Академический Документы

Профессиональный Документы

Культура Документы

Mesi art:10.1007/BF00905951

Загружено:

Abhijeet H Thaker0 оценок0% нашли этот документ полезным (0 голосов)

6 просмотров8 страницImportant for acidity reduction

Оригинальное название

Mesi_art%3A10.1007%2FBF00905951

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документImportant for acidity reduction

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

6 просмотров8 страницMesi art:10.1007/BF00905951

Загружено:

Abhijeet H ThakerImportant for acidity reduction

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

DEALKYLATIONOFMESITYLENE ANDASSOCIATED

ALKYLATIONOF BENZENE ANDTOLUENE INPRESENCE

OF SYNTHETIC ALUMOSILICATES

A. V. T o p c h i e v , G. M. Ma me d a l i e v , a n d L. S. Ko v a l e v a

Institute of Pet rochemi cal Synthesis, Academy of Sciences, USSR

Translated from Izvest i ya Akademi i Nauk SSSR, Otd. I<'himicheskilah

Nauk, 1961, No. 5,

pp. 868-876, May, 1961

Original art i cl e submitted February 8, 1960

Deal kyl at i on of xylenes and the associated al kyl at i on of benzene in presence of al umi num chloride [ 1- 7] , and

also of natural and synthetic al umosi l i cat es [8,9] has been studied in the works of a series of authors. These investi-

gations had as their goal the devel opment of a met hod of industrial production of toluene. Latterly, in connect i on

with the widespread devel opment of the production of a whole series of synthetic mat eri al s, the isomeric xylenes have

achi eved exceedi ngl y i mport ant pract i cal significance. One of the prospective methods for p- xyl ene production, as

has al ready been noted by us [10-12] and subsequently by other authors [13-16], is the isomeric conversion of m- and

o- xylenes into the para- isomer, achi eved compar at i vel y easi l y in presence of synthetic al umosol i cat es under at mos-

pheric pressure and in vacuo.

In our works it has been shown that the xylenes can be synthesized by deal kyl at i on and associated al kyl at i on of

ar omat i c hydrocarbons derived from pol yal kyl benzene sources included in the products of pyrol yt i c coke- gas produc-

tion and of industrial ar omat i zi ng reformat i on of narrow gasoline fractions [17,18]. Thus, on cat al yt i c t r eat ment of

a mi xt ure of toluene and the solvent from coke-gas production (mai nl y a mi xt ure ofpseudocumene, mesi t yl ene and

TABLE 1. Properties of Products of Cat al yt i c Tr eat ment of a Mixture of Benzene and

Mesi t yl ene (t emperat ure 480~ flow r at e 0.5 hour -1)

Fract i onal composition

Commencement of boiling

C. b . - 78

78-- 83

83-- 88

88--t03

103--t08'

108--t t 3

!.t3--118

t i 8--125

1 2 5 - - 1 3 6 9

136--144

t44--149

149--t60

t60--16~

165--i T

End of boiling, ~

Tot al yi el d, wt. %

Residue, Wto %

Losses, wt. %

Mat eri al bal ance, wt. %

Cat al yzat e

Coke -

Gas

Losses

Raw materia~ Expt,. 233, [ Expt. 232, I Expt.421,

mesitylene: , atmospheri~ 10 at m

benzene =1: 2~ 5 at m

79 I 74

Yield of fraction,

- - 4,45

64--69 55,57

0,70

i , 66

0,98

1,77

0,72 0, t8

0,56

t , 42

6,64

0, t 8

0,88

29,90 4,38

t4, 63

165,5 i72, 3

98,77 94,00

3,46 3,04

t , 33 2,96

97,3

0,9

Z } i , 8

I 7 i 7 8

wt. %

t , 83

51,06 49,4i

0,50 0, i 9

0, 7l 0,67

1,05 0,49

i t , 21 t8, 72

0,53 0,24

0,48 0,33

0,81 t , 09

t5, 40 16.2i

0,63 0,63

t , t 6 0,97

t , 87 t , 29

5,64 3,43

167,5 168

92,88 93,6i

4, 8t 4,76

2,3t t , 78

93,4 93,7

2,4 3,6

1,8 i , i

2,4 t , 6

Expt. 286,

15 at m

62

0,34

45,68

0,36

0,85

0,79

22,32

0,35

0,42

3, 2i

i4,01

0,46

0,92

i , 07

3,05

i69,5

93,83

3,20

2,97

9i , 2

4,6

t , 9

2,3

801

TABLE 2. Properties of Basic Aromat i c Fractions

,,, , , ,

Raw mat eri al

Properties of fractions mesi t yl ene Expt. 233

b e n z e n e =I:

