Академический Документы

Профессиональный Документы

Культура Документы

Yamaha TRX Tdm850 Manual

Загружено:

Gherghel Marius0 оценок0% нашли этот документ полезным (0 голосов)

294 просмотров528 страницYamaha Trx Tdm850 maintenance Manual that it's easy to use for all motorcycle fans that want to repair the small problems themselves and not to contact a mechanic. tips and tricks for all tdm and trx models owners.

Оригинальное название

Yamaha Trx Tdm850 Manual

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документYamaha Trx Tdm850 maintenance Manual that it's easy to use for all motorcycle fans that want to repair the small problems themselves and not to contact a mechanic. tips and tricks for all tdm and trx models owners.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

294 просмотров528 страницYamaha TRX Tdm850 Manual

Загружено:

Gherghel MariusYamaha Trx Tdm850 maintenance Manual that it's easy to use for all motorcycle fans that want to repair the small problems themselves and not to contact a mechanic. tips and tricks for all tdm and trx models owners.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 528

o.8 Safety first!

Professional mechanics are trained in safe

working procedures. However enthusiastic you

may be about getting on with the job at hand,

take the time to ensure that your safety is not put

at risk. A moment's lack of attention can result in

an accident, as can failure to observe simple

precautions.

There will always be new ways of having

accidents, and the following is not a

comprehensive list of all dangers it is intended

rather to make you aware of the risks and to

encourage a safe approach to all work you carry

out on your bike.

Asbestos

! "ertain friction, insulating, sealing and

other products # such as brake pads, clutch

linings, gaskets, etc. # contain asbestos.

$%treme care must be taken to avoid

inhalation of dust from such products since it

is ha&ardous to health. 'f in doubt, assume

that they do contain asbestos.

Fire

! (emember at all times that petrol is highly

flammable. )ever smoke or have any kind of

naked flame around, when working on the

vehicle. *ut the risk does not end there # a

spark caused by an electrical short#circuit, by

two metal surfaces contacting each other, by

careless use of tools, or even by static

electricity built up in your body under certain

conditions, can ignite petrol vapour, which in

a confined space is highly e%plosive. )ever

use petrol as a cleaning solvent. +se an

approved safety solvent.

! Always disconnect the battery earth terminal

before working on any part of the fuel or electrical

system, and never risk spilling fuel on to a hot

engine or e%haust.

! 't is recommended that a fire e%tinguisher of

a type suitable for fuel and electrical fires is kept

handy in the garage or workplace at all times.

)ever try to e%tinguish a fuel or electrical fire with

water.

Fumes

! "ertain fumes are highly to%ic and can

,uickly cause unconsciousness and even death if

inhaled to any e%tent. Petrol vapour comes into

this category, as do the vapours from certain

solvents such as trichloro#ethylene. Any draining

or pouring of such volatile fluids should be done

in a well ventilated area.

! -hen using cleaning fluids and solvents,

read the instructions carefully. )ever use

materials from unmarked containers # they may

give off poisonous vapours.

! )ever run the engine of a motor vehicle in an

enclosed space such as a garage. $%haust

fumes contain carbon mono%ide which is

e%tremely poisonous if you need to run the

engine, always do so in the open air or at least

have the rear of the vehicle outside the

workplace.

The battery

! )ever cause a spark, or allow a naked

light near the vehicle's battery. 't will normally

be giving off a certain amount of hydrogen

gas, which is highly e%plosive.

! Always disconnect the battery ground .earth/

terminal before working on the fuel or electrical

systems .e%cept where noted/.

! 'f possible, loosen the filler plugs or cover

when charging the battery from an e%ternal

source. 0o not charge at an e%cessive rate or the

battery may burst.

! Take care when topping up, cleaning or

carrying the battery. The acid electrolyte,

evenwhen diluted, is very corrosive and should

not be allowed to contact the eyes or skin. Always

wear rubber gloves and goggles or a face shield.

'f you ever need to prepare electrolyte yourself,

always add the acid slowly to the water never

add the water to the acid.

Electricity

! -hen using an electric power tool, inspection

light etc., always ensure that the appliance is

correctly connected to its plug and that, where

necessary, it is properly grounded .earthed/. 0o

not use such appliances in damp conditions and,

again, beware of creating a spark or applying

e%cessive heat in the vicinity of fuel or fuel

vapour. Also ensure that the appliances meet

national safety standards.

! A severe electric shock can result from

touching certain parts of the electrical system,

such as the spark plug wires .HT leads/, when

the engine is running or being cranked,

particularly if components are damp or the

insulation is defective. -here an electronic

ignition system is used, the secondary .HT/

voltage is much higher and could prove fatal.

Remember...

.X Don't start the engine without first ascer#

taining that the transmission is in neutral. X

Don't suddenly remove the pressure cap from

a hot cooling system # cover it with a cloth and

release the pressure gradually first, or you may

get scalded by escaping coolant. X Don't

attempt to drain oil until you are sure it has

cooled sufficiently to avoid scalding you.

X Don't grasp any part of the engine or

e%haust system without first ascertaining that it

is cool enough not to burn you. X Don't allow

brake fluid or antifree&e to contact the

machine's paintwork or plastic components.

X Don't siphon to%ic li,uids such as fuel,

hydraulic fluid or antifree&e by mouth, or allow

them to remain on your skin. X Dont inhale

dust # it may be injurious to health .see

Asbestos heading/. X Dont allow any spilled oil

or grease to remain on the floor # wipe it up

right away, before someone slips on it. X Don't

use ill#fitting spanners or other tools which may

slip and cause injury. X Dont lift a heavy

component which may be beyond your

capability # get assistance.

