Академический Документы

Профессиональный Документы

Культура Документы

Compressive Strength Test On Concrete Core

Загружено:

Syed Mohd MehdiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Compressive Strength Test On Concrete Core

Загружено:

Syed Mohd MehdiАвторское право:

Доступные форматы

COMPRESSIVE STRENGTH TEST ON

CONCRETE CORE

Compressive Strength Test on Drilled Concrete Cores is required to determine the

strength ofhardened concrete in structure. Following are the specification for drilled

concrete cores to be suitable for compressive strength test:

Diameter of concrete core:

The diameter of the core specimen for the determination of compressive strength in

load bearing structural members shall be at least 3.70 inch[94 mm]. For concrete with

nominal maximum size of aggregate greater than or equal to 1.5 inch[37.5 mm], the

preferred minimum core diameter shall be ,three times the nominal maximum size of

coarse aggregate but it should be at least two times the nominal maximum size of the

coarse aggregates.

Length of concrete core:

The preferred length of capped specimen is between 1.9 and 2.1 times the diameter.

High lengths can be trimmed and for specimens having low length, correction factor has

to be applied in compressive test.

Moisture conditioning of concrete core:

After cores have been drilled, wipe off the surface drilled water and allow the surface

moisture to evaporate. When surface appears dry, but not greater than 1 hour after

drilling, place cores in separate bags or non absorbent containers and seal to prevent

moisture loss.

Maintain cores at ambient temperatures and protect from exposure to direct sunlight.

Transport the cores as soon as possible to laboratory. Cores can be taken out of the

bags for a maximum tie of 2 hrs to permit

capping before testing. If water is used for grinding or sawing the core ends, complete

these operations as soon as possible, but not later than 2 days after drilling. Minimize

the duration of exposure to water during end preparation.

Allow the cores to remain in the sealed plastic bags or non absorbent containers for at

least 5 days after last being wetted and before testing.

Sawing of the ends of concrete core:

The ends of core specimen shall be flat, and perpendicular to the longitudinal axis.

Sawing should be such that prior to capping the following requirements are met:

a) Projections, if any shall not extend more than 0.2 inch[5mm] above the end surfaces

b) The end surfaces shall not depart from perpendicularity to the longitudinal axis by a

slope of more than 1.8 d or 1:0.3d where d is the average core diameter.

Capping of concrete core:

If the ends of cores do not confirm to the perpendicularity and plainness

requirement, they shall be sawed or ground or capped.

If cores are capped, the capping device shall accommodate actual core diameters

and produce caps that are concentric with the core ends.

The material used for capping shall be such that its compressive strength is greater

than that of the concrete in the core.

Caps shall be made as thin as practicable and shall not flow or fracture before the

concrete fails when specimen is tested.

Capped surface shall be right angles to the axis of the specimen and shall not

detach depart from a plane by more than 0.05 mm.

Measure core lengths to the nearest 0.1 inch [2 mm] before capping.

Measurement of concrete core:

Before testing, measure the length of the capped or ground specimen to the nearest

0.1 inch [2 mm] and compute this to calculate the length diameter [L/D] ratio.

Determine the average diameter by averaging the two measurements taken at

right angles to each other at the mid height of the specimen.

Measure core diameters to the nearest 0.01 inch[.2 mm] when the difference in core

diameters does not exceed 2% of their average, otherwise measure to the nearest

0.1 inch[2mm].

Do not test cores if the difference between smallest and largest diameter of the core

exceeds 5% of their average.

Testing of concrete core:

Test the specimen within 7 days after coring.

Calculation of compressive strength:

Calculate the compressive test of the specimen using the computed cross sectional area

based on average diameter of the specimen. If the L/D ratio is 1.75 or less, correct the

result obtained by multiplying with

correction factors as given below:

L/D Ratio

Correction

Factor

1.75 0.98

1.5 0.96

1.25 0.93

1.0 0.87

The value obtained after multiplying with correction factor is called corrected

compressive strength, this being equivalent strength of a cylinder having L/D ratio of 2.

The equivalent cube strength can be calculated by multiplying the corrected cylinder

strength by 5/4.

