Академический Документы

Профессиональный Документы

Культура Документы

CFBC

Загружено:

Jeevan KumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CFBC

Загружено:

Jeevan KumarАвторское право:

Доступные форматы

Search

Go

POWER Home

NEW POWERblog

by Ken Maize

February 2007 Issue

Archives

Webcast

POWER Awards

Contact POWER

Subscribe Now

Buyers' Guide

Classified

Free Product Info

Industry Resources

Related Events

Media Kit

Electronic Advertising

Power -Volume149, Issue2

Publication Date (15-Mar-05):

BACK

CFBs anchor premier approach to extracting value from solid fuels

AES is, arguably, the world's leading owner/operator of coal-fired circulating fluidized-bed boilers. The company's

expertise is reinforced by its approach to extracting the most holistic value from a coal-fired power plant with the

least environmental impact.

By J ason Makansi, Pearl Street Inc.

AES Corp. (Arlington, Va.) owns and operates five coal-fired circulating fluidized bed (CFB) power stations in the

U.S. (including Puerto Rico) with a total capacity of more than 1,300 MW. In many ways, the company and CFB

technology have matured together. As fluidized bed boilers began to penetrate the power industry in the mid-

1980s, AES was an early adopter. Each CFB-based power station that AES brought on-line over a 20-year period

pushed the envelope with respect to scale up, emissions, efficiency, by-product recovery, and other design and

performance factors.

In this article, the company shares its experience with the technology by analyzing O&M and performance-related

topics at one of the latest facilities to come on-lineAES Puerto Ricoand one of the earliest onesAES Shady

Point. In addition, the company's CFB facilities illustrate how AES has always taken a different approach to its

power generation business (see "Measuring a plant's holistic value," p. 34).

Coal comes to an island

The AES power plant in Guayama, Puerto Rico, comprises two 255-MW CFB units with a net capacity of 454 MW

(Figure 1). In addition to being among the largest operating "commercial" (built without government funding and not

classified as technology demonstration) CFB units in the world, they brought coal-fired electricity to an island that

previously had none (see "PREPA counts on AES for large share of generation," p. 36).

A coal-receiving and unloading terminal was built to serve the power station. Although sulfur is absorbed and

removed from the flue gas as part of the fluidized bed process, AES Puerto Rico includes a circulating dry

scrubber (CDS) for additional SO2 removal (Figure 2)another technological first. Urea injection (Figure 3) is also

used to reduce NOx emissions from the already low levels characteristic of CFB boilers. Finally, AES Puerto Rico

employs a zero-discharge water treatment system and provides steam to neighboring industrial facilities.

1. Big, clean contributor. The 454-MW (net) AES facility

in Guayama, Puerto Rico, has two 255-MW CFB boilers

and accounts for 15% of the island's generation. Note

the coal bargereceiving terminal at top left.

Courtesy: AES

Page 1of 6 POWER Magazine

3/18/2007 http://www.powermag.com/archive_article.asp?a=2Z0050Mr3x091Q2A08Wp59_1&y=20...

For these reasons, the plant is among the cleanest coal-fired plants in the world. The plant accomplishes 99% SO2

removal from Colombian coal, which is already extremely low in sulfur (0.6%). The final SO2 discharge level is

around 9 ppm, and NOx emissions are held to 0.1 lb/million Btu. But the environmental story doesn't stop there.

In many ways, AES Puerto Rico has put into practice what some in the academic and environmental communities

call the principles of industrial ecology and symbiosis. The power station's raw water supply is the discharge from a

public wastewater treatment facility, and additional wastewater exchanges are being considered. High- and low-

pressure steam from the power station is sold to a neighboring refinery, allowing the refinery to retire four industrial

boilers firing high-sulfur residual oil. The plant's ash management strategy is to develop on-island and off-island

beneficial markets for the so-called manufactured aggregatea mixture of CFB spent bed ash, flyash, and water.

Waste exchanges have obvious financial benefits to AES and offer cascading environmental benefits as well. To

illustrate: Recycled manufactured aggregate displaces virgin material for structural fill applications, avoiding the

environmental impacts of extracting these materials from the earth and the energy consumption and emissions that

result from processing them. It's also worth noting that the water discharged from the AES plant is far cleaner than

the water discharged from the municipal treatment facility.

