Академический Документы

Профессиональный Документы

Культура Документы

Cogen Heat Recovery Boiler Three Element Feed Water Control

Загружено:

anaastutiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cogen Heat Recovery Boiler Three Element Feed Water Control

Загружено:

anaastutiАвторское право:

Доступные форматы

Cogen Heat Recovery Boiler Three Element Feed Water Control

1.0 Introduction

This technical report describes how a cogeneration power plant functions. Component

sizing as well as an appropriate control system for the heat recovery boiler is determined

in this report. Several control loops are used to properly control the heat recovery boiler.

Three element feed water control combines a level loop and two flow loops to properly

maintain the water level inside the boiler. Continuous boiler blowdown has also been

used to maintain boiler efficiency. Proper pump sizing pipe sizing as well as orifice plate

sizing are calculated throughout the sections of this report. Certain loops that I have

selected are also animated using the P!C"# which is available in our lab.

This report has been written to meet the re$uirements of the third year %utomation

Technology course. Cogeneration power plants are an environmentally friendly method

of producing power& this is because they produce two types of energy. 'eat and power

using only one fuel source are produced. The heat produced can then be turned into

steam which powers a second turbine and produces additional power. (asically a

cogeneration plant ta)es wasted energy and turns it into usable power.

*y report contains a full P+I diagram wiring diagrams P!C programming component

selection and sizing for valves pipes as well as orifice plates. I have also documented the

1

separate loops which automate my system. Several drawings are also found throughout

my technical report to illustrate certain parts of the process.

,.0 Cogen Power -eneration

,.1 .efiniton

Cogeneration power plants are power generating facilities that produce both heat and

electricity using a single fuel such as natural gas. 'eat produced from the production of

electricity such as the firing of a gas turbine is recycled and used to produce steam. This

additional steam can be used for additional plant processes for domestic purposes or to

power a second turbine which produces additional electricity.

,., (enefits

The benefits of cogen are numerous. Single purpose thermal electric power plants re/ect

between #00 and 1#0 of the fuel heat to rivers la)es the ocean or the atmosphere.

Cogeneration systems use this re/ected heat into a usable power source. (y using wasted

heat and turning it into a usable source of energy the cogen power plants can increase

their efficiency This added efficiency is e2tremely desirable nowadays because of the

ever 3 increasing price of fuel as well as the growing concerns for our environment.

%nother benefit of cogeneration type power plants is the lac) of line losses& this is

,

because power is generated on site and the need to run additional power lines is non"

e2istent.

,.4 Se$uence of 5peration

(asically all cogen power plants have some form of primary fuel that is burned 6this can

be fuel natural gas coal ect.7. The primary fuel is burned which creates a lot of heat and

pressure this heat and pressure is then used to spin a turbine which in turn spins a

generator. Power is then produced from the generator. %ll the while the primary

combustion is occurring the cogen power plant uses as waste heat boiler. The hot

e2haust gases left over from the primary combustion process are sent through heat

e2changers which heat up steam in a boiler. It is only after that most of the heat energy

is removed from the hot e2haust gasses is it sent up the stac) and released to atmosphere.

The additional steam produced by the heat recovery boiler is then used to power a steam

turbine which powers a second generator. %dditional power is generated from the

second generator ma)ing the cogen power plants more efficient. 8or a visual on how the

system actually wor)s refer to 8igure ,.4.1.

4

Figure 2.3.1 Cogen Overvie !htt"#$$.cogen.org$cogen%challenge$&u""ort$image&.htm'

4.0 'eat 9ecovery (oiler Control

The overall P+ I drawing for my control system can be found in the following section.

:ou will also find 4 element feedwater boiler blowdown and basic boiler safety in the

following section of this report.

4.1 Process and Instrumentation .iagram

The overall process and instrumentation diagram for the boiler control system is pictured

in figure 4.1.1.

;

Figure 3.1.1 Overall ( ) * +iagram

#

4., Three <lement 8eed =ater Control

Three element feed water control has been selected in this case. The water level inside

the boiler is critical. If boiler level is too low the heating tubes will be e2posed which

will damage them. Too high a level will interfere with steam separation. (oth cases can

prove disastrous. In a three element system input flow output flow as well as level are

measured. *easuring and controlling three elements will ensure tight boiler level

control. 8igure 4.4.1 shows three element feed water control. :ou can see the outlet

steam flow feed water flow as well as boiler drum level are all monitored.

