro estimates

saving approximately 70 percent

in material and labor per hanger

installed, with substantially more pre-

cision. Upon realizing those astonish-

ing numbers, the Cannistraro team

started coming up with new ways to

use these innovations.

Taking it a Step Further

Cannistraro has invested in a mobile

coring rig that increases the num-

ber of holes drilled per day. While

the Trimble unit has saved time and

greatly improved accuracy of laying

out core holes, Cannistraro has taken

the idea one step further by integrating

the Trimble with the mobile rig. By

mounting the prism and Nomad (hand-

held controller) directly to the mobile

rig, the rig can layout the hole and core

it. Reducing a two-man job (layout and

coring) to a one-man job has cut labor

costs even further.

Setting a LEAN Standard

for Efficiency

Cannistraros basic processes

now constitute a LEAN construc-

tion standard. They create small

batches of work broken down into

four basic tasks (generate pre-fab

sheets, generate pre-fab hangers,

install Bang-Its, install hangers)

that can be repeated with efficiency,

accuracy, and speed.

The need for one or two installers to

carry around tools and stock for several

tasks has been eliminated. The job is

reduced to a single man, a rolling cart

full of numbered hangers, and a lift.

Each task is completed with minimal

tools and minimal stock. More impor-

tantly, Cannistraro is less dependent

on other trades to complete work.

Anytime a step can be eliminated or

improved, its a worthwhile venture,

said Mierzejewski.

These efficiencies are achieved as

a result of information included in

Cannistraros 3D drawings produced

with CAD-Mech. A small amount of

additional effort in the office has trans-

lated to significant savings in the pre-fab

shop and on the jobsite. Further, savings

are realized in less wear-and-tear on

small power tools, reduced rental time of

a lift, and, most importantly, the elimina-

tion of potential eye injuries and back

strain from overhead drilling.

3D BIM Provides Competitive

Advantage

With TSI BIM Solutions,

Cannistraros plans become multi-

dimensional construction models that

show the whole project in a 3D, ani-

mated view where the team can see

every fitting, hanger, and supportas

well as dimensional, material, cost,

and labor databefore a job is

installed. Its a great tool that helps

us do our job better and gives J .C.

Cannistraro that competitive advan-

tage, Mierzejewski concluded.

Mike Cannistraro, vice president

of engineering at J.C. Cannistraro,

will explain how his company has

used the BIM process to create

fabrication and preassembly effi-

ciencies that greatly improve labor

productivity and provide a competi-

tive advantage on September 13 at

MCAAs 2011 Mid-Year Conference

in Indianapolis, IN (visit www.mcaa.

org/education for more details). For

more information about TSI, visit

www.technicalsalesinternational.com.

Opportunities to Improve Efficiency and Savings with BIM

Automatic intelligent hanger and sleeve generation

Piping spools and pipe pre-fabrication

Hanger pre-fabrication

Reduced field labor for hanger inserts and sleeves

Increased productivity of hanger installation because of exact measurements

and pre-fabricated hangers

Reduced rework of pipe fabrication because of exact location of hangers and

sleeves

Reduced field manpower as a result of pipe prefabrication

Reduced safety costs with less field labor

Increased LEAN construction by using just-in-time delivery

More green building adherence because of fewer materials and less waste at

the jobsite

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

8

By using Johnson Controls products

for the renovation of five schools

in Dunkirk, NY, D.V. Brown &

Associates, Inc. (DVB) not only keeps

installation costs down but also helps

the school meet energy-efficiency

requirements that will result in energy

savings. Dunkirk City School District

is in the second phase of a two-phase

renovation project that began in July

2010. Responsibility for making $3 mil-

lion in mechanical equipment upgrades

to four elementary schools and the

districts middle school rests with DVB,

headquartered in Tonawanda, NY.

We are replacing and upgrading equip-

ment that is at least 20 years old, said

Don Brown, DVB president and CEO

and a member of MCAAs Board of

Directors. The project engineer pro-

vided us with options for new equip-

ment that will meet the specifications

for the project. Based on our previous

experience and the reliability of their

products, we opted to go with products

from Johnson Controls and the York

brand of Johnson Controls.

The HVAC systems upgrades include

indoor and outdoor Solution air-

handling units, blower coils, Series 10

packaged rooftop units, unit ventilators,

hot water coils and hot water unit heat-

ers, FW Series fan-coil units, condens-

ing units, and a YLAA air-cooled scroll

chiller. All of the equipment meets or

exceeds the energy efficiency require-

ments for the buildings. School districts

like Dunkirk are facing limited funding

and tight budgets, so administrators are

looking to save money by improving the

efficiency of their buildings and reduc-

ing their energy consumption.

