Академический Документы

Профессиональный Документы

Культура Документы

Backcalculation of Residual Tensile Strength

Загружено:

Mehdi BakhshiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Backcalculation of Residual Tensile Strength

Загружено:

Mehdi BakhshiАвторское право:

Доступные форматы

Backcalculation of residual tensile strength of regular and high

performance ber reinforced concrete from exural tests

Barzin Mobasher

a,

, Mehdi Bakhshi

b

, Christopher Barsby

c

a

School of Sustainable Engineering and Built Environment, Arizona State University, Tempe, AZ 85287-5306, United States

b

AECOM, New York, NY 10005, United States

c

PK Associates Structural Engineers, Scottsdale, AZ 85250, United States

h i g h l i g h t s

Closed form equations for measuring tensile constitutive response from exural tests.

Parameters obtained from routine experimental data can be used for design of FRC elements.

Correlation of backcalculated tensile data from exural and direct tension tests.

Comparison of nature of the stress distribution under the two tension and exural tests.

Residual tensile strength, and post crack stiffness correlated with the ber type and content.

a r t i c l e i n f o

Article history:

Received 4 October 2013

Received in revised form 4 July 2014

Accepted 16 July 2014

Keywords:

Concrete

Fiber

Flexural behavior

Momentcurvature response

Postcracking tensile strength

Stressstrain response

a b s t r a c t

The tensile stressstrain response of a ber reinforced concrete dominates the performance under many

loading conditions and applications. To represent this property as an average equivalent response, a

back-calculation process from exural testing is employed. The procedure is performed by model tting

of the three-point and four-point bending load deection data on two types of macro synthetic polymeric

bers, one type of steel ber and one type of Alkali Resistant (AR) glass ber. A strain softening tensile

model is used to simulate the behavior of different FRC types and obtain the experimental exural

response. The stressstrain model for each age, ber type and dosage rate is simulated by means of

the inverse analysis procedure, using closed-form momentcurvature relationship and loaddeection

response of the piecewise-linear material. The method of approach is further applied to one external data

set for High Performance Fiber Reinforced Concrete (HPFRC) with two different types of steel bers and

validated by tensile test results reported. Results of back-calculation of stressstrain responses by

tri-linear tensile model for all mixtures are compared and correlated with the corresponding standard

method parameters used for post crack behavior characterization and a regression analysis for compar-

ative evaluation of test data is presented.

2014 Elsevier Ltd. All rights reserved.

1. Introduction

Fiber reinforced concrete is widely used in infrastructure

applications because of improved mechanical properties such as

fracture toughness, ductility, durability, and crack-width control

[15]. Steel, glass, natural, and synthetic bers have been used over

40 years in industrial slabs, oors, and pavements to primarily

reduce shrinkage and thermal cracking [611], reduce the required

slab thickness, and increase the allowable joint spacing [1218].

Experimental tests show that bers increase the exural and

ultimate load carrying capacity in proportion to their volume and

aspect ratio [1924]. Fiber reinforced concrete is used in elevated

slabs and water distribution infrastructure. Structural applications

of bers include but are not limited to precast structural elements

[25], tunnel linings [26,27], shotcrete [2832], offshore structures,

seismic applications, thin and thick repairs [33], crash barriers,

footings, and hydraulic structures [34,35]. The bers are also added

to concrete to enhance spalling resistance during exposure to high

temperature [36].

The mechanical properties depend on the characteristics of the

concrete matrix but also on the type and geometry of the bers

that governs their bond mechanism with the matrix [37,38]. Fibers

offer increased abrasion and impact resistance as well [39,40]. The

http://dx.doi.org/10.1016/j.conbuildmat.2014.07.037

0950-0618/ 2014 Elsevier Ltd. All rights reserved.

Corresponding author. Tel.: +1 (480)965 0141; fax: +1 (480)965 0557.

E-mail address: barzin@asu.edu (B. Mobasher).

Construction and Building Materials 70 (2014) 243253

Contents lists available at ScienceDirect

Construction and Building Materials

j our nal homepage: www. el sevi er . com/ l ocat e/ conbui l dmat

effectiveness of short, randomly distributed bers may be superior

to other forms of reinforcement such as welded wire mesh, or

rebars since the small diameter of the individual bers ensures a

more uniform dispersion, along with a far superior bond strength.

Moreover, due to the reduced specic spacing, bers strengthen

the composite at the micro level by bridging the microcracks

before they reach the critical aw size [41]. Among all mechanical

parameters, residual tensile strength and toughness are the most

improved parameters which are a direct consequence of macro

ber bridging mechanisms across the crack surfaces [42,43].

Hybrid ber reinforced concrete combining micro- with macro-

bers with an improved resistance against both types of cracks is

also useful for a variety of applications, including thin repairs

and patching [44,45].

Flexural tests are routinely done as a means of quality control

and limited material properties are extracted from their results.

Furthermore, the scatter and variations in these tests due to

notched or un-notched samples, or the choice of control variable

used in experiments, are compounded by the methods used to

report the results especially in the post-peak region. For example,

scatter is much smaller for synthetic bers than steel bers due to

the higher number and more homogeneous distribution across the

fracture surface [42]. Scatter is also lower for samples tested as

round panel specimens tested under ASTM C1550 than ASTM

C1609 beam specimens [46]. Scatter in the case of ASTM C1609

may also be attributed to the degree of rigidity of the support reac-

tions, or frictional sliding at the supports. There is a need to better

utilize the exural test data for realistic materials property.

This paper validates a back-calculation procedure for exural

test results and obtains tension stressstrain response from a

variety of tests conducted on notched and un-notched beams of

different sizes, ber types, shapes, lengths, and dosage rates. The

objective is to correlate the residual strength results with empirical

residual strength methods of ASTM C1609 [46], RILEM TC 162-TDF

[47], and JCI-SF4 [48] which propose calculation of residual

strength using simple engineering bending theory for linear elastic

materials and uncracked section properties. A database used for

analysis containing three internal data sets for tests conducted

on polymeric, AR Glass and steel bers at the Structural Engineer-

ing Laboratory at the Arizona State University, and one external

data set for reported test results of Kim et al. [49] on High

Performance Fiber Reinforced Concretes (HPFRCs). A correlation

is studied between backcalculated residual strengths and various

standard exural parameters. In lieu of empirical correlation val-

ues between these parameters that are currently in use in the

FRC industry, this paper provides a theoretical approach to obtain

such correlation factor.

2. Materials and methods

2.1. Flexural tests

Set one of internal database consisted of two polymeric bers of modied

polypropylene, polyethylene and olen blends, both at a dosage rate of 3 kg/m

3

(5 lb/yd

3

). Set two consisted of AR Glass bers at three different ber lengths, and

Set 3 consisted of one type of steel bers at three different dosage rates. All samples

were tested under exural testing conguration and the load-deformation response

in the post-peak region was measured. Physical and mechanical properties of the

bers used in the test program are presented in Table 1. The analysis section also

discusses results from published work on four different mixtures of HPFRC by

Kim et al. [49]. This was designated as Set 4 and included both tensile and exural

test results.

2.2. Testing program

Proportions of eight different mixtures prepared and tested under three-point

bending conguration are shown in Table 2. The rst letter on the samples labels

refers to the general type of ber used, i.e. P in case of polymeric, G in case of

glass ber and S in case of steel ber. The following number is the dosage of

the ber presented in kg/m

3

. For polymeric and steel bers, the letter following this

number refers to the type of bers shown in Table 1, while for glass bers; the num-

ber following this number is the length of ber. In the results section, a nal num-

ber added at the end of the labels designates the age at testing. In addition to the

samples tested, one set of published HPFRC data by Kim et al. [49] was used with

employed two different types of steel bers, H for hooked bers and designation

T was introduced to refer to longitudinally twisted bers. Subsequently, parame-

ter L refers to large size of specimen with depth, width and span of 150, 150 and

450 mm, respectively, to differentiate the results from results of medium size spec-

imens reported by Kim et al. [49].