Fraction 78 - 83*

Yield, wt. ~

d ~

Iodine number

Fraction I 0 8 - I 1 3 0

Yield, wt. ~/o

Iodine number

Fraction 136- 144 ~

Yield, wt. %

Iodine number

Fraction 160- 165 ~

Yield, wt. %o

2o

n D

d ~

4

Iodine number

Fraction 165- 175 ~

Yield, wt. %

Iodine number

Expt. 232 Expt. 421

63,69

t,5017

0,8776

0

55,57

1,5000

0,874t

0

5t, 06

t,4984

0,8731

0

49,4t

1,5009

0,8743

0

- - - 7 -

29,90

i,4995

0,8663

0

1,77

t,498~

0

6, 64

1,499t

O, 8659

0,3

4,38

I , 5043

O, 8749

0

t4, 63

t , 505t

0, 8743

0

t l , 21

t,4975

0,8672

0

15,40

t,4990

0,8674

0

t , 87

1,5029

0

5,64

i,5049

0,8745

0

t8, 72

1,4978

0,8668

0

t6,21

1,4990

0,8656

0

1,29

t,5015

3,43

1,5032

0

Expt, 235

45,68

t,5014

0,8779

0

22,32

1,4982

0,8676

0

! 4, 0t

1,4990

0,8684

0

t , 07

1,50t3

3,05

t,5045

0,8754

0

hemi mel l i t ol ) under opt i mmn t emperat ure and pressure conditions, yield of xylenes in one operation amount ed to

28% [19]. This process consists of a complex of a number of reactions occurring together and interdependently:

deal kyl at i on, al kyl at i on, dismutation, and isomeric conversions of initial aromat i c compounds.

In studying these reactions it was expedi ent to carry out an exper i ment al investigation on conversion of indi-

vidual al kyl ar omat i c hydrocarbons. A study had been made previously of demet hyl at i on and al kyl group transfer of

pseudocumene in presence of toluene and benzene over synthetic al umosi l i cat es. It was shown that on cat al yt i c t r eat -

ment of a mi xt ure of pseudocumene and benzene, deal kyl at i on of pseudocumene and associated al kyl at i on of benzene

t ook pl ace mai nl y, with format i on of - 20% toluene and - 17% xylenes. Similar conversions were observed on

50

2 0

c - - . 4 . -

J

I I

5 ~ 75

Pl~SSUre ~ at m

Fig. 1, Relationship between ar omat i c hydrocarbon

yield and pressure during t r eat ment of a benzene -

mesi t yl ene mixture: 1) benzene; 2) toluene; 9b xy-

lenes; 4) t ri met hyl benzenes.

t reat i ng a mixture of pseudocumene and toluene. In the

present communi cat i on resuks are given of an investigation

of deal kyl at i on, transfer of mesi t yl ene met hyl groups and

associated al kyl at i on of benzene and toluene in presence

of synthetic al umosi l i cat es.

EXP ERI MENTAL

As the i ni t i al products the following were used:

mesitylene (boiling range 164.5-164.8~ 1.5002;

0.8668), cryoscopic benzene (78.5-80'~ nnZ~ dZ. ~

0.8790), toluene (109.9-111~ n ~ 1. 4970, -d~ 0 0.8669). 4

Experiments were carried out in ci rcul at ory reactor

equi pment with a stationary cat al yst l ayer, the scheme and

description of which were given in the work [18]. Spectral

investigations of basic products of mesi t yl ene conversion

were carried out in the laboratory of physi cochemi cal

investigation methods by A. N. Kislinskii.

802

Demet hyl at i on of Mesi t yl ene and Associ at ed Met hyl at i on of Benzene. A mi xt ure of mesi t yl ene and benzene

in the r at i o by wei ght 1. 2 was subj ect ed t o cat al yt i c t r eat ment . The product was passed once over the cat al yst at a

t emper at ur e of 480*, flow rat e 0. 5 hour "1 and vari ous pressures. The mat er i al bal ance of the process, propert i es of

t he i ni t i al mi xt ur e and the cat al yzat es obt ai ned from its t r eat ment and t hei r basic ar omat i c fract i ons are gi ven in

Tabl es 1 and 2. Curves showi ng rel at i onshi p bet wenn a r oma t i c hydr ocar bon yi el d and pressure are gi ven in Fig. 1.

