Академический Документы

Профессиональный Документы

Культура Документы

RPT Syllabus

Загружено:

Sreejith S NairАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RPT Syllabus

Загружено:

Sreejith S NairАвторское право:

Доступные форматы

11ME911 RAPID PROTOTYPING AND

TOOLING

L T P C M

3 0 0 3 100

AIM:

To impart knowledge on different types of Rapid Prototyping systems and its

applications in various fields

OBJECTIVES:

On successful completion of the course, the students will be able to

Know about liquid based and solid based rapid prototyping systems and applications

Understand data preparation and 3 D printing for RP systems

Explain the different types of rapid tooling processes, and materials used in RP

systems

UNIT I INTRODUCTION 6

Introduction: Need for time compression in product development, Product

development conceptual design development detail design prototype

tooling

UNIT II

LIQUID BASED AND SOLID BASED RAPID PROTOTYPINGSYSTEMS 10

Classification of RP systems, Fusion Deposition Modeling Principle

process parameters Applications. Laminated Object Manufacturing

Principle process parameters Applications, Stereo lithography systems

Principle process parameters process details , Applications.-Selective

laser sintering (SLS) -Direct Metal Laser Sintering (DMLS) system Direct

Metal Deposition- Principle process parameters Applications-Solid ground

curing

UNIT III DATA PREPARATIONFOR RAPID PROTOTYPING

TECHNOLOGIES

10

Basic concept- Digitization techniques Model Reconstruction Data

Processing for Rapid Prototyping: CAD model preparation, Data

Requirements geometric modeling techniques: Wire frame, surface and

solid modeling data formats - Data interfacing, Part orientation and support

generation, Support structure design, Model Slicing and contour data

organization, direct and adaptive slicing, Tool path generation

UNIT IV THREE DIMENSIONAL PRINTING 10

Three dimensional Printing (3DP):Principle, basic process, Physics of 3DP,

types of printing, process capabilities, material system. Solid based, Liquid

based and powder based 3DP systems, strength and weakness,

Applications and case studies. Shape Deposition Manufacturing (SDM):

Introduction, basic process, shape decomposition, mold, SDM and

applications. Selective Laser Melting, Electron Beam Melting Rapid

manufacturing

UNIT V RAPID TOOLING 9

Classification: Soft tooling, Production tooling, Bridge tooling; direct and

indirect Fabrication processes, Applications. Case studies - automotive,

aerospace and electronic industries

L: 45

T:0TOTAL:45

TEXT BOOKS:

1. Rapid prototyping: Principles and applications, second edition, Chua C.K., Leong

K.F., and Lim C.S., World Scientific Publishers, 2010

2. Pham,D.T. &Dimov.S.S., Rapid manufacturing, Springer-Verlag, 2001. Terry

wohlers, Wohlers Report 2000, Wohlers Associates, 2000.

REFERENCES:

1. Rapid prototyping, Andreas Gebhardt, Hanser Gardener Publications, 2003

2. Rapid Prototyping and Engineering applications: A tool box for prototype

development, LiouW.Liou, Frank W.Liou, CRC Press, 2007.

3. Paul F Jacobs, Rapid Prototyping and manufacturing Fundamentals

ofStreolithography, Society of Manufacturing Engineering Dearborn, 1992.

4. Rapid Prototyping and Tooling, Industrial Design Centre, IIT, 1983 Rapid

Prototyping: Theory and practice, Ali K. Kamrani, EmadAbouel Nasr, Springer, 2006.

5. Rapid Tooling: Technologies and Industrial Applications, Peter D.Hilton,

Hilton/Jacobs, Paul F.Jacobs, CRC press, 2000.

6. User Guide to Rapid Prototyping,Todd Grimm ,Todd Grimm and Associates

Inc,2004.

