Академический Документы

Профессиональный Документы

Культура Документы

13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service Manual

Загружено:

victover0 оценок0% нашли этот документ полезным (0 голосов)

32 просмотров2 страницыCheck wiring harness and mating connector for damaged wires or pins. Submerge sensor in container of water up to connector with wiring harness connected. Turn ignition switch on. (DO not START ENGINE) 5. Slowly remove sensor from water.

Исходное описание:

Оригинальное название

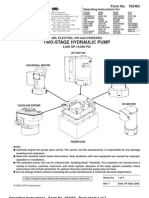

Guidelines Water Pump 4.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документCheck wiring harness and mating connector for damaged wires or pins. Submerge sensor in container of water up to connector with wiring harness connected. Turn ignition switch on. (DO not START ENGINE) 5. Slowly remove sensor from water.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

32 просмотров2 страницы13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service Manual

Загружено:

victoverCheck wiring harness and mating connector for damaged wires or pins. Submerge sensor in container of water up to connector with wiring harness connected. Turn ignition switch on. (DO not START ENGINE) 5. Slowly remove sensor from water.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 5-60-98 13-30a

13.8.4.6 Stop Engine Light did not Illuminate

If stop engine light did not illuminate, use the following procedure:

1. Check wiring harness and mating connector for damaged wires or pins.

2. Remove and clean sensor. Wash with mild detergent and rinse with clean water.

3. Submerge sensor in container of water up to connector with wiring harness connected.

4. Turn ignition switch on.(DO NOT START ENGINE.)

5. Slowly remove sensor from water.

6. The light should illuminate, indicating low coolant level.

7. If light does illuminate, system is working properly.

8. If light still does not illuminate, replace sensor and return it to DDC.

combustion efficiency.

13.8.5 Turbocharger

Inspect the mountings, intake and exhaust ducting and connections for leaks. Check the oil inlet

and outlet lines for leaks and/or restrictions to oil flow. Check for unusual noise or vibration and,

if excessive, remove the turbocharger and correct the cause. Refer to section 6.4.2.

13.8.6 Battery

On batteries equipped with charge indicator eyes, periodically check for adequate charge. If

batteries are the filler cap type, check the level of the electrolyte every 100 hours or every 7,500

miles (12,000 km). In warm weather, however, it should be checked more frequently due to a

more rapid loss of water from the electrolyte. Electrolyte should be maintained in accordance with

the battery manufacturer's recommendations. Periodically remove, check and clean battery post

terminals and connections. Replace corroded or damaged parts. Refer to section 8.3.2.

13.8.7 Tachometer Drive

A typical tachometer drive take-off location is the camshaft drive gear access cover on the front

of the gear case cover. Lubricate the tachometer drive (if so equipped) every 150 hours or 15,000

miles (24,000 miles) with an all purpose grease. At temperatures above -1 C (+30 F), use a

No. 2 grade grease. Use a No. 1 grade grease below this temperature.

13.8 DESCRIPTION OF MAINTENANCE ITEMS

All information subject to change without notice.

13-30b From Bulletin 5-60-98 6SE483 9610 1996 DETROIT DIESEL CORPORATION

13.8.8 Drive Belts

New standard vee-belts will stretch after the first few hours of operation. Run the engine for 10 to

15 minutes at 1200 r/min to seat the belts, then readjust the tension. Check the belts and tighten

the fan drive, battery charging generator or alternator and other accessory drive belts after 1/2

hour or 15 miles and again after 8 hours or 250 miles (402 km) of operation. Thereafter, check

the tension of the drive belts every 100 hours or 7,500 miles (12,000 km) and adjust, if necessary.

Belts should be neither too tight nor too loose. Belts that are too tight impose excess loads on the

crankshaft, fan and/or alternator bearings, shortening both belt and bearing life. Excessively

overtightened belts can result in crankshaft breakage. A loose belt will slip and may cause damage

to accessory components.

Replace ALL belts in a set when one is worn . Single belts of similar size should not be used as

a substitute for a matched belt set: premature belt wear can result because of belt length variation.

All belts in a matched belt set are within .032 in. (0.81 mm) of their specified center distances.