Figure 3.2.1 Three Element Feed Water

4.4 Continuous (oiler (lowdown

(oiler feedwater even after having been treated will contain impurities and minerals. If

these minerals aren>t removed from the boiler scaling and corrosion will occur on it>s

inside surfaces. This buildup can be avoided with proper boiler blowdown. (lowdown

1

will occur in , areas of the boiler drum. The first blowdown line will lead up to the top

watermar) in the boiler when this valve is opened all froth will be evacuated from the

drum. The second blowdown line will be installed into the bottom mud drum where all

the heavier solids will accumulate. Continuous boiler blowdown will be used in this

case& this signifies that a set ratio of blowdown will occur in proportion to the input of

feedwater flow. % set ratio of 100?1 will suffice for continuous blowdown versus inlet

flow.

4.; (asic (oiler Safety

%s was e2plained in an %<T: in class handout because of the energy in boilers safety

during start"up shutdown and normal operation is very important. Safety is a go @ no go

situation. If safety limits are e2ceeded 5A@588 controls disable the operation of the

boiler.

(elow you will find the basic safety interloc)s?

Purge interloc) "prevents fuel from being admitted to an unfired furnace until the

furnace is thoroughly purged with air

!ow air flow "fuel is shut off upon loss of air flow

!ow fuel supply "fuel is shut upon loss of fuel supply

!oss of flame "all fuel is shut off upon loss of flame in furnace and or to an

individual burner

B

8an Interloc) "stop forced draft upon loss of induced draft fan

!ow water "shut off fuel on low water level in boiler

.amper interloc) "shut dampers if fans are not operating

;.0 P!C # Programming

%llen (radley>s P!C # as well as 9oc)well %utomation>s 9Slogi2 P!C programming

software is used for automating the system.

;.1 P!C Information

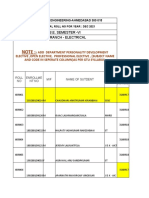

The following table lists all cards installed into the P!C rac)?

Ta,le -.1.1 (.C *n/ormation

Processor Type : Allen Bradley PLC-5/40C - 16 slot rack

Rack # Slot # escr!pt!on Part #

00 C0 Ethernet Adapter Card

00 C1 AC Input Module 1771-IA2

00 C2 Analog Input Module 1771-IFE/C

00 C3 Analog Output Module 1771-OFE/B

00 C4 Empty

00 C Empty

00 C! Empty

00 C7 Empty

01 C" Empty

01 C# Empty

01 C10 Empty

01 C11 Empty

01 C12 Empty

01 C13 Empty

01 C14 Empty

01 C1 Empty

C

;., Symbol Table

The following table lists all the I@5 addresses as well as descriptions.

Ta,le -.2.1 (.C 0ym,ol Ta,le

Address "a#e Type escr!pt!on

I$001/0 %A%% &I %e'el Alarm ()gh - ()gh

I$001/1 %A%% &I %e'el Alarm ()gh

I$001/2 %A( &I %e'el Alarm %o*

I$001/3 %A(( &I %e'el Alarm %o* - %o*

+10$ C,1 AO Bo)ler Feed -ater ,al'e

+10$! C,2 AO Bo)ler Blo*do*n ,al'e

+10$7 C,3 AO Bo)ler Blo*do*n ,al'e

+10$22 F.1 AI /team Output Flo* .ran0m)tter

+10$23 F.2 AI Bo)ler Blo*do*n Flo* .ran0m)tter

+10$24 F.3 AI Bo)ler Blo*do*n Flo* .ran0m)tter

+10$2 F.4 AI

Bo)ler Feed -ater Flo*

.ran0m)tter

+10$2! %. AI Bo)ler %e'el .ran0m)tter

;.4 Aetwor) .escriptions

The complete P!C ladder logic programming as well as individual networ) descriptions

is found in %ppendi2 % 3 DP!C ProgramE at the end of this report.

F

#.0 9Sview

9oc)well %utomation>s 9Sview software is used to create a -GI 6-raphical Gser

Interface7. 8igures #.0.1 shows a screen capture of the completed -GI.

Figure 1.2.1 R03ie 0creen Ca"ture

1.0 =iring .iagrams

1.1 (oiler !evel Switch =iring?

