Академический Документы

Профессиональный Документы

Культура Документы

Thomson Movorail Components Catalog

Загружено:

ElectromateАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Thomson Movorail Components Catalog

Загружено:

ElectromateАвторское право:

Доступные форматы

Web site www.DanaherMotion.

com

1

: :

MOVORAIL COMPONENTS

www.DanaherMotion.com

SEP 2004

GB

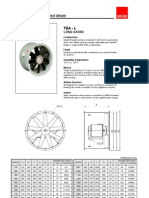

Movorail Crane Rail System

Light weight crane rail sytem

Made of extruded anodised

aluminium proles

Five rail sizes available

For loads up to 600 kg

Simple and fast to install

Easy rolling trolleys

Modular design

Accessories such as switches,

suspensions, current track

and motor trolleys.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Overview

Introduction

For over 20 years the Thomson Movorail system from Danaher Motion has been used and proven by companies

around the world and has become one of the leading light weight rail systems on the market.

The success of the Movorail system can be attributed to its highly modular design, light weight material, its simple

and quick installation and the broad range of accessories which accompany the range. Its as easy to install a Movorail

system as it is to move, enlarge, rebuild or rearrange one. In other words, a Movorail system is an investment that can

grow and change as demands change.

This folder only highlights the Movorail range of standard components, however in addition we have years of

application experience and a large network of distributors and system houses to assist you with your project.

Denitions of dimensions and directions

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Movorail profile data

Maximimum permissible deection of the rails

The diagram is based on a maximum deection of 1/500 of the distance between the suspensions (Lmax).

SPR 85 SPR 125 SPR 160A SPR 295B SPR 295W

X [mm] 85 125 160 295 295

C [mm] 68,8 71,5 73,5 73,5 73,5

Prole lengths [m]* 4, 5, 6, 8 4, 5, 6, 8 4, 5, 6, 8 4, 5, 6, 8 4, 5, 6, 8

Inertia [cm

4

] 97 333 812 1368 3700

Weight/meter [kg/m] 3 5 7,8 14 14,1

SPR 85, SPR 125, SPR 160A SPR 295B, SPR 295W

Technical data for rail proles

*Longer rails available upon request.

Prole length

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

::

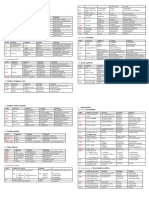

X-prole Y-prole X Y A B H

SPR 85 SPR 85 85 85 57,5 52 279,5

SPR 85 SPR 125 85 125 58,5 49,5 318

SPR 85 SPR 160A 85 160 58,5 45 348,5

SPR 125 SPR 85 125 85 55 52 317

SPR 125 SPR 125 125 125 56 49,5 355,5

SPR 125 SPR 160A 125 160 56 45 386

SPR 160A SPR 85 160 85 50,5 52 347,5

SPR 160A SPR 125 160 125 51,5 49,5 386

SPR 160A SPR 160A 160 160 51,5 45 416,5

SPR 295B(W) SPR 85 295 85 50,5 52 482,5

SPR 295B(W) SPR 125 295 125 51,5 49,5 521

SPR 295B(W) SPR 160A 295 160 51,5 45 551,5

Installation dimensions for standard systems using BGV trolleys [mm]

X

A

H

Y

B

X-prole Y-prole a b c d e f Max. Load F [N]

SPR 85 SPR 85 2000 1000 1000 229 250 200 400

SPR 85 SPR 85 3000 1500 1000 229 250 200 300

SPR 85 SPR 85 4000 2000 1000 229 250 200 250

SPR 125 SPR 125 2000 1000 1000 307 250 200 1400

SPR 125 SPR 125 3000 1500 1000 307 250 200 1000

SPR 125 SPR 125 4000 2000 1000 307 250 200 900

SPR 160A SPR 160A 2000 1000 1000 372 250 200 3000

SPR 160A SPR 160A 3000 1500 1000 372 250 200 2500

SPR 160A SPR 160A 4000 2000 1000 372 250 200 2000

Installation dimensions and load capacity for systems with telescopic crane rail [mm]*

a e e

b

c f

F

d

*The table above only show a few examples of all possible combinations of loads and dimensions.

