Академический Документы

Профессиональный Документы

Культура Документы

Star Delta Connection

Загружено:

Yaj PerezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Star Delta Connection

Загружено:

Yaj PerezАвторское право:

Доступные форматы

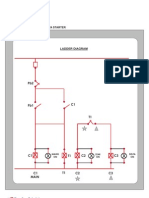

Star delta connection

Working Principle of Star-Delta Starter

This is the reduced voltage starting method. Voltage reduction during star-delta starting is achieved by physically reconfiguring the

motor windings as illustrated in the figure below. During starting the motor windings are connected in star configuration and this

reduces the voltage across each winding 3. This also reduces the torque by a factor of three.

Scheme - Working Principle of Star-Delta Starter

After a period of time the winding are reconfigured as delta and the motor runs normally. Star/Delta starters are probably the most

common reduced voltage starters. They are used in an attempt to reduce the start current applied to the motor during start as a means

of reducing the disturbances and interference on the electrical supply.

The Star/Delta starter is manufactured from three contactors, a timer and a thermal overload. The contactors are smaller than the single

contactor used in a Direct on Line starter as they are controlling winding currents only. The currents through the winding are 1/root 3

(58%) of the current in the line.

There are two contactors that are close during run, often referred to as the main contractor and the delta contactor. These are AC3

rated at 58% of the current rating of the motor. The third contactor is the star contactor and that only carries star current while the

motor is connected in star.

The current in star is one third of the current in delta, so this contactor can be AC3 rated at one third (33%) of the motor rating.

Size of each part of Star-Delta starter

1. Size of Over Load Relay

For a star-delta starter there is a possibility to place the overload protection in two positions, in the line or in the windings.

Overload Relay in Line:

In the line is the same as just putting the overload before the motor as with a DOL starter.

The rating of Overload (In Line) = FLC of Motor.

Disadvantage: If the overload is set to FLC, then it is not protecting the motor while it is in delta (setting is x1.732 too high).

Overload Relay in Winding:

In the windings means that the overload is placed after the point where the wiring to the contactors are split into main and delta. The

overload then always measures the current inside the windings.

The setting of Overload Relay (In Winding) =0.58 X FLC (line current).

Disadvantage: We must use separate short circuit and overload protections.

2. Size of Main and Delta Contractor

There are two contactors that are close during run, often referred to as the main contractor and the delta contactor. These are AC3

rated at 58% of the current rating of the motor.

Size of Main Contactor= IFL x 0.58

3. Size of Star Contractor

The third contactor is the star contactor and that only carries star current while the motor is connected in star. The current in star is 1/

3= (58%) of the current in delta, so this contactor can be AC3 rated at one third (33%) of the motor rating.

Size of Star Contactor= IFL x 0.33

Motor Starting Characteristics of Star-Delta Starter

Available starting current: 33% Full Load Current.

Peak starting current: 1.3 to 2.6 Full Load Current.

Peak starting torque: 33% Full Load Torque.

1. Standard Size of Transformer (IEEE/ANSI 57.120)

Single Phase Transformer Three Phase Transformer

5KVA, 10KVA, 15KVA, 25KVA, 37.5KVA, 50KVA, 75KVA,

100KVA, 167KVA, 250KVA, 333KVA, 500KVA, 833KVA,

1.25KVA, 1.66KVA, 2.5KVA, 3.33KVA, 5.0KVA, 6.6KVA,

8.3KVA, 10.0KVA, 12.5KVA, 16.6KVA, 20.8KVA, 25.0KVA,

33.33KVA

3KVA, 5KVA, 9KVA, 15KVA, 30KVA, 45KVA, 75KVA,

112.5KVA, 150KVA, 225KVA, 300KVA, 500KVA, 750KVA,

1MVA, 1.5MVA, 2MVA, 2.5MVA, 3.7MVA, 5MVA, 7.5MVA,

10MVA, 12MVA, 15MVA, 20MVA, 25MVA, 30MVA,

37.5MVA, 50MVA, 60MVA, 75MVA, 100MVA

2. Standard Size of Motor (HP)

Electrical Motor (HP)

1, 1.5, 2, 3, 5, 7.5, 10, 15, 20, 30, 40, 50, 60, 75, 100, 125, 150, 200, 250, 300, 400,

450, 500, 600, 700, 800, 900, 1000, 1250, 1250, 1500, 1750, 2000, 2250, 3000, 3500

and 4000

3. Approximate RPM of Motor

HP RPM

< 10 HP 750 RPM

10 HP to 30 HP >600 RPM

30 HP to 125 HP 500 RPM

125 HP to 300 HP 375 RPM

4. Motor Line Voltage

Motor (KW) Line Voltage

< 250 KW >440 V (LV)