Вам также может понравиться

- Rapid Prototyping and ToolingДокумент1 страницаRapid Prototyping and Toolingroscilla100% (1)

- Logic Design SyllabusДокумент2 страницыLogic Design Syllabusnaciye karademirОценок пока нет

- Network Security Revised-EricДокумент3 страницыNetwork Security Revised-EricJojo CansinoОценок пока нет

- Computer Network Syllabus GateДокумент4 страницыComputer Network Syllabus GatebrightstudentОценок пока нет

- 15 Network ManagementДокумент46 страниц15 Network ManagementCatur IswahyudiОценок пока нет

- Internet of Things Course SyllabusДокумент3 страницыInternet of Things Course SyllabusTanimunОценок пока нет

- Computer Network - CS610 Power Point Slides Lecture 01Документ19 страницComputer Network - CS610 Power Point Slides Lecture 01Ibrahim ChoudaryОценок пока нет

- Assignment ResumeДокумент7 страницAssignment ResumeHumayun KhalidОценок пока нет

- CC2063 Grid Computing Course PlanДокумент3 страницыCC2063 Grid Computing Course PlanVanitha JanakiramanОценок пока нет

- Unit 3: Preparing For An Engineering Career: Engr. Roman M. Richard, MengДокумент9 страницUnit 3: Preparing For An Engineering Career: Engr. Roman M. Richard, MengRoman MarcosОценок пока нет

- COEN 3134 - Logic Circuits and Switching Theory Syllabus - CANSINOДокумент4 страницыCOEN 3134 - Logic Circuits and Switching Theory Syllabus - CANSINOjocansino4496Оценок пока нет

- (BSIT) New Curriculum 18-19 No Highlight With Gen Ed UpdateДокумент4 страницы(BSIT) New Curriculum 18-19 No Highlight With Gen Ed UpdateEvsu-Occ Tigers100% (1)

- Facial Recognition Using LabVIEWДокумент2 страницыFacial Recognition Using LabVIEWAnjali Naidu33% (3)

- Living in Network in Centric WorldДокумент43 страницыLiving in Network in Centric WorldNazrulazhar BahamanОценок пока нет

- DaggykiddДокумент19 страницDaggykiddDaggy KiddОценок пока нет

- Computer NetworkingДокумент37 страницComputer NetworkingDisha GoyalОценок пока нет

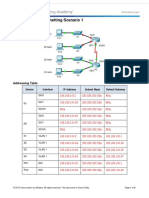

- 8.1.4.7 Packet Tracer - Subnetting Scenario 1Документ4 страницы8.1.4.7 Packet Tracer - Subnetting Scenario 1Rubén Darío Saa MontañoОценок пока нет

- Unit1introduction 150307091201 Conversion Gate01 PDFДокумент101 страницаUnit1introduction 150307091201 Conversion Gate01 PDFVipul KaushikОценок пока нет

- Identifying Network Devices and CablingДокумент6 страницIdentifying Network Devices and CablingImron RosyadiОценок пока нет

- Pjsmith IP Addressing & Subnetting Made EasyДокумент93 страницыPjsmith IP Addressing & Subnetting Made EasyNaveen Narasimha MurthyОценок пока нет

- Seminar Report TemplateДокумент31 страницаSeminar Report TemplateSubin M MadhuОценок пока нет

- 01 Intelligent Systems-IntroductionДокумент82 страницы01 Intelligent Systems-Introduction1balamanianОценок пока нет

- 1-Classical EncryptionДокумент54 страницы1-Classical EncryptionMuhammad ShakeelОценок пока нет

- Presentation About Computer NetworkingДокумент55 страницPresentation About Computer NetworkingAbhishek AnandОценок пока нет

- MODULE 3 Embedded System ComponennewtsДокумент209 страницMODULE 3 Embedded System ComponennewtsRuthvik ThumuluriОценок пока нет

- Network Fundamentals: by A. AwadhiДокумент26 страницNetwork Fundamentals: by A. Awadhigurudasi007Оценок пока нет

- Intel Edge AI Open VINOДокумент14 страницIntel Edge AI Open VINOShaukat Hussain100% (1)

- POP Using C Module 1 NotesДокумент55 страницPOP Using C Module 1 Notesnidhidgowda185Оценок пока нет