Movorail system dimensions

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Figure Designation Use with rail size Remark Part number Notes

Rail proles

SPR 85-4 L = 4 m D108 614

SPR 85-5 L = 5 m D108 615

SPR 85-6 L = 6 m D108 616

SPR 85-8 L = 8 m D108 618

SPR 85- L = specify length

SPR 125-4 L = 4 m D100 214

SPR 125-5 L = 5 m D100 215

SPR 125-6 L = 6 m D100 216

SPR 125-8 L = 8 m D100 218

SPR 125- L = specify length

SPR 160A-4 L = 4 m D100 254

SPR 160A-5 L = 5 m D100 255

SPR 160A-6 L = 6 m D100 256

SPR 160A-8 L = 8 m D100 258

SPR 160A- L = specify length

SPR 295B-4 L = 4 m D119 204

SPR 295B-5 L = 5 m D119 205

SPR 295B-6 L = 6 m D119 206

SPR 295B-8 L = 8 m D119 208

SPR 295B- L = specify length

SPR 295W-4 L = 4 m D119 304

SPR 295W-5 L = 5 m D119 305

SPR 295W-6 L = 6 m D119 306

SPR 295W-8 L = 8 m D119 308

SPR 295W- L = specify length

Curved rail proles

SPB 85-90 SPR 85 Angle = 90 D108 629

SPB 85- SPR 85 Angle = specify angle

SPB 125-90 SPR 125 Angle = 90 D100 239

SPB 125- SPR 125 Angle = specify angle

SPB 160A-90 SPR 160A Angle = 90 D100 269

SPB 160A- SPR 160A Angle = specify angle

Rail connections

SK 85R SPR 85 For straight rails D114 410

SK 125/160AR SPR 125/160A/295B(W) For straight rails D103 830

SK 85R/B SPR 85 For straight to curved rails D114 910

SK 125/160AR/B SPR 125/160A/295B(W) For straight to curved rails D116 230

T-slot bolts

TBM 8-28 SPR 85 M8, h = 24 mm D111 620

TBM 8-45 SPR 85 M8, h = 41 mm D111 615

TBM 12-32 SPR 125/160A/295B(W) M12, h = 26 mm D102 510

TBM 12-48 SPR 125/160A/295B(W) M12, h = 42 mm D102 525

TBM 12-95 SPR 125/160A/295B(W) M12, h = 89 mm D102 515

Movorail components data

Movorail components

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

::

Movorail components data

Movorail components

Figure Designation Use with rail size Remark Part number Notes

I-beam clamps

Flexible suspensions

Adjustable suspensions

Z-suspensions

Universal safety cables

Endplates

Endstops (STP), Endplate supports

(EPF) and Walter bolts (WBM)

VBKLA 85 SPR 85 Pair. Max. load 1000 N D101 048

VBKLA 125/160A SPR 125/160A/295B(W) Pair. Max. load 6000 N D101 047

DBSU 85-100* SPR 85 Max. load 1000 N D106 202

DBSU 125/160A-600* SPR 125/160A/295B(W) Max. load 6000 N D106 209

* The suspension can be installed in any direction in relation to the I-beam

ASU 125/160A-600 SPR 125/160A/295B(W) Max. load 6000 N D106 215

* The suspension can be installed in any direction in relation to the I-beam and is adjustable 50 mm in height

