Академический Документы

Профессиональный Документы

Культура Документы

Manufacturing Processes and Products of Steel Pipes and Tubes

Загружено:

ezzularabАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Manufacturing Processes and Products of Steel Pipes and Tubes

Загружено:

ezzularabАвторское право:

Доступные форматы

1

Abstract:

JFE Steel operates manufacturing facilities for seam-

less pipes and various types of welded pipes in order to

respond to a wide range of customer requirements. Dis-

tinctive products and manufacturing processes include

large diameter, heavy wall electric resistance welded

(ERW) pipe for linepipes, UOE pipe for high strength,

high performance linepipes, and high performance, high

formability welded steel tubes used in automotive parts.

This paper presents an outline of the distinctive features

of the manufacturing processes at JFE Steel, together

with representative steel pipe and tube products.

1. Introduction

As a result of the merger of the former Kawasaki

Steel and former NKK in April 2003, the steel pipe and

tube manufacturing system at the newly-created JFE

Steel was expanded to include four districts, the Chiba

District and Keihin District of East Japan Works, Fuku-

yama District of West Japan Works, and Chita Works

specialized in pipe mills. With a product line encom-

passing seamless pipe and welded pipes, including butt

welded pipe, electric resistance welded (ERW) pipe,

UOE pipe, and spiral welded pipe, JFE Steel supplies

all major types of steel pipe and tube products and has

established a system which is capable of responding to a

wide range of customer requirements.

In fscal year 2004, the companys annual production

of all types of steel pipes and tubes was approximately

1.85 million tons.

2. Distinctive Features

of Steel Pipes and Tubes at JFE Steel

2.1 Pipe and Tube Manufacturing System

JFE Steel operates manufacturing facilities for seam-

less pipe and welded pipe at its East Japan Works, West

Japan Works, and Chita Works.

An outline of the pipe and tube manufacturing pro-

cess is shown in Fig. 1. Depending on the manufacturing

process, welded pipes can be divided into three classes

by welding method, i.e., arc welding, electric resis-

tance welding, and butt welding. Pipes manufactured

by the arc welding method can be further divided into

UOE pipe, bending press pipe, and spiral welded pipe,

depending on differences in the forming method. Among

welded pipes, hot rolled steel sheet is used as the mate-

rial for electric resistance welding tube, butt welded

tube, and spiral tube, while steel plates are used as mate-

rial for UOE and bending press products.

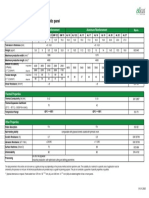

JFE Steels pipe and tube manufacturing facilities

comprise one UOE line each at East Japan Works and

West Japan Works, one ERW line at East Japan Works

and four ERW lines at Chita Works, one spiral welded

pipe line at West Japan Works, and two seamless pipe

lines at Chita Works. Table 1 shows the manufacturing

facilities for pipe and tube production at JFE Steel.

The size range of the pipe and tube products in JFE

Steel is shown in Fig. 2. The available size range differs

due to differences in materials and processing and form-

ing methods. Appropriate use of each product type cor-

responding to the application is important.

Manufacturing Processes and Products

of Steel Pipes and Tubes in JFE Steel

MASAMURA Katsumi

*1

NAGAHAMA Yutaka

*2

Originally published in JFE GIHO No. 9 (Aug 2005), p. 16

JFE TECHNICAL REPORT

No. 7 (Jan. 2006)

*2

General Manager, Tubular Products

Business Planning Dept.,

JFE Steel

*1

Dr. Eng.,

Staff General Manager,

Tubular Products Business Planning Dept.,

JFE Steel

2 JFE TECHNICAL REPORT No. 7 (Jan. 2006)

Manufacturing Processes and Products of Steel Pipes and Tubes in JFE Steel

The distinctive features of JFE Steels pipe and tube

manufacturing technologies are outlined in the follow-

ing.