150 KW to 3000KW 2.5 KV to 4.1 KV (HV)

200 KW to 3000KW 3.3 KV to 7.2 KV (HV)

1000 KW to 1500KW 6.6 KV to 13.8 KV (HV)

5. Motor Starting Current

Supply Size of Motor Max. Starting Current

1 Phase < 1 HP 6 X Motor Full Load Current

1 Phase 1 HP to 10 HP 3 X Motor Full Load Current

3 Phase 10 HP 2 X Motor Full Load Current

3 Phase 10 HP to 15 HP 2 X Motor Full Load Current

3 Phase > 15 HP 1.5 X Motor Full Load Current

6. Motor Starter

Starter HP or KW Starting Current Torque

DOL <13 HP (11KW) 7 X Full Load Current Good

Star-Delta 13 HP to 48 HP 3 X Full Load Current Poor

Auto TC > 48 HP (37 KW) 4 X Full Load Current Good/ Average

VSD 0.5 to 1.5 X Full Load Current Excellent

Motor > 2.2KW Should not connect direct to supply voltage if it is in Delta winding

7. Impedance of Transformer (As per IS 2026)

>MVA % Impedance

< 1 MVA 5%

1 MVA to 2.5 MVA 6%

2.5 MVA to 5 MVA 7%

5 MVA to 7 MVA 8%

7 MVA to 12 MVA 9%

12 MVA to 30 MVA 10%

> 30 MVA 12.5%

. Standard Size of Transformer

Standard Size of Transformer KVA

Power Transformer (Urban) 3, 6, 8, 10, 16

Power Transformer (Rural) 1, 1.6, 3.15, 5

Distribution Transformer 25, 50, 63, 100, 250, 315, 400, 500, 630

\

Electro pneumatics

PLC

Fire alarm

Security System / Burglar Alarm - Sample DSC Alarm System

This guide uses the DSC Power 864 security system with DSC accessories as an example to detail exactly how to wire a security system. Actual

wiring diagrams and pictures are provided for real DSC products. This guide assumes that all of the components will work together. See the

Alarm Wiring guide for more information.

This is the master wiring diagram for a Power 864 main panel. The Power 864 supports 64 different zones, but only 8 zones are available with

the main board. Additional boards would have to be purchased to expand this system. This panel contains connections for power, the siren,

keypads, devices, and sensors. Each will be covered in detail below.

DSC PC 5020 - Power 864 Panel

Click for full size image

Power Wiring

The power connections consist of the AC power and the backup battery. Note that I am working from the left to the right on the circuit board,

but the power should be the last thing you connect.

For this alarm system, the wires for the battery come directly out of the side of circuit board. First, verify that the power requirements of the

circuit board match those of the battery. In this case, they should both be 12 volt 7 amp-hours. Buying the recommended BD7-12 battery or

purchasing the battery, power supply, and main board in a kit is easier. The wire colors will be red & black which match perfectly the red and

black terminals on the battery itself. Connect the ground first (black), and then the power (red).

Using 18 AWG or better wire, measure the length of wire needed to connect the power supply at the power outlet to the power terminals on

the circuit board. First connect the wires to the power supply, then the wires to the alarm panel, and then finally plug in the power supply to the

electrical outlet. The power supply will either have 2 screw terminals (+, -) or 3 terminals (+, -, ground). Typically, both the power supply and

alarm panel will have power connections labeled + and -. Connect the + terminals together and the - terminals together. Usually your power wire

will be colored, labeled with + or -, or will have a stripe (for power) to differentiate the positive and negative wires.

For this alarm, the ground is located at the opposite end of the circuit board. You could run the ground from the ground connector on the

power supply and it will work since this ground will run back to the electrical box and then to the building's main ground. I prefer to tap directly

into the building's main ground. This is easy for me because my wiring panel (which is only a couple of feet from the electrical box) already has a

direct ground connection for other wiring. Tapping the building's main ground normally means clamping a wire to the copper water pipe as a

ground or connecting it to a driven ground rod. There is no need to figure this out for yourself. Your home should already have a VERY thick wire

that is clamped to this ground connection and run to the electrical box. Also, any coaxial cables for cable TV or satellite will also be grounded

right as they enter the home and you can either leverage that ground or trace it back to the grounding clamp. Finding a good ground is another

good reason to locate the alarm panel with other wires in a basement or utility closet.

The alarm system also recommends that you also ground the metal alarm panel box. This is done in case a power wire comes lose and contacts

the cabinet. With the cabinet grounded, that lose wire will be grounded in case it comes in contact with the cabinet. To ground the cabinet,

connect a ring connector to the end of the ground wire. Then, cut another short length of wire and connect a ring connector to one end of that

wire. Using one of the existing holes in the cabinet (alarm panel box), bolt both wires to the cabinet as indicated above: bolt, cabinet hole, star

washer, long ground wire to building ground with ring connector, lock washer, nut, short ground wire with ring connector, lock washer, nut. For

this specific alarm system, all of these parts were included in the kit. Note: The star connector is required to scratch the paint off of the cabinet.

Paint doesn't conduct electricity.