Factory Packaging Ensures

Quality, Saves Time and Headaches

But just as important to the school dis-

trict and DVB is the fact that much of

the equipment features factory-packaged

controls from Johnson Controls.

We both benefit, Brown explained.

As the installer, we know we are get-

ting equipment with controls that have

been consistently installed in a controlled

environment, ensuring quality and saving

time. In fact, technicians in the factory

have easy access to all segments of the

equipment, making precise installation

and wiring easy and efficient.

By the time the equipment arrives

at the jobsite, it is already tested and

integrated with the control system, sav-

ing us time and limiting or eliminating

many of the headaches associated with

startup, Brown continued. Johnson

Controls has a reputation for equipment

that is very well laid out and very ser-

viceable. All the key components and

controls are very well thought out, mak-

ing installation easy and an efficient use

of our time.

With air-handling units, factory

mounting maintains leakage perfor-

mance. Factory wiring is plug-and-

playthat is, the equipment is ready

to go once its installed. Sensor probes

are pre-engineered to determine the

best mounting location, ensuring

accurate and reliable readings. Each

mounted and wired device is tested

at the factory, and each unit includes

factory-generated control diagrams.

Ease of Installation of Johnson Controls/York Products Helps D.V.

Brown & Associates Keep School Renovations On Time, On Budget

Energy-Efficient Products and Digital Controls Will Help School District Cut Energy Costs

D.V. Brown & Associates selected rooftop units and other Johnson Controls products for a school renovation

project in Dunkirk, NY, because they are reliable, easy to install, and help the school meet energy-efficiency

requirements.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

9

As a result, installation of the equip-

ment requires less time.

Factory packaging makes our job easier

and less costly, said Brown. But lower

installation costs also benefit the school

district, and the time savings we real-

ize with these controls helps to keep the

construction schedule on budget and

on time. This is especially important to

school districts, where accomplishing

work over the summer, between the end

of the school year and prior to the start of

the new year in September, is critical.

Metasys System Allow Wireless

Access, Customizable Reports

In addition to the benefits offered by

digital controls applied to the mechani-

cal equipment, the school system will

also appreciate the advantages of hav-

ing wireless controls on network-based

equipment. The Metasys

building man-

agement system from Johnson Controls

integrates building technologies and

automates and manages systems in a

single building or multiple buildings.

Information on system performance

and status can be accessed from any

web-based device. The Metasys Ready

Access Portal delivers information

on standard web browsers (including

Apple

iPhone

and iPod

touch plat-

forms), enabling facility managers to

monitor building systems and facility

usage and respond quickly to changes or

operating challenges, no matter where

they are.

In addition, Metasys provides easily

customizable reports that help school

districts optimize operation of all the

facilities on the network even as it helps

to ensure redundancy and reduce life-

cycle costs going forward. Improved

graphics make it easy to use, which can

result in better cost management and

improved system performance.

The school district can also anticipate

improved comfort as a result of new

controls and equipment upgrades, con-

tributing to an environment that is more

conducive to learning. At the same

time, school district efficiency goals

are achievable, thanks to the improved

energy performance of the new equip-

ment and controls.

The use of Johnson Controls equip-

ment, with its factory-packaged con-

trols and wireless field bus system, is

a win-win for all concerned, Brown

concluded. As the mechanical contrac-

tor, were enjoying all the advantages of

a simpler, less time-consuming installa-

tion process while feeling confident in

the reliability and quality of the equip-

ment were installing. Meanwhile, the

school district is realizing efficiency

improvements that will result in energy

savings and control flexibility that

will ensure improved performance and

a more comfortable, productive envi-

ronment for students and staff.

For more information, visit www.

johnsoncontrols.com.

Ten Tips for Preventing Equipment Theft

With the price of used equipment at an all-time high, the current uncertain economic conditions, and the inherent vulnerability of

jobsites and yards, CNA encourages you to implement strategies to protect against jobsite burglaries, vandalism, and equipment

theft. The following tips can help:

Do not leave machines on unfenced properties or jobsites. When possible, temporarily move machines to fenced yards or

locate a secure lot near the jobsite, such as a car dealership.

Disable machines that have to be left on jobsites. Disconnect batteries; pull fuses, relays, or ignition circuits; and remove tires.

Do not leave machines or materials on trailers. Equipment on trailers is much easier to steal.

Randomly check jobsites during off-hours. Give designated employees a list of what machines, tools, and materials should be

at each jobsite, so that missing property is not overlooked.

Do not leave hand tools or small equipment at jobsites. Lock boxes should be secured with additional locks, chains, etc.

Advise jobsite security guards if any activity is expected. Thieves are often familiar with the work site and may even have cre-

dentials that allow them to be on the site or to move equipment. Be sure security guards have a contact number so that they can

alert you about suspicious activity.