Closed loop control exural tests were conducted on pre-notched FRC samples

of polymeric and AR glass bers in accordance with RILEM TC 162-TDF recommen-

dation in order to monitor post-peak response [47]. Dimensions of Set 1 Polymeric-

FRC sample and Set 2 AR glass-FRC samples were 450 mm 100 mm 100 mm

with an initial notch length of 12 mm and test span of 400 mm. Un-notched

steel-FRC samples in Set 3 were tested in accordance with ASTM C1609 under

four-point bending loading conguration using 510 mm 150 mm 150 mm

specimens with a test span of 450 mm. The diameter of steel bers used was

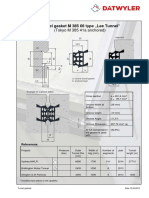

0.3 mm. Test setup, specimen dimensions and instrumentation are shown in Fig. 1.

Tests were performed under closed loop control with Crack Mouth Opening

Deformation (CMOD) as the controlled variable for testing sets one and two, and

load point deection as the controlled variable for testing set three. Both the CMOD

and deection were measured using a Linear Variable Differential Transformer

(LVDT) with a working range of 2.5 mm. In notched specimens, cracks initiated

from the notch and extended up along the depth of the beam. The crack opening

Table 1

Properties of bers used in study.

Fiber type P-type A P-type B Glass (G) Steel (S)

Base Monolament polypropylene/polyethylene blend Modied olen Alkali resistant glass Hooked (H)

Length (mm) 50 50 6, 12, 24 50

Density (g/cm

3

) 0.92 0.92 2.7 7.9

Tensile strength (MPa) 600650 552 1724 2300

Elastic modulus (GPa) 5 10 69 200

Table 2

Mixture proportions and compressive strength of all mixtures.

Set Mix ID Portland

cement (kg/m

3

)

Fly ash

(kg/m

3

)

Silica fume

(kg/m

3

)

Fine aggregate

(kg/m

3

)

Coarse aggregate

(kg/m

3

)

Water

(kg/m

3

)

Fiber type/dosage

(kg/m

3

)

w/c s/c Compressive

strength (MPa)

1 P3-A 475 60 15 1100 450 230 P-A/3 0.42 2 29

P3-B 475 60 15 1100 450 230 P-B/3 0.42 2 34

2 G6-6 796 80 0 578 760 350 G-6 mm/10 0.4 0.66 41

G6-12 796 80 0 578 760 350 G-12 mm/10 0.4 0.66 41

G6-24 796 80 0 578 760 350 G-24 mm/10 0.4 0.66 41

3 S13-HL 380 125 0 1343 1816 242 S-HL/13 0.48 2.66 28

S26-HL 380 125 0 1343 1816 242 S-HL/26 0.48 2.66 28

S39-HL 380 125 0 1343 1816 242 S-HL/39 0.48 2.66 28

244 B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253

was resisted by bridging bers which pulled out under this loading. The presence of

ber signicantly increases the ductility and resulted in a stable crack opening up to

high range of deections. The loaddeection curve is characterized by the maxi-

mum load and its associated deection, elastic stiffness, maximum exural strength

and exural toughness. The post-peak behavior of the samples was also reported as

elastically equivalent residual strengths as measured by three alternative methods

of ASTM C1609 (f

D

150

), JCI-SF4 (r

b

) and RILEM TC 162-TDF (f

eq,3

).

3. Test results

Results of experimental analysis on three- and four-point

bending tests on different macro synthetic, glass and steel bers

are summarized in Table 3. A wide range of responses in the data

such as apparent exural strength and toughness correlate with

the ber type, ber content, loading rate, and age at testing. The

toughness measure is obtained as the area under the load deec-

tion curve and as an age-dependent property correlates with

strength gain. Therefore, toughness after 28 days of curing was

used as the control and results obtained after 14 and 56 days for

steel bers were correlated with the 28 day results.

Effect of curing duration on exural response of polymeric ber

types A and B in Set 1 are shown in Fig. 2a. Average elastic exural

stiffness of P3-A samples increased by 20%. The maximum load

increased by 22%, and the deection associated with the maximum

load level did not change signicantly, while the toughness dou-

bled from 14 to 28 days. The increase in apparent exural strength

from 14 to 28 days was from 1.57 to 1.92 MPa (+22%). In P3-B

samples with 3 kg/m

3

of type B polymeric bers, elastic exural

stiffness increased by 27%. The maximum load increased by 18%

and its associated deection decreased slightly by 13%, while the

toughness increased from 2.2 to 4.3 kN mm (+95%) from 14 to

28 days.

It is clear that the primary parameter that differentiates among

the age of these systems is the toughness which is affected by the

post cracking response. When overall toughness is specied as a

design parameter, standard procedures can be utilized to select

ber type, length, and volume content. Such procedures, however,

are costly and vary for each ber type. It would be ideal to develop

a procedure to back-calculate the tensile response from each ex-

ural test so that the design procedures can utilize these results.

Effect of ber length at 28 days on exural response of AR-glass

bers in Set 2 are shown in Fig. 2b for three different ber lengths

of 6, 12 and 24 mm. Results show that the glass ber length does

not affect the elastic exural stiffness and deections at maximum

exural load; however, exural strength increased by 12% from

5.79 to 6.50 MPa at 28 days as the ber length changes from 12

to 25 mm. The exural toughness is showing a marginal decrease

with increasing ber length.

Comparative evaluation of the mixtures shows that there is no

discerning of the effect of ber type at these loading levels, and as

shown in Fig. 2, minimal changes are observed for all mixes of Set

1, namely P3-A, P3-B, and Set 2 AR-Glass ber mixtures. As far as

exural strength is concerned, little or no effect on the effect of

age or ber length is observed. However, the exural toughness

is clearly affected in the case of polymeric bers. Therefore, it is

concluded that the general increase in the post peak response from

14 to 28 days is the main parameter affected by the curing

duration.

Effect of steel ber dosage rate on samples of testing Set 3 is

shown in Fig. 3. Note that for the low ber contents in the range

of 1326 kg/m

3

, the effect of steel bers is observed in the post

crack response while as the ber content increases, behavior

changes from strain softening to strain hardening. The transition

from strain softening to hardening is best shown by the increase

in the ultimate strength and post crack resistance in terms of

toughness.

4. Analysis

4.1. Strain softening and hardening models

A formulation is presented to back-calculate material properties

by tting experimental data with a closed form relationship of the

load deection using a nonlinear material model [5052]. The

adaptation of this tri-linear model provides a precise correlation

of the exural response to back-calculate material parameters

Fig. 1. Test setup for three-point bend notched exural test.

Table 3

Summary of average experimental analysis for all FRC samples.

Set Sample ID Age (days) Elastic exural

stiffness (kN/mm)

Deection at max

exural load (mm)

Maximum exural

load (kN)

Bending strength,

f

p

(MPa)

Flexural toughness,

T (kN mm)

1 P3-A-14d 14 149 0.067 5.63 1.57 2.06

P3-A-28d 28 180 0.069 6.89 1.92 4.35

P3-B-14d 14 149 0.068 5.17 1.44 2.19

P3-B-28d 28 189 0.059 6.08 1.70 4.28

2 G6-6-28d 28 249 0.050 7.73 5.87 1.33

G6-12-28d 28 249 0.048 7.63 5.79 1.05

G6-25-28d 28 249 0.050 8.56 6.50 0.95

3 S13-HL-28d 28 822 0.043 23.34 3.01 32.27

S13-HL-56d 56 822 0.042 21.18 2.74 31.36

S26-HL-28d 28 822 0.054 26.07 3.10 46.20

S26-HL-56d 56 731 0.052 24.93 3.22 77.98

S39-HL-28d 28 548 0.082 25.07 3.24 122.60

S39-HL-56d 56 548 0.080 22.23 2.87 109.37

B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253 245

and could explain the differences between the tensile and exural

strengths of strain hardening and strain softening composites

[53,54].