In figure 1.1.1 you can see both level alarms which each contain two probes& they are

wired into the %C input module in slot C1 of the P!C #.

10

Figure 4.1.1 .evel 0itch Wiring +iagram

1., !evel and 8low Sensing <lements?

8igure 1.,.1 shows the wiring for all flow and level transmitters. They all happen to be

9osemount 11#1 differential pressure transmitters.

11

Figure 4.2.1 Tran&mitter Wiring +iagram

1,

B.0 Pump Calculations

B.1 Pump Sizing

5' 0tatic 0uction .i/t H #0> of li$uid I B00 psia H ",0#F.F,;>

B' 0uction 0ide .o&&e& H

Pipe Size? #E sch ;0

Ta,le 6.1.1 (um" *nlet Fitting& .o&&e&

P$#p %nlet & '!tt!n(s Losses

Component 1 Ft E2u)'3 lenth 4uant)ty

Entry 037" 20 1

E5)t 1 2 1

El6o* 7#089 30 14 1

: 0;h 40 ! 1

.otal E2u)'alent <)pe %ength$ 124=

.P !e H 1.B0 psi H #.004>

C' Total +ynamic 0uction .i/t H ",0#;.F,1>

+' 0tatic +i&charge Head H 10>

E' +i&charge 0ide .o&&e& H

Pipe Size? #E sch ;0

14

Ta,le 6.1.2 (um" +i&charge Fitting& .o&&e&

P$#p !sc)ar(e & '!tt!n(s Losses

F)tt)ng 1 Ft E2u)'alent %ength 4uant)ty

Entry 037" 20 1

E5)t 1 2 1

El6o* 7#089 30 14 2

: 0;h 40 10 1

.otal E2u)'alent <)pe %ength$ 223=

.P !e H 4.01 psi H F.00#>

F' Total +ynamic +i&charge Head H 1F.00#

7' Total +ynamic 0uction .i/t H ",0#;.F,1

H' Total +i&charge Head 8 912 "&ia H ,BF#.#1>

T+H H B10.#1#>

B., Calculating pump motor horsepower

=ater 'orsepower? 6JKT.'KS.-.7 @ 4F10

H B#.41# 'P

(ra)e 'orsepower? H14B.0,B 'P

B.4 Pump Specifications

1;

8igure B.4.1 is the pump curve for the selected pump. Aote that I have made a mar) on

the drawing where #00 -P* and B10 T'. meet so that I may gather the rest of the

information that is re$uired to purchase a correct pump.

Figure 6.3.1 7ould (um" Curve !5ET: in cla&& handout'

'ere is a list of the specifications needed for this application?

1#

;a<e# -ould

;odel# 4B00

0i=e# 4L;"11

*m"eller 0i=e# 1;E

0"eed# 4##0 9P*

Hor&e"oer# 14B.0,B

E//iciency# ##0

C.0 Malve sizing

There are 4 control valves in the overall P+I drawing. :ou will find the specifications as

well as size calculations for these valves in the following section.

C.1 8eedwater valve sizing

11

Cv H J s$r. 9oot 6-f @ .p7

> H #00 gpm

7/ H 0.BC;C

+" H 10 psi

0olution H Cv H 1;0.0B

C., (lowdown valves sizing

Cv H J s$r. 9oot 6-f @ .p7

> H ,.#

7/ H 0.BC;C

+" H 10 psi

0olution H Cv H 0.B00

C.4 Malve Selection

1B

8or complete valve selection order code brea)down see appendi2 ( entitled DControl

Malve SelectionE at the bac) of this report. Table C.4.1 contains re$uired valve

specifications.

Ta,le ?.3.1 3alve &"eci/ication&

F.0 Pipe sizing

1C

In the following section the size or various pipes is calculated losses through the fittings

are also ta)en into account.

F.1 Pump discharge to boiler pipe

Figure 9.1.1 (um" +i&charge to Boiler (i"ing +iagram

Ta,le 9.1.2 .o&&e& through Fitting&

1F

P$#p !sc)ar(e to Bo!ler P!pe & '!tt!n(s Losses

F)tt)ng 1 Ft E2u)'alent %ength 4uant)ty

Entry 037" 20 1

E5)t 1 2 1

El6o* 7#089 30 14 2

: 0;h 40 10 1

.otal E2u)'alent <)pe %ength$ 223=

'ere are the re$uired formulas to size the pipe as found in the Crane manual?