At at mospher i c pressure yi el d of r eact i on product s amount ed t o 97. 3 %, gas - f or mat i on was pr act i cal l y unob-

served, coke deposits on cat al ys t amount ed t o 0.901o, Even under these condi t i ons a cer t ai n amount of mesi t yl ene

deal kyl at i on and associ at ed benzene al kyl at i on was observed. Yi el d of t ol uene f r act i on amount ed to 1. 7%, of xyl ene~-

- 7%. Increase of pressure to 5 at m. not i ceabl y i nt ensi fi ed the r eact i on di r ect i on i nt ended. As a resul t of i nt ensi fi -

cat i on of t ransfer of the me t hyl group from t he mesi t yl ene mol ecul e t o the benzene mol ecul e, cont ent of t ol uene

and xyl ene f r act i on in the cat al yzat e i ncreased r espect i vel y t o 11. 2 and 15. 4%. Yi el d of c a t a l yz a t e amount ed t o

- 93%, of g a s - 1. 8%, of coke- 2. 401o. At 10 at m. pressure yi el d of t ol uene and xyl ene f r act i on i ncreased and a-

mount ed t o 18.7 and 17% r espect i vel y. Amount of benzene f r act i on decr eased from - 64% in the i ni t i al mi xt ure

to ~ 49% in the c a t a l yz a t e , t r i met hyl benzene f r act i on from ~ 30% t o 4. 5%. At 15 at m. pressure the process was

char act er i zed by c ompa r a t i ve l y l arge coke - and gas- f or mat i on (4.6 and 1.9% r espect i vel y) . Yi el d and qual i t y of

basi c ar omat i c fract i ons did not di ffer subst ant i al l y f r om the dat a of the exper i ment car r i ed out at 10 at m.

At a t emper at ur e of 480 ~ and 5- 10 at m. pressure cat al yt i c t r eat ment of a mi xt ur e of mesi t yl ene and benzene

over al umosi l i cat es resul t ed ma i nl y in mesi t yl ene deal kyl at i on and associ at ed benzene al kyl at i on

I t

_ / / \ _

%/

/ / \

\ /

In addi t i on, under the exper i ment al condi t i ons i somer i c conversi ons of mesi t yl ene t ook pl ace, as a resul t of

whi ch t he t r i met hyl benzene fract i ons of t he c a t a l yz a t e were char act er i zed by a hi gh pseudocumene cont ent .

Demet hyl at i on of Mesi t yl ene and Associ at ed Met hyl at i on of Tol uene. A mi xt ur e of t ol uene and mesi t yl enr in

the r at i o by wei ght 2: 1 was subj ect ed t o c a t a l yt i c t r eat ment . Anal yt i c dat a on t he cat al yzat es obt ai ned and t hei r

basi c a r oma t i c fract i ons are gi ven in Tabl es 3 and 4. Experi ment s were car r i ed out at a t emper at ur e of 480 ~ rat e of

raw ma t e r i a l i nfl ow 0.5 hour -1 and vari ous pressures. Curves showi ng r el at i onshi p bet ween yi el d of t ol uene, xyl enes,

t r i met hybenzenes , and pressure are gi ven in Fi g. 2.

At amospher i c pressure yi el d of c a t a l yz a t e yi el d amount ed t o 99. 4%, gas - f or mat i on was not observed, and

yi el d of c oke - l i ke r eact i on product s did not e xc e e d 0.4~ As a resul t of mesi t yl ene deal kyl at i on and associ at ed t o-

l uene al kyl at i on -~ 14% of xyl enes was f or med, as a resul t of whi ch cont ent of t ol uene and t r i met hyl benzene f r ac-

tions decr eased r es pect i vel y from 65. 3 and 31. 1% in t he i ni t i al mi xt ur e t o 56.7 and 20.101o in t he c a t a l yz a t e . I n-

crease in pressure t o 3- 5 at m. l ed t o i ncrease in yi el d of xyl ene f r act i on t o 26. 7 and 32%r es pect i vel y. At t he same

t i me, as a resul t of par t i al hydr ocr acki ng of side chai ns of i ni t i al and resul t i ng ar omat i c hydrocarbons, f or mat i on of

- 2-301o benzene was observed.