Adjust the belt tension as listed in Table 13-1 , using J 41251-B .

Fan Drive Single Belt Fan Drive 2 or 3 Belts New Alternator Belts

2 1/2 in.

Used Alternator Belts

2 1/2 in.

14-100 lb (355 - 455 N) 60-80 lb (266 - 355 N) 125 lb (556 N) 100 lb (445 N)

Table 13-1 Table Belt Tensions

If a belt tension gage is not available, adjust the belt tension so that a firm push with the thumb, at

a point midway between the two pulleys, will depress the belt 12.70-19.05 mm (.500 -.750 in.).

NOTE:

When installing or adjusting an accessory drive belt, be sure the bolt at the accessory

adjusting pivot point is properly tightened, as well as the bolt in the adjusting slot.

NOTE:

Drive belts (vee and poly-vee) should be replaced every 2,000 hours or 100,000 miles

(160,000 km).

A single poly-vee belt is used with the 50 DN Alternator. The 50 DN alternator drive belt tension

is set at 1558 N (350 lb) during engine assembly and belt replacement. A new belt loses tension

rapidly during the first few minutes of operation. Therefore, it is important to check the tension

after 30 minutes of operation. Allow the belt to cool with the engine off for 30 minutes before

measuring tension.

o If the tension on the belt is greater than or equal to 1115 N (250 lb), no further tensioning

is required.

o If the tension on the belt is less than 1115 N (250 lb), tension the belt to 1115 N (250 lb).

Periodic tensioning of the belt is required to maximize belt life. The belt tension should be

measured once per month or every 7,500 miles (12,000 km), whichever comes first.

Вам также может понравиться

- Model 55000-100 Hydraulic Tubing TongДокумент75 страницModel 55000-100 Hydraulic Tubing TongPrejit Radhakrishna50% (2)

- Graffiti Model Lesson PlanДокумент9 страницGraffiti Model Lesson Planapi-286619177100% (1)

- Manual de Operacion y Mantenimiento Motor Caterpillar c2.2Документ37 страницManual de Operacion y Mantenimiento Motor Caterpillar c2.2Robinson Guaneme83% (6)

- 120 Hydrostatic Tractor Electrical System and Fuel System GuideДокумент54 страницы120 Hydrostatic Tractor Electrical System and Fuel System Guidemalakas_123100% (1)

- 78 Dt400e DT250E ManualДокумент18 страниц78 Dt400e DT250E Manualdisgustipate0% (1)

- 3044C Industrial Engine-Maintenance IntervalsДокумент28 страниц3044C Industrial Engine-Maintenance Intervalsyoga_jpbmbm67% (3)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003От EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Рейтинг: 5 из 5 звезд5/5 (1)

- 2012 Components Technical Manual UkДокумент154 страницы2012 Components Technical Manual UkBrummerОценок пока нет

- Oil Country 45000Документ70 страницOil Country 45000char_lyn100% (2)

- 3116 MaintenanceДокумент33 страницы3116 MaintenanceCesar Gongora100% (8)

- Maintenance Intervals: Operation and Maintenance Manual ExcerptДокумент30 страницMaintenance Intervals: Operation and Maintenance Manual Excerpt08088338Оценок пока нет

- Actuador Electrico AutomaxДокумент12 страницActuador Electrico AutomaxLuis Guerra VegaОценок пока нет

- Moocoowooodoo 987Документ32 страницыMoocoowooodoo 987scribbedd55Оценок пока нет

- Governador para Motor PerkinsДокумент4 страницыGovernador para Motor Perkinsacere18Оценок пока нет

- Manual EatonДокумент92 страницыManual Eatonruben_cruz_34100% (1)

- Maintenance ScheduleДокумент16 страницMaintenance ScheduleSiska0806Оценок пока нет

- Sebu6617-04 MДокумент38 страницSebu6617-04 MCDDPPJОценок пока нет

- AC Motor Installation Maintenance GuideДокумент4 страницыAC Motor Installation Maintenance GuideEkakitie EseОценок пока нет

- Detroit Diesel Series 92 Workshop Service Repair Manual - 2101-2185Документ85 страницDetroit Diesel Series 92 Workshop Service Repair Manual - 2101-2185Sole LuОценок пока нет