X Don't rush to finish a job or take

unverified short cuts.

X Don't allow children or animals in or

around an unattended vehicle.

X Don't inflate a tyre above the

recommended pressure. Apart from

overstressing the carcass, in e%treme cases

the tyre may blow off forcibly.

! Do ensure that the machine is supported

securely at all times. This is especially

important when the machine is blocked up

to aid wheel or fork removal.

</ Do take care when attempting to loosen a

stubborn nut or bolt. 't is generally better to pull

on a spanner, rather than push, so that if you

slip, you fall away from the machine rather

than onto it.

! Do wear eye protection when using power

tools such as drill, sander, bench grinder etc.

! Do use a barrier cream on your hands prior

to undertaking dirty jobs # it will protect your

skin from infection as well as making the dirt

easier to remove afterwards but make sure

your hands aren't left slippery. )ote that long#

term contact with used engine oil can be a

health ha&ard.

! Do keep loose clothing .cuffs, ties etc. and

long hair/ well out of the way of moving

mechanical parts.

! Do remove rings, wristwatch etc., before

working on the vehicle # especially the

electrical system.

! Do keep your work area tidy # it is only too

easy to fall over articles left lying around.

! Do e%ercise caution when compressing

springs for removal or installation. $nsure that

the tension is applied and released in a

controlled manner, using suitable tools which

preclude the possibility of the spring escaping

violently.

! Do ensure that any lifting tackle used has a

safe working load rating ade,uate for the job.

! Do get someone to check periodically that

all is well, when working alone on the vehicle.

! Do carry out work in a logical se,uence and

check that everything is correctly assembled

and tightened afterwards.

! Do remember that your vehicle's safety

affects that of yourself and others. 'f in doubt

on any point, get professional advice. ! 'f in

spite of following these precautions, you are

unfortunate enough to injure yourself, seek

medical attention as soon as possible.

1caned by 1talker

+)($2'1T$($0 3'

'dentification numbers 09

4rame and engine numbers

The frame serial number is stamped into the

right side of the steering head. The engine

number is stamped into the top of the crankcase

on the right#hand side of the engine. *oth of

these numbers should be recorded and kept in a

safe place so they can be furnished to law

enforcement officials in the event of a theft. There

is also a carburettor identification number on the

intake side of each carburettor body, and a colour

code label on the top of the rear fender under the

passenger seat. The colour code label may also

contain the bike's production year and model

code.

The frame serial number, engine serial number,

carburettor identification number and colour code

should also be kept in a handy place .such as

with your driver's licence/ so they are always

available when purchasing or ordering parts for

your machine.

The procedures in this manual identify the

bikes by model type .eg T05/ and if necessary

by production year. )ote that the production year

does not necessarily correspond with the year of

sale or registration.

The model code number is very useful when

ordering parts for your bike and is linked to the

production year as shown in the accompanying

table. There should be a sticker on the bike's rear

frame section .usually visible once the seat is

lifted/ which gives the model code number .eg

6T76, meaning a 8999 T05/, the :amaha

production code number, and a letter indicating

the colour code. The frame and engine numbers

can also be used to establish the production year

and model code, although these are not available

for post#899; models. The accompanying table

gives model identification data for models

available in the +< market.

*uying spare parts

=nce you have found all the identification

numbers, record them for reference when buying

parts. 1ince the manufacturers change

specifications, parts and vendors .companies that

manufacture various components on the

machine/, providing the '0 numbers is the only

way to be reasonably sure that you are buying

the correct parts.

-henever possible, take the worn part to the

dealer so direct comparison with the new

component can be made. Along the trail from the

manufacturer to the parts shelf, there are

numerous places that the part can end up with

the wrong number or be listed incorrectly.

The two places to purchase new parts for your

motorcycle # the accessory store and the

franchised dealer # differ in the type of parts they

carry. -hile dealers can obtain virtually every

part for your motorcycle, the accessory dealer is

usually limited to normal high wear items such as

shock absorbers, tune#up parts, various engine

gaskets, cables, chains,

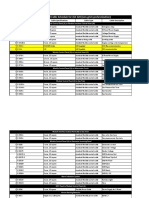

o!el ty"e #ro!$r o!el co!e Frame %o. En&ine %o.

T05>;? 8998 @308 ???8?8 on ???8?8 on

899A @306 ?AA8?8 on ?AA8?8 on

899@ @30; ?6?8?8 on ?6?8?8 on

8996 @30B ?C?8?8 on ?C?8?8 on

899; @309 ?B98?8 on ?B98?8 on

899C 6T78 not available

899B 6T7A not available

899> 6T7@ not available

8999 6T76 not available

T(7>;? 899C 6+)8 ???8?8 on ???8?8 on

899B 6+)@ not available

899>D9 6+)6 not available

7TEB;? 89>9 @F08 ???8?8 on ???8?8 on

899? @+0@ ?@A8?8 on ?@A8?8 on

8998 @F06 ?6>8?8 on ?6>8?8 on

899A @F0; ?C@8?8 on ?C@8?8 on

899@ @F0C ?B98?8 on ?B98?8 on

8996 @F0B ?9A8?8 on ?9A8?8 on

899; @F0> 8??8?8 on 8??8?8 on

your worn part to the breaker's yard for direct

comparison.