2.2 Seamless Pipes and Tubes

JFE Steel has two seamless pipe manufacturing lines

at Chita Works, the small-diameter seamless pipe mill

using the Mannesmann piercing/mandrel mill process

and the medium-diameter seamless pipe mill using

the Mannesmann piecing/plug mill process. The small-

diameter mill produces pipes and tubes with outer

diameters up to 177.8 mm (5), while the medium-

Fig. 1 Manufacturing procedure of pipes and tubes in JFE Steel

Kind Works Line

Available size (mm)

Remarks

OD Wall thickness Length

Seamless pipe

Chita Works

Small diameter

seamless pipe mill

25.4 177.8 2.340.0 22 000

Mannesmann piercing/

Mandrel mill

Chita Works

Medium diameter

seamless pipe mill

177.8 426.0 5.165.0 13 500

Mannesmann piercing/

Plug mill

Welded pipe

UOE

East Japan Works

(Chiba)

Chiba UOE pipe mill 508.41 625.6 6.444.5 18 300

West Japan Works

(Fukuyama)

Fukuyama UOE

pipe mill

406.41 422.4 6.050.8 18 300

External and internal

coating facility

Spiral

West Japan Works

(Fukuyama)

Spiral pipe 600. 2 540.0 6.030.0 35 000

Electric

resistance

welded pipe

Chita Works

Small diameter

ERW pipe mill (3)

28.6 76.4 0.610.0 18 000

Chita Works

Small diameter

ERW pipe mill (6)

60.5 168.3 0.610.0 18 000

Chita Works

Small diameter

ERW pipe mill (4)

HISTORY

21.3 114.3 1.812.7 16 000

Chita Works

Large diameter

ERW pipe mill (26)

318.5 660.4 4.023.8 20 000

250. 250.0 6.025.0 18 000 For square pipes

East Japan Works

(Keihin)

24 ERW mill

177.8 609.6 3.219.1 18 500 External coating facility

200. 200.0 4.522.0 18 000 For square pipes

Butt welded

pipe

East Japan Works

(Keihin)

Butt weld mill 21.7 114.3 2.8 4.5 7 000 Plastic lining facility

Table 1 Manufacturing facilities for pipe and tubes production in JFE Steel

JFE TECHNICAL REPORT No. 7 (Jan. 2006) 3

Manufacturing Processes and Products of Steel Pipes and Tubes in JFE Steel

diameter mill produces products with outer diameters

from 177.8 mm (5) to 426.0 mm (16).

Among materials for seamless pipes and tubes, carbon

steel and low alloy steel are melted and rolled at West

Japan Works (Kurashiki District) and supplied to Chita

Works. High alloy materials such as 13% Cr, etc. are

melted and cast into slabs at East Japan Works (Chiba

District); billet rolling is then performed at West Japan

Works (Kurashiki District), and the materials are sup-

plied to Chita in billet form.

High Cr seamless steel pipes used in oil country

tubular goods (OCTG) and boiler tubes are one of JFE

Steels main product lines, and the company has a high

level of know-how in rolling technology for these prod-

ucts. In the past, seamless pipes and tubes of high Cr

alloy steel and stainless steel were generally produced

by piercing using a hot extrusion process, followed by

rolling. JFE Steel was the frst steel maker in the world

to succeed in obtaining stable product quality in these

products in manufacturing by the Mannesmann pierc-

ing process. These products were realized for the frst

time as a result of improvement in the properties of the

materials by heavy processing in the slab stage, in com-

bination with the establishment of various pipe rolling

technologies, including billet temperature control during

pipe rolling, optimization of piercing conditions, optimi-

zation of the pass schedule in mandrel rolling, etc

1)

.

The seamless pipe mill also has processing equip-

ment for production of threaded joints for OCTG.

2.3 ERW Pipes and Tubes

As manufacturing facilities for ERW pipes and tubes,

JFE Steel has a four ERW lines at Chita Works and a one

ERW line at East Japan Works (Keihin District).

These facilities each have distinctive features, giv-

ing the company a system for manufacturing steel pipes

and tubes by the optimum process corresponding to the

application.