Let employees know that management will be making spot checks of jobsites. Let the grapevine work to your advantage.

Create an accurate list of all important equipment, with serial numbers. The list will help aid in the potential recovery of any

stolen equipment.

Mark all tools with the company name and address. Make it as large and as permanent as possible.

Register your equipment on the National Equipment Register today: www.ner.net.

Its always a good time to prevent theft.

For more information on CNAs insurance solutions, please visit www.cna.com/construction.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

10

While Shinn Mechanical, Inc. of Kent,

WA, has already increased its MIG

weld quality to the point where opera-

tors cant remember their last rejected

weld, its welders also complete joints

three to four times faster than shops

that rely solely on stick and TIG tech-

nology by using the new PipeWorx

Welding System, a pipe-specific mul-

tiprocess welding system from Miller

Electric Mfg. Co.

PipeWorx features the Pro-Pulse

pulsed MIG and RMD (Regulated

Metal Deposition) processes, as well

as stick, TIG, and flux-cored pro-

cesses that have been optimized spe-

cifically for pipe fabrication. It also

provides traditional MIG processes.

Switching between processes requires

pushing one button. Because operators

do not need to manually switch polar-

ity, cables, or hoses, they are more

productive, and a potential source of

errors is eliminated.

Same Quality, Three to

Four Times Faster

While some code requirements and

weld procedure specifications require

TIG or stick welding or both, Shinn

Mechanical has worked with its cus-

tomers to qualify as many applications

as possible for the RMD and Pro-

Pulse. For example, welding 4- and

6-diameter pipe generally requires

two passes. We would run an RMD

root with a Pro-Pulse cap, said Steve

Sayers, a pipefitter/welder with UA

Local 32 who has worked at Shinn

Mechanical since 2005. We go to

Pro-Pulse on every size that requires

more than two passes whenever codes

and procedures allow.

Sayers continued, It would be a

minimum of double, if not three

times, faster to put in an RMD root

as opposed to a standard TIG or stick

weld. With the Pro-Pulse capabilities,

because of how much metal you can

put down with still having an x-ray-

quality weld, your production times

[are] three to four times faster [with]

the same quality of work you could

[do] with a TIG or stick procedure.

We havent had a wire [welding]

reject in well over a year.

With Miller Electric Mfg.

Cos PipeWorx Welding

System, Your production

times [are] three to four

times faster [with] the same

quality of work you could

[do] with a TIG or stick

procedure. We havent had

a wire [welding] reject in

well over a year.

Steve Sayers, Shinn Mechanical

Miller engineers have confirmed

Sayers estimates for RMD. While

productivity rates vary depending on

joint configuration, diameter, sched-

ule, material, etc., general travel

speeds for root pass welding are as

follows:

TIG: 24 inches per minute (ipm)

Stick: 58 ipm

RMD: 612 ipm

On average, the RMD process creates

a root pass weld with a 1/8- to 1/4-

throat. In many instances, the amount

of root pass metal deposited can sup-

port the heat input requirements of a

pulsed MIG fill pass. In many applica-

tions, Shinn Mechanical eliminates the

traditional hot pass, which can save

1015 minutes of time on 12-diam-

eter, Schedule 40 pipe.

Multipurpose Machine

Saves Money

On any given day, pipefitter/welders

need TIG, stick, flux-cored, MIG, and

pulsed MIG welding capabilities. A

traditional pipe shop would equip its

welding areas with a TIG/stick welder

and perhaps a multiprocess welder,

which typically doesnt have a high-

frequency start function.

With the PipeWorx, you have the

ability to have a high-frequency

start, which is huge when youre

doing quality work, said Sayers.

Now you dont have a scratch start,

which always takes a chance of leav-

ing a tungsten inclusion. [PipeWorx]

keeps us from having to buy an

additional welding machine just to

have the high-frequency capabilities

in the start, which is a huge money

savings.

The PipeWorxs push-button process

change capabilities also provide a

significant savings. In a matter of sec-

onds, operators can switch between:

DC TIG, with Lift-Arc starts or

high frequency for non-contact arc

starts;

stick, with arc performance opti-

mized for E6010 or E7018 elec-

trodes in pipe applications;

flux-cored;

conventional MIG; or

RMD or Pro-Pulse processes.

To illustrate, Lets say I just did a Pro-

Pulse cap and then wanted to switch

back to a TIG start, said Sayers. It can

Shinn Mechanical Increases Pipe Fabrication Quality and

Productivity with PipeWorx Welding System

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

11

take me a minute to grab my torch, my

foot pedal, set it up, and Im ready to go

within a minutes time between change-

overs. And the only reason it takes that

long is because my TIG torch and foot

pedal are all wrapped up. In order to

change between the TIG setup and the

wire setup, it takes all of two seconds.