- CompressedДокумент282 страницыCompressedBayan Al-dosriОценок пока нет

- Operating SystemДокумент31 страницаOperating Systemshalini singhОценок пока нет

- Computer Security GoalsДокумент72 страницыComputer Security GoalsAnkur Agrawal100% (2)

- Jansons Institute of Technology: Model ExamДокумент4 страницыJansons Institute of Technology: Model ExamBhuvaneshwar AОценок пока нет

- CAMSHIFT Tracking Algorithm: CSE/EE 486: Computer Vision I Computer Project Report #: Project 5Документ7 страницCAMSHIFT Tracking Algorithm: CSE/EE 486: Computer Vision I Computer Project Report #: Project 5Engr EbiОценок пока нет

- Security System For DNS Using CryptographyДокумент7 страницSecurity System For DNS Using CryptographyAbhinavSinghОценок пока нет

- IT Infrastructure and Network Technologies Part 4Документ17 страницIT Infrastructure and Network Technologies Part 4Junice IlaganОценок пока нет

- Troubleshooting of ComputerДокумент11 страницTroubleshooting of ComputerAlpesh ThesiyaОценок пока нет

- Ict Notes 4,5,6 Pre UpdateДокумент19 страницIct Notes 4,5,6 Pre UpdateAtif Mehmood100% (1)

- Fundamentals of Data Science: Nehru Institute of Engineering and TechnologyДокумент17 страницFundamentals of Data Science: Nehru Institute of Engineering and Technologysakthisubi100% (1)

- Lab Report Computer NetworkДокумент3 страницыLab Report Computer NetworkSAMUDDINОценок пока нет

- Chapter 2 - Processes in Conducting ResearchДокумент38 страницChapter 2 - Processes in Conducting ResearchBulbula KumedaОценок пока нет

- Week1-Introduction To ICTДокумент49 страницWeek1-Introduction To ICTMAAZ CHOUDHRYОценок пока нет

- Oops ConceptsДокумент8 страницOops ConceptsManoj ManoharanОценок пока нет

- Analisis Dan Desain Sistem - Bab 5Документ43 страницыAnalisis Dan Desain Sistem - Bab 5Nur Dzatu Ummu KhollilaОценок пока нет

- Computer ScienceДокумент10 страницComputer ScienceLudwigVonBeethovenОценок пока нет

- Cyber Security Module-1 NotesДокумент33 страницыCyber Security Module-1 Notesdr.reshmabanuvvietОценок пока нет

- Information Technology FundamentalsДокумент2 страницыInformation Technology FundamentalsLemuel Campiseño100% (1)

- Foundations of Information Systems in BusinessДокумент56 страницFoundations of Information Systems in BusinessYasir HasnainОценок пока нет

- Computer Science and Engineering - 2019 Scheme s4 Syllabus - Ktustudents - inДокумент153 страницыComputer Science and Engineering - 2019 Scheme s4 Syllabus - Ktustudents - inAswin AyyappadasОценок пока нет

- Data Communication & NetworkДокумент12 страницData Communication & Networkmkhalil94100% (1)

- Seminar PPT AutomationДокумент27 страницSeminar PPT Automationamitesh_iitkgp83Оценок пока нет

- Technical Seminar Report On Wireless Application ProtocolДокумент25 страницTechnical Seminar Report On Wireless Application ProtocolPankaj Dubey100% (4)

- Iot Workshop Concept ProposalДокумент14 страницIot Workshop Concept ProposalNguyễn HàОценок пока нет

- Week 2 Period 1 Lesson NoteДокумент6 страницWeek 2 Period 1 Lesson Notek3lvynОценок пока нет

- 10 Truths of Network TroubleshootingДокумент4 страницы10 Truths of Network TroubleshootingDaniel ChecchiaОценок пока нет

- Ethics in A Computing Culture: Computing and Vulnerable GroupsДокумент15 страницEthics in A Computing Culture: Computing and Vulnerable GroupsJoseph CailaoОценок пока нет