Report of compressive strength test:

Report the results with addition of the following information:

a) Length of core drilled to the nearest 5 mm

b) Length of the specimen before and after capping to nearest 2 mm and average

diameter of core to the nearest 0.2 mm or 2 mm.

c) Compressive strength to the nearest 0.1 MPa when diameter is measured to nearest

0.2 mm and to the nearest 0.5 MPa when diameter is measured to the nearest 2mm

after correction for L/D ratio.

d) Direction of application of load with respect the horizontal plane of the concrete as

placed

e) Moisture conditioning history

f) If water was used during end preparation, the date and time end preparation was

completed and core was placed in concealed bags.

g) The date and time when tested

h) Nominal maximum size of the aggregates.

Also Read: Tips for Core Extraction & Testing of Concrete

Вам также может понравиться

- Insulation e BookДокумент48 страницInsulation e BookAl7amdlellah100% (1)

- RCC Is Provision NotesДокумент4 страницыRCC Is Provision NotessameerОценок пока нет

- Mix Design ProcedujersДокумент19 страницMix Design ProcedujersAbinet AlemuОценок пока нет

- Working Capital Management, EleconДокумент56 страницWorking Capital Management, Eleconrrpatel_idol100% (1)

- Compaction TestДокумент9 страницCompaction TestFernando PascualОценок пока нет

- Concrete Mix Design ProportionsДокумент88 страницConcrete Mix Design ProportionsjinshadОценок пока нет

- Concrete Mix Design GuideДокумент15 страницConcrete Mix Design Guidekarthiksamp100% (1)

- Igt - Boot Os List Rev B 10-28-2015Документ5 страницIgt - Boot Os List Rev B 10-28-2015Hector VillarrealОценок пока нет

- Determine Concrete Strength with Digital Compression TesterДокумент57 страницDetermine Concrete Strength with Digital Compression Testerneroshan1978100% (2)

- Concrete Mix DesignДокумент7 страницConcrete Mix Designadil271Оценок пока нет

- Compressive Strength of ConcreteДокумент9 страницCompressive Strength of ConcreteAmos kiprutoОценок пока нет

- Concrete Mix Design (Notes) PDFДокумент11 страницConcrete Mix Design (Notes) PDFMohamad Khaled Nordin100% (1)

- 3.3 Road Note No. 4-1Документ40 страниц3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Self-Compacting Concrete SeminarДокумент16 страницSelf-Compacting Concrete SeminarAnubhab GhoshОценок пока нет

- Testing Concrete CoresДокумент7 страницTesting Concrete CoresvigneshwarimahamuniОценок пока нет

- A Simple Guide To Concrete Cube TestingДокумент4 страницыA Simple Guide To Concrete Cube TestingmsohaibazizОценок пока нет

- Bs Mix Design Doe MethodДокумент22 страницыBs Mix Design Doe Methodsanthu25693% (27)

- Comparison Between Marshall MethodДокумент57 страницComparison Between Marshall MethodAbdullah100% (1)

- Managerial Accounting and Cost ConceptsДокумент67 страницManagerial Accounting and Cost ConceptsTristan AdrianОценок пока нет

- Ultrasonic Pulse VelocityДокумент3 страницыUltrasonic Pulse VelocitySougata DasОценок пока нет

- Cement Chemistry Guide: Types, Properties & ApplicationsДокумент9 страницCement Chemistry Guide: Types, Properties & ApplicationsSyed Mohd MehdiОценок пока нет

- BS 1881 1983 Part 101Документ10 страницBS 1881 1983 Part 101paladin7Оценок пока нет

- Concrete Mix Design GuideДокумент42 страницыConcrete Mix Design GuidesereneОценок пока нет

- Sustainability in Construction & Civil EngineeringДокумент4 страницыSustainability in Construction & Civil EngineeringSyed Mohd MehdiОценок пока нет

- SANS5861-3 - Making and Curing of Test SpecimensДокумент5 страницSANS5861-3 - Making and Curing of Test SpecimensBrendon GovaОценок пока нет

- Group 2 - Quality ControlДокумент94 страницыGroup 2 - Quality ControlZairah Ann Borja100% (1)

- Manage Hospital Records with HMSДокумент16 страницManage Hospital Records with HMSDev SoniОценок пока нет

- Mix DesignДокумент29 страницMix Designshahhassa9Оценок пока нет

- Cast Resin Busduct PDFДокумент48 страницCast Resin Busduct PDFanand2k1100% (1)