Furt her i ncrease in pressure t o 10 at m. had no subst ant i al ef f ect on yi el d of basi c ar omat i c hydrocarbons,

Sever al exper i ment s were car r i ed out at 5 a t m. pressure over t he t emper at ur e range 425- 480". In Fig. 3 is

shown the r el at i onshi p bet ween yi el d of basic ar omat i c cat al yzat e fract i ons and t emper at ur es. At 425* xyl ene f r ac-

t i on yi el d amount s t o 96% as agai nst 30% at 480*~ Further decr ease in t emper at ur e depresses me t hyl group transfer,

and t he c a t a l yz a t e is char act er i zed by compar at i vel y l ow xyl ene cont ent .

803

TABLE 3. Properties of Products of Cat al yt i c Tr eat ment of a Mixture of Tol uene

. . . . . . . . . . . Raw ma -

Fractional composi t i on t i al , me = Temper at ur e 480"

and properties of product fi t yl ene: atmospheric [ 3 at m 5 at m

toluene =

= 1 : 2 expt . 219 I expt . 221 expt . 220

Commencement of boiling, *C

C. b. -78

78-- 83

83-- 88

88--103

10"3--]08

108--t t 3

t t 3 - - t t 8

1t 8--i 25

t25--136

136--144

144--149

149--i60

160--i65

165--175

i75--185

End of boi l i ng, ~

Tot al yi el d, wt. %

Residue

Losses

Mat eri al bal ance, wt. %

Ca t al yzat e

or e

Gas

L o s s e s

t06

0,26

65,32

0,I0

0,17

0,25

0,13

0,16

0,68

3 t , t t

164,8

98,18

1,70

0, t2

75 i 53

Yield of f r act i on, wt.

0,18 0,23

0,33 2,69

0,20 0,24

0,56 0,78

0,90 0,50

56,70 50,73

0,24 0, t 8

0,25 0,72

0,67 0,55

13,93 26,69

0,48 0,88

0,93 0,96

3,86 2,75

t7, 33 8,95

{73 i 7i

96,56 96, 46

t , 72 2,71

1,72 0,80

99,4i 95,7

0,38 2,3

0,2f } 2,0

75

0,27

3,03

0,13

0,65

1,14

43,04

0,56

0,71

2,21

30,01

0,63

t , 06

t , 62

10,36

0,96

176

96,38

3,00

0,62

94,2

2,6

1,8

t , 4

) )

%/ %/

% /

% /

-L 11_

% /

50

4 0 ! I ) .

IO

2 ~-- I ' L T 1

495 r

i

) ,

!

os

Fig. 3. Relationship between yield of basic aromat i c

fractions and t emperat ure: 1) benzene~ 2) toluene~

3) xylenes; 4) trimethylbertzenes.

! , ) "

0 t 2 3 e 5

Pressure, at m

Fig. 2. Relationship between yield of ar omat i c hydro-

carbons and pressure in t reat ment of a t ol uene- mesf -

t yl ene m/ xt ure: 1) benzene; 2) t ol uene; 3) xyl enes;

4) t ri met hyl benzenes.

Results of investigations carried out showed t hat under

opt i mum conditions (480*; 5 at m. pressure; flow rat e 0.Shr "1)

t r eat ment of a mi xt ure of toluene and mesi t yl ene over al umo-

si l i cat e was charact eri zed mai nl y by occurrence of mesi t y-

lone demet hyl at i on and associated toluene met hyl at i on with

f o r ma t i o n of 30-82% of a mi xt ure of xylenes. According to

spect ral anal yt i cal data, the cat al yzat e xylene fraction con-

sisted of a mi xt ure of ~ 50% m- xyl ene, - 20% p- xyl ene

and ~ 30% o-xylCne. As a result of isomeric mesi t yl ene

804

TABLE 4.

Properties of fractions

Properties of Basle Ar omat i c Fractions

Raw ma t e r i a l

mesi t yl ene : Expt. 2!9

toluene =l: 2

Fraction 78--83*

Yield, wt. %

Iodine number

Fraction 108- 113 ~

Yield, wt. %

d~ 0

Iodine number

Fraction 136-144"

Yi el d, wt. %

n~

dZ0

4

Iodine number

Fraction 160-165 ~

Yield, wt. %

ng

Iodine number

Fraction 165-175"