-hether buying new, used or rebuilt parts, the

best course is to deal directly with someone who

specialises in parts for your particular make.

Starte! by Stal'er

+)($2'1T$($0 3$(1'=) =4 P'"T+($#0$1<

The frame number is stam"e! on the ri&ht(

han! si!e of the steerin& hea!

The en&ine number is stam"e! into the to"

of the cran'case on the ri&ht(han! si!e of

the en&ine.

brake parts, etc. (arely will an accessory outlet have

major suspension components, cylinders,

transmission gears, or cases.

+sed parts can be obtained for roughly half the

price of new ones, but you can't always be sure of

what you're getting. =nce again, take

o.io 0aily .pre#ride/ checks

%ote) The daily (pre-ride) checks outlined in the owner's manual covers those items which should be inspected on a daily basis.

* En&ine+transmission oil le,el chec'

-e,el chec' "roce!ure

! Position the bike upright .not on its sidestand/

on a level surface.

! =n 8998 to 899; T05 models, remove the

seat .see "hapter >/. =n 7TE models, remove

the right#hand side cover .see "hapter >/.

! "heck the oil level as shown in the appropriate

photo se,uence and top up if necessary.

! )ow start the engine and warm it up to normal

operating temperature.

Caution: Do not run the engine in an

enclosed space such as a garage or

workshop.

! -ith the bike still in an upright position, let it

idle for a further 8? seconds then stop the

engine.

! Taking care to avoid scalding your hands,

recheck the oil level and top up if necessary.

The correct oil

! 5odern, high#rewing engines place great demands on their oil. 't is very important that the correct

oil for your bike is used.

! Always top up with a good ,uality oil of the specified type and viscosity and do not overfill the oil

tank.

Caution: Yamaha advise against using chemical oil additives, or oils with a grade of SH/CD

or higher, or oils labelled !"#Y C$!S"%&!# &&. Such additives or oils could cause

clutch slip.

.il ty"e AP' grade 1$, 14 or 12

.il ,iscosity 1A$8?-@?or8?-6?

/i'e care)

! 'f you have to add oil fre,uently, you should check whether you have any oil leaks. 'f there is no sign

of oil leakage from the joints and gaskets the engine could be burning oil .see Fault Finding).

TD800 1*99* to *9902 an! XT3400 mo!els

'=n T05 models, remove the seat .see "hapter >/ to access the oil filler cap .arrowed/.

=n 7TE models, remove the right#hand side cover .see "hapter >/ to access the oil filler cap .arrowed/.

nscrew the oil filler cap from the oil

tank. The dipstick is integral with the oil

filler cap, and is used to check the engine

oil level. "heck the condition of the cap =#ring

and renew it if damaged or deteriorated.

6 +sing a clean rag or paper towel, wipe all oil from the dipstick. 'nsert the clean dipstick back into the tank, but do not screw it in.

@+n tar

(emove the dipstick and observe the level of the oil, which should be somewhere in between the 4 .full/ and $ .empty/ level lines .arrowed/.

'f the level is below the $ line, top the oil tank up with the recommended grade and type of oil, to bring the level up to the 4 line on the dipstick. 0o not overfill.

Scane! by Stal'er

0aily .pre#ride/ checks o. **

TD800 1*995(on2 an! TRX mo!els

-ipe the oil level window .arrowed/ in the oil tank so that it is clean.

>

-ith the motorcycle held vertical, the oil level should lie between the upper and lower level lines marked on the oil tank .arrowed/.

r 'f the level is below the lower line, remove the filler cap .arrowed/

from the top of the oil tank.

10

Top the tank up with the recommended grade and type of oil,

to bring the level up to the upper line on the window.

Scane! by Stal'er

+)($2'1T$($03'

+)($2'1T$($03'

0.*6 Daily 1"re(ri!e2 chec's

6 /ra'e flui! le,el chec's

A

'arning: (rake h)draulic fluid can harm )our e)es and damage painted surfaces, so use e*treme caution when handling and

pouring it and cover surrounding surfaces with rag. Do not use fluid that has been standing open for some time, as it absorbs

moisture from the air which can cause a dangerous loss of braking effectiveness.

*efore you startG

! 1upport the motorcycle in an upright position,

using an au%iliary stand if re,uired.

! -hen checking the front brake fluid level turn

the handlebars until the top of the master cylinder

is as level as possible.

! =n 7TE models remove the right#hand side

cover to view the rear brake fluid level .see

"hapter >/.

! 5ake sure you have the correct hydraulic fluid.

0=T 6 is recommended.

! -rap a rag around the reservoir being worked

on to ensure that any spillage does not come into

contact with painted surfaces.

*ike careG

! The fluid in the front and rear brake master

cylinder reservoirs will drop slightly as the brake

pads wear down.

! 'f any fluid reservoir re,uires repeated topping#

up this is an indication of an hydraulic leak

somewhere in the system, which should be

investigated immediately.

! "heck for signs of fluid leakage from the

hydraulic hoses and components # if found,

rectify immediately.

! "heck the operation of both brakes before

taking the machine on the road if there is

evidence of air in the system .spongy feel to

lever or pedal/, it must be bled as described

in "hapter B.

Front bra'e flui! le,el

=n T(7 models, the front brake fluid level is

visible through the reservoir body # it must

be between the +PP$( and F=-$( level

lines .arrowed/.