- BS 812-109-1990 Testing Aggregates. Methods For Determination of Moisture ContentДокумент13 страницBS 812-109-1990 Testing Aggregates. Methods For Determination of Moisture ContentHaris KyriazisОценок пока нет

- CORE TESTING FOR CONCRETE STRENGTHДокумент13 страницCORE TESTING FOR CONCRETE STRENGTHvempadareddyОценок пока нет

- BS 1881 Part 120 83Документ8 страницBS 1881 Part 120 83tss13723100% (1)

- Bsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsДокумент14 страницBsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsEngr. Jahanzeb MaharОценок пока нет

- Introduction To Management: Planning & Goal SettingДокумент31 страницаIntroduction To Management: Planning & Goal SettingMaisarah NorzihanОценок пока нет

- Windsor Probe and Quantab TestДокумент28 страницWindsor Probe and Quantab Testsabareesan09Оценок пока нет

- Unbound Aggregates in RoadsОт EverandUnbound Aggregates in RoadsR.H. JonesОценок пока нет

- Concrete Without CementДокумент2 страницыConcrete Without CementSyed Mohd MehdiОценок пока нет

- Hardened ConcreteДокумент50 страницHardened ConcreteMayank KapriОценок пока нет

- Xu10j4 PDFДокумент80 страницXu10j4 PDFPaulo Luiz França100% (1)

- Method Statement Concrete Coring (ASTM C 142)Документ2 страницыMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- Testing and Evaluation of Hardened Concrete StrengthsДокумент27 страницTesting and Evaluation of Hardened Concrete StrengthsShepherd NhangaОценок пока нет

- Concrete Flow TestДокумент7 страницConcrete Flow TestDarrenTofuОценок пока нет

- Series 4000 - Bituminous Layers and SealsДокумент52 страницыSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- BS 1881-103Документ13 страницBS 1881-103tipe123456789Оценок пока нет

- ACI Mix-Design Summary SheetДокумент3 страницыACI Mix-Design Summary SheetAbu ZaforОценок пока нет

- Compaction Factor Test&Slump Test ReportДокумент1 страницаCompaction Factor Test&Slump Test ReportMUN SIM SOHОценок пока нет

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Документ6 страницExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- Assessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsДокумент8 страницAssessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsAnonymous ELujOV3Оценок пока нет

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Документ10 страницMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnОценок пока нет

- Determination of The International Roughness Index (IRI) Using ARRB TR Walking ProfilerДокумент9 страницDetermination of The International Roughness Index (IRI) Using ARRB TR Walking Profilerतिप्लोकाची तिरुनचिपल्ली केरकेट्टा100% (1)

- Concrete TechnologyДокумент36 страницConcrete Technologyshalu R FОценок пока нет

- Cover Block Method StaДокумент1 страницаCover Block Method StaRavi kumarОценок пока нет

- 02525Документ3 страницы02525uddinnadeem0% (1)

- Soil testing methods guideДокумент2 страницыSoil testing methods guideDr Wong Kim YuenОценок пока нет

- Ready Mix Concrete PlantДокумент15 страницReady Mix Concrete PlantKartik PandyaОценок пока нет

- Jisg 3112.2010Документ2 страницыJisg 3112.2010Mani MaОценок пока нет

- Fresh ConcreteДокумент28 страницFresh ConcreteAmar WadoodОценок пока нет

- BS 1881 - 109-1983 Testing ConcreteДокумент10 страницBS 1881 - 109-1983 Testing ConcreteAlsonChinОценок пока нет

- BS For Highways TestsДокумент12 страницBS For Highways Testsdbg2012Оценок пока нет

- Plate Bearing Load TestДокумент1 страницаPlate Bearing Load TestTk Kendrick Lau100% (1)

- Measure Concrete Consistency with Slump TestДокумент5 страницMeasure Concrete Consistency with Slump TestLove Rosiee100% (1)

- Testing Concrete: BS 1881: Part 116: 1983Документ8 страницTesting Concrete: BS 1881: Part 116: 1983Muhammad AmmarОценок пока нет

- Is2720 Part09Документ6 страницIs2720 Part09anvesh_kumar_16Оценок пока нет

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985От EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Оценок пока нет

- Experiment # 9: Obtaining and Testing Cores of Concrete Scope and SignificanceДокумент5 страницExperiment # 9: Obtaining and Testing Cores of Concrete Scope and SignificanceSaad MughalОценок пока нет