Yi el d, wt. '%

n D

Iodine number

m

65;32

1,4977

0,8660

0

31,1t

1 , 5 0 0 4

0,8756

0

m

m

0,33

1 , 4 9 0 4

56,70

1,4977

0,8678

0

t3,93

t,4998

0,8675

0

3,86

1,50t3

0,8700

0

17,33

t,5058

0,8764

0,8

Expt. 221

2, (9

t,4990

0,874i

0

50,37

1,4980

0,8656

0

26,69

t,4999

0,8660

0

2,75

t , 50t 8

0,8686

0

8,95

t,5054

0,8757

0,7

Expt. 220

3,03

1 , 4 9 9 0

2 . 2

4 3 , 0 4

~,4978

0,8652

0

3 0 , 0 i

1 , 4 9 9 0

0,8666

0

1,62

t,5017

0

t0, 36

1,5048

0,8731

0

,3

93o

/0

I , I i i

0 1 g .~

Pressure, at m

Fig. 4. Relationship between yield of ar omat i c hydro-

carbons and pressure during t r eat ment of mesi ryl ene:

1) t ol uene; 2) xylenes; 3) t ri met hl benzenes; 4) t et r a-

met hyl benzenes.

conversion the resulting t ri met hyl benzene fraction of the

cat al yzat e cont ai ned a considerable amount of pseudo-

cumene. In this case, mesi t yl ene dismutation was pract i -

cal l y unobserved.

Met hyl Group Transfer and Isomeric Mesitylene Con-

version. Cat al yt i c treatnaent of mesi t yl ene in presence of

benzene and toluene, as has been shown, was charact eri zed

by occurrence of demet hyl at i on and associated met hyl at i on

of i ni t i al aromat i c hydrocarbons. Presence of benzene and

toluene depressed mesi t yl ene dismutation and appreci abl e

format i on of t et ramet hyl benzenes was not observed.

A series of experi ment s was carried out on cat al yt i c

t r eat ment of mesi t yl ene. The mat er i al bal ance of the

process and results of analysis of resulting cat al yzat es and

their aromat i c fractions are given in Tables 5 and 6.

Curves showing relationship between yield of basic con-

version products and pressure are given in Fig. 4.

At at mospheri c pressure - 40% of the initial mesi t yl ene underwent dismutation with format i on of 16% xylenes

and 24% t et ramet hyl benzenes. Yield of liquid react i on products amount ed to 94%, of g a s - 1 . 4 %, of coke-1. 6~

Increase in pressure not i ceabl y intensified disproportionation of mesi t yl ene met hyl groups. In addition, part i al mesi -

805

TABLE 5. Properties of Products of Cat al yt i c Mesitylene Conversion (flow rat e 0.5 hour -1)

Fractional composition

and product properties

a t m o s -

p h e r i c

expt. 223

Temperature 480*

Commencement of boiling, *C t09,5

" - 7 "

0,30

0,33

0,42

0,56

t 5, 90

0,88

2,38

2t , 31

30,74

2,88

t80

75,70

24,05

0,25

94,4

t , 6

t , 4

2,6

__2ai m 8 ai m I 5 ai m

expt. 231 expt. 228 [ expt. 226

90 I 84,5

Yield of fraction, wt . %

C.b. - - 88

88--103

103--108

t08--t13

t t 3- - 1t 8

t t 8- - t 25

t25--t36

136--t44

t 44--t 49

t 49--t 62

t62--167

t 67--t 72

t72--180

End of boiling

Tot al y i e l d , wt. %

R e s i d u e

L o s s e s

Mat eri al bal ance, wt. @o

Cat al yzat e

Coke

Gas

Loses

0,52

0,35

3,77

0, t 6

0,39

0,86

25,52

0, t 3

1,26

1t,94

26,59

4,09

t80

75,58

23,47

0,95

90,8

4,8

4,2

0,2

0, t 4

0,50

0,29

5,11

0,31

0,37

t , 27

.)6, 52

0,83

1,61

L2,75

).3,00

3, 40

t ~0

'6, t0

',0,72

3, t 8

;3,6

7,3

6,4

2,7

Temperature

400*

3 at m

expt. 236

83,5 80,5

0, t 7 0, t t

0, t 5 0,33

0,30 0,23

2,50 0,61

0,22 0,22

0, 49 0,34

t , 04 0,77

23,68 15,63

0,33 0,63

4, 3t 1,61

26,86 15,72

i2,76 35,2t

2,79 3,16

t80 t80

75,60 74,57

22,6t 24,98

t , 79 0,45

84,7 97,0

9,9 0,7

5, t

0,3 2,3

tylene cracking occurred with formation of 4-5% toluene. At 2 ai m. yield of xylene fraction amounted to 25%, of

t et ramet hyl benzene to - 28%. With increase in pressure, a noticeable increase was observed in yield of coke-l i ke

and gaseous reaction products.