Fig. 4 presents the constitutive model for homogenized strain

softening/hardening ber reinforced concrete. The tension model

in Fig. 4a is described by a tri-linear response with an elastic range

E, rst cracking tensile strain (e

cr

) and post cracking modulus

E

cr

= gE , which g is assigned a negative or positive scalar value

in order to simulate either strain softening or hardening materials.

The third region in the tensile response is a constant stress range

dened with stress r

cst

in the post crack region. Two strain mea-

sures dene the rst cracking and transition strains (e

cr

, e

trn

). The

tensile response terminates at the ultimate tensile strain level of

e

tu

. The linear portion of an elastic-perfectly-plastic compressive

stressstrain response with compressive modulus of E

c

terminates

at yield point (e

cy

, r

cy

). The response remains constant at a

compressive yield stress level of r

cy

until reaching the ultimate

compressive strain e

cu

shown in Fig. 4b. To convert this approach

into a closed-form solution of momentcurvature response and

load deection calculation, parameters must be expressed in nor-

malized terms. Two intrinsic material parameters of rst cracking

tensile strain e

cr

and tensile modulus E are used to dene seven

normalized parameters as shown in Fig. 4a and b and Eq. (1):

x

e

cy

e

cr

; a

e

trn

e

cr

; b

tu

e

tu

e

cr

; k

cu

e

cu

e

cr

; c

E

c

E

; g

E

cr

E

;

l

r

cst

Ee

cr

1

In a exural test, the moment curvature diagram for a rectangu-

lar cross section with a width b and depth d is derived using the

assumption of plane sections remaining plane. The maximum ten-

sile strain b and maximum compressive strain k are linearly related

to the neutral axis depth ratio, k as presented in Eq. (2). e

ctop

and

e

tbot

are the compressive strain at the top ber and the tensile

strain at the bottom ber, respectively.

b

e

tbot

e

cr

; k

e

ctop

e

cr

;

ke

cr

kd

be

cr

d kd

or k

k

1 k

b 2

Using the normalized parameters dened in Eqs. (1) and (2), the

compressive stress (r

c

), the tensile stress (r

t

) and the toughness

(G

f

) are expressed as:

r

c

k

Ee

cr

ck 0k x

cx x<k k

cu

0 k

cu

<k

8

>

<

>

:

r

t

b

Ee

cr

b 0b1

1g b1 1<ba

l a<bb

tu

0 b

tu

b

8

>

>

>

<

>

>

>

:

3

G

f

1

2

Ee

2

cr

a l1 a 2b

tu

4

By assuming linear strain distribution across the depth and

ignoring shear deformations, stress distribution across the cross

section at three stages of imposed tensile strain: 0 6 b 6 1,

1 < b 6 a and a < b 6 b

tu

are obtained in closed form [53]. Internal

moment is obtained using the force components and their distance

from the neutral axis and the curvature is determined as the ratio

of compressive strain at top ber (e

ctop

= ke

cr

) to the depth of

neutral axis kd. The moment M

i

and curvature /

i

at each stage i

Fig. 2. (a) Effect of curing time on load deection response for polymeric ber type

A and B with ber content of 3 kg/m

3

(Set 1), (b) Effect of ber type on load

deection response for glass with three different lengths at 6 kg/m

3

at age of

28 days (Set 2).

Fig. 3. Effect of ber dosage on load deection response for hooked steel bers with

large sample size at 28 days (Set 3).

Fig. 4. Material models for FRC materials: (a) tension for strain softening

composites, (b) compression.

246 B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253

are then normalized with respect to the values at cracking M

cr

and

/

cr

and presented in Eqs. (5) and (6). The transition from deection

softening to deection hardening is dened by critical normalized

post-peak tensile strength (l

crit

) as dened in Eq. (7).

M

i

M

0

M

cr

; M

cr

1

6

bd

2

Ee

cr

5

/

i

/

0

i

/

cr

; /

cr

2e

cr

d

6

l

crit

x

3x1

7

Calculation of k, M

0

and /

0

for the ve stages of governing strain

is presented in Table 4. During stage 1, the tensile and compressive

zones are both elastic with a linear momentcurvature plot and

the neutral axis at the centroid of the sample. This case continues

until reaching the point of rst cracking. There are two potential

regions when the elastic Stage 1 ends and the tensile cracking as

dened in Stage 2 starts. The compression side may or may

not enter the plastic zone. Elastic compression shown in Fig. 5a

is denoted as Stage 2.1, while tensile cracking, with the

compression in plastic range is dened as Stage 2.2 (tension-plastic

compression).

Two potential regions at the end of Stage 2 depending on

whether the transition takes place form region 2.1 or 2.2 exist.

Stage 3.1 shown in Fig. 5b is an elastic response in compression

while plastic compression is dened as Stage 3.2. It is important

to note that depending on the relationship among material param-

eters, any of the stages 2.1, and 2.2, or 3.1, and 3.2 are potentially

possible in succession.

By applying the moment-area method to the bilinear moment

curvature response, mid-span deection of three-point bending

tests can be derived explicitly [50]. After cracking, the curvature

distribution depends on the normalized post-peak tensile strain.

The maximum deection during the elastic stage of loading is

determined from the curvature at cracking (/

cr

) and Eq. (8). If

l > l

crit

, as the post-crack curvature increases, the moment contin-

ues to increase with the deection determined by Eq. (9). On the

other hand, if l < l

crit

, as the post-crack curvature increases, the

moment either increases or decreases at the levels below the bilin-

ear cracking moment M

cr

, the deection during this stage is deter-

mined by Eq. (10), and the term L

p

represents the length of

localization zone.

d

cr

1

12

L

2

/

cr

8

d

u

L

2

24M

2

u

2M

2

u

M

u

M

cr

M

2

cr

/

u

M

2

u

M

u

M

cr

/

cr

h i

l > l

crit

9

d

u

/

u

L

p

8

2L L

p

M

u

/

cr

L

12M

cr

L 2L

p

l < l

crit

10

Similarly, a set of equations for the four-point bending can be

written as

d

cr

23

216

L

2

/

cr

11

d

u

L

2

216M

2

u

23M

2

u

4M

u

M

cr

M

2

cr

/

u

4M

2

u

4M

u

M

cr

/

cr

h i

l>l

crit

12

d

u

5/

u

L

2

72

M

u

L

2

/

cr

27M

cr

l < l

crit

13

Table 4

Governing equations for the calculation of k, M

0

and /

0

for each stage specied by strains at top and bottom bers (c = 1 in the present study).