=n T(7 models, if the level is below the

F=-$( level line, remove the reservoir cap

clamp screw .arrowed/, then

unscrew the cap and remove the diaphragm

plate and the diaphragm.

=n T05 and 7TE models, the front brake fluid

level is visible through the window in the

reservoir body # it must be above the F=-$(

level line .arrowed/.

=n T05 and 7TE models, if the level is

below the F=-$( level line, remove the

two reservoir cover screws and remove the

cover and the diaphragm.

; Top up with new clean hydraulic fluid of the recommended type, until the

level is above the F=-$( level line. Take care to avoid spills

.see 7arnin& above/.

Starte! by Stal'er

+)($2'1T$($03$(1'=) =4 P'"T+($#0$1<

$nsure that the diaphragm is correctly seated before installing the

plate .T(7 models/ and cover or cap.

0aily .pre#ride/ checks 013

Rear bra'e flui! le,el

=n T05 models, the rear brake fluid level is visible by looking up under the seat from the left#hand side of the rear wheel # it must be above F=-$( level

line .arrowed/.

B

> =n T(7 models, the rear brake fluid level is visible through the reservoir body # it must be above F=-$( level line .arrowed/.

=n 7TE models, remove the right#hand side cover .see "hapter >/ # the rear brake fluid level is visible through the reservoir body # it must be above F=-$(

level line .arrowed/.

9

! 'f topping up is re,uired, on T05 models remove the seat and " on T(7 models remove the side covers .see "hapter >/. =n T(7 and 7TE models, remove

the cap clamp, then on T(7 models support the reservoir or refit the screw. +nscrew the reservoir cap .arrowed/ and remove the plate and diaphragm. #

6 Top up with new clean hydraulic fluid of the recommended #6 = ' type, until the level is above the lower mark. Take care to avoid ' H spills .see

7arnin& above/.

8

$nsure that the diaphragm is correctly seated before installing the plate and cap. Tighten the cap securely. =n T(7 and 7TE models, fit the cap clamp.

tone! by Stal'er

0*14

0aily .pre#ride/

checks

8 9oolant le,el chec'

'arning: D$ !$+ remove the radiator

pressure cap to add coolant. +opping

up is done via the coolant reservoir tank

filler. D$ !$+ leave open containers of

coolant about, as it is poisonous.

$

*efore you startG

: 5ake sure you have a supply of coolant

available # a mi%ture of ;?I distilled water and

;?I corrosion inhibited ethylene glycol anti#

free&e is needed. %ote) %amaha speci!y that so!t

tap water can be used& but '(T hard

water. )! in doubt& boil the water !irst or use only

distilled water.

! Always check the coolant level when the

engine is cold.

! 1upport the motorcycle in an upright position,

using an au%iliary stand if re,uired, whilst

checking the level. 5ake sure the motorcycle is

on level ground.

*ike careG

! +se only the specified coolant mi%ture. 't is

important that anti#free&e is used in the system

all year round, and not just in the

winter. 0o not top the system up using only

water, as the system will become too diluted.

! 0o not overfill the reservoir tank. 'f the coolant

is significantly above the +PP$( level line at any

time, the surplus should be siphoned or drained

off to prevent the possibility of it being e%pelled

out of the breather hose.

! 'f the coolant level falls steadily, check the

system for leaks .see "hapter 8/. 'f no leaks are

found and the level continues to fall, it is

recommended that the machine is taken to a

:amaha dealer for a pressure test.

=n T05 models, the coolant reservoir 4+FF and F=- level lines are visible by looking up under the seat from the left#hand side of the rear wheel. The

coolant level lines .arrowed/ are marked on the reservoir.

'

=n T(7 models, remove the seat .see "hapter >/. The coolant 4+FF and F=- level lines .arrowed/ are marked on the inside of the reservoir.

=n 7TE models, the coolant reservoir 4+FF and F=- level lines are visible by looking up under the mudguard from the right#hand side of the rear wheel.

The coolant level lines .arrowed/ are marked on the reservoir.

@

'f the coolant level is not between the +PP$( and F=-$( markings, on T05 models remove the seat and on 7TE models the left#hand side cover .see

"hapter >/. (emove the reservoir filler cap. 6

Top the coolant level up with the recommended coolant mi%ture. 4it the cap securely, then install the seat, and on 7TE models the side cover .see

"hapter >/. ;

Scane! by Stal'er

0aily .pre#ride/ checks ?.8;

6 Tyre checks

The correct pressuresG

! The tyres, must be checked when col!; not

immediately after riding. )ote that low tyre

pressures may cause the tyre to slip on the rim or

come off. High tyre pressures will cause

abnormal tread wear and unsafe handling.

! +se an accurate pressure gauge.

! Proper air pressure will increase tyre life and

provide ma%imum stability and ride comfort.

Tyre careG

! "heck the tyres carefully for cuts, tears,

embedded nails or other sharp objects and

e%cessive wear. =peration of the motorcycle with

e%cessively worn tyres is e%tremely ha&ardous,

as traction and handling are directly affected.

! "heck the condition of the tyre valve and

ensure the dust cap is in place.

! Pick out any stones or nails which may have

become embedded in the tyre tread. 'f left, they

will eventually penetrate through the casing and

cause a puncture.

! 'f tyre damage is apparent, or une%plained

loss of pressure is e%perienced, seek the advice

of a tyre fitting specialist without delay.