Just walk right over to the machine, pull

the trigger on either one of the guns and

Im right back into the MIG position.

With all other multiprocess welding

systems, process changeover takes 5

10 minutes. Operators usually need to

change the welding lead (TIG torch to

stick electrode holder to wire feeder,

etc.) as well as swap the work lead

because different processes require

different polarities. In pipe fabrication

shops, MIG, stick, and flux-cored pro-

cesses use reverse polarity (DCEP),

whereas TIG welding uses straight

polarity (DCEN).

Pipefitter/welders typically change

processes an average of eight times

per day, which adds up to a total of

4080 minutes of changeover time.

Using a conservative overhead rate

of $60/hour, changeover costs of old

welding systems quickly add up:

$40$80 per day per operator

$200$400 per week

$10,000$20,000 per year

By eliminating unproductive process

changeover time to all of two sec-

onds, coupled with faster welding

speeds, Shinn Mechanical pipefitter/

welders can easily achieve their daily

goal of 200 weld inches (i.e., complet-

ing 20 joints on 10-diameter pipe).

Pre-Programming Settings

Saves Time

As noted earlier, Shinn Mechanical

works to qualify many procedures

for the RMD and Pro-Pulse pro-

cesses. To facilitate quick change-

over between these processes,

Sayers uses a dual wire feeder that

stores four welding programs on

each side. He uses the right side to

put in the root pass.

Ive got my RMD setting, MIG set-

tings for different applications, and

then Ive also got a pulsed setting for

Because Miller Electric Mfg. Co.s PipeWorx Welding System allows operators to switch quickly between multiple types of weld processes, Shinn Mechanical not

only saves labor time, but also avoids having to buy an additional welding machine just to have the high-frequency capabilities in the start, which is a huge money

savings, observed Steve Sayers of Shinn Mechanical.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

12

certain applications, said Sayers.

I can put a bead into anything with

any of those four settings. Then I just

switch over to my left side gun, and

thats where my Pro-Pulse side is for

my fill and my caps. I can generally,

off of those four programs, run any-

where from 2, Schedule 40 pipe all

the way up to as large a pipe as there

is just by adjusting wire feed speed.

To switch between programs, Sayers

uses the trigger select function, which

eliminates the need to return to the

feeders control panel to switch

between passes.

Arcs Designed for Pipe Welding

Unlike other multiprocess welding

systems, the PipeWorx features arc

characteristics specifically designed

for pipe welding. For example, the arc

characteristics, metal transfer, wet out,

and puddle control of Pro-Pulse and

RMD produce optimum results in the

joints and welding positions typical of

pipe welding.

You can get out of position a little

easier, and it seems to hold a puddle

better, observed Sayers. RMD also

leaves less wagon tracks in your weld

in the side walls of the pipe. When

youre doing high-quality work, you

dont have to grind out nearly as

much of your base metal to get down

to clean metal again [before] your sec-

ond pass.

Sayers estimated that RMD reduces

grinding time by 30 percent compared

with conventional short-circuit MIG.

On 12-diameter pipe or larger, RMD

can save five minutes or more of

grinding time per joint, which helps

Sayers accomplish his daily goal of

200 weld inches per day.

Sayers also noted that RMD looks

closer to TIG-like. It lays down flat-

ter than short-circuit welding does.

It doesnt seem to fall in as much.

It tends to hug the sides of the walls

of the pipe to where it does have the

tendency of laying flatter, maybe

a little wider and get really good pen-

etration. It doesnt seem to drop in

nearly as easily as short arc does. That

way, you dont have excessive pen-

etration on your root pass.

RMD Is a Quick Study

Historically, pipe fabricators refused

to adopt conventional MIG processes,

or they limited use to non-critical

applications. Fabricators felt that

consistently producing code-quality

welds with no or little rework required

a high degree of skill and significant

training. Miller designed RMD so that

novice welders could learn it in a mat-

ter of days, and experienced welders

could learn it in hours.

The fabrication time

you save is just

unbelievable. I couldnt

imagine trying to do it

any other way.

Steve Sayers, Shinn Mechanical

RMD runs extremely smooth, said

Sayers. Its easy to tell when you

do have a problem because it will

be noticeable. The machine will let

you know to stop because the arc

will have a crackle sound thats not

familiar. When its running consis-

tently, it always has the same sound;

it doesnt change. Further, if it cre-

ates a little bit of a keyhole, you just

slow down, and it seems to fill itself

right back in.

One of the biggest challenges in

pipe welding occurs when two sec-

tions of pipe are misaligned, known

as a high-low situation. Sayers

stated that if the misalignment is

within 1/8, RMD generally has no

problem picking up both of those

edges and doing a good tie-in [so]

you dont have to try to go back and

grind or try to make a repair. [It]

doesnt thin out your walls too much

to where when you try to put your

secondary pass in it doesnt want to

blow through.