Stage Parameters k M

0

= M/M

cr

/

0

= ///

cr

1

0 < b < 1

k

1

1

2

for c 1

1

c

p

1c

for c1

(

M

0

1

2b c1 k

3

1

3k

2

1

3k11

1k1

/

0

1

b

2 1k1

2.1

1 < b < a

k

21

D21

D21cb

2

p

D21cb

2

M

0

21

2cb

3

C21 k

3

21

3C21k

2

21

3C21k21C21

1k21

/

0

21

b

2 1k21

0 < k < x

D

21

g b

2

2b 1

2b 1 C

21

2b

3

3b

2

1g3b

2

1

b

2

2.2

1 < b < a k

22

D22

D222xcb

,

M

0

22

3cxb

2

C

22

k

2

22

2C

22

k

22

C

22

,

/

0

22

b

2 1k22

x < k < k

cu

D

22

D

21

cx

2

C

22

C

21

cx

3

b

2

3.1

a < b < b

tu

k

31

D31

D31cb

2

p

D31cb

2

M

0

31

2cb

3

C31 k

3

31

3C31k

2

31

3C31k31C31

1k31

/

0

31

b

2 1k31

0 < k < x D

31

g a

2

2a 1

2l b a 2a 1

C

31

2a

3

3a

2

1g3l a

2

b

2

3a

2

1

b

2

3.2

a < b < b

tu

k

32

D32

D322xcb

,

M

0

32

3cxb

2

C

32

k

2

32

2C

32

k

32

C

32

,

/

0

32

b

2 1k32

x < k < k

cu

D

32

D

31

cx

2

C

32

C

31

cx

3

b

2

ctop cr

=

tbot cr =

1

1

hc1

h

t1

kh

h

1

1

yc1

y

t1

Fc1

y

t2

f

t1

f

c1

2 h

t2

cr

F

t2 2

ft2

F

t1

2.1

(a)

ctop cr

=

tbot cr =

1

1

hc1

h

t1

kh

h

1

1

yc1

y

t1

Fc1

y

t2 f

t1

f

c1

2

h

t2

cr

F

t2

2

f

t2

F

t1

3.1

3 ht3 3 Ft3

y

t3

ft3

trn

(b)

Fig. 5. Strain and stress diagrams at the post crack stage, (a) Stage 2.1 in Table 4; (b)

Stage 3.1 in Table 4.

B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253 247

From the approximate bilinear momentcurvature diagram, the

total load P

i

at a given stage of loading i can be calculated by Eq.

(14) for /

i

through /

u

, where S = L/2 for three point bending tests,

respectively.

P

i

2M

i

S

14

When a exural specimen is loaded well into the post peak

region, two distinct zones develop and the deformation localizes

in the cracking region, while the remainder of the specimen under-

goes general unloading. To correlate the stress-crack width rela-

tionship into the stressstrain approach, localization is treated as

an average response within the cracking region. Results are used

as a smeared crack in conjunction with the momentcurvature

diagram to obtain load deformation behavior as presented by

Soranakom and Mobasher, and Bakhshi et al. [53,55].

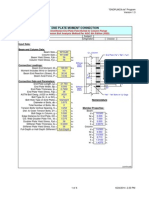

4.2. Prediction of loaddeection response of FRC

The back-calculation procedure computes the tensile material

properties from experimental three- and four-point bending

loaddeection data. Results of back-calculation of stressstrain

responses by trilinear tensile model for all mixtures are shown in

Table 5. Fig. 6 represent the effect of curing time on the back cal-

culated tensile stressstain response and exural loaddeection

response of type A and B macro synthetic bers. The initial

response is linear elastic up to the rst crack stage at about

2 MPa for 14 day and increased to 2.32.6 MPa for 28 day samples.

After cracking, load is transferred to the bers bridging the cracks

resulting in the signicant drop in the sample stiffness and increas-

ing the crack width. Back-calculated tensile stressstrain responses

show that after an average strain level of about 0.0030.004 mm/

mm, the residual strength of the macro synthetic ber composites

reaches a constant value and that strain is maintained until 34%

level. The post-crack residual strength at this plateau zone

increased from about 0.4 to 0.7 MPa between 14 to 28 days.

The load versus deection response based on the simulated t

of the data matches the experimental response as shown in

Fig. 6b. The overall predictions are well established. Representative

properties for the simulation of upper and lower bound values

obtained from these samples indicate E = 1821 GPa, a = 3040,

l = 0.210.3, g = 0.020.026 and e

cr

= 107125 lstr. In all these ts,

the parameters for the ratio of compressive to tensile stiffness and

strength were held constants at c = 1, and x = 10. The limits of the

modeling were set at b

tu

= 267406 and k

cu

= 70.

Back-calculated tensile stressstrain response and experimen-

tal and simulated loaddeection response for AR-glass bers are

shown in Fig. 7a and b, respectively. The tensile strength of the

glass ber campsites are affected only marginally by the ber

length as the tensile strength increased from about 2.92 to

3.6 MPa by increasing the ber length from 6 to 24 mm. The

back-calculated tensile strength for parameter l in this case is

0.11, 0.05 and 0.06, representing the effect of ber length from 6

to 12 and 24 mm and corresponds to residual tensile strength at

the plateau zone for glass ber reinforced samples in the range

of 0.20.3 MPa. Representative properties for the simulation of

Table 5

Average back calculated tensile parameters.

Sample ID Youngs

modulus

First crack

tensile strain

First crack

tensile strength

Post crack

modulus

Post crack

tensile strength

Transitional tensile strain Ultimate tensile strain Tensile toughness

E, GPa e

cr

, lstr r

cr

MPa g l a e

trn

, lstr e

tu

, mm/mm b

tu

G

f

, MPa

P3-A-14d 19 107 2.07 0.020 0.21 40 4280 0.029 267 0.016

P3-A-28d 21 125 2.63 0.026 0.26 30 3750 0.045 359 0.034

P3-B-14d 18 107 1.88 0.020 0.23 40 4280 0.031 292 0.016

P3-B-28d 20 115 2.3 0.024 0.3 30 3450 0.047 406 0.035

G6-6-28d 32 90 2.92 0.026 0.11 35 3150 0.025 286 0.012

G6-12-28d 32 98 3.18 0.023 0.05 42 4116 0.033 340 0.011

G6-24-28d 33 110 3.64 0.049 0.06 20 2200 0.018 160 0.008

S13-HL-28d 31 61 1.89 0.126 0.12 8 488 0.033 545 0.008

S13-HL-56d 31 54 1.68 0.106 0.15 9 486 0.029 543 0.008

S26-HL-28d 31 63 1.95 0.074 0.33 10 630 0.032 509 0.021

S26-HL-56d 28 72 1.99 0.111 0.22 8 576 0.043 597 0.019

S39-HL-28d 21 89 1.84 0.064 0.42 10 890 0.038 431 0.030

S39-HL-56d 21 76 2.09 0.049 0.41 13 988 0.041 542 0.036

Fig. 6. (a) Effect of curing time on back calculated tensile stress strain response. (b)

Effect of curing time on experimental and simulated load deection response for

polymeric bers. (Set 1).

248 B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253

upper and lower bound values obtained from these samples indi-

cate E = 3233 GPa, a = 2042, l = 0.060.11, g = 0.0230.049,

e

cr

= 90110 lstr. The simulated loaddeection responses show

good agreements with experimental data and the descending part

of loaddeection response is tted quite well.

Effect of steel ber was evaluated using different dosages of 13,

26 and 39 kg/m

3

using data from Set 3. Hooked-end steel bers

designated as type H ber were used in the concrete mixes poured

into samples specied as type L specimens (450 mm 150 mm

150 mm). At 28 days, the steel ber reinforced samples showed

increases in exural toughness as ber dosage increased. This is

evidenced by the calculation of the area under loaddeection dia-

gram shown in Fig. 8b. Flexural toughness increased by 43% and

165% by increasing steel ber dosages from 13 kg/m

3

to 26 kg/m

3

and 39 kg/m

3

, respectively. The residual exural loads increased

proportionally with the ber dosage. While this improvement is

clearly evident in the measured toughness (l = 0.120.15 to

0.220.33 and to 0.42 for the 13, 26 and 39 kg/m

3

dosages, respec-

tively), rst crack tensile strength is not largely affected by the

ber dosage and is stable at around 1.89, 1.95 and 1.84 MPa with

increasing ber content. Simulations presented in Fig. 8b are

reasonable ts for the 13 and 26 kg/m

3

dosage curves, but fail to

capture the almost linear unloading in the post cracking region

of the 39 kg/m

3

. This may be attributed to uneven distribution of

bers in the mix or larger concentrations of steel in the tensile

region. Representative properties for the simulation of upper and

lower bound values obtained from these samples indicate E = 21

31 GPa , a = 813, g = 0.0490.126, e

cr

= 5489 lstr. The choice of

the model used in the back calculation procedure may be altered

using parameters, a and, g to change from a strain softening to

strain hardening model to properly capture both the peak and

residual strength values. It is noted that there is a clear and consis-

tent post crack residual strength measure that is similar to metal

plasticity as the yielding behavior extends to deections in excess

of 4 mm.