- 5.4) Job Procedure - Concrete Core CuttingДокумент6 страниц5.4) Job Procedure - Concrete Core CuttingDeepak Kumar MallickОценок пока нет

- CS StrengthДокумент2 страницыCS StrengthCeddie PamintuanОценок пока нет

- CEB 711 - Structural Design II: Semester 2, 2020 2Документ32 страницыCEB 711 - Structural Design II: Semester 2, 2020 2Asnil PrakashОценок пока нет

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersДокумент4 страницыUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersYENCEIОценок пока нет

- Exp 9Документ10 страницExp 9sju65Оценок пока нет

- Final Sustainable Sand Mining Management Guidelines 2016Документ101 страницаFinal Sustainable Sand Mining Management Guidelines 2016Salil86Оценок пока нет

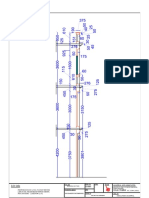

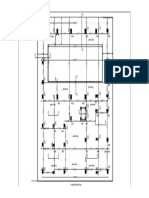

- Furniture Layout Plan - ModelДокумент1 страницаFurniture Layout Plan - ModelSyed Mohd MehdiОценок пока нет

- Lighting Trade Price List w.e.f. 1st November, 2015Документ80 страницLighting Trade Price List w.e.f. 1st November, 2015Syed Mohd MehdiОценок пока нет

- REV01 CEILING ELECTRICAL-Model PDFДокумент1 страницаREV01 CEILING ELECTRICAL-Model PDFSyed Mohd MehdiОценок пока нет

- Extra Item Rate HQДокумент9 страницExtra Item Rate HQSyed Mohd MehdiОценок пока нет

- ACI Journal - Evaluation of Ratio Between Splitting Tensile StrengthДокумент10 страницACI Journal - Evaluation of Ratio Between Splitting Tensile StrengthSyed Mohd MehdiОценок пока нет

- Stone Dust & RubberДокумент64 страницыStone Dust & RubberSyed Mohd Mehdi100% (1)

- Dissertation Phase 1Документ33 страницыDissertation Phase 1Syed Mohd Mehdi100% (1)

- Analysis of RatesДокумент5 страницAnalysis of Ratesakstrmec23Оценок пока нет

- Time Extension Letter. (24.09.2016) DocxДокумент1 страницаTime Extension Letter. (24.09.2016) DocxSyed Mohd MehdiОценок пока нет

- 1) MouldingДокумент1 страница1) MouldingSyed Mohd MehdiОценок пока нет

- A3 JAL NIGAM HEAD Office Last Final 12.08.15-ModelДокумент1 страницаA3 JAL NIGAM HEAD Office Last Final 12.08.15-ModelSyed Mohd MehdiОценок пока нет

- Walls - Types, Features and Design ConceptДокумент2 страницыWalls - Types, Features and Design ConceptSyed Mohd MehdiОценок пока нет

- BUILDING ORIENTATION FOR HOT AND DRY CLIMATESДокумент2 страницыBUILDING ORIENTATION FOR HOT AND DRY CLIMATESSyed Mohd Mehdi75% (4)

- Save Environment With Green BuildingsДокумент2 страницыSave Environment With Green BuildingsSyed Mohd MehdiОценок пока нет

- Green Roofing - A Step Towards SustainabilityДокумент4 страницыGreen Roofing - A Step Towards SustainabilitySyed Mohd MehdiОценок пока нет

- CV PDFДокумент4 страницыCV PDFSyed Mohd MehdiОценок пока нет

- Green Building Site and Landscape PlanningДокумент3 страницыGreen Building Site and Landscape PlanningSyed Mohd MehdiОценок пока нет

- How To Make A Building GreenДокумент5 страницHow To Make A Building GreenSyed Mohd MehdiОценок пока нет

- Performance of Various Types of Buildings During EarthquakeДокумент5 страницPerformance of Various Types of Buildings During EarthquakeSyed Mohd Mehdi100% (1)

- Selection of Green Building MaterialsДокумент3 страницыSelection of Green Building MaterialsSyed Mohd MehdiОценок пока нет