-oa!in&+s"ee! Front Rear

*99* to *990 TD mo!els

(ider only

(ider and passenger, or high speed

68 psi 16.0 *ar/ 68

psi 16.0 *ar/

@@ psi .A.A; *ar/ @C

psi .A.;? *ar/

*995(on TD mo!els

All loadsDspeeds

6? psi .A.B; *ar/

88 psi .A.A; *ar/

TRX mo!els

(ider only

(ider and passenger, or high speed

88 psi .A.A; *ar/ 85

psi .A.;? *ar/

@C psi .A.;? *ar/ 68

psi .A.>? *ar/

XT3 mo!els

(ider only

(ider and passenger, or high speed

88 psi .A.A; *ar/ 88

psi .A.A; *ar/

@@ psi .A.A; *ar/ @C

psi .A.;? *ar/

Tyre tread depthG

! At the time of writing +< law re,uires that tread

depth must be at least 8 mm over @D6 of the tread

breadth all the way around the tyre, with no bald

patches. 5any riders, however, consider a

minimum of A mm tread depth to be a safer limit.

:amaha recommend a minimum of 8.; mm on

the front and A mm on the rear.

"heck the tyre pressures when the tyres

are cold and keep them properly inflated. 8

5easure tread depth at the centre of the

tyre using a tread depth gauge.

S

@ Tyre tread wear indicator bar location marking

.usually either an arrow, a triangle or the letters

T-'/ on the sidewall .arrowed/.

Scane! by Stal'er

! 5any tyres now incorporate wear indicators in

the tread. 'dentify the triangular pointer on the

tyre sidewall to locate the indicator bar and

replace the tyre if the tread has worn down to the

bar.

11

9ha"ter *

(outine maintenance and 1ervicing

9ontents

Air filter # cleaning and renewal ............................................................. ;

*attery # charging ................................................................ see "hapter 9

*attery # check........................................................................................ 88

*attery # removal, installation, inspection and

maintenance...................................................................... see "hapter 9

*rakes # fluid change and seal renewal .................................................AC

*rake hoses # renewal .......................................................................... A9

*rake pads # wear check ....................................................................... >

*rake system # check.............................................................................. 9

"arburettors # synchronisation................................................................. 6

"lutch # check and adjustment................................................................. 8?

"ooling system # check .......................................................................... 8C

"ooling system # draining, flushing and refilling.......................................AB

"ylinder compression # check ................................................................. @8

0rive chain and sprockets # check, adjustment and lubrication ... 8

$ngine oil pressure # check .................................................................. @A

$ngineDtransmission # oil change............................................................. B

$ngineDtransmission # oil change and filter renewal.................................AA

4ront forks # oil change............................................................................ @6

4uel hoses # renewal............................................................................... @@

4uel filter # renewal .8999 T05 models/..................................................A@

4uel system # check ................................................................................ C

Headlight aim # check and adjustment.....................................................@?

'dle speed # check and adjustment ........................................................ @

)uts and bolts # tightness check .............................................................8;

1idestand #check..................................................................................... 86

1idestand, lever pivots and cables # lubrication.......................................8>

1park plugs # gap check and adjustment................................................. A

1teering head bearings # freeplay check and adjustment ........................A8

1teering head bearings # lubrication........................................................ A;

1uspension # check ............................................................................... A?

1wingarm and suspension bearings .T05 and T(7 models/ #

lubrication .......................................................................................... A6

1wingarm and suspension bearings .7TE models/ # lubrication ... 89

Throttle and choke cables # check...........................................................8B

3alve clearances # check and adjustment ..............................................A>

-heels and tyres # general check .........................................................8A

-heel bearings # check ......................................................................... 8@

De&rees of !ifficulty

Easy; suitable for Jk

novice with little

e%penence <<=

Fairly easy; suitable Jjs, for

beginner with tH some

e%perience >S

Fairty !ifficult; Jk

suitable for competent H

0': mechanic ?<S

Difficult; suitable for H,

e%perienced 0': @K

mechanic H

3ery difficult,

suitable for e%pert 0': H

or professional 6S

Scane! by Stal'er

.@

8.A (outine maintenance

S"ecifications

En&ine

"ylinder identification.........................................................

1park plugs

Type .............................................................................

$lectrode gap ................................................................

$ngine idle speed

T05 8998 to 899; models.............................................

T05 899C#on models and all T(7 models.....................

7TE models...................................................................

"arburettor synchronisation # intake vacuum

T05 8998 to 899; models.............................................

T05 899C#on models.....................................................

T(7 and 7TE models ....................................................

"arburettor synchronisation # ma%. difference between

T05 8998 to 899; models and all 7TE models ....

T05 899C#on models and all T(7 models.....................

3alve clearances ."=F0 engine/

'nlet valves ...................................................................

$%haust valves .............................................................

"ylinder compression T05

8998 to 899; models

1tandard ...................................................................

5a%imum ................................................................

5inimum....................................................................

5a%. difference between cylinders.............................

T05 899C#on models and all T(7 models

1tandard ...................................................................

5a%imum ................................................................

5inimum....................................................................

5a%imum difference between cylinders.....................

7TE models

1tandard ...................................................................

5a%imum ................................................................

5inimum....................................................................

5a%imum difference between cylinders.....................