Note that there is a hole located at the top of the power supply housing. If your wall outlet has a screw in the middle of the wall plate, then you

can remove that screw, plug the power supply into the bottom outlet, and then put the screw through the hole in the top of the power supply

and back through the wall plate. This prevents the power supply from falling out of the outlet or someone removing it by mistake. Also make

sure you don't use an outlet that can be turned off by a wall switch.

Bell Wiring

The siren/horn/bell for the system basically makes lots of noise when the alarm goes off. As before, if the siren didn't come as part of a kit, then

verify that the siren doesn't draw too much current for the panel, in this case no more than 700 milliamps. This means that the siren must be

labeled 700 mA or less.

The siren will either have + and - terminals or black (-) and red (+) wires coming out of it. Connect these wires to the black and red wires of the

alarm wire that runs back to the + and - bell terminals on the main panel. For this example, the siren also has an optional yellow (+) wire that can

be used instead of the red wire. Using the yellow wire makes a yelp noise and the red wire makes a steady tone.

Keypad Wiring

Keypads typically require 4 wire connections. For multiple keypads, run each wire from the keypad back to the control panel and simply place

multiple wires in each connection. The terminals on the keypad are labeled Z G Y B R. The G (Green), Y (Yellow), B (Black), and R (Red), are the

standard 4 colors for alarm wiring. The DSC Z model keypads contain a 5th Z connection that can be used to monitor an additional zone.

Remember that the Power 864 panel supports up to 64 zones but only has connectors for 8. The sensor wiring description below details how to

use the Z terminals.

Device Wiring

The Device terminals are for smoke detectors and other programmable devices. Below are the instructions for wiring 2 or 4 wire smoke

detectors to a DSC alarm. Consult your alarm manual for any specific instructions on wiring programmable devices.

Sensor Wiring

All sensors use the COM (common) Z connectors on the control panel circuit board. Powered sensors (Ex: motion detectors) also require the +

& - auxiliary power connections. All 4 COM connectors on the board are identical and any of the can be used. The idea is that Z1 & Z2 use the

first COM terminal, Z3 & Z4 use the second...

At the alarm panel side, connect the wires using the colors shown below. Door and window sensors don't require Aux Power, so don't connect

the red and black wires. You may be tempted to connect these wires when unused just to get them out of the way. That is a bad idea, because it

means there will be live +12V power at the other end of that wire. A short could cause the alarm to malfunction or a short could damage the

circuit board.

Panel Connector Color

Powered Sensor

Connector

Door/Window

Sensor

Z Green Normally Closed (NC) Either wire

COM Yellow Common (C) Either wire

Aux + Red Power (+12V)

Aux - Black Ground (GND)

Below are sample DSC sensors: Motion Detector, Glass Break Sensor, Window Sensor, and a Door Sensor. Specifics for wiring each type of

device follows. Be sure to read our sections on Alarm Wiring and Tamper Proof Wiring before you do any wiring yourself.

Non-powered sensors like door and window sensors come in 2 parts. The first has 2 wires or 2 connectors on it that connect to the green and

yellow wires from the alarm panel. It doesn't matter which wire goes to which connector. The second part of the sensor contains a magnet. It is

best to wait to permanently mount the second part of the sensor until the alarm system is running and you are able to verify proper placement.

The motion detector above and the glass break sensor below use all 4 wires. The extra 2 wires are for power. As indicated in the control panels

diagram, the power draw for all powered devices (including sensors) cannot exceed 550mA. As and example, this motion detector can draw up

to 20mA and the glass break sensor can draw 32mA so there is pleanty of headroom for many sensors.

The Normally Closed (NC) connections are preferred over Normally Open (NO) ones. Cutting a wire to a NC sensor will set off the alarm while

cutting a wire to a NO sensor will disable that sensor.

This glass break sensor also includes a tamper connection that can be wired as a separate zone or in series with the Normally Closed contacts.

Wiring the tamper circuit to the alarm will activate the alarm when the cover of the sensor is removed.

Phone Wiring

The phone connection is required so that the alarm system can call the alarm monitoring company when the alarm goes off. Even if you are not

paying for monitoring, you will want to make the phone connection. Otherwise, the control panel will detect this missing connection as a

problem and the Trouble light on the alarm will stay lit.

If you have an phone outlet available, the easiest way to make the phone connection is to take a spare phone wire and cut off one of the ends.

Then strip the wires and connect the cut end to the control panel. Otherwise, run the wire from the alarm panel to any phone wire you can find

in the basement and make the connection there.

Pin Use Alarm Color Standard Phone Wire Color Cat3/Cat5e Color

1 Green Stripe

2 Line 2 Tip Brown Black Orange Stripe

3 Line 1 Ring Red Red Blue

4 Line 1 Tip Green Green Blue Stripe

5 Line 2 Ring Gray Yellow Orange

6 Green

The phone wire colors on this alarm (at least for Line 2) don't match standard phone wire colors. Also, in new homes many builders use Cat5e

cable for phone wire. It is easier and cheaper to buy one large spool of Cat5e cable and use it for both internet and phone lines. Your own phone

wires can be any color. Just make sure that you match up the correct colors when using different types of wires.