4.3. Model extension to HPFRC

Kim et al. [49] performed an experimental study on the effect of

Hooked (H) and twisted (T) steel bers on exural and tensile

responses of high strength cementitious matrix (84 MPa) with a

ber content of 79 kg/m

3

. Flexural tests were performed on three

different geometries of specimens, S (small) for 50 mm

25 mm 300 mm specimens, M (medium) for 100 mm 100 mm

300 mm and L (large) for 150 mm 150 mm 450 mm. Proper-

ties of hooked bers in this study are very similar to the ones pre-

sented in the previous section, with the exception of length of

bers and diameter of the hooked bers which are 30 mm, and

0.38 mm in Kims study, respectively. The ratio of water to cemen-

titious materials was 0.26, and other details of mix design can be

found in the reference paper [49].

Present method of approach is validated by comparing results

of back calculated stressstrain responses with experimental

tensile results. As shown in Fig. 9, the present approach predicts

the experimental results quite well. The results of exural tests

on HPFRC are also shown in Fig. 10b which represents the compar-

ison of two steel ber types of hooked (H) and twisted (T) at two

Fig. 7. a) Effect of ber length on back calculated tensile stress strain response, b)

Effect of ber length on experimental and simulated load deection response for

glass bers. (Set 2).

Fig. 8. (a) Effect of steel ber dosage on back calculated stress strain response. (b)

Effect of steel ber dosage on experimental and simulated load deection response.

(Set 3).

B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253 249

different specimen sizes. The ber content in all mixtures is 79 kg/

m

3

. The HPFRC showed very clear delineations between sample

size (M or L) and ber deformation type (H or T). The twisted bers

in both the M and L sample sizes showed increases in exural

toughness, (+116%) and hooked bers (+190%).

Peak tensile strength of about 5 MPa and peak exural strength

in the range of 1214 MPa are observed in these samples and do

not seem to be inuenced by sample size and ber distributions.

The maximum loads are 40, 57, 87 and 98 kN for the HM, TM, HL

and TL samples respectively. The larger (L) samples show a slightly

higher deection capacity with 6 mm total deection compared to

the medium (M) samples at 4 mm deection. This additional duc-

tility could be from the combined effect of length and high dosage

rate of steel bers which deform and yield as the load increases.

Back-calculated tensile stressstrain responses resulted in sim-

ulated loaddeection responses for HPFRC mixtures with steel

bers are shown in Fig. 10a and b for the Twisted bers with the

exural simulation which compare the twisted and hooked bers

and show an excellent t for the experimental data through sample

failure. Parameters related to this simulation are summarized in

Table 6. As shown in this table and Fig. 10a, back calculated

stressstrain responses for hooked bers for both medium and

large size specimens are very similar. Back calculated stressstrain

responses for twisted bers however differ from medium to large

size samples. The rst crack tensile strength of the twisted bers

in medium specimens are 30% higher than large specimens which

may be attributed to a more uniform ber distribution in large

samples. The back-calculated tensile strength parameter l in cases

of both bers are also as much as 35% higher for medium size

specimens. Similar to residual stress parameter, transitional tensile

strains are 20 + 25% more in favor of medium size samples, but

ultimate tensile strains are almost identical for all samples. None-

theless, the difference between exural test results of different

sizes are much more signicant than predicted stressstrain

responses using this method of approach.

4.4. Residual strength comparison with ASTM C1609 (f

D

150

), RILEM, and

JCI-SF4 (r

b

)

Flexural FRC beams results are also analyzed using the data

reduction approach according to ASTM C1609 [46]. Load and net

deection are recorded up to an end-point deection of L/150.

Residual strength (f

D

150

) is calculated using an elastically equivalent

approach:

f

D

150

P

D

150

L

bd

2

15

where L is the span length, P

D

150

is the residual load at net deection

of L/150, b and d are the average width and depth. ASTM C 1609

method uses an elastically equivalent elastic measure and overesti-

mates the residual uniaxial tensile strength lEe

cr

obtained based on

the present approach by almost three times. Therefore, it is imper-

ative to note that the f

D

150

parameter is not even an equivalently elas-

tic stress and can not to be associated with the post crack tensile

strength parameter r

cst

in Fig. 4a.

Fig. 9. (a) Simulation of exural responses of HPFRC materials with hooked-end

bers, (b) comparing back calculated tensile stressstrain responses with experi-

mental tensile stressstrain response for data set of Kim et al. [45]. (Set 4).

Fig. 10. (a) Effect of sample size and steel ber deformation on back calculated

stress strain response (H or T represents hooked or twisted and M or L represents

Medium or Large), (b) Effect of sample size and steel ber content on experimental

and simulated load deection responses for data set of Kim et al. [45]. (Set 4).

250 B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253

Similar to ASTM C 1609, JCI-SF recommends testing ber rein-

forced concrete by third-point loading and measuring the net

deection by Linear Variable Differential Transformers (LVDTs).

Equivalent exural strength (r

b

) is calculated by Eq. (16) [48].

r

b

T

b

d

tb

:

L

bd

2

16

where r

b

is the equivalent exural strength (N/mm

2

), T

b

is the ex-

ural toughness (N mm), L is the span length (mm), d

tb

is the deec-

tion of 1/150 of span (mm), b is the width of failed cross-section

(mm) and d is the height of failed cross-section (mm).

According to RILEM TC 162-TDF [47] bending test method can

be used for the determination of residual exural tensile strength

as well. The tensile behavior is obtained by the loaddeection

curve of a simply supported notched beam of 150 150 mm cross

section and 500 mm loaded under three-point bending arrange-

ment tested using CMOD (Crack Mouth Opening Displacement)

control. The residual exural tensile strength (f

eq,3

) is dened with

respect to d

3

, dened as:

d

3

d

L

2:65 mmmm 17

where d

L

is the deection at the limit of proportionality (mm).

The energy absorption capacity, D

Bz,3

is measured as the area

under the loaddeection curve up to a deection d

3

and consists

of two parts. The part that includes the inuence of steel bers (D

f

-

BZ,3

) is used for calculation of the equivalent exural tensile

strength, f

eq,3

, by means of the following equation.

f

eq;3

3

2

D

f

BZ;3

2:5

!

:

L

bh

2

sp

18

where L is the span length (mm), b is the width of the specimen

(mm), and h

sp

is the distance between tip of the notch and top of

cross section (mm).

As shown in Fig. 11, direct correlation of JCI residual strength

and the present method indicate JCI-SF4 method overestimates

the residual uniaxial tensile strength lEe

cr

by as much as 3.22

times. The exact correction factor for the JCI method is 1/(3.22).