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionДокумент2 страницы8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverОценок пока нет

- Speed Switches: InstructionsДокумент3 страницыSpeed Switches: InstructionsmuthakkerОценок пока нет

- U35000 PDFДокумент16 страницU35000 PDFsujit5584Оценок пока нет

- 25F-PRCServ PDFДокумент38 страниц25F-PRCServ PDFsindelu60Оценок пока нет

- Gilera GP 800 I.E. (EN)Документ437 страницGilera GP 800 I.E. (EN)ManuallesОценок пока нет

- Steering System PDFДокумент12 страницSteering System PDFGeorge Guerrero100% (1)

- Oil Country WF Model 57802-100TK Hydraulic Tubing TongДокумент83 страницыOil Country WF Model 57802-100TK Hydraulic Tubing Tongwuillian barreto100% (1)

- 3208 Marine 75v1-Up 01z1-UpДокумент52 страницы3208 Marine 75v1-Up 01z1-UpCristobal Campos100% (3)

- Leeson BrakeДокумент4 страницыLeeson BrakeCèsar PreciadoОценок пока нет

- Starter: 1991 Mitsubishi MonteroДокумент9 страницStarter: 1991 Mitsubishi MonteroAnimemanuel MuñozОценок пока нет

- Electrical System of EngineДокумент12 страницElectrical System of EngineGreg HannaОценок пока нет

- Alternator 2 PDFДокумент2 страницыAlternator 2 PDFvictoverОценок пока нет

- Instruction Manual Garrard 401Документ21 страницаInstruction Manual Garrard 401CGWSPAMОценок пока нет

- 1986 Landcruiser Maintenance ProceduresДокумент40 страниц1986 Landcruiser Maintenance ProceduresnapobОценок пока нет

- Oil Country - Llave Hidraulica 57853-100 (OSM-166 57853-100)Документ75 страницOil Country - Llave Hidraulica 57853-100 (OSM-166 57853-100)jhogs74100% (3)

- Motor Installation and Maintenance ManualДокумент23 страницыMotor Installation and Maintenance ManualVenkat CherukuriОценок пока нет

- Power Team PE55 ManualДокумент13 страницPower Team PE55 ManualTitanplyОценок пока нет

- 143T-449T TECO Welding House GeneralДокумент9 страниц143T-449T TECO Welding House GeneralChristian TorresОценок пока нет

- Piaggio Mp3 400 I.E Service Station Manual-7Документ20 страницPiaggio Mp3 400 I.E Service Station Manual-7H. KeithОценок пока нет

- Speed Sensor - AdjustДокумент6 страницSpeed Sensor - AdjustЕвгений АбрамовОценок пока нет

- Adjust electric mower clutch airgapДокумент2 страницыAdjust electric mower clutch airgapkentpeg100% (1)

- Maintain and Operate Unitized PumpДокумент29 страницMaintain and Operate Unitized Pumplucian.voinicaОценок пока нет

- Manual de Motor c1 1 Caterpillar LuminariasДокумент36 страницManual de Motor c1 1 Caterpillar LuminariasrobertОценок пока нет

- RX8 - Conventional Brake System Location IndexДокумент143 страницыRX8 - Conventional Brake System Location IndexghettotalonОценок пока нет

- Special Features of The f5r 740 EngineДокумент146 страницSpecial Features of The f5r 740 EngineBen Van Der MerweОценок пока нет

- Electricclutchtesting PDFДокумент2 страницыElectricclutchtesting PDFMark HefterОценок пока нет

- Belt Inspect Adjust Replace PDFДокумент4 страницыBelt Inspect Adjust Replace PDFnay hlaing SoeОценок пока нет

- JCV 360 Engine Manual v115Документ66 страницJCV 360 Engine Manual v115clanon100% (1)

- Manual Taller Suzuki SavageДокумент3 страницыManual Taller Suzuki SavageELORIA ELORIA0% (1)

- WPKT 0005Документ3 страницыWPKT 0005José BenavidesОценок пока нет

- Prueba de BombaДокумент4 страницыPrueba de BombaUilmerKrdenas100% (1)