However, to accomplish all this, the CFB process has become far more complex.

The learning curve

Like all plants pushing the technology envelope, Puerto Rico has had to wrestle with design deficiencies,

performance-related issues, and technological and contractual "surprises." These have involved ash management,

CDS operation, boiler optimization, and early turbine failures, according to Plant Manager Al Dyer.

The CDS, which "polishes" the flue gas for additional SO2 removal, is essentially a small fluidized bed downstream

of the combustor. Hydrated lime, and solids recycled from the electrostatic precipitator (ESP), are injected into the

2. Kinks worked out. The circulating dry scrubber achieves additional SO2 removal, but its operation caused

early problems with the downstream electrostatic precipitator that have since been corrected.

Courtesy: AES

3. Going even lower. Urea (manifold shown) for NOx

reduction is injected at the inlet to the cyclones and the

cyclone outlet duct.

Courtesy: AES

Page 2of 6 POWER Magazine

3/18/2007 http://www.powermag.com/archive_article.asp?a=2Z0050Mr3x091Q2A08Wp59_1&y=20...

CDS along with water, and the turbulent interaction of the sorbent and flue gas achieves additional SO2 removal.

Heat in the flue gas quickly dries the reacted solids. However, the CDS increases the particulate loading on the

downstream ESP by a factor of 400 and the chloride concentration of the water as well (brine sourced from the

reverse osmosis [RO] units at the zero-discharge plant serves as makeup water to the CDS). Severe corrosion

was experienced in the ESP. To handle the high-chloride water, new RO units and storage tanks and

interconnecting piping were added, and modifications were made to the pug mills (Figure 4). These steps solved

the problem.

Part of the complexity at the Puerto Rico plant involves the consumables necessary for such a clean CFB process.

Aragonite, a form of limestone, is used as bed material to absorb SO2; urea is injected in the cyclones in a

selective noncatalytic reduction process for NOx; and hydrated lime is added to the CDS unit. Reducing the

expenses for these materials "has been a real success story," notes Dyer.

Hydrated lime, for example, costs 17 times as much as limestone. According to Elias Sostre, the plant's operations

manager, the following optimization steps reduced the cost of all consumables by 58% over the past year:

Increased the overall furnace differential pressure by 5 inches (H2O). By doing so, the plant gained about 2

inches of differential pressure in the upper part of the furnace. It was one of the most effective changes made.

Maximized the flow of primary air vs. secondary air, which improved heat transfer in the CFB evaporator panel

section.

Changed the airflow distribution in the combustor by adding more air to the front of the combustor.

Changed the configuration of the urea injection. Originally, more urea was added to the cyclone inlets than to the

outlets. After finding that injecting urea in the cyclone outlets was far more effective, the configuration was changed

to inject more urea there. Since this change, the plant has reduced its urea consumption by 20%.

Increased sulfur removal in the boilerrather than in the CDSby adding more limestone.

The feed controllers for limestone, urea, and hydrated lime were placed in automatic mode, and they were tuned

to the current conditions of the units.

4. Keeping the CDS going. AES Puerto Rico's zero-

discharge system, whose input is the outflow of a

nearby municipal water treatment system, had to be

changed to handle the high-chloride water produced by

the circulating dry scrubber. The fix entailed adding new

reverse-osmosis units and storage tanks and

interconnecting piping, and modifying the pug mills.

Courtesy: AES

Page 3of 6 POWER Magazine

3/18/2007 http://www.powermag.com/archive_article.asp?a=2Z0050Mr3x091Q2A08Wp59_1&y=20...

Reduced the excess O2 coming out of the boiler. This essentially helped reduce urea consumption.

In the boiler itself, the plant experienced three separate events of high-cycle-fatigue tube leak failure inside the

external fluidized bed heat exchangersa characteristic of the CFB design used here. These failures were caused

by bolted handcuff clamps. Plant personnel made a temporary fix in one unit, but a double clamp arrangement

appears to be a satisfactory permanent solution.