At 3 at m. decrease in temperature to 400* depressed mesitylene hydrocracking, and in addition lowered the

dismutation ef f ect somewhat. Yield of xylene and t et ramet hyl benzcnes amounted to - 17% and ~ 25%. Cat ai yzat e

composition in this experi ment was pract i cal l y i dent i cal to the composition of the cat al yzat e obtained at atmospheric

pressure and 480*.

According to spectral anal yt i cal data, the xylene consisted of a mixture of - 45% m- xyl ene, - 25% o-xyl ene,

Thus, cat al yt i c mesitylene conversion over alumosilicates at 480* and 2-3 at m. pressure was charact eri zed

mai nl y by disproportionation of met hyl groups with formation of xylenes and tetramethylbenzenes:.

I

//\

- i

%/

%/

%/

i

I

%/

//\

%/

%/

//\

-I L

%/

806

TABLE 6. Properties of Basic Ar omat i c Fractions of Products of Mesi t yl ene Conversion

Properties of fract i on

Fraction 108- 113 ~

Yield, wt. %

Iodine number

Fraction 136- 144 ~

Y i e l d , wt. %

d ~ ~

~ o d i n e n u m b e r

Fraction 1 6 2 - 1 6 7 "

Yield, wt. %

G ~

Iodine n u m b e r

Fraction 1 6 7 - 1 7 2 ~

Yield, wt. ,~o

G ~

Iodine n u m b e r

Fraction 1 7 2 - 1 8 0 ~

Expt. 223

0,30

i,4942

1 5 , 9 0

i , 4 9 9 0

0 , 8 6 9 2

0

2 1 , 3 i

1 , 5 0 1 8

0 , 8 7 0 4

0,3

30,74

t,5052

0,8769

0,2

Expt. 281

3,77

t,4952

0,8659

0,28

2 5 , 5 2

1 , 4 9 9 9

0 , 8 6 7 8

0 , 2 0

i l , 94

i,5040

0,8728

0

26,59

1,5058

0,876i

0

Expt. 228

5, i i

1,496i

0,8636

0

26,52

1 , 4 9 9 8

0,8662

0

12,75

1,5020

0,8689

0

23,00

1 , 5 0 5 i

0,8755

0

Expt. 226 } Expt. 236

2,50

t,4959

0,8666

1,2

23,68

i , 4 9 9 0

O, 8662

1,5

26,86

t,5040

O, 8727

0,3

i2, 76

l , 5055

O, 8754

0,8

Yield, wt. %

d ~ ~

I o d i n e n u m b e r

R e s i d u e

Y i e l d , w t .

n ~

I o d i n e n u m b e r

S u l f o n a b i l i t y , v o l , %

2,88

1,5t05

O, 8868

0

24,05

1,5t75

O, 8960

0,2

lO0

4,09

i , 5092

O, 8820

0

23,47

O, 9014

1,8

lO0

3,40

i,5119

O, 8881

4,1

20,72

t , 5233

O, 9032

5,5

t00

2,79

i , , 5 0 7 3

2 2 , 6 i

t , 5f 34

O, 9006

1,5

iO0

0 , 6 1

i,4880

15,63

1,4982

O, 8628

0,5

15,72

1,5006

0,8677

0

35,21

t,5035

0,8753

0

3,16

1,5t03

0,8872

24,98

1,5174

0

LO0

In the course of the process a cert ai n amount of mesi t yt ene i someri zed with format i on of pseudocumene and

part i al l y of semi met l i t ene

% / % / % /

I

Besides the conversions indicated, hydrocracking of al kyl benzenes with format i on of a cert ai n amount of toluene,

met hane and its homologs occurred to a compar at i vel y smal l ext ent ,

807

S UMMAR Y

1. Cat al yt i c conversi on of mesi t yl ene mi xed with benzene was studied. Under condi t i ons of an el evat ed pressure

of 10- 15 at m. and a t emper at ur e of 480", deal kyl at i on of mesi t yl ene and associ at ed al kyl at i on of benzene occurs

mai nl y, with f or mat i on of 18- 22% t ol uene and - 17% xyl enes.