- Concrete Mix DesignДокумент5 страницConcrete Mix Designkom1984Оценок пока нет

- IS16(Part1):1991 Shellac SpecificationДокумент6 страницIS16(Part1):1991 Shellac SpecificationsdmelОценок пока нет

- Concrete Mix Design Comparison Between BIS and ACIДокумент7 страницConcrete Mix Design Comparison Between BIS and ACIPraveen JainОценок пока нет

- Is 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsДокумент10 страницIs 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsPrapa KaranОценок пока нет

- Rules for Rounding Off Numerical Values in Technical DocumentsДокумент18 страницRules for Rounding Off Numerical Values in Technical Documentsসন্দীপ চন্দ্রОценок пока нет

- Determination of Specific Gravity of CementДокумент1 страницаDetermination of Specific Gravity of CementSyed Mohd MehdiОценок пока нет

- Oteco 3Документ12 страницOteco 3VRV.RELATORIO.AVARIA RELATORIO.AVARIAОценок пока нет

- SESSON 1,2 AND 3 use casesДокумент23 страницыSESSON 1,2 AND 3 use casessunilsionОценок пока нет

- JIG LFO Pack 231 PDFДокумент16 страницJIG LFO Pack 231 PDFPratiek RaulОценок пока нет

- Parents Day Script - PDF - Schools - LeisureДокумент17 страницParents Day Script - PDF - Schools - LeisureNAIDU SHAKEENAОценок пока нет

- G.R. No. 226140 - People Vs EspirituДокумент24 страницыG.R. No. 226140 - People Vs EspirituAlfred Robert BabasoroОценок пока нет

- B JA RON GAWATДокумент17 страницB JA RON GAWATRon GawatОценок пока нет

- MATLAB code for Mann–Kendall test and Sen's slope estimationДокумент7 страницMATLAB code for Mann–Kendall test and Sen's slope estimationTubaiNandiОценок пока нет

- G.R. No. 175350 June 13, 2012 Equitable Banking Corporation, Inc. Petitioner, Special Steel Products, and Augusto L. Pardo, RespondentsДокумент8 страницG.R. No. 175350 June 13, 2012 Equitable Banking Corporation, Inc. Petitioner, Special Steel Products, and Augusto L. Pardo, RespondentsHp AmpsОценок пока нет

- Recognition & Derecognition 5Документ27 страницRecognition & Derecognition 5sajedulОценок пока нет

- Lecture 2 Leader-Centred PerspectivesДокумент24 страницыLecture 2 Leader-Centred PerspectivesLIVINGSTONE CAESARОценок пока нет

- Web Based Tour Management for Bamboo ParadiseДокумент11 страницWeb Based Tour Management for Bamboo Paradisemohammed BiratuОценок пока нет

- Letter Advocating For Hazard PayДокумент2 страницыLetter Advocating For Hazard PayQueens PostОценок пока нет

- Direct FileActДокумент17 страницDirect FileActTAPAN TALUKDARОценок пока нет

- Lifetime Physical Fitness and Wellness A Personalized Program 14th Edition Hoeger Test BankДокумент34 страницыLifetime Physical Fitness and Wellness A Personalized Program 14th Edition Hoeger Test Bankbefoolabraida9d6xm100% (27)

- Real-Time Java and ATCДокумент44 страницыReal-Time Java and ATCdnk_victon6248Оценок пока нет

- Solar Winds OrionAPM DatasheetДокумент4 страницыSolar Winds OrionAPM DatasheetArun J D'SouzaОценок пока нет

- PC-II Taftan Master PlanДокумент15 страницPC-II Taftan Master PlanMunir HussainОценок пока нет

- D882 - Pruebas A Películas.Документ11 страницD882 - Pruebas A Películas.CamiloSilvaОценок пока нет

- Pabahay Bonanza: Philippine National Bank As of September 30, 2009Документ80 страницPabahay Bonanza: Philippine National Bank As of September 30, 2009ramonlucas700Оценок пока нет

- 1st WeekДокумент89 страниц1st Weekbicky dasОценок пока нет

- BVM Type B Casing Tong ManualДокумент3 страницыBVM Type B Casing Tong ManualJuan Gabriel GomezОценок пока нет

- Gil Sanchez, Labason Zamboanga Del Norte: AmacaДокумент2 страницыGil Sanchez, Labason Zamboanga Del Norte: AmacaMacky BirdОценок пока нет