RMD provides these benefits because

it precisely and consistently controls

metal transfer. Uniform droplet depo-

sition produces a stable and more

controllable weld puddle (as opposed

to the explosion of traditional

short-circuit transfer). RMD enables

consistent tie-in to the sidewall, com-

pensates for high-low misalignment,

easily bridges gaps of up to 3/16, and

creates more consistent root reinforce-

ment on the inside of the pipe.

Consistent, High-Quality Results

Shinn Mechanical has had nearly two

years of experience with the RMD and

Pro-Pulse processes and one year with

the PipeWorx Welding System. In that

time, the PipeWorx Welding Systemhas

paid for itself many times over. This new

welding technology consistently produces

x-ray quality results in critical applications

for root, fill, and cap welding. Add in

productivity-enhancing features, such as

quick process changeover, trigger select,

and welding speeds that help accomplish

a daily goal of 200 weld inches, and pip-

efitter/welders such as Steve Sayers say

theres no way they would go back to

older welding technology.

With the PipeWorx setup that weve

got and all of the things that weve

brought in with our [new] shop, its

unbelievably fast, said Sayers. The

fabrication time you save is just unbe-

lievable. I couldnt imagine trying to

do it any other way.

Thanks to Shinn Mechanical for dem-

onstrating its Articulated Weld Boom

for participants at MCAAs Pre-Fab

Seminar in Seattle, WA, May 46,

2011. The Articulating Weld Boom won

the company the 2008 E. Robert Kent

Award for Management Innovation.

For more information about PipeWorx,

visit www.millerwelds.com.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

13

Using Get The Points Total Station

Solution software and equipment, Shinn

Mechanical laid out and installed pipe

hangers and sleeves efficiently and

accurately for a parking garage and

rental car office facility for SeaTac

International Airport. Shinn recognized

a significant labor savings compared

with the original installation estimate,

overcoming many of the time-consum-

ing challenges of conventional layout

and point positioning.

Parking Garage Poses Challenges

Shinn Mechanical installed mechani-

cal piping on five levels of garage and

office/tenant space. The parking garage

was constructed using post-tension slabs,

requiring precisely located inserts for

hangers. Post-installed concrete anchors

were not permissible. Furthermore, the

roof structure over the tenant lease space

on the top floor was made up of steel

beams with limited capacity. Hanger

locations had to be detailed and coordi-

nated among the trades to place attach-

ments accurately to the structure while

ensuring that maximum-rated loads for

the beams were not exceeded.

Through the coordination process,

Shinn Mechanical located every hanger

for all hydronic piping within the 3D

AutoCAD model. The question then

became how best to transmit the infor-

mation to the field crews for layout.

Traditional, dimensioned shop drawings

were considered, but this process would

have been labor-intensive and ineffi-

cient given the congestion of trades and

the fact that there were few flat surfaces

for layout. The structure incorporated

compound slopes throughout the garage,

as the slab was broken up into grid sec-

tions with differing grades in multiple

directions. A conventional layout on the

floor would have been extremely time-

consuming.

The benefits of Get The Points Total

Station Solution software and equip-

ment were immediately apparent. Shinn

had little time to spare; the detailer

familiarized himself with the software

and quickly produced the point lists

for input into the Total Station. The

learning curve for the detailer and field

crew was minimal, and Shinn soon had

hanger attachment points installed

ahead of schedule.

One-Touch Positioning Speeds

Layout Time

Trying to shoot a laser to the ceil-

ing presented a problem, but with Get

The Points patent-pending GTP X-Y

Positioner, Shinn was able to identify

the points on the ceiling and on the

ground. The basic concept of the tool is

to get within a foot or so of the desired

point, and then operate the tool with the

touch of a finger, instead of picking up

the prism pole, moving, leveling, and

repeating until a 0,0 read-

out is achieved. This approach

allowed Shinn to speed up lay-

out time even further.

The project also involved exten-

sive seismic bracing require-

ments, which were placed using

the Get The Point Total Station

Solution. With the inputs from

Shinns 3D AutoCAD model,

the system precisely located

all of these components, elimi-

nating conflicts between the

bracing/cables and other trades.

Thanks to the successful instal-

lation and significant labor sav-

ings, Shinn Mechanical intends

to put the Get The Point system

to use on many more projects in

the future.

For more information, visit

www.gogtp.com.