DZ 85 SPR 85 Max. load 1000 N D116 810

DZ 125/160A SPR 125/160A/295B(W) Max. load 6000 N D116 410

SLU4 SPR 85 Cable diameter = 4 mm D190 605

SLU6 SPR 125/160A/295B(W) Cable diameter = 6 mm D190 604

TPL 85 SPR 85 STP or EPF required for mounting D107 410

TPL 125 SPR 125 STP or EPF required for mounting D103 720

TPL 160A SPR 160A/295B(W) STP or EPF required for mounting D103 730

STP 85 SPR 85 With rubber bumper D107 110

STP 125/160A SPR 125/160A/295B(W) With rubber bumper D102 910

EPF 85/125/160A For all sizes No rubber bumper D102 915

WBM 12 For all sizes Secure position of STP in the rail D102 912

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Movorail components data

Movorail components

Figure Designation Use with rail size Remark Part number Notes

Crab trolleys

Bogie trolleys

Bogie trolleys with rollers

Flexible bolt connections

Trolley safety cable

Pick up trolleys

Motor trolleys

Trolley cardan joints

LPV 100 A For all sizes Max. load 1000 N D125 610

LPV 100 B* For all sizes Max. load 1000 N D125 620

LPV 300 A SPR 125/160A/295B(W) Max. load 6000 N D104 520

* This trolley can not be used in combination with current rail in rail size SPR 85

BGV 100 E For all sizes Max. load 1000 N D115 210

BGV 100 G* For all sizes Max. load 1000 N D115 220

BGV 300 C SPR 125/160A/295B(W) Max. load 6000 N D117 330

* This trolley can not be used in combination with current rail in rail size SPR 85

BGV 100 LS* SPR 85 Max. load 1000 N D115 242

BGV 100 KS SPR 125 Max. load 1000 N D115 241

BGV 100 JS SPR 160A/295B(W) Max. load 1000 N D115 240

BGV 300 HSE SPR 125/160A/295B(W) Max. load 6000 N** D117 341

* This trolley can not be used in combination with current rail in rail size SPR 85 **Max. load is 3000 N when used with rail size SPR125

BUB 85 SPR 85 One SLV4 is included D105 720

BUB 125/160A SPR 125/160A/295B(W) One SLV6 is included D105 710

TBUB12 SPR 125/160A/295B(W) D105 715

SLV4 SPR 85 Cable diameter = 4 mm D190 601

SLV6 SPR 125/160A/295B(W) Cable diameter = 6 mm D190 600

STV5-85 SPR 85 Max. 10 A @ 60 % ED D121 910

STVG5-125* SPR 125 Max. 10 A @ 60 % ED D121 940

STVG5-160A* SPR 160A/295B(W) Max. 10 A @ 60 % ED D121 945

* This type of pick up trolley must be connected to a LPV or BGV trolley and is shipped with a MBE1B type of trolley cardan joint.

TMT SPR 125/160A/295B(W) See page 10 and 11 for technical data and ordering key

MBE1B* Can be used with curved rails D119 920

MBE3* For use with straight rails only D119 930

* A trolley cardan joint is used to connect a pick up trolley or a motor trolley to a LPV or a BGV trolley

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Movorail components data

Movorail components

Figure Designation Use with rail size Remark Part number Notes

Distance girders

Cable trolleys

Kits for attachment of cables to

rails and trolleys

Motion limiter kits

DNS 125/160A-700 SPR 125/160A/295B(W) Flexible connection of two crane rails D125 410

SD 125/160A-700 SPR 125/160A/295B(W) Rigid connection of two crane rails D125 470

KBV + FB For all sizes Trolley with at cable clamp D190 512

KBV + KUL For all sizes Trolley with ball joint (KK needed) D190 511

KBVA + KUL For all sizes Trolley with ball joint (KK needed) D126 809

KBVS For all sizes Trolley with strap for round cables D190 520

KBV + KUL + SB For all sizes Trolley for hoses 30 - 80 mm D190 513

KK 10-16* Clamp for cables 10 - 16 mm D126 816

KK 17-25* Clamp for cables 17 - 25 mm D126 817

KK 26-36* Clamp for cables 26 - 36 mm D126 818

* KK clamps can be stacked on to each other. On a KBV + KUL a maximum of two clamps can be stacked. On a KBVA + KUL an

unlimited number of clamps can be stacked as long as the load does not exceed 50 kg.