......................... )o. 8 .left#hand/, no. A .right#hand/

......................... )2< 0P(>$A#9 or )ippondenso 7A6$P(#+9

......................... ?.> to ?.9 mm

......................... 8??? to 8A?? rpm

......................... 8?;? to 8A;? rpm

......................... 88?? to 8A?? rpm

......................... A;? to AB? mm Hg

......................... AB? to A9? mm Hg

......................... A6? to AC? mm Hg

carburettors

......................... 8? mm Hg

......................... ; mm Hg

......................... ?.8; to ?.A? mm

......................... ?.A; to ?.@? mm

8;A psi .8?.; *ar/

8;> psi .8?.9 *ar/

86C psi .8?.8 *ar/

86.; psi .8.? *ar/

8B; psi .8A.? *ar/

8>A psi .8A.; *ar/

86; psi .8?.? *ar/

86.; psi .8.? *ar/

8@> psi .9.; *ar/

866 psi .9.9 *ar/

8@A psi .9.8 *ar/

86.; psi .8.? *ar/

9ycle "arts

0rive chain slack

T05 models .....................................................

T(7 models.......................................................

7TE models.......................................................

4ront brake lever freeplay .7TE models/...............

(ear brake pedal height .see te%t/

T05 8998 to 899; models.................................

T05 899C#on models........................................

T(7 models.......................................................

7TE models.......................................................

*rake pad friction material wear limit

T05 and T(7 models.......................................

7TE models.......................................................

"lutch cable freeplay

T05 8998 to 899; models.................................

All other models ................................................

Throttle cable freeplay

T(7 models.......................................................

All other models ...............................................

Tyre pressures .cold/ and minimum tread depth

1wingarm # 7TE models

1ide clearance ................................................

*earing spacer length .right#hand/....................

*earing spacer length .left#hand/......................

-asher thickness .............................................

6? to ;? mm

A? to @? mm

A; to @; mm

A to ; mm

8B to 68 mm A9

mm ;B mm ; to

A; mm

?.; mm 8.;

mm

> to 8A mm

8? to 8; mm

@ to B mm

@ to ; mm

see *aily (pre-ride) checks

?.6 to ?.B mm 9?.9; to

98.8?mm >?.9; to

>8.8? mm 8.9 to A.?

mm

TorAue settin&s

(ear a%le nut

T05 8998 to 899; models........................................................................ 8?; )m

T05 899C#on models................................................................................ 8?B )m

T(7 models............................................................................................... 88B )m

7TE models............................................................................................... 9? )m

(ear brake caliper bracket bolt .T05 models/.............................................. @; )m

"rankcase oil drain plug................................................................................ @; )m

=il filter housing drain plug............................................................................ @? )m

=il filter cover bolts........................................................................................ 8? )m

1teering head bearing adjuster nut .using service tool/ 8998 to

899; T05 models

'nitial setting ........................................................................................ ;A )m

4inal setting........................................................................................... @ )m

899C#on T05 models and all T(7 models

'nitial setting ........................................................................................ 6> )m

4inal setting........................................................................................... 8C )m

7TE models

'nitial setting ........................................................................................ @> )m

4inal setting........................................................................................... C )m

1teering stem nut

8998 to 899; T05 models........................................................................ 88? )m

899C#on T05 models................................................................................ 8?> )m

T(7 models............................................................................................... 88? )m

1teering stem bolt .7TE models/ ................................................................ >? )m

4ork clamp bolts .top yoke/ ......................................................................... A@ )m

"ooling system drain plugs ......................................................................... 8?)m

=il gallery bolt............................................................................................... 8? )m

+)($2'1T$($03'

(outine maintenance 8.@

Stane! by Stal'er

+)($2'1T$($0 3$(1'=) =4 P'"T+($#0$1<

Recommen!e! lubricants an! flui!s

$ngineDtransmission oil type.......................................................................... AP' grade 1$, 14 or 12 motor oilL

$ngineDtransmission oil viscosity .................................................................. 1A$ 8?-@? or 8?-6?

$ngineDtransmission oil capacity T05 8998 to 899;

models and all 7TE models

=il change............................................................................................. @.> litres

=il and filter change .............................................................................. @.9 litres

4ollowing engine overhaul # dry engine, new filter................................. 6.A litres

T05 899C#on models and all T(7 models

=il change............................................................................................. @.; litres

=il and filter change .............................................................................. @.C litres

4ollowing engine overhaul # dry engine, new filter................................. 6.A litres

"oolant type.................................................................................................. ;?I distilled water, ;?I corrosion#inhibited ethylene glycol anti

free&e. %ote) %amaha speci!y that so!t tap water can be used& but

'(T hard water. )! in doubt& boil the water !irst or use only distilled

water.

"oolant capacity

(adiator and engine ................................................................................. 8.B litres

(eservoir

7TE models........................................................................................... ?.6; litre

All other models ................................................................................... ?.@ litre

*rakefluid...................................................................................................... 0=T6

4ront fork oil type, capacity and level............................................................ see "hapter C 1pecifications

0rive chain .................................................................................................. 1A$ @? to ;?- engine oil or chain lubricant suitable for =#ring

chains

1teering head bearings................................................................................. Fithium#based multi#purpose grease

1wingarm pivot bearings # T05 and T(7 models......................................... 5olybdenum disulphide grease

1wingarm pivot bearings # 7TE models......................................................... Fithium#based multi#purpose grease

1uspension linkage bearings # T(7 models ............................................... 5olybdenum disulphide grease

1uspension linkage bearings # 7TE models................................................... Fithium#based multi#purpose grease

-heel bearings and grease seal lips............................................................. Fithium#based multi#purpose grease

2earchange leverDclutch leverDfront brake leverDrear brake

pedalDsidestand pivots................................................................................... 8?-@? motor oil

"ables........................................................................................................... 8?-@? motor oil

Throttle grip ................................................................................................ 5ulti#purpose grease or dry film lubricant

'%amaha advise against using chemical oil additives& or oils with a grade o! +,/-* or higher& or oils labelled .'./0% -('+./1)'0 )). +uch

additives or oils could cause clutch slip.