Get The Point Software and System Allow Shinn Mechanical

to Speed Up Piping Installation

Shinn Mechanical saved labor costs and time by using Get The Points Total Station Solution software and equipment to

transmit layout information to field crews installing pipe hangers and sleeves in a parking garage and rental car office

facility for SeaTac International Airport.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

14

By using Grinnell Grooved Products

for a new research, education,

and consulting facility at Wright-

Patterson Air Force Base, the Kirk

Williams Company completed an

aggressive 24-month project on

time with reduced labor costs. The

Columbus-based Kirk Williams

included Grinnell Mechanical

Products, a premium brand of Tyco

International, in their bid for the

HVAC and plumbing systems in

the new Human Performance Wing,

a 680,000-square-foot complex in

Dayton, OH.

Because Kirk Williams had worked with

Grinnell products previously, they knew

that Grinnell Products unique grooved

couplings and fittings design and top-

notch Grinnell Mechanical Services

(GMS) team would be assets on this

demanding project. We chose Grinnell

Products for the grooved piping systems

in part because they were able to draft

the mechanical equipment rooms for us,

enabling our drafting department to focus

on the core areas of the building and

keep up with the aggressive MEP coordi-

nation schedule, said Rich Null of Kirk

Williams Company.

Located in the northeastern corner

of the base, this massive complex

includes the newly established 711

Human Performance Wing, as well

as the Navys Aerospace Medical

Research Laboratory and the Air

Forces Physiological Training Unit.

Upon completion in late 2010, it

became the first human-centric war-

fare wing to consolidate research,

education, and consultation under

a single organization. According

to Mark Yates, chief of the U.S.

Army Corps of Engineers Louisville

Kirk Williams Company Selects Grinnell Grooved Products and

Services to Cut Installation Costs on Air Force Base Expansion

Kirk Williams Company relied on Grinnell Grooved Products and the Grinnell Mechanical Services team to meet the aggressive timeline and cut labor costs dramatically

for the new Human Performance Wing at Wright-Patterson Air Force Base.

continued on page 18

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

15

With copper prices at an all-time

high and jobsite copper thefts in the

news, Cincinnati-based Thomas J .

Dyer Company (TJ Dyer) quickly

embraced the alternative polypro-

pylene-random (PP-R) piping by

Aquatherm for the heating system

of a new senior living commu-

nityThe Kenwood by Senior Star.

With its fusion welding process, light

weight, and imperviousness to cold,

Aquatherms Climatherm

pipe sys-

tem allowed TJ Dyer to realize 2025

percent savings in labor costs over

copper piping.

Located on the bluffs of the Ohio

River Valley in Northeast Cincinnati,

The Kenwood includes a 15-story

tower and one three-story residential

building. Climatherm was used on

the high-rises hot water lines feed-

ing Trane heat exchangers, from

four-inch down to 3/4-inch. Chris

Kleinholz, TJ Dyer foreman, appreci-

ated that Climatherm did not require

constant on-site security during the

installation (as copper would have)

and offered other benefits.

Innovative System Is Safer to

Install, More Durable Than

Copper

Aquatherms PP-R pipe systems have

been proven in over 70 countries for

nearly four decades. TJ Dyers major

plan and spec projects manager,

J im Ramsey, was most impressed

with the products longevity and the

Aquatherm warranty.

A key to Aquatherms success is the

fusion welding process that connects

the pipe. The fusion process cre-

ates seamless connections that last

a lifetime when properly executed,

eliminating the need for toxic materi-

als, glues and resins, and open flames

in piping installations. The PP-R

pipe and desired fitting are simply

inserted onto an Aquatherm weld-

ing device and heated for a specified

time (typically only seconds), then

joined together. Once fused, pipes

and fittings have the same physical

properties, eliminating systematic

weaknesses.

Additionally, a faser-composite

layer in the pipe reduces linear

expansion of the pipe by 75 per-

cent compared with other plastics,

ensuring that it hangs rigidly even

when subjected to high operating

temperatures (up to 200 F). Fully

recyclable, Climatherm is designed

specifically for HVAC and industrial

applications.

2025 Percent Labor Savings

We hit a cold spell during installa-

tion, and we didnt have to stop once,

Kleinholz recalled. With copper,

water in the lines would have frozen,

but it didnt with Aquatherm.

Kleinholz added that his crew typi-

cally realized labor savings of 2025

percent versus copper, because there is

no cleaning and fluxing of the pipe and

because Climatherm is lightweight rel-

ative to metal. TJ Dyer installer Dexter

Campbella 30-year industry vet-

eranadded that while there is a learn-

ing curve involved with the Aquatherm

TJ Dyer Cuts Labor Costs by 20 Percent with Aquatherms

Innovative Pipe System

Durable Alternative to Copper, PVC, Allows for Faster, Easier Installation

TJ Dyer saved labor costs by using Aquatherms Climatherm piping for the heating system of The

Kenwood by Senior Star senior living community in Cincinnati. Climatherm installation involves a fusion

weld system that is similar to open-flame welding but faster and safer, while the plastic is lighter than

copper and impervious to cold.

continued on page 18

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

16

Using BuildingAdvice, J .E. Shekell,

Inc., of Evansville, IN, helped a non-

profit human services provider cut

its energy expenses in half, stay in

line with state building code require-

ments, and qualify for energy rebates.