KFFB For all sizes For attachment of KBV + FB D190 508

KFKK For all sizes For attachment of KBV + KUL D190 507

KFVS For all sizes For attachment of KBVS D190 521

KFSB For all sizes For attachment of KBV + KUL + SB D190 509

BGR 85* SPR 86 ASL included D107 930

BGR 125* SPR 125 ASL included D107 920

BGR 160A* SPR 160A/295B(W) ASL included D107 910

* Motion limiters are used to stop LPV, BGV or TMT trolleys before they reach the end of the rail. The distance between the motion

limiter and the end of the rail can be used for cable trolleys or to restrict the access for trolleys to certain areas. ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Movorail components data

Movorail components

Figure Designation Use with rail size Remark Part number Notes

Service sections

Current tracks, 5 pole

Power supply currect track for

installation at the rail end

Power supply current track for mid

rail installation

Current track end

Current track joint connection

Cable gland end plates

Pneumatic switches

Pneumatic switch current track kits

Pneumatic turntables

Turntable current track kit

Load sign

SSKT 125* SPR 125 D180 020

SSKT 160A* SPR 160A/295B(W) D180 030

* The exact position where the service section should be placed on the rail must be specied.

SB 5-4 For all sizes L = 4 m / Max. current = 55 A D190 110

SB 5-1 For all sizes L = 1 m / Max. current = 55 A D190 109

SB 5.90.1200 For all 90 curves Radius = 1,2 m / Max. current = 55 A D190 113

ATSA 5 For all sizes L = 1 m / Max. current = 25 A D190 310

TPI 5-125/160A SPR 125/160A Max. current = 25 A D190 117

* The exact position where the cable gland plate should be placed on the rail must be specied.

EST 5 + LED 5 For all sizes Included in ATSA 5 D190 115

ATSK 5 For all sizes Max. current = 25 A D190 116

TPLH 85 SPR 85 EFP or STP required for mounting D107 420

TPLH 125 SPR 125 EFP or STP required for mounting D103 740

TPLH 160A SPR 160A/295B(W) EFP or STP required for mounting D103 750

HXL 85 SPR 85 Right turn (shown in picture) D180 113

HXL 125 SPR 125 Right turn (shown in picture) D180 123

HXL 160A SPR 160A/295B(W) Right turn (shown in picture) D180 133

VXL 85 SPR 85 Left turn D180 112

VXL 125 SPR 125 Left turn D180 122

VXL 160A SPR 160A/295B(W) Left turn D180 132

SBHX For use in all HXL / TPI 5 included D180 141

SBVX For use in all VXL / TPI 5 included D180 140

VSL 85 SPR 85 D180 211

VSL 125 SPR 125 D180 221

VSL 160A SPR 160A/295B(W) D180 231

SBVS For use in all VSL / TPI 5 included D180 240

For all sizes Sticker D301 114

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Trolley joints Pneumatic cylinder sensor bracket

Dimensions

MBE1B

MBE3

MBE1B - for straight and curved rails, p/n D119 920

MBE3 - for straight rails only, p/n D119 930

The sensor bracket is mounted on the motor

trolley and can hold a cylindrical sensor that

will indicate the position of the pneumatic

cylinder.

p/n D120 190

Pneumatic release Spring loaded

Spring setting and adjustment for rail size

Movorail motor trolley dimensions

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Unit type

Tollo Motor Trolley TMT

Prole type

SPR 125

SPR 160A

125

160

Type of TMT trolley

With spring loaded drive wheel (standard)

With pneumatically released drive wheel

With spring and power pick up

With pneumatic release and power pick up

S

P

T

Q

Colour

Blue (standard)

Yellow

B

Y

Gear ratio ( i ) - the worm gears comes with ange and coupling for IEC 71/B14 motors

00 (if no gear, use for code G and H )

