Академический Документы

Профессиональный Документы

Культура Документы

Homework 5 Solution MEEN 3650-CHEN 3453 S2014

Загружено:

Dave BrimleyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Homework 5 Solution MEEN 3650-CHEN 3453 S2014

Загружено:

Dave BrimleyАвторское право:

Доступные форматы

PROBLEM5.

6

KNOWN: Diameter and initial temperature of steel balls cooling in air.

FIND: Time required to cool to a prescribed temperature.

SCHEMATIC:

ASSUMPTIONS: (1) Negligible radiation effects, (2) Constant properties.

ANALYSIS: Applying Eq. 5.10 to a sphere (L

c

= r

o

/3),

( ) ( )

2

o

c

h r / 3 20 W/m K 0.002m

hL

Bi 0.001.

k k 40 W/m K

= = = =

Hence, the temperature of the steel remains approximately uniform during the cooling

process, and the lumped capacitance method may be used. From Eqs. 5.4 and 5.5,

( )

3

p

p

i i

2

s

D / 6 c

Vc

T T T T

t ln ln

hA T T T T

h D

t

t

= =

( )

3

2

7800kg/m 0.012m 600J/kg K

1150 325

t ln

400 325

6 20 W/m K

=

t 1122 s 0.312h = = <

COMMENTS: Due to the large value of T

i

, radiation effects are likely to be significant

during the early portion of the transient. The effect is to shorten the cooling time.

PROBLEM5.12

KNOWN: Diameter, density, specific heat and thermal conductivity of aluminum spheres used in

packed bed thermal energy storage system. Convection coefficient and inlet gas temperature.

FIND: Time required for sphere to acquire 90% of maximum possible thermal energy and the

corresponding center temperature. Potential advantage of using copper in lieu of aluminum.

SCHEMATIC:

Aluminum sphere

D = 75 mm, T = 25 C

i

o

Gas

T C

g,i

o

= 300

h = 75 W/m -K

2

= 2700 kg/m

3

k = 240 W/m-K

c = 950 J/kg-K

ASSUMPTIONS: (1) Negligible heat transfer to or from a sphere by radiation or conduction due to

contact with other spheres, (2) Constant properties.

ANALYSIS: To determine whether a lumped capacitance analysis can be used, first compute Bi =

h(r

o

/3)/k = 75 W/m

2

K (0.025m)/150 W/mK = 0.013 < 0.1. Hence, the lumped capacitance

approximation may be made, and a uniform temperature may be assumed to exist in the sphere at any

time. From Eq. 5.8a, achievement of 90% of the maximum possible thermal energy storage

corresponds to

( )

t

i

Q

0.90 1 exp t /

cV

t

u

= =

where

3 2

t s

Vc / hA Dc / 6h 2700 kg / m 0.075m 950 J / kg K / 6 75 W / m K 427s. t = = = = Hence,

( )

t

t ln 0.1 427s 2.30 984s t = = = <

From Eq. (5.6), the corresponding temperature at any location in the sphere is

( )

( )

( )

g,i i g,i

T 984s T T T exp 6ht / Dc = +

( )

( )

2 3

T 984s 300 C 275 C exp 6 75 W / m K 984s / 2700kg / m 0.075m 950J / kg K =

( ) T 984 s 272.5 C = <

Obtaining the density and specific heat of copper from Table A-1, we see that (c)

Cu

~ 8900 kg/m

3

400 J/kgK = 3.56 10

6

J/m

3

K > (c)

Al

= 2.57 10

6

J/m

3

K. Hence, for an equivalent sphere

diameter, the copper can store approximately 38% more thermal energy than the aluminum.

COMMENTS: Before the packed bed becomes fully charged, the temperature of the gas decreases

as it passes through the bed. Hence, the time required for a sphere to reach a prescribed state of

thermal energy storage increases with increasing distance from the bed inlet.

PROBLEM5.51

KNOWN: Thickness, initial temperature and properties of furnace wall. Convection conditions at

inner surface.

FIND: Time required for outer surface to reach a prescribed temperature. Corresponding

temperature distribution in wall and at intermediate times.

SCHEMATIC:

L = 0.15 m x

h = 100 W/m -K

2

T C

o

= 950

oo

Combustion gases

Fire-clay brick:

T C

i

o

= 20

T (0,t) = 750 C

f

o

= 2600 kg/m

3

c = 1000 J/kg-K

p

k = 1.5 W/m-K

ASSUMPTIONS: (1) One-dimensional conduction in a plane wall, (2) Constant properties, (3)

Adiabatic outer surface, (4) Fo > 0.2, (5) Negligible radiation from combustion gases.