A plot of corresponding values from two tests reects the relation-

ship between the two residual strength measures. It is imperative

to note that the f

D

150

parameter can be used as a tensile stress mea-

sure associated with the post crack tensile strength parameter r

cst

in Fig. 4a, so long as this parameter is corrected by a scale factor of

1/(2.94). Correction factors for presented standard parameters are

as follows:

f

D

150

2:94lr

cr

f

eq;3

3:10lr

cr

r

b

3:22lr

cr

19

Similar to other test methods, direct correlation of RILEM resid-

ual strength and the present method indicates that RILEM method

overestimates the residual uniaxial tensile strength lEe

cr

by as

much as three times. Alternatively, standard residual exural

strength parameters can be correlated to the tensile strength by

a coefcient factor of 1/3. This value is in accordance with the draft

of ACI 544.3R report based on the stress coefcients values adopted

by Barros 2004 [56] who presented a linear relationship between

tensile stress at large strains and exural strength using a coef-

cient factor of 0.27.

r

3

0:27f

R 4

20

It is noted that in the proposed methods for design by FIB [57], a

correction factor of 1/3 is used for scaling the parameter f

R3

from

exural tests to obtain f

Ftu

as the ultimate residual strength. This

correction factor can be justied by calibration of various specimen

sizes, and various ber types and dosages. The proposed value and

the present calculation therefore correlate quite well. The present

approach can be used as theoretical justication for the empirical

values obtained and used in the FIB model code.

Since the inherent assumption of the available standard method

assumes that the neutral axis is still at the centroid of the speci-

men, and the stress distribution is linear throughout. This leads

to very high nominal exural stress levels in tension ber which

are far more than tensile strength. Extreme caution must be

exercised in application of the ASTM 1609, JCI-SF4 and RILEM TC

162-TDF methods in design and analysis of ber reinforced con-

crete sections, as the results show overestimation of the residual

parameter by as much as 2.943.22 times. These results are very

similar to the results of previous study on toughness parameters

of early age ber reinforced concrete materials [58].

5. Conclusions

Characterization of tensile-exural strain softening of ber

cement composites with alternative ber types, ber content and

lengths shows that the presence of ber signicantly increases

Table 6

Average 28-day back calculated tensile parameters of HPFRC (Kim et al. [45]).

Sample ID Youngs

modulus

First crack

tensile strain

First crack

tensile strength

Post crack

modulus

Post crack

tensile strength

Transitional tensile strain Ultimate tensile strain Tensile toughness

E, GPa e

cr

, lstr r

cr

MPa g l a e

trn

, lstr e

tu

, mm/mm b

tu

G

f

, MPa

S79-HM-28d 20 260 5.2 0.006 0.2 140 0.0364 0.061 235 0.0532

S79-TM-28d 20 380 7.6 0.007 0.2 110 0.0418 0.062 163 0.0916

S79-HL-28d 20 260 5.2 0.008 0.13 105 0.0273 0.061 235 0.0378

S79-TL-28d 20 290 5.8 0.008 0.13 115 0.0334 0.062 214 0.0439

cr

cr

eq, 3 cr

2

b

2

cr

2

Fig. 11. Comparison of residual strength (lr

cr

) with JCI-SF4, RILEM and ASTM

C1609 residual parameters (Sets 1,2, 3, 4).

B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253 251

the ductility of the material. Based on the results of experiments

and analyses in this study, following conclusions may be drawn:

1. By applying the load deection back-calculation technique one

can generate tensile constitutive data with a higher degree of

accuracy than the current standard methods.

2. Using a closed form set of governing parameters and variables

applied through each stage of material response, the stress dis-

tribution that considers a shifting neutral axis also provide a

more accurate representation of the residual strength and

toughness of FRC.

3. The inherent assumption of the available standard method

assumes that the neutral axis is still at the centroid of the

cracked specimen, and the stress distribution is linear through-

out. This leads to very high nominal exural stress levels in ten-

sion ber which are far more than residual tensile strength.

4. Caution must be exercised in application of the ASTM C1609,

JCI-SF4 and RILEM TC 162-TDF methods in design and analysis

of ber reinforced concrete sections, as the results show overes-

timation of the residual parameter by as much as 2.943.22

times. Strength parameters provided by these standards must

be scaled by as much as 0.310.34 before designing FRC ele-

ments for bending loadings.

References

[1] diPrisco M, Plizzari G, Vandewalle L. Fibre reinforced concrete: new design

perspectives. Mater Struct 2009;42(9):126181.

[2] Walraven J. High performance ber reinforced concrete: progress in

knowledge and design codes. Mater Struct 2009;42(9):124760.

[3] AASHTO-AGC-ARTBA. The use of state-of-the-practice of ber reinforced

concrete. Task Force 36 Report, Subcommittee on New Highway Materials.

AASHTO-AGC-ARTBA Joint Committee; 2001.

[4] ACI. State-of-the-art report on ber reinforced concrete. ACI 544.1R-96,

American Concrete Institute, Farmington Hills, MI; 1997.

[5] The Concrete Society. Concrete industrial ground oors a guide to their

design and construction. Slough, Technical Report 34, 2nd ed.; 1994.

[6] Mindess S, Young JF, Darwin D. Concrete. 2nd ed. Upper Saddle River

(NJ): Prentice-Hall; 2003.

[7] Bentur A, Mindess S. Fibre reinforced cementitious

composites. London: Elsevier Applied Science; 1990.

[8] Bakhshi M, Mobasher B. Experimental observations of early-age drying of

Portland cement paste under low-pressure conditions. Cem Concr Comp

2011;33(4):47484.

[9] Bakhshi M, Mobasher B. Simulated shrinkage cracking in the presence of Alkali

Resistant Glass bers. ACI Special Publication; 2011. 280.

[10] Soranakom C, Bakhshi M, Mobasher B. Role of Alkali resistant glass bers in

suppression of restrained shrinkage cracking of concrete materials. In: 15th

international glass bre reinforced concrete association congress, GRC 2008,

CD-Proceedings. Prague; April 2023, 2008.

[11] Rahmani T, Kiani B, Bakhshi M, Shekarchizadeh M. Application of different

bers to reduce plastic shrinkage cracking of concrete. In: 7th RILEM

international conference on cracking in pavements. Springer, Netherlands;

2012. P. 63542.

[12] Belletti B, Cerioni R, Meda A, Plizzari G. Design aspects on steel ber-reinforced

concrete pavements. J Mater Civ Eng 2008;20(9):599607.

[13] Sorelli LG, Meda A, Plizzari GA. Steel ber concrete slabs on ground: a

structural matter. ACI Struct J 2006;103(4):5518.

[14] Pelisser F, Santos Neto AB, La Rovere HL, Pinto RCA. Effect of the addition of

synthetic bers to concrete thin slabs on plastic shrinkage cracking. Construct

Build Mater 2010;24:21716.

[15] Vondran GL. Applications of steel ber reinforced concrete. Concr Int

1991;13(11):449.

[16] Rollings RS. Corps of Engineers Design Procedures for Rigid Aireld Pavements.

In: Proceedings, second international conference on concrete pavement

design. Purdue University, West Lafayette (IN); 1981.

[17] Parker F. Steel brous concrete for airport pavement applications. Technical

Report 5-74-12. Vicksburg (MS): US Army Engineer Waterways Experiment

Station; 1974.

[18] Romualdi JP, Batson GB. Mechanics of crack arrest in concrete. J Eng Mech Div,

ASCE 1963;89:14768.

[19] Beckett D, Van De Woestyne T, Callens S. Corner and edge loading on ground

oors reinforced with steel bers. Concrete 1999;33(3):224.

[20] Falkner H, Teutsch M. Comparative investigations of plain and steel bre

reinforced industrial ground slabs. Germany: Institut Fur Baustoffe, Massivbau

und Brandschutz, Technical University of Brunswick; 1993. No. 102.

[21] Tatnall PC, Kuitenbrouwer L. Steel ber reinforced concrete in industrial oors.

Concr Int 1992;14(12):437.

[22] Beckett D. Comparative tests on plain, fabric reinforced and steel bre

reinforced concrete ground slabs. Concrete 1990;24(3):435.