8.6 "omponent locations

T05

# +teering head bearings

2 -lutch cable upper ad3uster

4 $ir !ilter

5 6attery (#77# to #778)

8 (il !iller cap/dipstick (#77# to #778)

9 -oolant reservoir

: *rive chain ad3uster

; )dle speed ad3uster

7 (il drain plug

T05

# /ear brake !luid reservoir

2 (il level window (#779-on)

4 (il !iller cap (#779-on)

5 Front brake !luid reservoir

; Throttle cable upper ad3uster

9 /adiator pressure cap

: -oolant drain plug on water

pump

-lutch cable lower ad3uster

(il !ilter and !ilter housing

drain plug

#< 6attery (#779-on)

1caned by 1talker

"omponent locations 8.;

TRX

# -oolant reservoir

2 /ear brake !luid reservoir

4 (il level window

5 (il !iller cap

8 Front brake !luid reservoir

9 Throttle cable upper ad3uster

: /adiator pressure cap

; -oolant drain plug on water

pump

7 -lutch cable lower ad3uster

#< (il !ilter and !ilter housing

drain plug

TRX

# -lutch cable upper ad3uster

2 +teering head bearing

ad3uster

4 $ir !ilter

5 )dle speed ad3uster

8 6attery

9 *rive chain ad3uster

: (il drain plug

Stane! by Stal'er

+)($2'1T$($03$(1'=) =4 P'"T+($#0$1<

.C "omponent locations

XT3

# /ear brake !luid reservoir

2 (il !iller cap/dipstick

4 Throttle cable upper ad3uster

5 Front brake !luid reservoir

8 +teering head bearing

ad3uster

9 -oolant drain plug on water

pump

: -lutch cable lower ad3uster

; (il !ilter and !ilter housing

drain plug

/adiator pressure cap

-lutch cable upper ad3uster

$ir !ilter

6attery

-oolant reservoir

*rive chain ad3uster

(il drain plug

Scane! by Stal'er

XT3

5aintenance schedule w

%ote) The daily (pre-ride) checks outlined in the owner's manual

covers those items which should be inspected on a daily basis. $lways

per!orm the pre-ride inspection at every maintenance interval (in

addition to the procedures listed). The intervals listed below are the

intervals recommended by the manu!acturer !or each particular

operation during the model years covered in this manual. %our owner's

manual may have di!!erent intervals !or your model.

0aily .pre#ride/

M 1ee '*aily (pre-ride) checks' at the beginning of this

$very 6??? miles .C??? km/ or

C months .whichever comes sooner/

.continued/

M (e#grease the swingarm and suspension linkage

bearings .7TE models/ .1ection 89/.

M "heck the suspension .1ection A?/

M "heck and adjust the steering head bearings

.1ection A8/

After the initial C?? miles .8??? km/

%ote) This check is usually per!ormed by a %amaha dealer a!ter the

!irst 9<< miles (#<<< km) !rom new. Therea!ter& maintenance is

carried out according to the !ollowing intervals o! the schedule.

$very @?? miles .;?? km/

M "heck, adjust and lubricate the drive chain

.1ection 8/

$very 6??? miles .C??? km/ or

C months .whichever comes sooner/

M "heck the spark plug gaps and plug condition

.1ection A/

M "heck and adjust the idle speed .1ection @/

0 "heckDadjust the carburettor synchronisation

.1ection 6/

M "lean and check the air filter element .1ection ;/

M "heck the fuel system and hoses .1ection C/ 0

"hange the engine oil .1ection B/

? "heck the brake pads .1ection >/

M "heck the brake system and brake light switch

operation .1ection 9/

M "heck and adjust the clutch .1ection 8?/

M "heck the battery .1ection 88/

0 "heck the condition of the wheels and tyres

.1ection 8A/

M "heck the wheel bearings .1ection 8@/

M "heck the sidestand .1ection 86/

M "heck the tightness of all nuts, bolts and

fasteners .1ection 8;/

M "heck the cooling system .1ection 8C/

M "heck and adjust the throttle and choke cables

.1ection 8B/

0 Fubricate the clutchDgearshiftDbrake leverDbrake

pedalDsidestand pivots and the throttleDchokeDclutch

cables .1ection 8>/

$very >??? miles .8A,??? km/ or 8A

months .whichever comes sooner/

-arry out all the items under the 5<<< mile (9<<< km) check& plus the

!ollowing=

M "hange the engine oil and filter .1ection AA/

M (enew the fuel filter .8999 T05 models/

.1ection A@/

$very 8C,??? miles .A6,??? km/ or

two years .whichever comes sooner/

-arry out all the items under the ;<<< mile (#2&<<< km) check& plus

the !ollowing=

M (e#grease the swingarm and suspension linkage

bearings .T05 and T(7 models/ .1ection A6/.

M (e#grease the steering head bearings .1ection A;/.