- Program Outcome and Course OutcomeДокумент300 страницProgram Outcome and Course Outcome1234nilesh1234Оценок пока нет

- Dr. Mahalingam College of Engineering and Technology, Pollachi - 642003Документ2 страницыDr. Mahalingam College of Engineering and Technology, Pollachi - 642003Sreejith S NairОценок пока нет

- Industrial AccidentsДокумент22 страницыIndustrial AccidentsSreejith S NairОценок пока нет

- GMAW Welding Optimization Using Genetic AlgorithmsДокумент7 страницGMAW Welding Optimization Using Genetic AlgorithmsSreejith S NairОценок пока нет

- Ijstev1i12005 PDFДокумент2 страницыIjstev1i12005 PDFSreejith S NairОценок пока нет

- Bench GrinderДокумент1 страницаBench GrinderSreejith S NairОценок пока нет

- AnsCrossword Puzzle Maker - Final PuzzleДокумент1 страницаAnsCrossword Puzzle Maker - Final PuzzleSreejith S NairОценок пока нет

- The Explosives Act, 1884 - Arrangement of SectionsДокумент12 страницThe Explosives Act, 1884 - Arrangement of SectionsSreejith S NairОценок пока нет

- Tools For Going Online: Windows Operating System (Installation Instructions)Документ10 страницTools For Going Online: Windows Operating System (Installation Instructions)Sreejith S NairОценок пока нет

- CO2: Explain The Measurement and Monitoring TechniquesДокумент41 страницаCO2: Explain The Measurement and Monitoring TechniquesSreejith S NairОценок пока нет

- A Toxicological Review of The Products of Combustion: J C WakefieldДокумент44 страницыA Toxicological Review of The Products of Combustion: J C WakefieldSreejith S NairОценок пока нет

- Course Content Organization and Sharing Via Google Drive: Kameswari Chebrolu Department of CSE, IIT BombayДокумент5 страницCourse Content Organization and Sharing Via Google Drive: Kameswari Chebrolu Department of CSE, IIT BombaySreejith S NairОценок пока нет

- 10principles 160307131348Документ11 страниц10principles 160307131348Sreejith S NairОценок пока нет

- 10/22/2013 at Kamlesh JainДокумент22 страницы10/22/2013 at Kamlesh JainSreejith S NairОценок пока нет

- Internet of Things (12 Weeks) On The SWAYAM Platform (Swayam - Gov.in)Документ1 страницаInternet of Things (12 Weeks) On The SWAYAM Platform (Swayam - Gov.in)Sreejith S NairОценок пока нет

- Classification of Composite MaterialsДокумент4 страницыClassification of Composite MaterialsSreejith S NairОценок пока нет

- Clamping Mechanisms: Report Submitted By: Report Submitted ToДокумент21 страницаClamping Mechanisms: Report Submitted By: Report Submitted ToSreejith S NairОценок пока нет

- Classification of Composite MaterialsДокумент4 страницыClassification of Composite MaterialsSreejith S Nair100% (1)

- Automotive Infotainment SystemДокумент20 страницAutomotive Infotainment SystemSreejith S NairОценок пока нет

- Corrosion Behavior of SMA490BW Steel and Welded JoДокумент12 страницCorrosion Behavior of SMA490BW Steel and Welded JoSreejith S NairОценок пока нет

- Nylon Is A Generic Designation For A Family ofДокумент2 страницыNylon Is A Generic Designation For A Family ofSreejith S NairОценок пока нет

- Results in Physics: SciencedirectДокумент10 страницResults in Physics: SciencedirectSreejith S NairОценок пока нет

- Carbon Fiber ApplicationsДокумент2 страницыCarbon Fiber ApplicationsSreejith S NairОценок пока нет

- Design of Joining ProcessДокумент30 страницDesign of Joining ProcessSreejith S NairОценок пока нет

- Experimental Design of Cu Content in Weathering ReДокумент20 страницExperimental Design of Cu Content in Weathering ReSreejith S NairОценок пока нет