[23] Kukreja CB et al. Ultimate strength of ber reinforced concrete slabs. In:

Proceedings of international symposium on ber reinforced concrete, vol. 1.

Madras; 1987. p. 23755.

[24] Sham SHR, Burgoyne CJ. Load tests on Dramix steel bre reinforced concrete

slabs a report to Sir Frederick snow and partners, consulting engineers

imperial college of science and technology, department of civil

engineering. Concrete Laboratories; 1986.

[25] Ferrara L, Meda A. Relationships between bre distribution, workability and

the mechanical properties of SFRC applied to precast roof elements. Mater

Struct 2006;39(288):41120.

[26] Gettu R, Barragn B, Garcia T, Ortiz J, Justa R. Fiber concrete tunnel lining.

Concr Int 2006;28(8):639.

[27] Bernard E. Correlations in the behaviour of bre reinforced shotcrete beam and

panel specimens. Mater Struct 2002;35(3):15664.

[28] Malhotra VM, Carette AGG, Bilodeau A. Mechanical properties and durability

of polypropylene ber reinforced high-volume y ash concrete for shotcrete

applications. ACI Mater J 1994;91(5):47886.

[29] Armelin HS, Helene P. Physical and mechanical properties of steel-ber

reinforced dry-mix shotcrete. ACI Mater J 1995;92(3):25867.

[30] Morgan DR. Steel ber reinforced shotcrete for support of underground

openings in Canada. Concr Int 1991;13(11):5564.

[31] Banthia N, Trottier JF, Wood D, Beaupre D. Inuence of ber geometry in steel

ber reinforced dry-mix shotcrete. Concr Int 1992;14(5):248.

[32] American Concrete Institute. State of the art report on ber reinforced

shotcrete, 506.1R-98. AC1 Committee 506, American Concrete Institute,

Detroit, MI; 1998.

[33] Mechtcherine V. Novel cement-based composites for the strengthening and

repair of concrete structures. Constr Build Mater 2013;41:36573.

[34] Mobasher B. Mechanics of ber and textile reinforced cement composites. 1st

ed. Boca Raton (FL): CRC Press; 2011.

[35] Glassbre Reinforced Concrete: practical design and structural analysis.

Dsseldorf: Publisher Beton-Verlag; 1995.

[36] Sukontasukkul P, Pomchiengpin W, Songpiriyakij S. Post-crack (or post-peak)

exural response and toughness of ber reinforced concrete after exposure to

high temperature. Constr Build Mater 2010;24:196774.

[37] Sueki S, Soranakom C, Mobasher B, Peled A. Pullout-slip response of fabrics

embedded in a cement paste matrix. ASCE J Mater Civil Eng 2007;19(9)

[September 1].

[38] Li CY, Mobasher B. Finite element simulations of ber pullout toughening in

ber reinforced cement based composites. Adv Cem Bas Mater 1998;7:12332.

[39] Roesler J, Gaedicke C. Fiber reinforced concrete for aireld rigid pavements.

Technical Note 3 Center of Excellence for Airport Technology (CEAT), Urbana

(IL); October 2004. 11p.

[40] Mechtcherine V, Millon O, Butler M, Thoma K. Mechanical behaviour of strain

hardening cement-based composites under impact loading. Cem Concr

Compos 2011;33:111.

[41] Mobasher B, Li CY. Mechanical properties of hybrid cement based composites.

ACI Mater J 1996;93(3):28493.

[42] Buratti N, Mazzotti C, Savoia M. Post-cracking behaviour of steel and macro-

synthetic bre-reinforced concretes. Constr Build Mater 2011;25:271322.

[43] Soulioti DV, Barkoula NM, Paipetis A, Matikas TE. Effects of bre geometry and

volume fraction on the exural behaviour of steel-bre reinforced concrete.

Strain 2011;47:e53541.

[44] Caggiano A, Cremona M, Faella C, Lima C, Martinelli E. Fracture behavior of

concrete beams reinforced with mixed long/short steel bers. Constr Build

Mater 2012;37:83240.

[45] Banthia N, Bindiganavile V. Repairing with hybrid-ber-reinforced concrete.

Concr Int 2001;23(6).

[46] ASTM C1609-10. Standard test method for exural performance of ber-

reinforced concrete (using beam with third-point loading). ASTM Standard

Book. V. 04.02; 2010.

[47] RILEM TC 162-TDF, RILEM nal recommendations on test and design methods

for steel bre reinforced concrete: bending test, Materials and Structures,

2002;35:57982.

[48] Japanese Concrete Institute, JCI-SF4. Methods of tests for exural strength and

exural toughness of ber reinforced concrete (using beam with third-point

loading). 1984; p. 4556.

[49] Kim D-J, Naaman AE, El-Tawil S. Correlation between tensile and bending

behavior of FRC composites with scale effect. In: Proceedings of FraMCoS-7,

7th international conference on fracture mechanics of concrete and concrete

structures. Jeju Island, South Korea. May 2328; 2010.

[50] Soranakom C, Mobasher B. Closed form solutions for exural response of ber

reinforced concrete beams. J Eng Mech 2007;133(8):93341.

[51] Soranakom C, Mobasher B. Closed-form moment-curvature expressions for

homogenized ber-reinforced concrete. ACI Mater J 2007;104(4):3519.

[52] Soranakom C, Mobasher B, Bansal S. Effect of material non-linearity on the

exural response of ber reinforced concrete. In: Proceeding of the eighth

international symposium on brittle matrix composites BMC8. Warsaw,

Poland; 2006. p. 8598.

[53] Soranakom C, Mobasher B. Correlation of tensile and exural responses of

strain softening and strain hardening cement composites. Cem Concr Compos

2008;30:46577.

252 B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253

[54] Soranakom C, Mobasher B. Flexural analysis and design of textile reinforced

concrete. In: 4th Colloquium on textile reinforced structures (CTRS4). Dresden,

Germany; June 35 2009. p. 27388.

[55] Bakhshi M, Barsby C, Mobasher B. Back-calculation of tensile properties of

strain softening and hardening cement composites. In: Parra-Montesinos GJ,

Reinhardt HW, Naaman AE, editors. High Performance ber reinforced cement

composites 6 (HPFRCC6). Ann Arbor, MI; 2012. p. 8390.

[56] Barros JAO, Cunha VMCF, Ribero AF, Antunes JAB. Postcracking behaviour of

steel bre reinforced concrete. Mater Struct 2004;37.

[57] b. Model Code 2010 - First complete draft, vol. 1. Bulletin 2010;55:22031.

[58] Bakhshi M, Barsby C, Mobasher B. Comparative evaluation of early age

toughness parameters in ber reinforced concrete. Maters Struct

2014;47:85372.