+( H 0.000,11 6f!pJN,7 @ dN# 6Crane 4",7

/ H I will use a friction factor of 0.011 6Crane %",17 to begin my calculation

. H ,,4 feet

" H ;C.F;C 6Specific gravity of boiler feedwater O #00K8 in cu.ft@lb7.

> H #00 gpm

+( H 10 psi.

0olution? 4.F4E i.d.

,0

This is a ballpar) figure the 9eynold>s number must be found to ensure a more accurate

calculation. This formula is?

Re H #0.1 6Jp7 @ du 6Crane 4",7

0olution H B F00 000

Crane %",# shows that the friction factor will change from .011 to .01B. %fter plugging

the correct friction factor into the first e$uation then solving the e$uation once again

yields a result of 4.FCE inner diameter.

The correct pipe size in this case is a #E sch;0 which has an inner diameter at #.0;B

inches.

,1

F., Pump Inlet Pipe

Figure 9.2.1 (i"ing +iagram

,,

Ta,le 9.2.2 .o&&e& through Fitting&

P$#p %nlet P!pe & '!tt!n(s Losses

Component 1 Ft E2u)'3 lenth 4uant)ty

Entry 037" 20 1

E5)t 1 2 1

El6o* 7#089 30 14 1

: 0;h 40 ! 1

.otal E2u)'alent <)pe %ength$ 124=

'ere are the re$uired formulas to size the pipe as found in the Crane manual?

+( H 0.000,11 6f!pJN,7 @ dN# 6Crane 4",7

+( H # psi

/ H 0.01B

. H 1,;>

" H ;C.F;C

> H #00 gpm

0olution# ;.01FE i.d.

5nce again the pipe size will be #E sch;0 which has an inner diameter of #.0;BE.

,4

F.4 Superheated steam boiler outlet pipe

Figure 9.3.1 0u"erheated 0team Boiler Outlet (i"e

Ta,le 9.3.2 .o&&e& through Fitting&

Bo)ler &)0;harge to /team .ur6)ne <)pe

Component 1 Ft E2u)'3 lenth 4uant)ty

Entry 037" 32 1

E5)t 1 44 1

El6o* 7489 1! # 2

El6o* 7#089 30 20 2

": 0;h 40 ! 1

.otal E2u)'alent <)pe %ength$ 10

,;

I used the DSE curve on page 4",, of the Crane manual to get a ballpar) pipe size of CE

sch ;0 pipe. This pipe size 6CE sch ;07 will be used in the rest of the calculations.

9eynold>s P for 1F; 441 lbs @ hr of steam through CE sch ;0 pipe.

Re H 1.41 6=@du7

W H 1F; 441 lbs@hr

d H B.FC1E

u H 0.0,C 6Crane %",7

0olution H # ;CB ;0C

Friction /actor 6Crane %",#7 H 0.01;

+( H 0.000 004 410 Q6f!=N,Mbar7 @ 6dN#7R

F H 0.0,C

. H 1#0>

W H 1F; 441 lbs@hr

3,ar H 1.0401 6Crane %"1B7

d H B.FC1E

The pressure lost through the pipe and fittings is ? 1;.F psi.

,#

F.; (oiler blowdown pipes

The flow rate through the boiler blowdown pipes is only ,.# gallons per minute. Gsing

,E sch ;0 pipe will suffice for this application. This size of pipe is certainly oversized for

the flow rate because of this& the pressure loss through the pipe and fittings is negligible.

The larger than needed ,E pipe will assure clear flow of boiler blowdown.

10.0 Component Selection

10.1 (oiler Point !evel .etection

8our point level detection points are incorporated into the boiler ?

1. !%!! 3 !evel %larm !ow

,. !%! 3 !evel %larm !ow

4. !%' 3 !evel %larm 'igh

;. !%'' 3 !evel %larm 'igh 'igh

(oth the !%!! and !%! are measured with one level switch same goes for the !%'

and !%''. 5ne single switch has , probes inside of it which ma)es it ideal for this

application. The switch is made by Clar) 3 9eliance part P <%101 with soc)et

welded connections pictured in figure 10.1.1 meets the re$uirements needed to

assure safe operation for the high temperature and pressure conditions. See %ppendi2

C 3 D!evel Switch 5rdering InformationE for data sheet.