Disclaimer

This model of burglar system was chosen because it is one that I am personally familiar with and I had parts and manuals that were available

for review. These instructions are provided as an example for how to interpret instruction manuals for different alarm systems so that you will

have a better understanding of them. It is not intended that you blindly wire an alarm system exactly as described above. Small changes to the

control panel or components may occur over time, so always reference the manual that came with your hardware before this site. Also, please

review the disclaimer on our Structured Home Wiring home page.

This example is not intended as an endorsement of DSC and this site is not affiliated with DSC. DSC (Digital Security Controls Ltd.) is a division of

Tyco International.

INTRODUCTION. The purpose of this article is to show you how to terminate and assemble Keystone RJ-45, RJ-12, and

miscellaneous jacks.

DESIGN. Pre-planning is essential so that your installation goes smooth. Keystone Wall Plates with 1, 2, 3, 4, and 6

positions are available as well as Surface Mount Boxes with 1 & 2 positions. It is a good idea to leave a unused position

in Wall Plates for future expansion. You can use a blank insert to cover up the unused position.

Keystone Inserts are available for RJ-45 (Network), RJ-12 (Telephone), F (Cable TV COAX), BNC (Video Coax), RCA

(Audio and Video), SVHS (Video), Banana Binding Posts (Speakers), ST ( Fiber Optic), and Blank to cover unused

positions in Wall Plates or to make your own custom insert.

Examples of RJ-45 Keystone Jacks

Step 1. Strip The Cable

Trim the jacket of the cable back approximately 1 inch (Caution: Do not damage conductors). If you nick them, cut the cable off and

start again. Fan out all four twisted pairs. Note: It is designed for use with solid conductor premise cable.

Step 2. Align The Wires In the Slots

Following the instruction of the color-coded wire positions printed on the jack, lay the conductors into the punch down slots.

Depending on the manufacturer, the connections may look different than the one shown. Some connections will be at 90 degrees of

the jack (like the one shown) and others are straight out the back of the jack. Keep pairs twisted as close to the punch down slots as

possible. They must be twisted within 1/2" to conform to Cat 5 specifications.

Standard Wiring for RJ45 Jack

(Jack face shown)

Step 3. Terminate The Wires In The Slots

The RJ-45 Jack Inserts are self terminating. A plastic header cover is included that is snapped down over the connector and provides a

secure connection. Make sure that the wires are in the proper slot. Press the plastic header down over the wires until the header

bottoms out on the top of the terminal. On some Inserts, the header is hinged on the back of the Insert and others are actual separate

plastic parts.

Specific Termination Notes

Front View

Top View

Position wires in the slots. Press the plastic terminal

header over the terminals which will press the wires into

the slot. Make sure that the header is pressed all of the

way down against the terminal.

.

Front View Rear View

Position wires in the slots. Press the plastic terminal

header over the terminals which will press the wires into

the slot. Make sure that the header is pressed all of the

way down against the terminal.

.

Front View

Rear View

Position wires in the slots. Press the hinged plastic

cover down over the wires until it snaps. This will push

the wires down into the slots. Then press the small

plastic lock down into the slot behind the clear plastic

hinged cover. This locks the cover down.

Step 4. Install Insert into Wall Plate

Carefully install the Insert into the Wall Plate hooking the bottom latch first and then pushing up on the Insert, engaging the upper

latch.

Frequently Asked Questions

Wiring Standards

Q. T568A and T568B wiring: whats the difference, and

how do I know which one to use?

A. T568A and T568B are the two wiring standards for an 8-

position modular connector, permitted under the TIA/EIA-

568-A wiring standards document. The only difference

between T568A and T568B (also known as Weco, AT&T

258A) is that the orange and green wire pairs (pairs two

and three) are interchanged.

Standard 4-Pair Wiring Color Codes

Pair 1 T

R

White/Blue

Blue/White

Pair 2 T

R

White/Orange

Orange/White

Pair 3 T

R

White/Green

Green/White

Pair 4 T

R

White/Brown

Brown/White

Note: For 6-wire jacks use pair 1, 2 and 3 color codes. For 4-wire jacks, use Pair 1 and 2

color codes.

How to decide which wiring pattern to use:

1. Does the job specification call out a wiring pattern?

2. Does the customer/end user have a preference for T568A or

T568B?

3. Have patch panels already been purchased for the job? If so,

they will probably be either T568A or T568B. The jacks should be

wired to the same pattern as the panels.

4. Are you adding on to an existing wiring plant? If so, your new

wiring should match the existing wiring.

If none of the factors above apply, either T568A or T568B may be

used. It is important to ensure that the workstation connectors and

the patch panels are wired to the same pattern. T568B is

commonly used in commercial installations, while T568A is

prevalent in residential installations.