2. As a result of si ngl e- st age t r eat ment of a mi xt ure of mesi t yl ene and t ol uene over an al umosf l i cat e, 30- 32%

of a xyl ene f r act i on is f or med, consi st i ng of 45- 50% m- xyl e ne , ~ 20- 25% p- xyl ene, and - 30% o- xyl ene. Presence

of t ol uene and benzene depresses mesi t yl ene di smut at i on pr act i cal l y ent i r el y.

3. On cat al yt i c t r eat ment of mesi t yl ene in presence of al umosi l i cat es, di sproport i onat i on of mot hy1 groups occurs

mai nl y, with f or mat i on of xyl enes and t et r amet hyl benzenes. In this case, part i al hydr ocr acki ng of mesi t yl ene me t hyl

groups occurs, with f or mat i on of a smal l amount of t ol uene, met hane and its homol ogs.

L I T E R AT UR E C I T E D

1. R. Anschut z, and H. I mmendor f , Bet. 18, 657 (1885).

2. R. Heise and A. To11, Liebigs Ann. Chem. 270, 155 (1892).

3. O. Jacobsen, Ber. 18, 338 (1885).

4. L. I . Smi t h a nd O. W. Gass, J. Amer . Chem. See. 54, 1603- 1621 (1932).

5. I . F . Norris and J. N. I ngr aham, I . Amer . Che m. Soc. 6_22, 1298 (1940).

6. J . F. Norris and G. T. Vaal a, J. Amer . Chem. Soc. 61, 2131 (1939).

7. Ch. Fri edel and I. M. Craft s, Compt . rend. 109, 692 (1885).

8. B. L. Mol davski i and L. S. Bezdel ' , Zhur. Obshchei Khi m. , 16, 1633 (1946).

9. R. C. Hansford, C. G. Mej ers, and A. N. Sachanen. , Industr. and Engng. Chem. 37, 671 (1945).

10. Yu. G. Mamedal i ev, A. V. Topchi ev, G. M. Mamedal i ev, and G. N. Sul ei manov, Dokl ady Akad. Nauk SSSR,

106, No. 6, 1027 (1956).

11. A. V. Topchi ev, G. M. Mamedal i ev, and Yu. G. Mamedal i ev, Izvest . Akad. Nauk SSSR, Ot del . Khi m. Nauk,

No. 11, 1390 (1956).

12. G. M. Mamedal i ev, Yu. G. Mamedal i ov, and A. V. Topchi ev, Izvest . Akad. Nauk SSSR, Ot del . Tekhn. Nauk,

No. 6, 91 (1958).

13. E. F. Boedeker and W. E. Erner, J. Amer . Chem. Soc. 76, 5, 3591 (1954).

14. A. D. Sul i mov, V. I. Karisev, T. V. Zhakhovskaya, V. M. Ol evski i , E. G. Wendel st ei n, E. I. s i r c h e n k o , N. V.

Shavol i na, and A. A. Voi t ekov, Khi mi ya/ i t ekhnol ogi ya t opl i va 1, 33 (1956).

15. N. I . Shuikin and Dashzhamt s Batyn, No. 3247 (1957).

16. N. I . Shuikin, E. D. Tul upova, and Z. P. Pol yakova, Izvest . Akad. Nauk SSSR, Ot del . Khi m. Nauk, 1958, 1476.

17. A. V. Topchi ev, G. M. Mamedal i ev, A. N. Kislinskii, and G. N. Ani ki na, Dokl ady Akad. Nauk SSSR, 112,

1071 (1957).

18. A. V. Topchi ev, G. M. Mamedal i ev, and S. M. Al i ev, Izvest . Akad. Nauk SSSR, Ot del . Khi m. Nauk, 1959, 861.

19. A. V. Topchi ev and G. M. Mamedal i ev, Dokl ady Akad. Nauk SSSR, 117, No. 6, 1007 (1956).

All abbreviations of periodicals in the 'above bibliography are l et t er-by-l et t er transliter-

at i ons of the abbrevi at i ons as given in the original Russi an journal. Some or all of t hi s peri-

odi cal l i t erat ure may wel l be avai l abl e in Engl i sh t ransl at i on. A complete l i st of the cover-t o-

cover Engl i sh t ransl at i ons appears at the back of this issue.