B. Mobasher et al. / Construction and Building Materials 70 (2014) 243253 253

Вам также может понравиться

- Jsce NL 05Документ8 страницJsce NL 05Mehdi BakhshiОценок пока нет

- Full Paper WTC2020 - 404 PDFДокумент5 страницFull Paper WTC2020 - 404 PDFMehdi BakhshiОценок пока нет

- Jsce SF4Документ4 страницыJsce SF4Mehdi BakhshiОценок пока нет

- Conmsiderations On The Usual Methods of Tunnel Lining DesignДокумент28 страницConmsiderations On The Usual Methods of Tunnel Lining DesignTony ChanОценок пока нет

- Tunnel Segment Gasket Design - Solutions and Innovations: Bakhshi, Mehdi and Nasri, VeryaДокумент10 страницTunnel Segment Gasket Design - Solutions and Innovations: Bakhshi, Mehdi and Nasri, VeryaMehdi BakhshiОценок пока нет

- Guideline For Design of SFRCДокумент65 страницGuideline For Design of SFRCscribdnikoОценок пока нет

- GT6R4A1Документ39 страницGT6R4A1Mehdi BakhshiОценок пока нет

- WTC 2020 - Full Paper 4 (REM Lining) - 414 - FinalДокумент8 страницWTC 2020 - Full Paper 4 (REM Lining) - 414 - FinalMehdi BakhshiОценок пока нет

- Dot 25309 DS1Документ251 страницаDot 25309 DS1dongheep811Оценок пока нет

- Diagram M 385 66Документ8 страницDiagram M 385 66Mehdi BakhshiОценок пока нет

- Befib 2020-Id 144Документ18 страницBefib 2020-Id 144Mehdi BakhshiОценок пока нет

- WTC 2020 - Full Paper 1 (ACI 533) - 402 - FinalДокумент6 страницWTC 2020 - Full Paper 1 (ACI 533) - 402 - FinalMehdi BakhshiОценок пока нет

- Deterioration of Concrete by The Oxidation of Sulphide Minerals in The AggregateДокумент10 страницDeterioration of Concrete by The Oxidation of Sulphide Minerals in The AggregateMehdi BakhshiОценок пока нет

- ITA WG2 Guidelines For The Design of Segmental Tunnel LiningsДокумент60 страницITA WG2 Guidelines For The Design of Segmental Tunnel LiningsMehdi Bakhshi100% (1)

- 13 15Документ108 страниц13 15Mehdi BakhshiОценок пока нет

- West End Dam-Section 35 20 23 DREDGINGДокумент6 страницWest End Dam-Section 35 20 23 DREDGINGMehdi BakhshiОценок пока нет

- Epoxy-Coated Reinforcement in Highway StructuresДокумент70 страницEpoxy-Coated Reinforcement in Highway StructuresMehdi BakhshiОценок пока нет

- Brochure - Tunnelling Applications - Permanent Spray Concrete LiningДокумент28 страницBrochure - Tunnelling Applications - Permanent Spray Concrete LiningMehdi Bakhshi100% (1)

- MFДокумент1 страницаMFMehdi BakhshiОценок пока нет

- Self-Healing Capability of Fibre Reinforced CementДокумент13 страницSelf-Healing Capability of Fibre Reinforced CementMehdi BakhshiОценок пока нет

- E EignungsprufungДокумент8 страницE EignungsprufungMehdi BakhshiОценок пока нет

- UFGS 35 20 23 - Dredging For Waterway and Marine ConstructionДокумент13 страницUFGS 35 20 23 - Dredging For Waterway and Marine ConstructionJose Leo MissionОценок пока нет

- Simulation of Train Load On Deformation of Big - Diameter Shield TunnelДокумент4 страницыSimulation of Train Load On Deformation of Big - Diameter Shield TunnelMehdi BakhshiОценок пока нет

- Concrete Tunnel Lining Fire Resistance and ProtectionДокумент8 страницConcrete Tunnel Lining Fire Resistance and ProtectionMehdi BakhshiОценок пока нет

- Cechar Abrasivity Index CAIДокумент86 страницCechar Abrasivity Index CAIRachmat S AraОценок пока нет

- 8 M Diameter 7 KM Long Beles Tailrace Tunnel (Ethiopia) Bored and Lined in Basaltic Formations in Less Than 12 MonthsДокумент13 страниц8 M Diameter 7 KM Long Beles Tailrace Tunnel (Ethiopia) Bored and Lined in Basaltic Formations in Less Than 12 MonthsMehdi BakhshiОценок пока нет

- Tac 2014 Paper 165Документ9 страницTac 2014 Paper 165Mehdi BakhshiОценок пока нет

- ACI TCMДокумент72 страницыACI TCMMehdi BakhshiОценок пока нет

- sp280 6Документ18 страницsp280 6Mehdi BakhshiОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Wear Rates Impact Maintenance PrioritiesДокумент8 страницWear Rates Impact Maintenance Prioritiesman_iphОценок пока нет

- Hubbert and Willis, 1972 Mechanics of Hydr FracДокумент19 страницHubbert and Willis, 1972 Mechanics of Hydr Fracnic7522Оценок пока нет

- Mse2 1Документ55 страницMse2 1binoОценок пока нет

- Forging + Quenching Knowledge PDFДокумент8 страницForging + Quenching Knowledge PDFAnonymous MAJuDk100% (1)

- CH 08Документ50 страницCH 08Aaron Guralski33% (3)

- Lab Report 3Документ3 страницыLab Report 3John HowellОценок пока нет

- SikaWrap Composite Fabrics For Structural and Seismic StrengtheningДокумент5 страницSikaWrap Composite Fabrics For Structural and Seismic StrengtheningTanОценок пока нет

- Yuguang Yang Thesis DigitalДокумент370 страницYuguang Yang Thesis Digitalmixel123Оценок пока нет

- Tension Members DesignДокумент42 страницыTension Members DesignVermuch CasioОценок пока нет

- Is 3400 ListДокумент1 страницаIs 3400 ListAjit SamalОценок пока нет

- HW02Документ4 страницыHW02Potatoes123Оценок пока нет

- "Tension Test": Duhok Polytechnic University Technical College Energy DepartmentДокумент14 страниц"Tension Test": Duhok Polytechnic University Technical College Energy DepartmentAryan IbrahemОценок пока нет

- Section Properties of UbДокумент9 страницSection Properties of UbEngDbtОценок пока нет

- Die Casting CalculationsДокумент5 страницDie Casting Calculationseeng.ali6515Оценок пока нет

- One-Way Slab DesignДокумент14 страницOne-Way Slab DesigndovermanОценок пока нет

- Theory of Metal Cutting Numericals PDFДокумент2 страницыTheory of Metal Cutting Numericals PDFsanjayОценок пока нет

- Cuong ExamДокумент16 страницCuong ExamCường Nguyễn MạnhОценок пока нет

- Pnictwical Applications of Fracture Mechanics: Agardograph No. 257Документ427 страницPnictwical Applications of Fracture Mechanics: Agardograph No. 257Prasanth ViratОценок пока нет

- Asphalt Institute Method FOR Flexible Pavement Design: Dr. Padma Bahadur ShahiДокумент30 страницAsphalt Institute Method FOR Flexible Pavement Design: Dr. Padma Bahadur ShahiPadma ShahiОценок пока нет

- Thermoplastic Elastomers TPE, TPR PDFДокумент6 страницThermoplastic Elastomers TPE, TPR PDFMohammad Amir AliОценок пока нет

- Lecture 18Документ8 страницLecture 18فردوس سليمانОценок пока нет

- RCD Reinforced Concrete Design Feu 2019Документ4 страницыRCD Reinforced Concrete Design Feu 2019Josephbraken Balderama Labacanacruz100% (1)

- University of Cape TownДокумент154 страницыUniversity of Cape TownDavis EscalonaОценок пока нет

- Heat TreatmentДокумент4 страницыHeat TreatmentSomnath DeyОценок пока нет

- Saka H Introduction To Phase Diagrams in Materials Science AДокумент188 страницSaka H Introduction To Phase Diagrams in Materials Science AEhsan MousaviОценок пока нет

- End Plate Moment ConnectionДокумент4 страницыEnd Plate Moment Connectionmahhor82_635643838Оценок пока нет

- Theory OF Plasticity: J. ChakrabartyДокумент4 страницыTheory OF Plasticity: J. Chakrabartynandasonu444100% (1)

- Module Taxation 1Документ2 страницыModule Taxation 1RyanCallejaОценок пока нет

- Problems in Continuum Mechanics For Engineers: Prof. Dr. E. Mazza Class Exercise 6 AS 2010Документ3 страницыProblems in Continuum Mechanics For Engineers: Prof. Dr. E. Mazza Class Exercise 6 AS 2010Mahir MahmoodОценок пока нет