Q. Whats the difference between 110 connections and 66 connections?

A. Both 66 and 110 blocks are insulation displacement connection (IDC)

devices, which are key to reliable data connections. 66-clip blocks have

been the standard for voice connections for many years. Although 66-clip

blocks historically have been used for data, they are not an acceptable

connection for Category 5 or higher cabling. The 110-type connection, on

the other hand, offers: (A) higher density (more wiring in a smaller space)

and (B) better control (less movement of the wires at the connection).

Since more and more homes and businesses call for both voice and data

connections, it is easy to see why it makes sense to install 110-type

devices in most situations.

Typical 110 Punch Block

Typical 66 Punch Block

Q. What does RJ mean?

A. RJ stands for Registered Jacks. These are telephone and

data jacks or applications registered with the FCC.

Numbers like RJ-11, RJ-45, etc. are widely misused in

the telecommunications industry. They are not actually

jack types. A much more precise way to identify a jack is

to specify the number of positions (width of opening) and

number of conductors. For example: "8-position, 8-

conductor jack" or "6-position, 4-conductor jack".

Q.

How do I wire a one- or two-jack telephone wallplate to my

telephone wiring if the plate has solid color wires and my

house has striped wires?

A. See the illustration below for wire color cross-compatibility.

Caution--if you encounter "Quad" wire (four non-twisted wires)

on the premises, take note: Quad wire is no longer acceptable

for installation in multi-line environments. Quad's lack of pair

twisting makes it susceptible to interference.

If encountered during a retrofit, quad wire should be replaced

with 100 ohm UTP (unshielded twisted pair). Connecting new

quad to installed quad will only amplify existing problems and

limitations associated with quad wire; leaving existing quad in

place and connecting 100 ohm UTP to it may also be ineffective,

as the quad wire may negate the desired effect of the UTP.

Q. What is the Category Rating System?

A. In the mid 1980s, companies representing the

telecommunications and computer industries were concerned

with the lack of a standard for building telecommunications

cabling systems. In response to that concern, the Electronic

Industries Association (EIA) developed a standard called

TIA/EIA-568-A.

One of the sections of that standard was the definition of

performance categories for 100-ohm UTP horizontal cabling.

Level 1 This category consists of basic telecommunications and

power-limited circuit cables. There are no electrical performance

test or bandwidth requirements for this classification. Level 1

cabling may not be used in horizontal cabling systems.

Level 2 This category consists of cables specified to 1 MHz.

Level 2 cabling may not be used in horizontal wiring cabling

systems.

Category 3 This is a performance designation for twisted-pair

cable and connecting hardware that can support frequency

transmission up to 16 Mhz, and data rates of 10 Mbps. Category

3 has the capability to support low speed data applications,

performing to the acceptable minimum for 100 ohm cabling

systems; however it is now primarily used for telephone wiring.

Category 4 This category consists of cables and connectors

specified up to 20 Mhz and data rates of 16 Mbps. Since the

development of Category 5, however, Category 4 wiring systems

are rarely used.

Category 5 This category consists of cables and connectors

specified up to 100 Mhz and data rates of 100 Mbps, providing

optimal performance for all data and phone systems. These

systems are quickly becoming the standard because they

provide a "safety net" to help ensure that current and future

high-speed applications will run with peak accuracy, efficiency

and throughput.

Q. How do I wire a QuickPort

jack?

A. Leviton Voice & Data has three different connectors. Two are wired the same way: the Category 5 Power Sum connector and the

GigaMax

TM

connector. See the diagram below for wiring directions:

The eXtreme

TM

connector is a proposed Category 6 connector and is wired differently.

Follow these general directions to terminate all three types of connectors:

1. Strip 2" of cable jacket and position first pair according to color code. The

center channel lets you preserve wire twisting to less than .5" from the

termination point.

2. Set 110-tool to low impact setting and turn cutting edge outward to

terminate first pair. The patented cutting ledge trims the wire as you

terminate, saving you a step.

3. As with the first pair, position and terminate each subsequent pair one at a

time until termination is complete.

4. Snap on strain relief caps. The connector is now ready to be snapped into

any QuickPort housing or wallplate.

To view a Diagram, click on a wiring pattern below. (Note: to retain detail, these graphic sizes are large, allow time to download.)

Q. Whats the difference between a keyed jack and a non-keyed jack?

A.

Modular, non-keyed 8 position connectors accept standard (non-keyed) 8 position patch cords

Modular, keyed connectors accept both keyed and non-keyed 8-position patch cords. A keyed connector is shaped to

accommodate the keyed male plug, which has a small, square notch on its end. A keyed plug will not fit into a female non-

keyed connector.

Unless a keyed connector is called out in a specification, it is usually assumed the parts needed are non-keyed.

Q. What is UTP Cable?

A.

UTP stands for "unshielded twisted pair". It is a cable type

with one or more pairs of twisted insulated copper

conductors contained in a single sheath. It is the most

common type of cabling used in desktop communications

applications.