Other sources of aggravation were two major forced outages of the steam turbine and one catastrophic failure of a

turbine blade on the next-to-last low-pressure stage. High vibrations experienced during commissioning caused the

turbine vendor to implement a vacuum breaking scheme. AES and its turbine vendors have since balanced both

turbines and removed the source of the vibrations.

Finally, perhaps the biggest challenge facing the AES Puerto Rico plant is ash management. AES had previously

contracted with a company in the Bahamas to take the manufactured aggregate for beneficial reuse markets in the

U.S. and the Caribbean Basin. However, the marketing effort has not kept pace with ash production, so the plant

has taken charge of the issue and is now directly marketing the aggregate and working to demonstrate reuse

options on the island.

In general, Dyer considers performance and O&M issues "stabilized," and he and his staff are pursuing near-term

opportunities for improvement. Currently, the plant is achieving 92% availability on a 12-month rolling average; the

Puerto Rico Electric Power Authority (PREPA)AES's customerrequires only 90%. The plant's capacity factor is

around 85%. All performance guarantees are being met, with the exception of a 2% deviation in the design heat

rate, or efficiency, of the plant. Because each of the two units consumes about 26 MW of parasitic power, or

around 10% of its output, that is one of the cost-saving opportunities that Dyer's staff is focusing on.

Shady Point: Legacy of success

Sited in Panama, Oklahoma, AES Shady Point (Figure 8) earned one of POWER's 1992 Powerplant Awards for,

among other things, applying reheat CFB technology in a cycling and dispatch mode and adding a process unit

that recovers 10% of the flue gas CO2 for recycling and sale to the food industry. The 320-MW facility has four 80-

MW boilers with refractory-lined cyclones and external fluid-bed heat exchangers, and two 175-MW steam turbine-

generators with 30% bypass capability.

Plant Manager Pete Norgeot reports that, although Shady Point is designed to burn Oklahoma coal, it currently is

firing around 50% Powder River Basin (PRB) because of some gaps in local coal supply. Shady Point also is

watching test burns of poultry litter/coal/limestone blends being conducted at a CFB pilot plant in Canada, and

Norgeot is considering a 5% to 10% co-burn on a regular basis. "There's 300,000 tons of this waste material in our

area," he says.

Gary Martin, boiler area team leader at Shady Point, reviews two areas that have seen significant changes over

the years in terms of their optimization and performance: control system modifications for cycling and air

distribution through the combustor. "Typically, we'll operate these units between 50% and full load to fulfill our

contract requirements with Oklahoma Gas & Electric [OG&E]," he observes.

Martin adds, "To allow the CFB to be dispatched at these levels, we had to develop new curves and control blocks

within our control system to keep from overfeeding or underfeeding fuel and air when load increases or decreases,

respectively." Finding the proper amount of fluidizing air to avoid problems is an ongoing effort, he says. "Moving

the proper amount of material through the boiler while maintaining the proper amount of heat transfer is a real

balancing act."

8. The sooner, the better. AES Shady Point, in the town

of Panama, helped revive Oklahoma's coal industry.

The plant also recovers 10% of the CO2 in its flue gas

and sells it to the food industry. Poultry litter may be a

future fuel.

Courtesy: AES

Page 4of 6 POWER Magazine

3/18/2007 http://www.powermag.com/archive_article.asp?a=2Z0050Mr3x091Q2A08Wp59_1&y=20...

Shady Point's average annual capacity factor is about 77%. However, during the year it commonly experiences

frequent daily load changes. What's more, the plant sits at minimum or maximum loads for long periods, depending

on OG&E's needs. This necessitates accurate airflow measurements and quick adjustments to the boiler.

Some of the other "points" on the learning curve at Shady Point include the following:

Sonic horns are now used in more than 15 locations in the superheater, economizer, and other sections of the

boiler to remove ash deposits.

An emergency supply of limestone is stored in a silo at the boiler. The silo was originally intended to store sand to

be used as bed makeup, but it was determined that sand was not needed.

Detection and repair of cracks in the refractory is important because of the cycling duty the boilers experience. In

general, the refractory materials have changed and improved over the years. For example, a "rammable" carbide

material has replaced ceramic tiles in the lower part of the combustor. Properly anchoring the refractory is a big

ongoing issue. The earliest systems did not properly account for ash that gets into every crack. Penetration of this

ash to the cold side of a wall caused the anchor to fail.