,1

Figure 12.1.1 Clar< Reliance E5121 .evel&itch !htt"#$$.clar<%

reliance.com$"roduct&$reliance$(roduct@.ine$.evelarm&.htm'

,B

Figure 12.1.2 .evel &itch dimen&ion&

!htt"#$$.clar<reliance.com$"roduct&$reliance$Catalog&$+3.1C."d/'

,C

Figure 12.1.3 .evel 0itch *n&tallation

10., 8low <lement Selection

5rifice plates are used for flow measurement e2clusively. Software available through

8o2boro was used to size the orifice plates and all of the ordering information as well as

sizing information can be found at the enof this report in appendi2 . 3 D5rifice Plate

Selection

,F

10.4 8low Transmitter Selection

FT1 0team Outlet Flo Tran&mitter

The 9osemount 11#1 differential pressure transmitter is used for steam outlet flow

measurement. It is connected to the process via flange taps as noted in the orifice sizing

section. The calibration settings are as follows?

Sero? 0E w.c.

Span? 1000E w.c.

The following order number is re$uired to assure the proper transmitter is ordered?

1111H( 4 0 12 B6 ;2

The model number table can be found in appendi2 . 3 DTransmitter 5rdering

InformationE at the end of this report.

FT2 ) FT3 Boiler Blodon Flo Tran&mitter&

9osemount 11#1 differential pressure transmitters are used for blowdown flow

measurement. They are connected to the process via flange taps as noted in the orifice

sizing section. The calibration settings are as follows?

Sero? 0E w.c.

Span? 100E w.c.

The following order number is re$uired to assure the proper transmitter is ordered?

1111H( - 0 12 B6 ;2

The model number table can be found in appendi2 . 3 DTransmitter 5rdering

InformationE at the end of this report.

40

FT- Boiler Feedater Flo Tran&mitter

The 9osemount 11#1 differential pressure transmitter is used for boiler feed water flow

measurement. It is connected to the process via flange taps as noted in the orifice sizing

section. The calibration settings are as follows?

Sero? 0E w.c.

Span? 1#0E w.c.

The following order number is re$uired to assure the proper transmitter is ordered?

1111H( 1 0 12 B6 ;2

The model number table can be found in appendi2 . 3 DTransmitter 5rdering

InformationE at the end of this report.

10.; (oiler !evel Transmitter

FT1 Boiler Water .evel Tran&mitter

The 9osemount 11#1 differential pressure transmitter is used to measure the water level

in the boiler via a wet leg setup as pictured in figure 10.;.1

41

Figure 12.-.1 .evel Tran&mitter *n&tallation

4,

The calibration settings for this level transmitter are as follows?

Sero? B.C;CE w.c.

Span? 41.4F,E w.c.

=ith the specific gravity of the boiler water being .BC;C the calibrations above will

monitor the boiler level between 0E and 40E inches of fluid. The following order number

is re$uired to assure the proper transmitter is ordered?

1111H( - 0 12 B6 ;1

11.0 Conclusion

This report has been written to meet the re$uirements of the third year %utomation

Technology course. I learned a lot while researching the various components that I have

selected throughout the report. There is without a doubt a lot of information to ta)e into

account when sizing and putting into play a control strategy such as three element feed

water. Paying close attention to detail in a report li)e this would pay off if the pro/ect

was ever underta)en. =iring diagrams and programming need to be perfect in order to

have a successful installation.

44

Re/erence&

1. http?@@www.energy.rochester.edu@cogen@chpguide.htm

,. http?@@www.cogeneration.org@

4. http?@@www.cogen.org@.ownloadables@Pro/ects@<.GC5-<ATCogenT-uide.pdf

;. http?@@www.cogeneration.net@

#. http?@@www.hatch.ca@<nergy@<nergyTConservation@<nergyT<fficiency@powerTcog

en.htm

1. http?@@appsci.$ueensu.ca@ilc@sustainability@energy@cogen.php

B. http?@@www.software.roc)well.com@

C. http?@@www.clar)"reliance.com@products@reliance@ProductT!ine@!evelarms.htm

F. http?@@www.emersonprocess.com@9osemount@

4;