Contractors like J .E. Shekell know

its not enough to promise energy

savings over time by replacing out-

dated systems with new, more effi-

cient ones; those new systems must

demonstrate significant savings

quicklyand meet strict standards to

qualify for utility rebates. Through

a BuildingAdvice Energy Audit

and subsequent improvements, J .E.

Shekell helped the Evansville ARC

(EARC), a nonprofit adult disability

rehabilitation and child daycare facil-

ity, realize dramatic savings.

Desperately Seeking Savings

EARC has had a commercial main-

tenance agreement with J .E. Shekell

for 25 years. Last year, as EARC felt

the recessions effects in decreased

fundraising, the executive director

aggressively sought savings oppor-

tunities to offset the bottom line.

Also in 2010, J .E. Shekell formed its

energy services division. President

Kevin Shekell saw that offering

energy benchmarks, assessments, and

measurement services under energy

service agreements was the key to

finding a new facet of the 33-year

old business. The BuildingAdvice

suite of products has been part of J .E.

Shekells energy services division

since the beginning.

EARCs 36-year-old building was

ripe for improvement. The original,

pneumatic control system was anti-

quated and outdated. The facility

needed a control system to combat

indoor comfort issues, such as wide

temperature swings and temperature

variances between spaces. State

codes require such care facilities

to maintain certain conditions, and

the facility would be in danger of

temporary closure or, in an extreme

case, losing its license, if EARC

could not maintain conditions within

an acceptable range. The leader-

ships top priority was to quantify

what savings they could achieve

with equipment upgrades: upgrades

they knew they needed, but were not

sure they could afford.

The BuildingAdvice

Energy Audit report

showed that improvements

proposed by J.E. Shekell

to EARCs facility could

decrease the annual energy

expenditure of $82,000

by over $50,000 in

under a year.

J .E. Shekell Engineer Aaron Derr

conducted a BuildingAdvice Energy

Audit, which benchmarked the build-

ing at an Energy Star score of 26 (on

a scale of 1100, where 100 is most

efficient) and shared the results with

the EARC Board of Directors. He

then proposed $200,000 in HVAC

project work, which included the

installation of Verify, AirAdvices

comprehensive measurement and veri-

fication tool providing real-time build-

ing performance metrics and giving

building managers intelligence needed

to reduce building energy waste. Derr

used Verify to establish baseline usage

and measure in real time the effect of

the project work: replacement of dual

duct constant volume (CV) boxes with

new dual duct VAV boxes, replace-

ment of pneumatic controls with a

direct digital control (DDC) system,

and installation of variable frequency

drives (VFDs) on the supply and

return fans in the main air handler and

also on the cooling tower fan. The

new control system incorporated the

required logic to sequence all of the

systems equipment together. An addi-

tional $10,000 would go to a lighting

retrofit.

Rapid Return on Investment

The return on investment, or payback

period, on the proposed $210,000

worth of upgrades was predicted to

be less than two years with rebates

and grants. The buildings annual

energy expenditure was $82,000. The

BuildingAdvice Energy Audit report

showed that improvements proposed

by J .E. Shekell could decrease that

cost by over $50,000 in under a year:

an estimated $45,899 per year on

electric and $5,095 on gas.

Naturally, there was a lot of skepti-

cism on the part of the client. The

potential savings were so large, they

really didnt believe they could save

that much. As Derr said, I didnt

believe the numbers myself at first.

Being new to BuildingAdvice, Id not

had an opportunity to field-test their

system and verify their results against

real-time data. But our manual and

model calculations were showing that

they could.

BuildingAdvice Report

Secures Grant

EARC began securing funding for the

upgrades. Based largely on data con-

tained in the BuildingAdvice Energy

Audit report, the Indiana Office of

J.E. Shekell Uses BuildingAdvice to Slash Energy Bills in Half

Energy Audit Results Help Evansville ARC Win Block Grant, Earn Utility Rebates

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

17

Energy Development awarded EARC

a block grant in April of 2010 total-

ing $100,000. All of the predicted

energy dollars saved came from the

BuildingAdvice report, Derr said.

Led by HVAC & Design/Build

Project Manager Mark Unfried,

J .E. Shekell completed installation

of equipment and control systems

in November 2010. By reviewing

the measurement and verification

data from Verify reports, Derr saw

usage decreases and trends showing

improvement immediately.