808

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Formula PerfumesДокумент5 страницFormula PerfumesArantxa YarzaОценок пока нет

- MMSA Methanol World Supply and Demand Summary Jan 2020Документ2 страницыMMSA Methanol World Supply and Demand Summary Jan 2020rifqi98Оценок пока нет

- Macromolecules PRACTICE Test 2012 2013Документ8 страницMacromolecules PRACTICE Test 2012 2013edeceОценок пока нет

- Pengaruh Penambahan Ekstrak Bawang Putih Terhadap Kadar Kolestrol Daging Kambing Peranakan Boer KastrasiДокумент5 страницPengaruh Penambahan Ekstrak Bawang Putih Terhadap Kadar Kolestrol Daging Kambing Peranakan Boer KastrasiBryan AswОценок пока нет

- Consuelo National High School: Bio-Plastic Experiment Video ScriptДокумент2 страницыConsuelo National High School: Bio-Plastic Experiment Video ScriptMarlon S. BarangganОценок пока нет

- Chemistry of COMPOUND Lipids.Документ60 страницChemistry of COMPOUND Lipids.QueenОценок пока нет

- Functional GroupДокумент20 страницFunctional GroupCatherine R. FelipeОценок пока нет

- Contoh SURVEY GIZIДокумент12 страницContoh SURVEY GIZINandya AgustinaОценок пока нет

- Introduction To Biopharmaceutics and PharmacokineticsДокумент40 страницIntroduction To Biopharmaceutics and PharmacokineticsSyeda Eshaal JavaidОценок пока нет

- On Lesson 14 Nucleic Acids and LipidsДокумент40 страницOn Lesson 14 Nucleic Acids and LipidsKamto EzenwamaduОценок пока нет

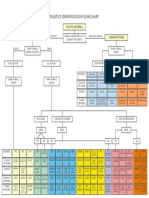

- Plastics Identification Flow ChartДокумент1 страницаPlastics Identification Flow ChartchiralicОценок пока нет

- IUBAC Naming Organic CompoundsДокумент28 страницIUBAC Naming Organic CompoundsLakshОценок пока нет

- Protein Synthesis Drag & Drop Activity 2021Документ6 страницProtein Synthesis Drag & Drop Activity 2021Gloria LaneОценок пока нет

- Product Catalogue-Henan Ouber Technology Co., Ltd.Документ8 страницProduct Catalogue-Henan Ouber Technology Co., Ltd.anna.zhangОценок пока нет

- Carbohydrates 2Документ81 страницаCarbohydrates 2smcm11Оценок пока нет

- Digestion & Absorption of TAGДокумент1 страницаDigestion & Absorption of TAGJanine Franchesca SuministradoОценок пока нет

- Protein MCQ Final RevisionДокумент11 страницProtein MCQ Final RevisionMohamed KhalelОценок пока нет

- Urea CycleДокумент13 страницUrea CycleShampa SenОценок пока нет

- GR 10 Unit Exam 1 (EM)Документ2 страницыGR 10 Unit Exam 1 (EM)chaminda dayarathneОценок пока нет

- 12~19 생화학 테뱅 정리Документ117 страниц12~19 생화학 테뱅 정리조주상Оценок пока нет

- Registered Medicine List 07-04-2014 Sse Frequently UpdatedДокумент116 страницRegistered Medicine List 07-04-2014 Sse Frequently Updatedjema; belihuОценок пока нет

- AQA Biology Topic 8.3 Structures of Ribonucleic AcidДокумент4 страницыAQA Biology Topic 8.3 Structures of Ribonucleic AcidfОценок пока нет

- BIS 102 MT 1 Hilt F10 BlankДокумент6 страницBIS 102 MT 1 Hilt F10 BlankKimОценок пока нет

- BCH101 - L1 - The Chemical Basis of LifeДокумент52 страницыBCH101 - L1 - The Chemical Basis of Lifesrabonty.siddikyОценок пока нет

- Update Stok 22 Juni 2023Документ8 страницUpdate Stok 22 Juni 2023Lulut Hening PrasetyoОценок пока нет

- Vitamins and MineralsДокумент4 страницыVitamins and MineralsNoreen Orro BernalОценок пока нет

- Bansal Chemistry 1Документ424 страницыBansal Chemistry 1Waseem0% (1)

- Methods of Synthesis of Deuterium-Labelled LipidsДокумент13 страницMethods of Synthesis of Deuterium-Labelled LipidsDavid SweedlerОценок пока нет

- Akema Fine ChemicalsДокумент1 страницаAkema Fine ChemicalsJulia BottiniОценок пока нет

- Addition Polymers (4.8.1)Документ4 страницыAddition Polymers (4.8.1)KeerthikaОценок пока нет