- Osm-093 57800-100Документ86 страницOsm-093 57800-100Taller cncОценок пока нет

- Kysor Service GuideДокумент24 страницыKysor Service GuideAlex Renne ChambiОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Diesel Engine Care and Repair: A Captain's Quick GuideОт EverandDiesel Engine Care and Repair: A Captain's Quick GuideРейтинг: 5 из 5 звезд5/5 (1)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedОт EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- Water Pump PDFДокумент2 страницыWater Pump PDFvictoverОценок пока нет

- Water Pump 2 PDFДокумент2 страницыWater Pump 2 PDFvictoverОценок пока нет

- Series 60 Service Manual: From Bulletin 19-60-98 1-288cДокумент2 страницыSeries 60 Service Manual: From Bulletin 19-60-98 1-288cvictoverОценок пока нет

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionДокумент2 страницы8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverОценок пока нет

- Two-Bolt Camshaft PDFДокумент7 страницTwo-Bolt Camshaft PDFvictoverОценок пока нет

- Jake Brake 1998 PDFДокумент10 страницJake Brake 1998 PDFvictoverОценок пока нет

- Two-Bolt Camshaft 2 PDFДокумент1 страницаTwo-Bolt Camshaft 2 PDFvictoverОценок пока нет

- 6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyДокумент2 страницы6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyvictoverОценок пока нет

- Figure 6-18A Checking Wastegate CalibrationДокумент6 страницFigure 6-18A Checking Wastegate Calibrationvictover100% (2)

- Steel Piston PDFДокумент14 страницSteel Piston PDFvictoverОценок пока нет

- Service Manual PDFДокумент2 страницыService Manual PDFvictoverОценок пока нет

- Steel Piston 2 PDFДокумент2 страницыSteel Piston 2 PDFvictoverОценок пока нет

- Jake Brake 1998 3 PDFДокумент2 страницыJake Brake 1998 3 PDFvictoverОценок пока нет

- Figure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service ManualДокумент2 страницыFigure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service Manualvictover100% (1)

- 13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualДокумент2 страницы13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualvictoverОценок пока нет

- 13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualДокумент2 страницы13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualvictoverОценок пока нет

- Guidelines Water Pump 3 PDFДокумент2 страницыGuidelines Water Pump 3 PDFvictoverОценок пока нет

- Figure 12-9 Adjusting Leveling Screw: Series 60 Service ManualДокумент2 страницыFigure 12-9 Adjusting Leveling Screw: Series 60 Service ManualvictoverОценок пока нет

- Guidelines Water Pump 2 PDFДокумент2 страницыGuidelines Water Pump 2 PDFvictoverОценок пока нет

- Figure 2-12 Electronic Unit Injector Terminal InstallationДокумент2 страницыFigure 2-12 Electronic Unit Injector Terminal InstallationvictoverОценок пока нет

- This Page Intentionally Left Blank.: Series 60 Service ManualДокумент2 страницыThis Page Intentionally Left Blank.: Series 60 Service ManualvictoverОценок пока нет

- Figure 1-301 Gasket Eliminator Application: Series 60 Service ManualДокумент2 страницыFigure 1-301 Gasket Eliminator Application: Series 60 Service ManualvictoverОценок пока нет

- Flywheel 2 PDFДокумент4 страницыFlywheel 2 PDFvictoverОценок пока нет

- Front Camshaft 2 PDFДокумент2 страницыFront Camshaft 2 PDFvictoverОценок пока нет

- 1.16.1 Repair or Replacement of Flywheel HousingДокумент2 страницы1.16.1 Repair or Replacement of Flywheel HousingvictoverОценок пока нет

- Drain Water Pump PDFДокумент2 страницыDrain Water Pump PDFvictoverОценок пока нет

- Forged Steel Piston PDFДокумент14 страницForged Steel Piston PDFvictoverОценок пока нет

- Tool Number Tool Name: Table 1-43 Engine-Cylinder BlockДокумент2 страницыTool Number Tool Name: Table 1-43 Engine-Cylinder BlockvictoverОценок пока нет