2.3.1 Large diameter, heavy wall ERW pipes

The 26 line at Chita Works produces ERW pipes

having the largest outer diameter in the world. With the

manufacture of linepipe using this feature as one of its

strong points, JFE Steel has commercialized extra-heavy

wall ERW linepipes and conductor casings as substitutes

for the conventional UOE products. To realize the same

strength, toughness, and weldability as in UOE pipe, in

these products, the composition design of the hot rolled

steel sheet used in the ERW pipe was optimized and the

cooling capacity of the hot rolling line was strengthened.

In parallel with this, Chita Works also strengthened

the pipe manufacturing capacity of the 26 ERW pipe

mill, developed an oxide control technique and weld

seam heat treatment technology to improve the tough-

ness of seam welds, and developed a weld seam quality

assurance technology for heavy wall products.

2.3.2 HISTORY tube

The 4 HISTORY pipe mill at Chita Works is a

unique JFE Steel manufacturing process which produces

high strength, high ductility tubular products by apply-

ing warm reduction after electric resistance welding.

As a steel tube for machine structural use which

satisfes both high strength and high ductility require-

ments, the HISTORY tube was developed for applica-

tions which assume high formability, such as automobile

suspension parts

2)

. The HISTORY tube manufacturing

process is shown in Fig. 3.

With this manufacturing process, strength and duc-

tility are improved by performing warm reducing, in

which the tube is heated after normal electric resistance

welding; this results in texture formation simultaneously

0.1

0

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0 25

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0 50

2.1

2.2

2.3

2.4

2.5

(mm) (inch)

10 20 30 40 50 60 70 80 90 100 110 120 130

3 200 2 500 1 000

Outside diameter

W

a

l

l

t

h

i

c

k

n

e

s

s

500 (mm)

(inch)

SMLS

UOE

Bending

WFW

Spiral

Fig. 2 Size range of JFE Steels pipe and tubes for products

4 JFE TECHNICAL REPORT No. 7 (Jan. 2006)

Manufacturing Processes and Products of Steel Pipes and Tubes in JFE Steel

with refnement of the crystal grain size and refnement

of carbides. These improved properties enable a 2030%

contribution to weight reduction in automotive parts.

The problem of hardening of the weld seam is also elim-

inated by warm reducing.

2.3.3 Outside coated products

The 24 mill at East Japan Works (Keihin District)

has outside coating equipment, making it possible to

manufacture pipes which require outside coatings.

2.4 Butt Welded Steel Pipes and Tubes

The butt welded pipe mill at East Japan Works (Keihin

District) mainly produces SGP as specifed in the Japa-

nese Industrial Standards (JIS)

3)

. This plant produces Zn

galvanized steel pipes used in city gas and water piping

and resin-coated corrosion-resistant steel pipes.

2.5 UOE Pipe

JFE Steel has one UOE mill each at West Japan

Works (Fukuyama District) and East Japan Works (Chiba

District). These plants mainly produce high grade

linepipes.

In manufacturing high quality linepipes, the proper-

ties and quality of the plates used as material are impor-

tant. The majority of materials for UOE pipes at JFE

Steel are supplied by Fukuyama District. The plate mill

at Fukuyama District operates the state-of-the-art Super-

OLAC (on-line accelerated cooling) thermo-mechanical

heat treatment equipment and HOP (heat treatment

on-line process), which is the worlds only on-line heat

treatment equipment for plates

4)

.

Utilizing these facilities, JFE manufactures as-rolled

high grade steel plates with high strength and excellent

weldability as material for UOE pipe.

3. Steel Pipe and Tube Products

Steel pipes and tubes are employed in a variety of

applications, from linepipes and OCTG

5)

used in the

Fig. 3 Schematic manufacturing procedure of HISTORY pipe

Table 2 Major products of pipe and tubes and their manufacturing procedures in JFE Steel

Application Manufacturing procedure Description

General and building structure UOE, SP, ERW Marin structure, Pile, Square pipe

Piping ERW, BW Galvanized pipe, Inside lining pipe, Polyethelen coated pipe

Oil country tubular goods SML, (ERW)

Tubing, Casing

Drill pipe

Line pipe SML, ERW, UOE Transpotation of oil, gas, and water

Boiler and heat exchanger SML, (ERW) Heat exchanger pipe for heat recovery boiler