Вам также может понравиться

- Thermodynamic Analysis of Rajby Industries Power and Boiler HouseДокумент20 страницThermodynamic Analysis of Rajby Industries Power and Boiler HouseSyed AhmedОценок пока нет

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Fluid Mechanics, Heat Transfer, and Thermodynamics Fall 2002 Design Project Production of Ethylene OxideДокумент13 страницFluid Mechanics, Heat Transfer, and Thermodynamics Fall 2002 Design Project Production of Ethylene OxideMarnel Roy MayorОценок пока нет

- Energy Balances and Numerical Methods Design Project Ethanol ProductionДокумент9 страницEnergy Balances and Numerical Methods Design Project Ethanol ProductionFatima Manzano OrtizОценок пока нет

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingОт EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingРейтинг: 5 из 5 звезд5/5 (1)

- Chapter 10: Vapor and Combined Power CyclesДокумент8 страницChapter 10: Vapor and Combined Power CyclesAhmad SairafiОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Steam Plant Alalysis ReportДокумент17 страницSteam Plant Alalysis Reportميسرة100% (11)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОт EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОценок пока нет

- Project 6 AmmoniaДокумент10 страницProject 6 AmmoniaAhmed AliОценок пока нет

- Final ReportttttttДокумент32 страницыFinal Reportttttttankitpanke100% (1)

- Introduction to the simulation of power plants for EBSILON®Professional Version 15От EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Оценок пока нет

- M - Electric Heater PIROBLOC EngДокумент11 страницM - Electric Heater PIROBLOC EngpikethОценок пока нет

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferОт EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferРейтинг: 5 из 5 звезд5/5 (2)

- Linea 24 and 28 Installation and Servicing InstructionsДокумент64 страницыLinea 24 and 28 Installation and Servicing Instructionskhairul_ezadОценок пока нет

- Parameters Influencing Boiler Efficiency: IssueДокумент11 страницParameters Influencing Boiler Efficiency: IssueJohn NgwokeОценок пока нет

- Boiler Tuning BasicsДокумент18 страницBoiler Tuning BasicsLester Pino100% (1)

- Boiler-Tuning Basics, Part I: What Constitutes Good Control?Документ11 страницBoiler-Tuning Basics, Part I: What Constitutes Good Control?Udhayakumar VenkataramanОценок пока нет

- FL 310 LG RTC enДокумент35 страницFL 310 LG RTC enandis_aОценок пока нет

- Manual For The Distillation Column: Jørgen K. Johnsen June 21, 2005Документ12 страницManual For The Distillation Column: Jørgen K. Johnsen June 21, 2005Abdul Gafoor ShaikhОценок пока нет

- MP 1Документ3 страницыMP 1Fake Account 1Оценок пока нет

- Tuning BoilerДокумент6 страницTuning BoilerGibby VonpoochcoughОценок пока нет

- Boiler Tuning BasicДокумент25 страницBoiler Tuning Basictrung2iОценок пока нет

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of StyreneДокумент12 страницFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of StyrenezarceloОценок пока нет

- 300 KW Electric Power Station Components: Commercial OfferДокумент5 страниц300 KW Electric Power Station Components: Commercial OfferLong Leo100% (1)

- O M Manual W818 PDFДокумент71 страницаO M Manual W818 PDFmujeebmehar100% (1)

- Ammonia B PDFДокумент9 страницAmmonia B PDFmehrdad_k_rОценок пока нет

- Sensor LambdaДокумент63 страницыSensor LambdaCarlos TetamuezОценок пока нет

- Superheat Charging Curve For TechniciansДокумент6 страницSuperheat Charging Curve For TechniciansBill ChambersОценок пока нет

- Boiler ManualДокумент178 страницBoiler ManualJay LawsonОценок пока нет

- Randell J. Mahabir: Mechanical EngineeringДокумент11 страницRandell J. Mahabir: Mechanical EngineeringCharlotte BОценок пока нет

- Acetone ProjectДокумент8 страницAcetone ProjectYo MarhoonОценок пока нет

- Brayton Cycle Experiment - Jet EngineДокумент10 страницBrayton Cycle Experiment - Jet EngineAsif MohammedОценок пока нет

- Ethanol BДокумент8 страницEthanol Barnold30Оценок пока нет

- Operation Book PDFДокумент118 страницOperation Book PDFArvind Shukla100% (1)