- Engine Coolant PDFДокумент1 страницаEngine Coolant PDFvictoverОценок пока нет

- Engine Coolant 2 PDFДокумент3 страницыEngine Coolant 2 PDFvictoverОценок пока нет

- Marketing Assignment (Cool Air India)Документ10 страницMarketing Assignment (Cool Air India)Mandira PantОценок пока нет

- HGДокумент64 страницыHGCharis PapadopoulosОценок пока нет

- P2-1 - NME1106 - Gas Turbine LabworkДокумент23 страницыP2-1 - NME1106 - Gas Turbine LabworkKoh JovenОценок пока нет

- Basf Masteremaco Application GuideДокумент15 страницBasf Masteremaco Application GuideSolomon AhimbisibweОценок пока нет

- Effective-Plant-Course Brochure NovДокумент8 страницEffective-Plant-Course Brochure NovAzri HafiziОценок пока нет

- DVOR Principle 코이카 양식Документ71 страницаDVOR Principle 코이카 양식Undral Batbayar100% (1)

- GulliverДокумент8 страницGulliverCris LuОценок пока нет

- Obeid Specialized Hospital - Riyadh: Inpatient DeptsДокумент4 страницыObeid Specialized Hospital - Riyadh: Inpatient DeptsLovelydePerioОценок пока нет

- Final Paper - PARTIALДокумент64 страницыFinal Paper - PARTIALDeanna GicaleОценок пока нет

- Delivered Voided Application (Surrender Instrument) Returned To at - Sik - Hata Nation of Yamasee MoorsДокумент20 страницDelivered Voided Application (Surrender Instrument) Returned To at - Sik - Hata Nation of Yamasee MoorsMARK MENO©™Оценок пока нет

- Marginal Field Development Concepts (Compatibility Mode)Документ17 страницMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- Detect and Diagnose HVAC Equipment ErrorsДокумент1 страницаDetect and Diagnose HVAC Equipment ErrorsCatalin DragomirОценок пока нет

- Trends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeДокумент53 страницыTrends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeNarasimhaReddy PangaОценок пока нет

- 8602 BookДокумент240 страниц8602 BookSohail100% (2)

- Toaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRДокумент5 страницToaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRMarco Antonio Gonzalez CastilloОценок пока нет

- Query Operation 2021Документ35 страницQuery Operation 2021Abdo AbaborОценок пока нет

- Toolbox Meeting Or, TBT (Toolbox TalkДокумент10 страницToolbox Meeting Or, TBT (Toolbox TalkHarold PonceОценок пока нет

- Be Circular Fibre Reinforced ConcreteДокумент4 страницыBe Circular Fibre Reinforced ConcreteLim Kang HaiОценок пока нет

- CA Ashish Dewani - Resume-1Документ2 страницыCA Ashish Dewani - Resume-1Payal JainОценок пока нет

- DLP IN ICT 9 1st MeetingДокумент2 страницыDLP IN ICT 9 1st MeetingHEDDA FULOОценок пока нет

- The Arcane Formulas or Mental AlchemyДокумент121 страницаThe Arcane Formulas or Mental AlchemyTim Boire100% (1)

- Automation & Control Esst en 200804Документ356 страницAutomation & Control Esst en 200804Sveinn Rúnar JúlíussonОценок пока нет

- Đề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnДокумент22 страницыĐề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnLily LeeОценок пока нет

- Maklumat Vaksinasi: Vaccination DetailsДокумент1 страницаMaklumat Vaksinasi: Vaccination Detailsaccung manОценок пока нет

- Drive Test For BeginnerДокумент88 страницDrive Test For Beginnerahwaz96100% (1)

- CitationCJ4-CB Checklists B v1.2Документ4 страницыCitationCJ4-CB Checklists B v1.2Joao Vitor RojasОценок пока нет

- Optimization Module For Abaqus/CAE Based On Genetic AlgorithmДокумент1 страницаOptimization Module For Abaqus/CAE Based On Genetic AlgorithmSIMULIACorpОценок пока нет

- Keynote Proficient End-Of-Course Test BДокумент7 страницKeynote Proficient End-Of-Course Test Bana maria csalinasОценок пока нет

- 1729Документ52 страницы1729praj24083302Оценок пока нет