Q. Why should I use home run or star topology wiring as

opposed to daisy chain wiring?

A. A Star Topology has been defined as the standard for

horizontal cabling in accordance with TIA/EIA-568-A. Star

Topology calls for workstations to be wired directly to a

central equipment hub that establishes, maintains and

breaks connections between workstations. When a star

topology is used, it is much easier to locate and isolate

wiring problems than it is with daisy chain wiring. The most

common means of star wiring is a telephone PBX.

Вам также может понравиться

- Introduction To The National Electrical CodeДокумент10 страницIntroduction To The National Electrical CodeRafael CossОценок пока нет

- Maintenance of Electrical Switch GearДокумент190 страницMaintenance of Electrical Switch Gearmustaqu100% (3)

- 33KV Abb C&R-63675-2015Документ79 страниц33KV Abb C&R-63675-2015RK KОценок пока нет

- Star Delta StarterДокумент40 страницStar Delta Startersupermannon100% (1)

- Voltage Drop After NEC RequirementsДокумент3 страницыVoltage Drop After NEC Requirementsnadeem UddinОценок пока нет

- Star Delta DiagramДокумент2 страницыStar Delta Diagramgarv84090% (10)

- A Standby Generator Maintenance ChecklistДокумент1 страницаA Standby Generator Maintenance ChecklistMelky LumainОценок пока нет

- Measurement of Total Earth Fault Loop ImpedanceДокумент2 страницыMeasurement of Total Earth Fault Loop ImpedanceWilson (Electrical Engineer)50% (2)

- AMF+ATS Control Panel Smart GenДокумент10 страницAMF+ATS Control Panel Smart Genziandiqi83% (6)

- Motor Starter Types - Technology of Motor Starter and ApplicationsДокумент10 страницMotor Starter Types - Technology of Motor Starter and ApplicationsShayan Asad0% (1)

- ACB ManualДокумент24 страницыACB Manual4usangeet100% (1)

- 06 - Diagram Panel AMF 1x20KVAДокумент6 страниц06 - Diagram Panel AMF 1x20KVAElita Rachmawati100% (4)

- Electric Motor StarterДокумент16 страницElectric Motor StarterCuong TranHung100% (1)

- List Wiring Diagram 290 BprimeДокумент54 страницыList Wiring Diagram 290 BprimeKo ZayОценок пока нет

- 500KVA Diesel Generator With AMF PanelДокумент18 страниц500KVA Diesel Generator With AMF PanelAnthony Robert X100% (1)

- Calculate Size of DOL and Star-Delta Starter ComponentsДокумент11 страницCalculate Size of DOL and Star-Delta Starter ComponentsBeshoy RedaОценок пока нет

- Design of Electrical System Based On Load Flow Analysis Using ETAP For IEC ProjectsДокумент6 страницDesign of Electrical System Based On Load Flow Analysis Using ETAP For IEC ProjectsAlejandro Palacios100% (1)

- Different Type of CB and Its Functions. Erection, Testing & Commissioning of CBДокумент56 страницDifferent Type of CB and Its Functions. Erection, Testing & Commissioning of CBDipan GhoshОценок пока нет

- Oscillator: How To Build An InverterДокумент7 страницOscillator: How To Build An InverterGopal Prasad BansalОценок пока нет

- Motor StarterДокумент24 страницыMotor Starteryohannes tesfahaunОценок пока нет

- y D Starter PDFДокумент13 страницy D Starter PDFnazar750Оценок пока нет

- Inverter TrainingДокумент66 страницInverter Trainingkhurazi100% (1)

- Electrical Engineering Question and Answer - POWER SYSTEM QUESTION and ANSWERДокумент4 страницыElectrical Engineering Question and Answer - POWER SYSTEM QUESTION and ANSWERchico brilliantoОценок пока нет

- 7080 HandbookДокумент139 страниц7080 Handbookdony prabuОценок пока нет

- MCCB FundamentalsДокумент40 страницMCCB FundamentalsPinaki Sharma100% (2)

- Electrical Interview QuestionДокумент118 страницElectrical Interview QuestionMumtaj Khan0% (1)

- 5-Lighting System Inspection ReportДокумент5 страниц5-Lighting System Inspection ReportAldrin TaghapОценок пока нет

- Switch Mode Power SupplyДокумент5 страницSwitch Mode Power SupplyAnonymous D8rZh4YmzaОценок пока нет

- IR-ADV DX C7700 Series Service Manual - en - 11.0Документ2 623 страницыIR-ADV DX C7700 Series Service Manual - en - 11.0ANDYОценок пока нет

- 4 Relays & ContactorsДокумент37 страниц4 Relays & Contactorsgm100% (1)

- Calculating TransformeДокумент5 страницCalculating Transformekrit_kasemОценок пока нет