10

15

20

24

30

40

48

60

00

10

15

20

24

30

40

48

60

Motor, gear and drive wheel conguration

No motor, with Benzler worm gear

Without motor and gear, with drive wheel

Without motor, gear and drive wheel

N

G

H

Ordering key for trolley with motor

Designation example TMT 125 S B 20 A 7 -2 N

Unit type

Tollo Motor Trolley TMT

Prole type

SPR 125

SPR 160A

125

160

Type of TMT trolley

With spring loaded drive wheel (standard)

With pneumatically released drive wheel

With spring and power pick up

With pneumatic release and power pick up

S

P

T

Q

Colour

Blue (standard)

Yellow

B

Y

Speed of trolley at nominal motor rpm ( v )

20 m/min

25 m/min

30 m/min

35 m/min

40 m/min

50 m/min

60 m/min

20

25

30

35

40

50

60

Motor, gear and drive wheel conguration

400 Vac 3 phase SEW motor, SEW gear and drive wheel (standard) A

Motor size

IEC 71

IEC 80

7

8

Motor poles

2 pole

4 pole

8/2 pole (2 speed motor)

-2

-4

82

Type of motor brake

No brake

Electromagnetic fail safe brake

Electronagnetic fail safe brake with hand release

N

B

H

Ordering key for trolley without motor Formulas

Designation example TMT 125 S B 10 N

Calculation of trolley speed:

rmpmotor 3,14 0,15

v =

i

Calculation of gear ratio:

rpmmotor 3,14 0,15

i =

v

v = travel speed [m/min]

i = gear ratio

Pneumatic release Spring loaded

Movorail motor trolley ordering key

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Вам также может понравиться

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Honor Seiki VTL Heavy DutyДокумент16 страницHonor Seiki VTL Heavy DutyCNC SYSTEMSОценок пока нет

- Aluminium Motors PDFДокумент8 страницAluminium Motors PDFelrajilОценок пока нет

- Efficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsДокумент12 страницEfficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsnkhhhОценок пока нет

- Dynaflo DP 60hz CatalogДокумент44 страницыDynaflo DP 60hz Catalognpclap67% (3)

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20От EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Оценок пока нет

- Mitsubishi diesel forklifts 1.5-3.5 tonnesДокумент2 страницыMitsubishi diesel forklifts 1.5-3.5 tonnesJoniОценок пока нет

- A Guide To The Preparation of Civil Engineering Drawing PDFДокумент186 страницA Guide To The Preparation of Civil Engineering Drawing PDFEraj100% (3)

- A Detailed Explanation of Solenoid ForceДокумент12 страницA Detailed Explanation of Solenoid Forceserleb44Оценок пока нет

- Cable Handling Equipment Catalogue GuideДокумент34 страницыCable Handling Equipment Catalogue Guidejeb13Оценок пока нет

- Macho Drum Winches Data v1.4Документ2 страницыMacho Drum Winches Data v1.4AdrianSomoiagОценок пока нет

- Ficha Tecnica Motor NeumaticoДокумент7 страницFicha Tecnica Motor NeumaticoDestaco IngenieroОценок пока нет

- BEMO RAIL BV expert rail systems worldwideДокумент19 страницBEMO RAIL BV expert rail systems worldwideTh NattapongОценок пока нет

- High Speed, Water Cooled 5 To 18 HPДокумент5 страницHigh Speed, Water Cooled 5 To 18 HPapi-311397395Оценок пока нет

- 130724Документ20 страниц130724Caracal MohОценок пока нет

- WallДокумент0 страницWallgks6043Оценок пока нет

- Dyadic Systems 2011 CatalogДокумент16 страницDyadic Systems 2011 CatalogElectromateОценок пока нет

- Amp Servo Products DatasheetДокумент16 страницAmp Servo Products DatasheetElectromateОценок пока нет

- Copperhead Conductor SystemДокумент24 страницыCopperhead Conductor SystembhsujanОценок пока нет

- Brosjyre GSSB EnglishДокумент3 страницыBrosjyre GSSB Englishrol_sonОценок пока нет