- CFBC DCPP at A Glance.Документ20 страницCFBC DCPP at A Glance.Sumit SuryavanshiОценок пока нет

- Air FanДокумент6 страницAir FanDevi PurnamasariОценок пока нет

- Boiler ManualДокумент86 страницBoiler ManualTateZhakata100% (1)

- Caterpillar C7.1 Industrial EngineДокумент13 страницCaterpillar C7.1 Industrial EngineFranky Fernandez83% (6)

- At M/S Jindal Steel &power Limited: For More ProjectsДокумент26 страницAt M/S Jindal Steel &power Limited: For More ProjectsvasqueznvОценок пока нет

- Steam Boiler Operating and Maintenance Manual 2497bДокумент19 страницSteam Boiler Operating and Maintenance Manual 2497bEngr. Shamim Hossain HridoyОценок пока нет

- 2 7Документ9 страниц2 7Rifat032017Оценок пока нет

- 2.7 Cogeneration - Revised (Table Format) PDFДокумент9 страниц2.7 Cogeneration - Revised (Table Format) PDFSagar Sanjay SonawaneОценок пока нет

- Manual 16 15Документ23 страницыManual 16 15LCCesar100% (1)

- CHAPTER 8 Sizing and CostingДокумент20 страницCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Steam Boiler Operating AND Maintenance Manual: Prepared by Meksis A.Ş. Service and R&D DepartmentДокумент19 страницSteam Boiler Operating AND Maintenance Manual: Prepared by Meksis A.Ş. Service and R&D DepartmentShambhu Mehta100% (1)

- Design of An Ethylene Oxide Production ProcessДокумент13 страницDesign of An Ethylene Oxide Production ProcessGie100% (4)

- PROJECT 5. Problems at The Cumene Production Facility, Unit 800Документ14 страницPROJECT 5. Problems at The Cumene Production Facility, Unit 800migelОценок пока нет

- Manual ECG - en - v2.1Документ25 страницManual ECG - en - v2.1JeremyYmerehОценок пока нет

- Combi 80e 105eДокумент44 страницыCombi 80e 105eRoberto JohnsonОценок пока нет

- Working of Steam Turbines and Its AuxillariesДокумент48 страницWorking of Steam Turbines and Its AuxillariesbalajigandhirajanОценок пока нет

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of CumeneДокумент11 страницFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of CumeneCarlos Benavidez AranibarОценок пока нет

- Elliot TurbineДокумент3 страницыElliot TurbineCal50% (2)

- Automotive Electronics - Vol 2Документ40 страницAutomotive Electronics - Vol 2Victor Balas100% (14)

- Double Regulating Valves (2601V)Документ7 страницDouble Regulating Valves (2601V)Sujit RajanОценок пока нет

- Simgas PRMS SimulationДокумент9 страницSimgas PRMS Simulationmatteo2009Оценок пока нет

- 27 Pozivil 2Документ3 страницы27 Pozivil 2Kristijan HorvatОценок пока нет

- Heat Recovery Steam Generator - HRSG General Usage: Combined-Cycle Gas Turbine CogenerationДокумент4 страницыHeat Recovery Steam Generator - HRSG General Usage: Combined-Cycle Gas Turbine CogenerationGustavo FamaОценок пока нет

- List of Studentwise Elective Sem-6 Circulation 27122021Документ34 страницыList of Studentwise Elective Sem-6 Circulation 27122021Parth PrajapatiОценок пока нет

- 1 5kW Raum Energy System Specs 2009Документ2 страницы1 5kW Raum Energy System Specs 2009LucasZheОценок пока нет

- Kotdwara, UttarakhandДокумент17 страницKotdwara, UttarakhandSadat Hossain RusadОценок пока нет

- Sun EdisonДокумент23 страницыSun EdisonMohana Priya SОценок пока нет

- Science9 Q3 SLM8Документ16 страницScience9 Q3 SLM8Zandra Musni Delos Reyes100% (1)

- Otec Plant FinalДокумент14 страницOtec Plant Finalshaikh afzalОценок пока нет

- Chemical Equation of Several Combustion ReactionsДокумент2 страницыChemical Equation of Several Combustion Reactionserwidodo50% (2)