Cleaning expansion joints every year is critical.

Dry ice production (Figure 9) was added to the liquid food-grade CO2 to meet additional market opportunities.

Some of the CO2 available from the recovery unit is now used to provide suppression capability in the PRB coal-

handling and storage area.

Good neighbor policy

Success with early CFB technology has been matched by the continued acceptance of the facility by the local

community and Oklahoma. Lundy Kiger, who was a middle school principal before joining AES in 1992 in

community and government relations, asserts that "Shady Point has helped to revive the Oklahoma coal industry."

Today, 70% of the coal mined in the state is used at the plant. Between the 77 jobs at the plant, the roughly 3,000

direct and indirect mining jobs created, the increased tax base, and other factors, Shady Point has had a $60

million annual impact on the economy of rural Oklahoma. Unemployment in Le Flore County has been reduced

from 14.9% before the plant started commercial operations in 1991 to around 4% to 5% today.

Some of Shady Point's ancillary activities are relatively small in financial terms, but they loom large in community

relations. For example:

AES "bought local" as much as possible during plant construction.

The plant initiated a 3-mile tree planting program through the governor's office for carbon sequestration and

scenic beautification and also developed a volunteer carbon sequestration project in South America involving more

than 3 million acres.

AES built a new elementary school in the town of Panamathe first time in the state's history a private company

did such a thing.

The plant has led community projects such as building a complex with four baseball fields in Poteauthe county

seatand a climbing tower for the Boy Scouts.

AES Shady Point spearheaded creation of the Le Flore County Coalition and the Two-State Coalition (with

9. Another beneficial by-product. Dry ice production was

added at Shady Point's CO2-recovery plant to exploit

additional market opportunities.

Courtesy: PREPA

Page 5of 6 POWER Magazine

3/18/2007 http://www.powermag.com/archive_article.asp?a=2Z0050Mr3x091Q2A08Wp59_1&y=20...

Arkansas) to expand regional economic development.

This list also could include countless smaller community efforts that include support for the area literacy council,

the Special Olympics, the Panama fire department, and Carl Albert State College. In fact, there's hardly a civic,

community, or educational organization in the area that Shady Point isn't involved in.

J ason Makansi is president of Pearl Street Inc., a Saint Louisbased consultancy that helps clients with

technology, deployment, communications, and energy industry investments. He can be reached at

jmakansi@pearlstreetinc.com or 314-621-0403.

2006 Tradefair Group, Inc. All Rights Reserved | Ph: 832-242-1969 | About Us | Privacy Policy | Terms & Conditions | For Advertisers

Page 6of 6 POWER Magazine

3/18/2007 http://www.powermag.com/archive_article.asp?a=2Z0050Mr3x091Q2A08Wp59_1&y=20...

Вам также может понравиться

- Total Losses in Power Distribution and Transmission Lines 1Документ6 страницTotal Losses in Power Distribution and Transmission Lines 1Ricardo A VergaraОценок пока нет

- Faults On Electrical SystemДокумент21 страницаFaults On Electrical Systemjosh bradley100% (3)

- B-Asic of Super Critical Boiler (660mw)Документ48 страницB-Asic of Super Critical Boiler (660mw)Jeevan KumarОценок пока нет

- Flexible AC Transmission Systems (FACTSДокумент33 страницыFlexible AC Transmission Systems (FACTSJeevan KumarОценок пока нет

- CFBCДокумент6 страницCFBCJeevan KumarОценок пока нет

- Cure Internet Verification Based On Image ProcessingДокумент8 страницCure Internet Verification Based On Image ProcessingYogesh YadavОценок пока нет

- Wireless Power Transmission Via Solar Power SatelliteДокумент25 страницWireless Power Transmission Via Solar Power Satelliteyuben joseph82% (34)

- Binary Tree Properties & RepresentationДокумент20 страницBinary Tree Properties & Representationkn_bsОценок пока нет

- Over Under VoltДокумент1 страницаOver Under Voltapi-3747180100% (1)

- Wireless Sensor Networks: Modelling and SimulationДокумент16 страницWireless Sensor Networks: Modelling and SimulationjawhaikazОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- JonWeisseBUS450 04 HPДокумент3 страницыJonWeisseBUS450 04 HPJonathan WeisseОценок пока нет