- Actuator RangeДокумент212 страницActuator RangeLL100% (1)

- Scule Pentru Abkant Trumpf Trumabend Si Trubend Si Compatibile - SMДокумент76 страницScule Pentru Abkant Trumpf Trumabend Si Trubend Si Compatibile - SMMihaiОценок пока нет

- Wabco Wall Chart For Trailer and Truck AbsДокумент1 страницаWabco Wall Chart For Trailer and Truck AbsJay RitschardОценок пока нет

- TP SeriesДокумент3 страницыTP SeriesPrasad KadamОценок пока нет

- TSKДокумент4 страницыTSKar174_569868987Оценок пока нет

- 12 Caldwell VL-8Документ1 страница12 Caldwell VL-8Thomas StempienОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Coel Catalogue 2006 1Документ58 страницCoel Catalogue 2006 1Danilo MontesanoОценок пока нет

- Eurobloc VT 9 10 11 12 GBДокумент6 страницEurobloc VT 9 10 11 12 GBToni RenedoОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Electric Reach Trucks Capacity 1400-2000 kg Technical SpecsДокумент6 страницElectric Reach Trucks Capacity 1400-2000 kg Technical Specsingenioso23Оценок пока нет

- AWT 1000 LeafletДокумент6 страницAWT 1000 Leafletphucgenji0% (1)

- Thomson Roundrail 1PB SpecsheetДокумент2 страницыThomson Roundrail 1PB SpecsheetElectromateОценок пока нет

- Torque Systems Ms400 SpecsheetДокумент2 страницыTorque Systems Ms400 SpecsheetElectromateОценок пока нет

- All Diafragms Meters Sb3500Документ17 страницAll Diafragms Meters Sb3500Ruben Romero SotoОценок пока нет

- TrelleborgДокумент10 страницTrelleborgrofiqq4Оценок пока нет

- Jost CatalogueДокумент227 страницJost CatalogueLechien LeОценок пока нет

- Fluid Couplings for Constant Speed ApplicationsДокумент26 страницFluid Couplings for Constant Speed ApplicationsSarfaraz Hoda100% (1)

- SRДокумент2 страницыSRJong JavaОценок пока нет

- Brochure Lighting ColumnsДокумент48 страницBrochure Lighting Columnsi_m_pranayОценок пока нет

- Roller BrochureДокумент16 страницRoller BrochurePeterson MagroОценок пока нет

- Shimpo Able EVB BrochureДокумент4 страницыShimpo Able EVB BrochureElectromateОценок пока нет

- Flex Buffalo - w000266150 - en - Noc36993Документ8 страницFlex Buffalo - w000266150 - en - Noc36993silvestre_25Оценок пока нет

- Extractores Mecanicos e Hidraulicos CATДокумент39 страницExtractores Mecanicos e Hidraulicos CATHenryMonteagudoParedes0% (1)

- Suitcase 8Rc and 12Rc: The Power of BlueДокумент2 страницыSuitcase 8Rc and 12Rc: The Power of BlueAnonymous mM1BZ9AWZ7Оценок пока нет

- All-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionДокумент8 страницAll-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionHong Chee FongОценок пока нет

- Groundworks BrochureДокумент19 страницGroundworks BrochureMagdy BakryОценок пока нет

- Colchester Standard Lathes PDFДокумент8 страницColchester Standard Lathes PDFmubashkОценок пока нет

- IAI 02 RC General CJ0203-2A P001-144 SliderДокумент144 страницыIAI 02 RC General CJ0203-2A P001-144 SliderElectromateОценок пока нет

- Spec Standard For 900 Widt Conveyor BeltДокумент3 страницыSpec Standard For 900 Widt Conveyor BeltManuel Mauro D' nogueiraОценок пока нет

- Conveyor BeltsДокумент22 страницыConveyor BeltsFavorSea Industrial Channel LimitedОценок пока нет