- Automatic Star Delta Starter Using Relay and Adjustable Electronic Timer For 3 Phase Induction MotorДокумент8 страницAutomatic Star Delta Starter Using Relay and Adjustable Electronic Timer For 3 Phase Induction MotorNoushz channelОценок пока нет

- Overcurrent and Earth Fault Relay Calibration CertificateДокумент2 страницыOvercurrent and Earth Fault Relay Calibration Certificateroslan yusofОценок пока нет

- 4 LCD+TV+Service+Guide+Handbook ENGДокумент61 страница4 LCD+TV+Service+Guide+Handbook ENGJorge Fernando de TivantaОценок пока нет

- GS-F34 - Generator Set System (Off Load Test)Документ2 страницыGS-F34 - Generator Set System (Off Load Test)Mohamed Firdaus Bin ZakariaОценок пока нет

- Maintenance of Low Voltage Circuit BreakersДокумент2 страницыMaintenance of Low Voltage Circuit BreakersJuvencio MolinaОценок пока нет

- ISC 2013 Physics Paper 1 Theory Solved Paper PDFДокумент30 страницISC 2013 Physics Paper 1 Theory Solved Paper PDFeltytanОценок пока нет

- Daikin Remote Controller BRC1C62Документ5 страницDaikin Remote Controller BRC1C62oioizoii100% (1)

- Idyoma o SawikainДокумент2 страницыIdyoma o SawikainYaj Perez100% (3)

- Electrical Q&A Part-1 - Electrical Notes & ArticlesДокумент44 страницыElectrical Q&A Part-1 - Electrical Notes & ArticlesSlardarRadrals0% (1)

- Training Dept (Eee) V Sem E-PlanДокумент33 страницыTraining Dept (Eee) V Sem E-PlanS.Dharanipathy100% (5)

- Maintenance Manual: Test SetДокумент50 страницMaintenance Manual: Test SetGusОценок пока нет

- DG Maintenance Manual PDFДокумент39 страницDG Maintenance Manual PDFvij200950% (2)

- Star Delta StarterДокумент1 страницаStar Delta Starterromilanon6150% (2)

- Board Exam ProblemsДокумент120 страницBoard Exam ProblemsLanz de la Cruz83% (6)

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanДокумент27 страницFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- Cummins GensetДокумент7 страницCummins GensetcspolaОценок пока нет

- Troubleshooting When Service CodeДокумент109 страницTroubleshooting When Service CodeAndi RusHmana100% (1)

- Calculate Size of Main ELCB & Brach MCB of Distribution Box - Electrical Notes & ArticlesДокумент10 страницCalculate Size of Main ELCB & Brach MCB of Distribution Box - Electrical Notes & Articlesshahnawaz ahmedОценок пока нет

- Control Circuits and Device NumbersДокумент27 страницControl Circuits and Device Numbersmuaz_aminu1422Оценок пока нет

- Hokkim Control & Protection RelaysДокумент2 страницыHokkim Control & Protection RelaysAhmad Radzi Sabtu100% (2)

- Contactors and Motor StartersДокумент5 страницContactors and Motor StartersZdan AhmadОценок пока нет

- Njr2-D Series Soft Starter: Instruction ManualДокумент21 страницаNjr2-D Series Soft Starter: Instruction ManualNguyen Van ChungОценок пока нет

- UPS Training - GailДокумент29 страницUPS Training - GailSatya VasuОценок пока нет

- Fully Automatic Star Delta StarterДокумент3 страницыFully Automatic Star Delta StarterHarish Gouda0% (1)

- ZAHRA Product CatalogueДокумент76 страницZAHRA Product Catalogueraza23967% (3)

- SMPS:-: Switched-Mode Power Supply (Switching-Mode Power Supply, SMPS, or Simplyswitcher) Is An ElectronicДокумент4 страницыSMPS:-: Switched-Mode Power Supply (Switching-Mode Power Supply, SMPS, or Simplyswitcher) Is An ElectronicSumit SrivastavaОценок пока нет

- Single PhasingДокумент41 страницаSingle PhasingdiljithОценок пока нет

- PLC Based Load Sharing On Slide ShareДокумент28 страницPLC Based Load Sharing On Slide ShareHemu Bhai PatelОценок пока нет

- Electrical Q&A Part-1 - Electrical Notes & ArticlesДокумент46 страницElectrical Q&A Part-1 - Electrical Notes & ArticlesAbdelrahman shokryОценок пока нет

- Local Media5941271462837301265Документ65 страницLocal Media5941271462837301265jason mr.perfect11Оценок пока нет

- Distribution Transformer Are Connected in ConfigurationДокумент4 страницыDistribution Transformer Are Connected in ConfigurationArun SamyalОценок пока нет

- How Do You Wire A Star Delta Motor?: (Type Text)Документ6 страницHow Do You Wire A Star Delta Motor?: (Type Text)nagrajtm_7Оценок пока нет

- Axis Drive Systems PDFДокумент62 страницыAxis Drive Systems PDFJoshОценок пока нет