- 21st CENTURY TECHNOLOGIES - PROMISES AND PERILS OF A DYNAMIC FUTUREДокумент170 страниц21st CENTURY TECHNOLOGIES - PROMISES AND PERILS OF A DYNAMIC FUTUREpragya89Оценок пока нет

- ARC-232, Material Construction 2Документ4 страницыARC-232, Material Construction 2danishali1090Оценок пока нет

- Pricing of A Revolutionary ProductДокумент22 страницыPricing of A Revolutionary ProductiluvparixitОценок пока нет

- Process Strategy: Powerpoint Slides by Jeff HeylДокумент13 страницProcess Strategy: Powerpoint Slides by Jeff HeylMuizzОценок пока нет

- 0 BA Design ENДокумент12 страниц0 BA Design ENFilho AiltonОценок пока нет

- How To Present A Paper at An Academic Conference: Steve WallaceДокумент122 страницыHow To Present A Paper at An Academic Conference: Steve WallaceJessicaAF2009gmtОценок пока нет

- Acampamento 2010Документ47 страницAcampamento 2010Salete MendezОценок пока нет

- Internship ReportДокумент36 страницInternship ReportM.IMRAN0% (1)

- Power System Planning and OperationДокумент2 страницыPower System Planning and OperationDrGopikrishna Pasam100% (4)

- Frequency Response For Control System Analysis - GATE Study Material in PDFДокумент7 страницFrequency Response For Control System Analysis - GATE Study Material in PDFNarendra AgrawalОценок пока нет

- Microeconomics Term 1 SlidesДокумент494 страницыMicroeconomics Term 1 SlidesSidra BhattiОценок пока нет

- Technical Data Sheet TR24-3-T USДокумент2 страницыTechnical Data Sheet TR24-3-T USDiogo CОценок пока нет

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideДокумент17 страницParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraОценок пока нет

- AstmДокумент5 страницAstmyanurarzaqaОценок пока нет

- Report On Marketing Strategy of Nestle MILKPAKДокумент13 страницReport On Marketing Strategy of Nestle MILKPAKAzeem Ahmad100% (1)

- Elastomeric Impression MaterialsДокумент6 страницElastomeric Impression MaterialsMarlene CasayuranОценок пока нет

- List of The Legend of Korra Episodes - Wikipedia PDFДокумент27 страницList of The Legend of Korra Episodes - Wikipedia PDFEmmanuel NocheОценок пока нет

- Business Statistic Handout Bba - Sem 2Документ7 страницBusiness Statistic Handout Bba - Sem 2hanirveshОценок пока нет

- Department of Education: Income Generating ProjectДокумент5 страницDepartment of Education: Income Generating ProjectMary Ann CorpuzОценок пока нет

- Buss40004 - Balance of PowerДокумент3 страницыBuss40004 - Balance of PowerVishwa NirmalaОценок пока нет

- Cad Data Exchange StandardsДокумент16 страницCad Data Exchange StandardskannanvikneshОценок пока нет

- Centrifuge ThickeningДокумент8 страницCentrifuge ThickeningenviroashОценок пока нет

- Jayesh PresentationДокумент22 страницыJayesh PresentationanakinpowersОценок пока нет

- Final Prmy Gr4 Math Ph1 HWSHДокумент55 страницFinal Prmy Gr4 Math Ph1 HWSHKarthik KumarОценок пока нет

- Adime 2Документ10 страницAdime 2api-307103979Оценок пока нет

- Protection in Distributed GenerationДокумент24 страницыProtection in Distributed Generationbal krishna dubeyОценок пока нет

- The BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptДокумент19 страницThe BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptCrown Publishing GroupОценок пока нет

- NGCP EstimatesДокумент19 страницNGCP EstimatesAggasid ArnelОценок пока нет

- Dissertation 7 HeraldДокумент3 страницыDissertation 7 HeraldNaison Shingirai PfavayiОценок пока нет