- Advul EnusДокумент17 страницAdvul EnusErlangga PrabowoОценок пока нет

- Factory Direct A/C Compressors CatalogueДокумент28 страницFactory Direct A/C Compressors CatalogueLiubomir MilanoffОценок пока нет

- Front Mount HF TechdataДокумент14 страницFront Mount HF TechdataAlexandru NicuОценок пока нет

- TDA-L LEA001.E2 NewДокумент4 страницыTDA-L LEA001.E2 NewsugiantoОценок пока нет

- Axial Flow Fan - LeafletДокумент4 страницыAxial Flow Fan - LeafletZwe1991Оценок пока нет

- Compact CBP Motors Powerful OpportunitiesДокумент24 страницыCompact CBP Motors Powerful Opportunitiesidontlikeebooks100% (1)

- Scule HidrauliceДокумент34 страницыScule HidraulicelucianbordeutОценок пока нет

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesДокумент1 страницаGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateОценок пока нет

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesДокумент2 страницыADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateОценок пока нет

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionДокумент1 страницаIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateОценок пока нет

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseДокумент1 страницаElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateОценок пока нет

- Meet The World's Most Precise Six-Axis RobotДокумент1 страницаMeet The World's Most Precise Six-Axis RobotElectromateОценок пока нет

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMДокумент2 страницыAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateОценок пока нет

- Electromate Recertified As A Great Place To Work' Press ReleaseДокумент1 страницаElectromate Recertified As A Great Place To Work' Press ReleaseElectromateОценок пока нет

- Exor X5 Wireless Press ReleaseДокумент1 страницаExor X5 Wireless Press ReleaseElectromateОценок пока нет

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaДокумент1 страницаElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateОценок пока нет

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsДокумент1 страницаNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateОценок пока нет

- Kollmorgen Debuts EKM Series Servo MotorsДокумент1 страницаKollmorgen Debuts EKM Series Servo MotorsElectromateОценок пока нет

- Electromate Extends Its Product Portfolio To Include Robots From MecademicДокумент1 страницаElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateОценок пока нет

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesДокумент2 страницыNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateОценок пока нет

- Electromate Elated With Win at The 2022 Business Achievement AwardsДокумент2 страницыElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateОценок пока нет

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotДокумент2 страницыMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateОценок пока нет

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesДокумент2 страницыElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateОценок пока нет

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsДокумент1 страницаPOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateОценок пока нет

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardДокумент2 страницыElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateОценок пока нет

- Electromate Recognized With 2021 AHTD Foundation AwardДокумент1 страницаElectromate Recognized With 2021 AHTD Foundation AwardElectromateОценок пока нет

- New 100 Amps Peak FlexPro Servo Drives Available From AMCДокумент1 страницаNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateОценок пока нет

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseДокумент1 страницаNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateОценок пока нет

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseДокумент2 страницыElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateОценок пока нет

- New Integrated Spindle Drives Available From JVLДокумент1 страницаNew Integrated Spindle Drives Available From JVLElectromateОценок пока нет

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesДокумент2 страницыExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateОценок пока нет

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsДокумент1 страницаNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateОценок пока нет

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsДокумент2 страницыElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateОценок пока нет

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsДокумент1 страницаNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateОценок пока нет

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Документ2 страницыElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateОценок пока нет

- ADVANCED Motion Controls Releases The FM060-25-CMДокумент1 страницаADVANCED Motion Controls Releases The FM060-25-CMElectromateОценок пока нет

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonДокумент1 страницаMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateОценок пока нет

- Tesla Regen, Brakes and Sudden AccelerationДокумент66 страницTesla Regen, Brakes and Sudden AccelerationmartinvvОценок пока нет

- 2.6 Rational Functions Asymptotes TutorialДокумент30 страниц2.6 Rational Functions Asymptotes TutorialAljun Aldava BadeОценок пока нет