ANALYSIS: The wall is equivalent to one-half of a wall of thickness 2L with symmetric convection

conditions at its two surfaces. With Bi = hL/k = 100 W/m

2

K 0.15m/1.5 W/mK = 10 and Fo > 0.2,

the one-term approximation, Eq. 5.44 may be used to compute the desired time, where

( ) ( )

o o i

T T / T T 0.215. u

-

= = From Table 5.1, C

1

= 1.262 and

1

, = 1.4289. Hence,

( )

( )

( )

o 1

2 2

1

ln / C

ln 0.215/1.262

Fo 0.867

1.4289

u

,

-

= = =

( )

( )

2

2

3

0.867 0.15m

Fo L

t 33, 800s

1.5W/ m K/ 2600 kg / m 1000 J / kg K

o

= = =

<

The corresponding temperature distribution, as well as distributions at t = 0, 10,000, and 20,000 s are

plotted below

COMMENTS: Because Bi >>1, the temperature at the inner surface of the wall increases much

more rapidly than at locations within the wall, where temperature gradients are large. The

temperature gradients decrease as the wall approaches a steady-state for which there is a uniform

temperature of 950C.

0 0.2 0.4 0.6 0.8 1

Dimensionless location, x/L

0

200

400

600

800

1000

T

e

m

p

e

r

a

t

u

r

e

,

C

t=0 s

t=10,000 s

t=20,000 s

t=33,800 s

PROBLEM5.67

KNOWN: Diameter and initial temperature of roller bearings. Temperature of oil bath and

convection coefficient. Final centerline temperature. Number of bearings processed per hour.

FIND: Time required to reach centerline temperature. Cooling load.

SCHEMATIC:

L = 1 m

Stainless steel

N = 10

D = 0.10 m

T C

i

o

= 500

T(0,t ) = 50 C

f

o Oil bath

h = 500 W/m -K

2

T C

o

= 30

oo

ASSUMPTIONS: (1) One-dimensional, radial conduction in rod, (2) Constant properties.

PROPERTIES: Table A.1, St. St. 304

( )

T 548K : = =7900 kg/m

3

, k = 19.0 W/mK, c

p

= 546

J/kgK, o = 4.40 10

-6

m

2

/s.

ANALYSIS: With Bi = h (r

o

/2)/k = 0.658, the lumped capacitance method can not be used. From

the one-term approximation of Eq. 5.52c for the centerline temperature,

( )

( )

2 2 o

o 1

1

i

T T 50 30

0.0426 C exp Fo 1.1382exp 0.9287 Fo

T T 500 30

u ,

-

(

= = = = =

(

where, for Bi = hr

o

/k = 1.316, C

1

= 1.2486 and

1

, = 1.3643 from Table 5.1.

( ) Fo n 0.0341 /1.86 1.82 = =

( )

2 2 6

f o

t For / 1.82 0.05m / 4.40 10 1031s 17min

= = = = o <

From Eqs. 5.47 and 5.54, the energy extracted from a single rod is

( ) ( )

o

i 1 1

1

2

Q cV T T 1 J

u

,

,

-

(

= (

(

With J

1

(1.3643) = 0.535 from Table B.4,

( )

2 3 7

0.0852 0.535

Q 7900kg / m 546J / kg K 0.05m 1m 470K 1 1.54 10 J

1.3643

(

(

= =

(

(

t

The nominal cooling load is

7

5

f

NQ 10 1.54 10 J

q 1.49 10 W 149 kW

t 1031s

= = = = <

COMMENTS: For a centerline temperature of 50C, Eq. 5.52b yields a surface temperature of

( ) ( ) ( )

o i o o 1

T r , t T T T J 30 C 470 C 0.0426 0.586 41.7 C

-

= + = + = u ,

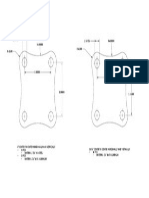

PROBLEM 4.41

KNOWN: Boundary conditions that change from specified heat flux to convection.

FIND: The finite difference equation for the node at the point where the boundary condition changes.

SCHEMATIC:

ASSUMPTIONS: (1) Two dimensional, steady-state conduction with no generation, (2) Constant

properties.