Machine structure SML, ERW, HIS Parts for automobile, Gas cylinder

SML: Seamless pipe, UOE: UOE pipe, SP: Spiral pipe,

ERW: Electric Resistance Welded Pipe, BW: Butt Welded pipe, HIS: HISTORY pipe

JFE TECHNICAL REPORT No. 7 (Jan. 2006) 5

Manufacturing Processes and Products of Steel Pipes and Tubes in JFE Steel

energy industry to steel tube columns and steel tube

piles for construction and tubes used as materials for

automobile parts. Table 2 shows the main steel pipe

and tube products at JFE Steel and their manufactur-

ing processes by application. JFE Steel supplies various

products for a wide range of applications by combining

the optimum chemical composition and manufacturing

process. Representative products are outlined in the fol-

lowing.

3.1 OCTG

Requirements for OCTG, used in oil and gas pro-

duction include high strength and corrosion resistance

against the hydrogen sulfde (H

2

S) and carbon dioxide

(CO

2

) contained in wells. The grades of OCTG supplied

by JFE Steel are shown in Table 3. In addition to the

grades specifed in American Petroleum Institute (API)

standards, the company also produces various unique

JFE Steel grades, which include high strength OCTG

for deep wells, collapse-resistant steel pipes which resist

collapse due to earth pressure, OCTG for sour service

in corrosive environments, and 13% Cr alloy OCTG for

CO

2

environments. In particular, from the early period

when 13% Cr OCTG were applied practically, JFE Steel

devoted great effort to establishing a mass production

technology and improving corrosion resistance. As a

result, JFE Steel has now become the worlds top maker

of 13% Cr OCTG.

Table 4 shows the chemical composition of corrosion

resistant OCTG at JFE Steel

6)

. In addition to 13% Cr,

which is the standard product, JFE steel also produces

HP1 and HP2, which provide improved corrosion resis-

tance in high temperature environments. Because the

service limit of HP2 is 160C, JFE Steel is developing

UP15Cr for higher temperature environments.

3.2 Linepipe

JFE Steel supplies a variety of steel pipes for use as

linepipe, taking advantage of the companys abundant

product line.

3.2.1 High strength, high performance

linepipe (UOE)

Among UOE pipe, JFE Steel mainly produces

large diameter, high strength linepipe and pipe for sour

service. In recent years, linepipe design has shifted from

strength-based design to strain-based design. Accom-

panying this, high deformability has also become a

requirement in linepipe. JFE Steel developed the HIPER

pipe as a product which meets to this requirement.

JFE Steel is also developing X100 and X120 grade

high strength linepipe (UOE), which are expected to be

Yield strength

(ksi)

API Standard

Deep well

service

High collapse

Sour service

Arctic service

Wet CO

2

service

General/Special High collapse General High temperature

40 H40

55 J55, K55

65 M65

80

N80, L80/Type 1

L80/13Cr

JFE-80T JFE-80S JFE-80TS JFE-80L JFE-13Cr80

85

JFE-85S

JFE-85SS

JFE-13Cr85

90 C90

JFE-90S

JFE-90SS

95

C95

T95

JFE-95T

JFE-95S

JFE-95SS

JFE-95TS JFE-95L JFE-13Cr95

JFE-HP1-13Cr95

JFE-HP2-13Cr95

110 P110 JFE-110T

JFE-110S

JFE-110SS

JFE-110L

JFE-HP1-13Cr110

JFE-HP2-13Cr110

125 Q125 JFE-125V JFE-125L JFE-UHP 15Cr125

140 JFE-140V

Table 3 Available grades of oil country tubular goods

(%)

Grade C Si maximum Mn P maximum S maximum Cr Ni Mo Cu maximum

JFE-13Cr 0.150.22 1.00 0.251.00 0.020 0.010 12.014.0

maximum

0.5

0.25

JFE-HP1-13Cr

maximum

0.04

0.50

maximum

0.06

0.02 0.01 12.014.0 3.504.50 0.801.50

JFE-HP2-13Cr

maximum

0.04

0.05

maximum

0.06

0.02 0.01 12.014.0 4.505.50 1.802.50

Table 4 Chemical composition of corrosion resistance material for OCTG

6

Manufacturing Processes and Products of Steel Pipes and Tubes in JFE Steel

next-generation products. In particular, JFE was the frst

in the world to produce X100 at the mass production

level and conduct construction tests of this product in

linepipe.