- Leonardo ENERGY Webinar: Photovoltaic Installations: Ton Van Der Wekken 9 May 2007Документ21 страницаLeonardo ENERGY Webinar: Photovoltaic Installations: Ton Van Der Wekken 9 May 2007Brzata PticaОценок пока нет

- PEF - Nick Sharma - IHS Markit - Panel 1Документ13 страницPEF - Nick Sharma - IHS Markit - Panel 1Nina KonitatОценок пока нет

- Pump Selection Condensate Pump: Deaerator Pressure With 10% Allowance Assuming Piping Pressure DropДокумент3 страницыPump Selection Condensate Pump: Deaerator Pressure With 10% Allowance Assuming Piping Pressure DropJom BonhayagОценок пока нет

- Absorption Cooling: Datasheet 07 FEB 2012Документ3 страницыAbsorption Cooling: Datasheet 07 FEB 2012mohamadОценок пока нет

- Energy Engineering Question Bank - NSДокумент7 страницEnergy Engineering Question Bank - NSNilesh Singh100% (1)

- Gas Turb CatДокумент31 страницаGas Turb CatPablo Gutierrez100% (1)

- PSOC MCQ, EE & EEE, 6th SEMДокумент105 страницPSOC MCQ, EE & EEE, 6th SEMAjit100% (1)

- ITPS Coal Unloading and SAFETY FOR WORKMANДокумент3 страницыITPS Coal Unloading and SAFETY FOR WORKMANRanjay KumarОценок пока нет

- Solar Power Plant: by Satyam Meena 18ESKEE748Документ15 страницSolar Power Plant: by Satyam Meena 18ESKEE748Saloni SharmaОценок пока нет

- Civil Solar TreeДокумент17 страницCivil Solar TreeLan MedinaОценок пока нет

- Directory: Eco Friendly GR NДокумент171 страницаDirectory: Eco Friendly GR NTsunami IntelligenceОценок пока нет

- PDF PDFДокумент2 страницыPDF PDFVastie RozulОценок пока нет

- IEA - IEA Renewables 2018-IEA (2018) PDFДокумент492 страницыIEA - IEA Renewables 2018-IEA (2018) PDFValeria BerrocalОценок пока нет

- Tank Cleaning Guide (BP 2004)Документ1 страницаTank Cleaning Guide (BP 2004)g66666100% (3)

- Hydroelectric Power Plants in The Philippine 1Документ20 страницHydroelectric Power Plants in The Philippine 1Gopalakrishnan SekharanОценок пока нет

- Gas Turbine PerformanceДокумент15 страницGas Turbine PerformanceKevin J. Mills0% (2)

- Chapter 1Документ29 страницChapter 1Ranjan DhungelОценок пока нет

- Potential of Solar Energy in Developing Countries For Reducing EnergyДокумент3 страницыPotential of Solar Energy in Developing Countries For Reducing EnergyPrashannaОценок пока нет

- Otec (New)Документ20 страницOtec (New)RJ BedañoОценок пока нет

- Power and Energy Industry in IndiaДокумент16 страницPower and Energy Industry in IndiaSayan MaitiОценок пока нет

- List of Power Plants in PakistanДокумент32 страницыList of Power Plants in PakistansrzaОценок пока нет

- Solar PumpДокумент3 страницыSolar PumpDaniel OkereОценок пока нет

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (51)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItОт EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItРейтинг: 4 из 5 звезд4/5 (25)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataОт EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataОценок пока нет

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОт EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОценок пока нет

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionОт EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionОценок пока нет

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersОт EverandBulk Material Handling: Practical Guidance for Mechanical EngineersРейтинг: 5 из 5 звезд5/5 (1)

- Safety Theory and Control Technology of High-Speed Train OperationОт EverandSafety Theory and Control Technology of High-Speed Train OperationРейтинг: 5 из 5 звезд5/5 (2)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)От EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Рейтинг: 4 из 5 звезд4/5 (12)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsОт EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongОценок пока нет

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Handbook of Mechanical and Materials EngineeringОт EverandHandbook of Mechanical and Materials EngineeringРейтинг: 5 из 5 звезд5/5 (4)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeОт EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeРейтинг: 4 из 5 звезд4/5 (9)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsОт EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsРейтинг: 4 из 5 звезд4/5 (9)