ANALYSIS: Performing an energy balance on the control volume x y/2,

in out

E - E = 0

& &

q

1

+ q

2

+ q

3

+ q

4

+ q

5

= 0

Expressing q

1

in terms of the specified heat flux, q

2

in terms of the known heat transfer coefficient and

environment temperature, and the remaining heat rates using the conduction rate equation,

1 s

x

q = q 1

2

2 m,n

x

q = h(T - T ) 1

2

m - 1,n m,n

3

k(T - T )

y

q = 1

x 2

m + 1,n m,n

4

k(T - T )

y

q = 1

x 2

m ,n - 1 m,n

5

k(T - T )

q = x 1

y

Letting x = y, substituting these expressions into the energy balance, and rearranging yields

s

m - 1,n m + 1,n m,n - 1 m,n

q x hx hx

T + T + 2T - 4 + T + T + = 0

k k k

<

m,n m +1,n m -1,n

y

q

1

q

2

q

4

q

5

q

3

h, T

x

y/2

x

m, n-1

s

q

m,n m +1,n m -1,n

y

q

1

q

2

q

4

q

5

q

3

h, T

x

y/2

x

m, n-1

m,n m +1,n m -1,n

y

q

1

q

2

q

4

q

5

q

3

h, T

x

y/2

x

m, n-1

s

q

PROBLEM 4.49

KNOWN: One-dimensional fin of uniform cross section insulated at one end with prescribed base

temperature, convection process on surface, and thermal conductivity.

FIND: Finite-difference equation for these nodes: (a) Interior node, m and (b) Node at end of fin, n,

where x =L.

SCHEMATIC:

ASSUMPTIONS: (1) Steady-state conditions, (2) One-dimensional conduction.

ANALYSIS: (a) The control volume about node m is shown in the schematic; the node spacing and

control volume length in the x direction are both x. The uniform cross-sectional area and fin

perimeter are A

c

and P, respectively. The heat transfer process on the control surfaces, q

1

and q

2

,

represent conduction while q

c

is the convection heat transfer rate between the fin and ambient fluid.

Performing an energy balance, find

( )

in out 1 2 c

m-1 m m+1 m

c c m

E E 0 q q q 0

T T T T

kA kA hP x T T 0.

x x

= + + =

+ + =

& &

Multiply the expression by x/kA

c

and regroup to obtain

2 2

m-1 m+1 m

c c

hP hP

T T x T 2 x T 0 1<m<n

kA kA

+ + + =

<

Considering now the special node m =1, then the m-1 node is T

b

, the base temperature. The finite-

difference equation would be

2 2

b 2 1

c c

hP hP

T T x T 2 x T 0 m=1

kA kA

+ + + =

<

(b) The control volume of length x/2 about node n is shown in the schematic. Performing an energy

balance,

( )

in out 3 4 c

n-1 n

c n

E E 0 q q q 0

T T x

kA 0 hP T T 0.

x 2

= + + =

+ + =

& &

Note that q

4

=0 since the end (x =L) is insulated. Multiplying by x/kA

c

and regrouping,

2 2

n-1 n

c c

hP x hP x

T T 1 T 0.

kA 2 kA 2

+ + =

<

COMMENTS: The value of x will be determined by the selection of n; that is, x =L/n. Note that

the grouping, hP/kA

c

, appears in the finite-difference and differential forms of the energy balance.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Toyota Service Specifications - 2000 To 2002Документ44 страницыToyota Service Specifications - 2000 To 2002Marcelo Pchevuzinske100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Catalogue2014 PDFДокумент158 страницCatalogue2014 PDFاشرينكيل مسونكيل100% (1)

- Shell Tellus S2 V 46 - Technical Data SheetДокумент3 страницыShell Tellus S2 V 46 - Technical Data SheetVelibor KaranovicОценок пока нет

- Kawasaki FH451V-FH721V 2003 Service Manual PDFДокумент153 страницыKawasaki FH451V-FH721V 2003 Service Manual PDFBrianCookОценок пока нет

- T H MorayOscTubeДокумент9 страницT H MorayOscTuberocism01100% (1)

- 6la-St, Lak-St, Lah-St, Lahk-St, Lah-SteДокумент201 страница6la-St, Lak-St, Lah-St, Lahk-St, Lah-SteJakewell Joyce Bucol100% (2)

- Ge312-1121 Columns - DrumДокумент20 страницGe312-1121 Columns - DrumDiarista Thoma SaputraОценок пока нет

- Heat Transfer ch-1Документ1 страницаHeat Transfer ch-1Fawazil NawesОценок пока нет