One example of the application of JFE Steels out-

standing steelmaking technology is linepipe for sour

service, which requires advanced inclusion control.

This is a technology for preventing the phenomenon of

hydrogen induced cracking (cracking due to hydrogen

penetration in steel) in environments which contain H

2

S,

and thus is extremely important for securing the safety

of linepipes

7)

.

3.2.2 Heavy wall, high strength, high toughness

linepipe (ERW pipe)

With the aim of substituting ERW pipe for small

diameter UOE pipe, which have the drawback of low

productivity, JFE Steel developed high strength, heavy

wall ERW linepipe using the 26 ERW mill at Chita

Works, resulting in a large increase in orders.

3.2.3 Martensitic stainless steel (MSS)

12Cr high corrosion resistance

linepipe (SML)

8)

The linepipe called a fow line which is used

between oil wells and the gas treatment facility is

exposed to the same corrosion environment as OCTG.

Because relatively small diameter pipe is used in this

application, JFE Steel developed a corrosion resistant

12% Cr seamless linepipe. As this material has a low C,

Ni- and Mo-added composition design, corrosion resis-

tance is improved and welding is easy in comparison

with the conventional 13% Cr steel.

3.3 Special Pipes and Tubes

Utilizing its high Cr alloy manufacturing technology,

JFE Steel has developed and manufactures 9% Cr steel

T91/P91 and W-added T23/P23 for thermal power plant

boilers. In particular, JFE Steel has the capability to

manufacture boiler tubes with a maximum length up to

22 m.

3.4 Steel Tubes for Automotive Applications

9)

Steel tubes are increasingly used in automobile sus-

pension parts in order to reduce weight. In addition to

material and product development, JFE Steel has also

devoted much effort to cooperation with users in second-

ary forming technologies and performance evaluation

technologies for steel tubes. The companys high form-

ability ERW tubes

10)

and HISTORY tubes are continuing

to be adopted as materials for automobile suspension

parts.

4. Conclusion

JFE Steel possesses products and manufacturing

facilities which are capable of responding to diverse cus-

tomer requirements. The company is also energetically

engaged in various technical development efforts. This

Special Issue of JFE Technical Reports introduces the

results of recent technical development.

References

1) Morioka, N. et al. Kawasaki Steel Giho. vol. 29, no. 2, 1997,

p. 5763.

2) Toyooka, T. et al. Kawasaki Steel Giho. vol. 33, no. 4, 2001,

p. 145150.

3) JIS G 3452.

4) Fujibayashi, A. et al. JFE Giho. no. 5, 2004, p. 812.

5) Teshimaru, S. et al. JFE Giho. no. 2, 2003, p. 5162.

6) Kimura, M. et al. Kawasaki Steel Giho. vol. 29, no. 2, 1997,

p. 8489.

7) Miura, H. et al. NKK Technical Report. no. 179, 2002, p. 63

68.

8) Miyata, Y. et al. Kawasaki Steel Giho. vol. 29, no. 2, 1997,

p. 9096.

9) Toyoda, S. JFE Giho. no. 2, 2003, p. 2832.

10) Toyoda, S. et al. SAE Technical Paper Series. 2004-01-0892,

2004.