- Protection v2 2Документ16 страницProtection v2 2Alexandr SemenkoffОценок пока нет

- Atmel AVR042 Avr Hardware Design Considerations Application Note 7 2013Документ17 страницAtmel AVR042 Avr Hardware Design Considerations Application Note 7 2013Naigel DiasОценок пока нет

- AC Regulator For Scooters and Motorcycles: OverviewДокумент7 страницAC Regulator For Scooters and Motorcycles: OverviewDJORJEОценок пока нет

- Agn102 BДокумент21 страницаAgn102 Bariwibowo100% (1)

- Solar Battery Charging and Single Phase Supply System: 1) What Is A Solar Cell?Документ14 страницSolar Battery Charging and Single Phase Supply System: 1) What Is A Solar Cell?ayushhjaveriОценок пока нет

- AVR Hardware Design ConsiderationsДокумент14 страницAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- Report On Automatic Phase Changer: Submitted ByДокумент32 страницыReport On Automatic Phase Changer: Submitted ByAndrea JohnsonОценок пока нет

- 120/240 Volts, 480Y/277 Volts, 600 VoltsДокумент1 страница120/240 Volts, 480Y/277 Volts, 600 VoltsYaj PerezОценок пока нет

- Dickey JohnДокумент74 страницыDickey JohnYaj PerezОценок пока нет

- Imers For All Pplications: FUJI Multi-Mode Timers With Full FeaturesДокумент5 страницImers For All Pplications: FUJI Multi-Mode Timers With Full FeaturesYaj PerezОценок пока нет

- Mindanao University of Science and Technology: College of Engineering & ArchitectureДокумент2 страницыMindanao University of Science and Technology: College of Engineering & ArchitectureYaj PerezОценок пока нет

- Schaums Outline of Electrical Power SystemsДокумент183 страницыSchaums Outline of Electrical Power SystemsRajesh Kumar100% (1)

- Inverter ManualДокумент126 страницInverter ManualYaj PerezОценок пока нет

- Experiment No - 14Документ8 страницExperiment No - 14Konem SolutionsОценок пока нет

- Xdm16Bt: Installation/Owner'S ManualДокумент14 страницXdm16Bt: Installation/Owner'S ManualJORGE SALGADO LAGUNAОценок пока нет

- Auto Drains00Документ2 страницыAuto Drains00Amir RahbariОценок пока нет

- New Laser Ignition SystemДокумент22 страницыNew Laser Ignition SystemShivananda DCОценок пока нет

- User Manual PB EnglishДокумент108 страницUser Manual PB EnglishFonchy CastroОценок пока нет

- Digitally Controlled Oscillator (DCO) - Based Architecture For RF Frequency Synthesis in A Deep-Submicrometer CMOS ProcessДокумент15 страницDigitally Controlled Oscillator (DCO) - Based Architecture For RF Frequency Synthesis in A Deep-Submicrometer CMOS ProcessNitin ChandОценок пока нет

- Ti Tas5630 EvmДокумент1 страницаTi Tas5630 EvmTrenton Astley IslaОценок пока нет

- EIE FormatДокумент13 страницEIE Formatapi-19989949Оценок пока нет

- GILL Capacity Analyser Owners ManualДокумент16 страницGILL Capacity Analyser Owners ManualBrunoОценок пока нет

- Fault Code List For Activ Break Assyst (ABA)Документ1 страницаFault Code List For Activ Break Assyst (ABA)Mahmoud SaudyОценок пока нет

- DX DiagДокумент13 страницDX DiagBernardus WasitaОценок пока нет

- Hs35a 2011Документ11 страницHs35a 2011Ross Mathew0% (1)

- Vacuum Pump Project PresentationДокумент5 страницVacuum Pump Project PresentationAlexandru Robert DumbravăОценок пока нет

- Delta-Star Connection of TransformerДокумент9 страницDelta-Star Connection of TransformernikolakaОценок пока нет

- TR 2 TremoloДокумент1 страницаTR 2 TremoloFouquetОценок пока нет

- Molecul h2 NormalisasiДокумент5 страницMolecul h2 NormalisasiendahОценок пока нет

- Redistart MV+ 12-18 ManualДокумент136 страницRedistart MV+ 12-18 ManualMaq QuinalhaОценок пока нет

- ARM Teaching MaterialДокумент33 страницыARM Teaching MaterialVishal NairОценок пока нет

- LogДокумент3 202 страницыLogriezl santosОценок пока нет

- Power: Circuit Diagrams and PWB LayoutsДокумент4 страницыPower: Circuit Diagrams and PWB LayoutsAmin SantanaОценок пока нет

- Alternador Delco Remy 24 VCD 100 Amo.19011153Документ2 страницыAlternador Delco Remy 24 VCD 100 Amo.19011153JoséLuisRodríguezSánchezОценок пока нет

- AO4466 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionДокумент4 страницыAO4466 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionErick V. BlancoОценок пока нет