- BracketsДокумент1 страницаBracketsDave BrimleyОценок пока нет

- Homework 1 Solution MEEN3650-CHEN3453 S2014Документ5 страницHomework 1 Solution MEEN3650-CHEN3453 S2014Dave BrimleyОценок пока нет

- Syllabus Senior Design I 4000 2014-V1Документ5 страницSyllabus Senior Design I 4000 2014-V1Dave BrimleyОценок пока нет

- Involute GearsДокумент34 страницыInvolute GearsDave BrimleyОценок пока нет

- Lab Section T AsДокумент1 страницаLab Section T AsDave BrimleyОценок пока нет

- 9.1 Prob 13.59Документ26 страниц9.1 Prob 13.59Dave Brimley0% (1)

- Scan Dec 1, 2013, 9 - 12 PMДокумент7 страницScan Dec 1, 2013, 9 - 12 PMDave BrimleyОценок пока нет

- Scan Dec 1, 2013, 9 - 12 PMДокумент7 страницScan Dec 1, 2013, 9 - 12 PMDave BrimleyОценок пока нет

- Physics 1 PagerДокумент2 страницыPhysics 1 PagerDave BrimleyОценок пока нет

- Models: 1828 and 1829 1845 and 1846: Forma Laminar Airflow Workstation Class 100Документ38 страницModels: 1828 and 1829 1845 and 1846: Forma Laminar Airflow Workstation Class 100Fabian FlandezОценок пока нет

- FINAL TEST 1 K 2Документ4 страницыFINAL TEST 1 K 2Nguyen Cuong100% (1)

- Class X Social Studies Important QuestionsДокумент17 страницClass X Social Studies Important QuestionsSai SiddharthОценок пока нет

- Maintenance Manual - Scissor LiftsДокумент103 страницыMaintenance Manual - Scissor LiftsStar SealОценок пока нет

- Pressure Vessel Head Shapes - Piping DesignerДокумент3 страницыPressure Vessel Head Shapes - Piping DesignerSampath KumarОценок пока нет

- Seminar Report GautamДокумент32 страницыSeminar Report GautamGautam DangiОценок пока нет

- EFS KitДокумент13 страницEFS KitAmalia PrassОценок пока нет

- Nuclear Physics Interview Questions and Answers 830 PDFДокумент7 страницNuclear Physics Interview Questions and Answers 830 PDFpeterjo raveloОценок пока нет

- PCM-Manual 0507Документ32 страницыPCM-Manual 0507PamellaОценок пока нет

- Hi-7 and Hi-8 Race Ignition Systems: Battery ConsiderationsДокумент8 страницHi-7 and Hi-8 Race Ignition Systems: Battery ConsiderationssphinxxxxОценок пока нет

- Manual MICOM P220 MotoresДокумент410 страницManual MICOM P220 MotoresGustavo TrilloОценок пока нет

- 1591812168893deepak Tiwari - OriginalДокумент4 страницы1591812168893deepak Tiwari - Originaldeepak tiwariОценок пока нет

- Design Basis Memorandum - Mechanical Equipment and SystemsДокумент26 страницDesign Basis Memorandum - Mechanical Equipment and SystemsLuojisi Cil50% (2)

- Three Phase Semi Controlled RectifierДокумент12 страницThree Phase Semi Controlled RectifierSvk NareshОценок пока нет

- Physics Past Paper (June 2005)Документ11 страницPhysics Past Paper (June 2005)Jotham Omoregie80% (5)

- The Haber Process: N + 3H > 2NH ΔH = −92 kJ molДокумент2 страницыThe Haber Process: N + 3H > 2NH ΔH = −92 kJ molShaeОценок пока нет

- Microprocessor Based Impedance RelayДокумент11 страницMicroprocessor Based Impedance RelaySuresh100% (1)

- Keitai LED Catalogue 2011-2012Документ85 страницKeitai LED Catalogue 2011-2012Adam McConnellОценок пока нет

- Technical Data: @perkinsДокумент8 страницTechnical Data: @perkinsdfheardОценок пока нет

- Boiler Tube FailureДокумент4 страницыBoiler Tube FailurenileshОценок пока нет

- N60 ENT M37: Installation InstructionsДокумент38 страницN60 ENT M37: Installation InstructionsSaid GhiryaniОценок пока нет

- Duracure WBC & WBWДокумент2 страницыDuracure WBC & WBWAman SahadeoОценок пока нет

- The Bicol Development PlanДокумент49 страницThe Bicol Development PlanGilbert MendozaОценок пока нет