The buildings new control system is,

to an extent, pre-programmed by the

manufacturer, but Derr uses Verify to

check its work. For example, controls

had been programmed to set back the

system on evenings and weekends,

but by checking against baseline

measurements at the outset of labor,

reports helped to show that the air

handler was running at low speed

constantly instead of shutting off

when it could. By monitoring these

reports daily, Derr has been able to

work with the control professionals

to optimize the programming.

Instant Results

In the month following equipment

installation, EARC saved 36 percent

in electrical energy and decreased

its bill by $2,065 compared with

the previous years bill for the same

month. What looked good on the

surface became great after the air

handler was reprogrammed. Energy

savings then totaled over 50 percent

less in each of the next two months

compared with previous usage, drop-

ping a total of $5,852. EARC is

on target to achieve the 50-percent

energy savings projectedeven with

current demand charges based on last

summers peak usage. EARC will

see additional savings once the high

demands from the old system are out-

side of the 12-month utility demand

reference window. Derr and EARC

continue to fine-tune the system to

squeeze out every bit of savings.

In early 2011, EARC received

rebates totaling over $20,000 from

their local utility , which uses a

third party to verify proposed sav-

ings before awarding rebates.

The third-party consultants didnt

believe the numbers coming out of

BuildingAdvice either and requested

supporting documentation for all of

the proposed savings and the calcu-

lations behind them. Derr worked

closely with the AirAdvice support

team members to back out, or

expose, all of the BuildingAdvice

calculations into a spreadsheet of

data more commonly produced

by energy engineers, showing all

the calculations manually. The

BuildingAdvice support team pro-

vided that level of detail and worked

directly with the utility consultants

to answer all of their questions.

In comparison with prior utility

bills, the buildings energy usage

has dropped radically. Last years

lowest monthly winter demand was

112 kilowatts, whereas the build-

ing has averaged 50 kilowatts in

demand since the project work was

completed. The company has saved

$7,917 in electric bills over the last

three-month period as compared with

a year ago.

For more information about

BuildingAdvice, visit www.airadvice.

com/solutions.

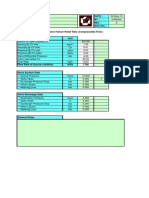

Left: BuildingAdvice measures Evansville

EARCs energy consumption against compa-

rable buildings usage and provides a metric

on targeted energy efficiency. The detailed

data allowed J.E. Shekell to increase EARCs

energy savings even more after the first

month by optimizing the programming.

Below: The BuildingAdvice report paints a

picture that resonates with customers. These

graphs of the carbon dioxide sensors show

whether a building is reaching ASHRAE stan-

dards and whether there is room to economize

its performance through energy improvements.

S M A R T S O L U T I O N S S U M M E R 2 0 1 1

18

Districts contracting division, the

project represented the largest single

military construction contract award

in the Louisville Districts history.

GMS Provides Roadmap to

Increased Productivity

The GMS team and Kirk Williams

worked together to develop a stream-

lined division of labor. GMS pro-

vided the roadmap for Kirk Williams,

which then oversaw fabrication

and installation. J ointly, they were

responsible for the design of the

facilitys hydronic hot-water system,

air conditioning system, and over-

all plumbing system. GMS created

a 3D map that outlined the needed

materials and specified every detail,

enabling the pipes to be fabricated

in a controlled environment, labeled,

tagged, and shipped directly to the

site. Grinnell Products process elim-

inates all of the guesswork, because

each piece is identified and matched

so the on-site contractor knows

exactly where each piece fits.

The enormous facility was designed

to house numerous laboratories with

highly technical and secure equip-

ment. The unique needs of these

labs drove the infrastructure design.

For example, bulkheads and other

structural elements could not impede

the laboratory equipment. Numerous

design changes were made on site.

And because the Department of

Defense had placed a strict two-year

timeframe on the construction, with

costly penalties for missing mile-

stone deadlines, construction had

to move forward even before final

designs were completed. We had

five different new construction or

remodel facilities for this project all

being constructed simultaneously.

With a local vendors help, Grinnell

Products was able to keep us sup-

plied with everything we needed at

each location on time. There was no

wasted effort in sorting materials in

order to get it to the right facility,

said Null.

This was a large-scale project that

was completed in record time, said

Michael Bedzyk, senior product

manager for Grinnell Mechanical

Products. Because of the pace and

strict guidelines, design changes

were being made all along the way.

Everyone at Grinnell Products

believes strongly in partnership and

that shows in our on-site management.

We were onsite at least twice a week

for the length of the project. This

ensured that deadlines were met and

that the design and installation pro-

cesses were seamless.

Grooved Products Dramatically

Reduced Labor Costs

By using grooved products instead of

soldering or welding, labor costs were

dramatically reduced. At the outset of

this project, more than 40 plumbers

and pipefitters were onsite at all times.

In the last 12 months of construction,