Вам также может понравиться

- Technical Characteristics 2020 ENДокумент1 страницаTechnical Characteristics 2020 ENezzularabОценок пока нет

- Load Capacity of Alkus Sheets Based on Span LengthДокумент3 страницыLoad Capacity of Alkus Sheets Based on Span LengthezzularabОценок пока нет

- 5d2dbd383497c-Home Buying Checklist 2019Документ1 страница5d2dbd383497c-Home Buying Checklist 2019ezzularabОценок пока нет

- EngiLab Frame.2D User ManualДокумент234 страницыEngiLab Frame.2D User ManualezzularabОценок пока нет

- Wilts & Berks Canal Trust Temporary Works ProcedureДокумент21 страницаWilts & Berks Canal Trust Temporary Works ProcedureezzularabОценок пока нет

- Holland Lift 220 ElectricДокумент3 страницыHolland Lift 220 ElectricezzularabОценок пока нет

- Flyer PASCHAL Ident ENДокумент2 страницыFlyer PASCHAL Ident ENezzularabОценок пока нет

- 01 Soldier SystemДокумент26 страниц01 Soldier SystemezzularabОценок пока нет

- FDP D Euro PropsДокумент6 страницFDP D Euro PropsezzularabОценок пока нет

- Mabey Propping and Jacking Brochure WebДокумент27 страницMabey Propping and Jacking Brochure WebezzularabОценок пока нет

- Tunnel System DokaCCДокумент104 страницыTunnel System DokaCCezzularabОценок пока нет

- Doka Circular Formwork enДокумент2 страницыDoka Circular Formwork enezzularabОценок пока нет

- Rapid Column ArmДокумент4 страницыRapid Column ArmezzularabОценок пока нет

- Appendix L Temporary Works Coordinator Training Course Aug19Документ14 страницAppendix L Temporary Works Coordinator Training Course Aug19ezzularabОценок пока нет

- TWf2019.03 - Temporary Works Procedure - 8 December 2019 - FINAL1Документ22 страницыTWf2019.03 - Temporary Works Procedure - 8 December 2019 - FINAL1ezzularabОценок пока нет

- Bringing Luxury Residential Complex to Life with FormworkДокумент1 страницаBringing Luxury Residential Complex to Life with FormworkezzularabОценок пока нет

- Section 2: Procedural Control of Temporary Works: 6 ProceduresДокумент38 страницSection 2: Procedural Control of Temporary Works: 6 Proceduresezzularab100% (3)

- MANAGEMENT OF TEMP WORKSДокумент14 страницMANAGEMENT OF TEMP WORKSezzularab100% (1)

- Abu Dhabi To Dubai Link Bridges: Case StudyДокумент1 страницаAbu Dhabi To Dubai Link Bridges: Case StudyezzularabОценок пока нет

- Welding ProcedureДокумент2 страницыWelding ProcedurefallalovaldesОценок пока нет

- Firmenflyer Blickle-ENДокумент2 страницыFirmenflyer Blickle-ENezzularabОценок пока нет

- Visa Security Infographic 102314 JC v30Документ1 страницаVisa Security Infographic 102314 JC v30ezzularabОценок пока нет

- Airlines GraphicДокумент1 страницаAirlines GraphicezzularabОценок пока нет

- Al Baleed Resort: Case StudyДокумент1 страницаAl Baleed Resort: Case StudyezzularabОценок пока нет

- RMD Kwikform India: Formwork ServicesДокумент10 страницRMD Kwikform India: Formwork ServicesezzularabОценок пока нет

- Lafarge Handbook PDFДокумент92 страницыLafarge Handbook PDFezzularabОценок пока нет

- Construction FormworkДокумент60 страницConstruction FormworkDev Bhangui100% (5)

- Lafarge Handbook PDFДокумент92 страницыLafarge Handbook PDFezzularabОценок пока нет

- Alcoa Insert 5052and6061 FINALДокумент2 страницыAlcoa Insert 5052and6061 FINALezzularabОценок пока нет

- Welding ProcedureДокумент2 страницыWelding ProcedurefallalovaldesОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Why Firefighters Die - 2011 September - City Limits MagazineДокумент33 страницыWhy Firefighters Die - 2011 September - City Limits MagazineCity Limits (New York)100% (1)

- Motorized Screw JackДокумент19 страницMotorized Screw JackPushpendra Kumar33% (3)

- 2011 Horizontal ScreensДокумент4 страницы2011 Horizontal ScreensNico RiquelmeОценок пока нет

- Schneider Electric Gulf Provides Complete Energy SolutionsДокумент8 страницSchneider Electric Gulf Provides Complete Energy SolutionsPMV DeptОценок пока нет