- Power Plant Engineering by G.R.nagpalДокумент729 страницPower Plant Engineering by G.R.nagpalGoutham Peri74% (23)

- Ficha Tecnica 750 GPMДокумент156 страницFicha Tecnica 750 GPMByron Chele0% (2)

- ALTERNATOR - ST170741: Parts ListДокумент2 страницыALTERNATOR - ST170741: Parts Listkaswade BrianОценок пока нет

- Presentation On BAJAJДокумент19 страницPresentation On BAJAJVaibhav AgarwalОценок пока нет

- YEZ-Conical Brake MotorДокумент3 страницыYEZ-Conical Brake MotorMech MallОценок пока нет

- Tda 1526Документ15 страницTda 1526Adilcio Melo0% (1)

- ARL-300 UCM Test Instructions For Hydraulic Lifts - enДокумент6 страницARL-300 UCM Test Instructions For Hydraulic Lifts - enkizonimeisterОценок пока нет

- F1FR80 Series Quick-Response SprinklersДокумент6 страницF1FR80 Series Quick-Response SprinklersAtila AmayaОценок пока нет

- 1HD-T - 1 Land Cruiser Engine Service ManualДокумент26 страниц1HD-T - 1 Land Cruiser Engine Service ManualMichael Dzidowski86% (7)

- The hyperwall: A multiple display wall for visualizing high-dimensional dataДокумент4 страницыThe hyperwall: A multiple display wall for visualizing high-dimensional dataMahendra PututОценок пока нет

- College Report of Optical Burst SwitchingДокумент21 страницаCollege Report of Optical Burst Switchingimcoolsha999Оценок пока нет

- Dont CryДокумент8 страницDont CryIolanda Dolcet Ibars100% (1)

- HTML Project RestaurantДокумент8 страницHTML Project RestaurantSandeep Chowdary0% (1)

- MCQ in Services MarketingДокумент83 страницыMCQ in Services Marketingbatuerem0% (1)

- Sample Style GuideДокумент5 страницSample Style Guideapi-282547722Оценок пока нет

- Pink Fun Doodles and Blobs Math Online Class Creative Presentation SlidesCarnivalДокумент28 страницPink Fun Doodles and Blobs Math Online Class Creative Presentation SlidesCarnivalraine castorОценок пока нет

- 7.qad-Dpr-11 ImteДокумент4 страницы7.qad-Dpr-11 ImteDhinakaranОценок пока нет

- Learning One-to-One - Book ReviewДокумент3 страницыLearning One-to-One - Book Reviewwhistleblower100% (1)

- OFFICE 365 PROXY GUIDEДокумент4 страницыOFFICE 365 PROXY GUIDErossloveladyОценок пока нет

- Form 1 Lesson 88 SpeakingДокумент2 страницыForm 1 Lesson 88 Speakinga multifandom fangirlОценок пока нет

- Ite 001aДокумент6 страницIte 001ajoshuaОценок пока нет

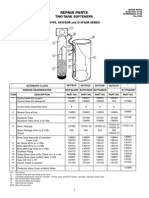

- Star S07FS32DR Water Softener Repair PartsДокумент1 страницаStar S07FS32DR Water Softener Repair PartsBillОценок пока нет

- Oracle SCM TrainingДокумент9 страницOracle SCM TrainingVishnu SajaiОценок пока нет

- Introduction To PLCsДокумент42 страницыIntroduction To PLCsArun Kumar YadavОценок пока нет

- LogДокумент27 страницLogmilli0chilliОценок пока нет

- Marco OH Lighting-Business Plan PDFДокумент43 страницыMarco OH Lighting-Business Plan PDFsjcoolgeniusОценок пока нет

- Ref Paper 2Документ4 страницыRef Paper 2Subhanjali MyneniОценок пока нет

- RELAY SEEDER PROTECTION GUIDE (P40 Agile CompactДокумент23 страницыRELAY SEEDER PROTECTION GUIDE (P40 Agile CompactvinodlifeОценок пока нет

- Trace MasterДокумент29 страницTrace Masterapi-3858801Оценок пока нет