- ENGG1330 2N Computer Programming I (20-21 Semester 2) Assignment 1Документ5 страницENGG1330 2N Computer Programming I (20-21 Semester 2) Assignment 1Fizza JafferyОценок пока нет

- Scramjet EngineДокумент2 страницыScramjet EngineSãröj ShâhОценок пока нет

- Cold Backup and Recovery From Archivelog - OrACLE-HELPДокумент4 страницыCold Backup and Recovery From Archivelog - OrACLE-HELPadelarduarteОценок пока нет

- Reference Mil-Aero Guide ConnectorДокумент80 страницReference Mil-Aero Guide ConnectorjamesclhОценок пока нет

- Login Form: User Name Password Remember MeДокумент8 страницLogin Form: User Name Password Remember MeBridget Anne BenitezОценок пока нет

- Verify scope acceptance of project deliverablesДокумент5 страницVerify scope acceptance of project deliverablesmypmpbooksОценок пока нет

- Network Layer: Computer Networking: A Top Down ApproachДокумент83 страницыNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadОценок пока нет

- Javascript Api: Requirements Concepts Tutorial Api ReferenceДокумент88 страницJavascript Api: Requirements Concepts Tutorial Api ReferenceAshish BansalОценок пока нет

- Power Theft Identification Using GSM TechnologyДокумент3 страницыPower Theft Identification Using GSM TechnologyIJORAT100% (1)

- Midterm Exam Result Ce199-1l 2Q1920Документ3 страницыMidterm Exam Result Ce199-1l 2Q1920RA CarpioОценок пока нет

- Eurotech IoT Gateway Reliagate 10 12 ManualДокумент88 страницEurotech IoT Gateway Reliagate 10 12 Manualfelix olguinОценок пока нет

- Die Science - Developing Forming Dies - Part I - The FabricatorДокумент6 страницDie Science - Developing Forming Dies - Part I - The FabricatorSIMONEОценок пока нет

- Superconductivity in RH S and PD Se: A Comparative StudyДокумент5 страницSuperconductivity in RH S and PD Se: A Comparative StudyChithra ArulmozhiОценок пока нет

- Microstation V8I Accudraw Basics: Bentley Institute Course GuideДокумент80 страницMicrostation V8I Accudraw Basics: Bentley Institute Course Guideh_eijy2743Оценок пока нет

- Introduction - Week 2Документ37 страницIntroduction - Week 2Tayyab AhmedОценок пока нет

- Instrument Resume OIL and GAS.Документ3 страницыInstrument Resume OIL and GAS.RTI PLACEMENT CELLОценок пока нет

- Affixation (Landscape)Документ4 страницыAffixation (Landscape)difafalahudinОценок пока нет

- Sample Question Paper Provides Practice for Class 9 Science ExamДокумент5 страницSample Question Paper Provides Practice for Class 9 Science ExamViswak BalajiОценок пока нет

- Power Cable Installation ManualДокумент50 страницPower Cable Installation ManualAnn DodsonОценок пока нет

- The Machining of Brake DiscsДокумент8 страницThe Machining of Brake DiscsBusu Cyp100% (1)

- Time TableДокумент7 страницTime TableChethan .H.GОценок пока нет

- Great Lakes PGDM Interview Access DetailsДокумент1 страницаGreat Lakes PGDM Interview Access DetailsJaswanth konkepudiОценок пока нет

- M6 2020 Binomial Distribution Lecture NotesДокумент27 страницM6 2020 Binomial Distribution Lecture Notescoyite8695Оценок пока нет

- Velocity profiles and incompressible flow field equationsДокумент2 страницыVelocity profiles and incompressible flow field equationsAbdul ArifОценок пока нет

- Cross Belt Magnetic Separator (CBMS)Документ2 страницыCross Belt Magnetic Separator (CBMS)mkbhat17kОценок пока нет

- Nord Factory Restore Instructions Edition CДокумент1 страницаNord Factory Restore Instructions Edition CTonino CannavacciuoloОценок пока нет