- 9ha Power PlantsДокумент2 страницы9ha Power PlantsIzzadAfif1990Оценок пока нет

- AMC BHS 2016 ExternalДокумент16 страницAMC BHS 2016 ExternalElgi Zacky ZachryОценок пока нет

- Eee-503 Elements of Power System 2013-14Документ3 страницыEee-503 Elements of Power System 2013-14Devesh RaiОценок пока нет

- Morgan Advanced Materials Carbon Brushes for Power GenerationДокумент4 страницыMorgan Advanced Materials Carbon Brushes for Power GenerationnguyenkuongОценок пока нет

- 2ND Training Cidi MutfakДокумент31 страница2ND Training Cidi Mutfakrakan alnajiОценок пока нет

- Ran K H1B Visa Sponsor Number of LCA Average SalaryДокумент7 страницRan K H1B Visa Sponsor Number of LCA Average SalaryKitty FitzgeraldОценок пока нет

- HVAC Patterson BrochureДокумент9 страницHVAC Patterson BrochureAnonymous 5RhHmNmgJОценок пока нет

- Porter Five ThreatsДокумент4 страницыPorter Five ThreatsAmit PandeyОценок пока нет

- ABB India 2003 Annual ReportДокумент76 страницABB India 2003 Annual ReportKunal DesaiОценок пока нет

- Caustic Soda Market in South Africa 2016-2021 Review - Sample PagesДокумент23 страницыCaustic Soda Market in South Africa 2016-2021 Review - Sample PagesShumani Pharamela100% (2)

- ZICTA 2015 ICT Survey ReportДокумент58 страницZICTA 2015 ICT Survey ReportJoeОценок пока нет

- Eliminate 7 Wastes to Reduce Costs & Improve ProfitsДокумент9 страницEliminate 7 Wastes to Reduce Costs & Improve Profitsmintesinot denekewОценок пока нет

- Permanent Well Abandonment: Kenny Campbell and Rod Smith, SchlumbergerДокумент3 страницыPermanent Well Abandonment: Kenny Campbell and Rod Smith, SchlumbergerLidiaОценок пока нет

- 152 Ice CreamДокумент47 страниц152 Ice CreamRuben StefaniОценок пока нет

- VP Director Government Public Affairs in Washington DC Resume Mark BurtschiДокумент2 страницыVP Director Government Public Affairs in Washington DC Resume Mark BurtschiMarkBurtschiОценок пока нет

- Powerplus Medium Voltage Cables OGPДокумент27 страницPowerplus Medium Voltage Cables OGPNestor PerezОценок пока нет

- Psalm Uc Guidelines PDFДокумент19 страницPsalm Uc Guidelines PDFRj FashionhouseОценок пока нет

- Aci 318-05 Building Code Requirements For Structural Concrete and Commentary Aci 318r-05Документ98 страницAci 318-05 Building Code Requirements For Structural Concrete and Commentary Aci 318r-05Insa IntameenОценок пока нет

- Inspection and Test Plan For Fire Tube BoilerДокумент4 страницыInspection and Test Plan For Fire Tube BoilerJayaram MV100% (1)

- Brick Manufacturing Report 2019Документ10 страницBrick Manufacturing Report 2019Praveen Kumar RoyОценок пока нет

- Design Project 5Документ3 страницыDesign Project 5pelayo240Оценок пока нет

- 50 - 60 HZ FrecuencyДокумент14 страниц50 - 60 HZ FrecuencyJorge WommezОценок пока нет

- Midea SERVICE MANUAL PDFДокумент44 страницыMidea SERVICE MANUAL PDFAhmed Azad67% (3)

- Energy Law Agreement Drafting Competition by RGNLUДокумент2 страницыEnergy Law Agreement Drafting Competition by RGNLUVasudha Gupta100% (1)

- Bombas Contra Incendio PattersonДокумент9 страницBombas Contra Incendio PattersonLENINROMEROH4168Оценок пока нет

- Detergent Powder AcknowledgementДокумент6 страницDetergent Powder AcknowledgementAbhayThakurОценок пока нет