0 "hange the brake fluid and renew the brake master

cylinder and caliper seals .see 1ection AC/

M (enew the coolant .1ection AB/

$very A>,??? miles .6A,??? km/

-arry out all the items under the 5<<< mile (9<<< km) check& plus the

!ollowing=

M "heck and adjust the valve clearances .1ection A>/

very four years

M (enew the brake hoses .1ection A9/

)on#scheduled maintenance

M "heck and adjust the headlight aim .1ection @?/

M "heck the cylinder compression .1ection @8/

M "heck the engine oil pressure .see 1ection @A/

M (enew the fuel hoses .1ection @@/

M "hange the front fork oil .1ection @6/

Sta&e! by Stal'er

*.8 ?ntro!uction

* This "hapter is designed to help the home

mechanic maintain hisDher motorcycle for safety,

economy, long life and peak performance.

6 0eciding where to start or plug into the routine

maintenance schedule depends on several

factors. 'f the warranty period on your motorcycle

has just e%pired, and if it has been maintained

according to the warranty standards, you may

want to pick up routine maintenance as it

coincides with the ne%t mileage or calendar

interval. 'f you have owned the machine for some

time but have

never performed any maintenance on it, then you

may want to start at the nearest interval and

include some additional procedures to ensure

that nothing important is overlooked. 'f you have

just had a major engine overhaul, then you may

want to start the maintenance routine from the

beginning. 'f you have a used machine and have

no knowledge of its history or maintenance

record, you may desire to combine all the checks

into one large service initially and then settle into

the maintenance schedule prescribed. @ *efore

beginning any maintenance or

repair, the machine should be cleaned

thoroughly, especially around the oil filter, spark

plugs, valve cover, side panels, carburettors, etc.

"leaning will help ensure that dirt does not

contaminate the engine and will allow you to

detect wear and damage that could otherwise

easily go unnoticed.

6 "ertain maintenance information is sometimes

printed on decals attached to the motorcycle. 'f

the information on the decals differs from that

included here, use the information on the decal.

E,ery 800 miles 1000 'm2

* Dri,e chain an! s"roc'ets # 8JN

check, adjustment and ON

lubrication H

Check

8 A neglected drive chain won't last long and can

,uickly damage the sprockets. (outine chain

adjustment and lubrication isn't difficult and will

ensure ma%imum chain and sprocket life.

A To check the chain, place the bike on its

sidestand and shift the transmission into neutral.

@ Push up on the bottom run of the chain and

measure the slack midway between the two

sprockets, then compare your measurement

*.8 #ush u" on the chain an! measure the

slac'

to that listed in this "hapter's 1pecifications 1see

illustration2. As the chain stretches with wear,

adjustment will periodically be necessary .see

below/. 1ince the chain will rarely wear evenly,

roll the bike forwards so that another section of

chain can be checked do this several times to

check the entire length of chain and position the

tightest spot midway between the sprockets on

the bottom run of the chain.

6 'n some cases where lubrication has been

neglected, corrosion and galling may cause the

links to bind and kink, which effectively shortens

the chain's length. 1uch links should be

thoroughly cleaned and worked free. 'f the chain

is tight between the sprockets, rusty or kinked,

it's time to renew it. 'f you find a tight area, mark

it with felt pen or paint, and repeat

0'($"T'=) =4 (=TAT'=)

$)2')$ 1P(="<$T ($A( 1P(="<$T

-=()T==TH -=()T==TH

*.4 9hec' the s"roc'ets in the areas

in!icate! to see if they are Born

eCcessi,ely

the measurement after the bike has been ridden.

'f the chain's still tight in the same area, it may be

damaged or worn. *ecause a tight or kinked

chain can damage the transmission countershaft

bearing, it's a good idea to renew it.

0 "heck the entire length of the chain for

damaged rollers, loose links and pins, and

missing =#rings and renew it if damage is found.

%ote) 'ever install a new chain on old sprockets&

and never use the old chain i! you install new

sprockets - renew the chain and sprockets as a

set.

5 'f you suspect that the chain may be worn out,

you can measure a 8?#link length and compare it

with the wear limit. This re,uires the chain to be

removed from the bike and first cleaned .see

"hapter C/.

4 (emove the front sprocket cover .see "hapter

C/. "heck the teeth on the engine sprocket and

the rear wheel sprocket for wear 1see

illustration2.

8 'nspect the drive chain slider on the swingarm

for e%cessive wear and renew it if worn .see

"hapter C/.

,d-ustment

9 (otate the rear wheel until the chain is

positioned with the tightest point at the centre

of its bottom run, then place the machine on

its sidestand. =n T05 models, slacken the

brake caliper bracket bolt on the top of the

swingarm 1see illustration2.

*0 -here fitted, remove the split pin from the

rear a%le nut. 1lacken the nut 1see illustrations2.

*.9 .n TD mo!els; slac'en the bolt 1arroBe!2

*.*0a Rear aCle nut 1arroBe!2 (TD mo!els

*.*0b Rear aCle nut 1arroBe!2 (TRX mo!els

Scane! by Stal'er

$very @?? miles .;?? km/ 8.9

*.**a .n TD an! XT3 mo!els; slac'en the loc'nut 1arroBe!2...

*.**b ... an! turn the a!<uster as reAuire!

*.**c .n TRX mo!els; slac'en the loc'nut 1A2 an! turn the a!<uster 1/2 as reAuire!

** 1lacken the adjuster locknut on each side of

the swingarm, then turn the adjusters evenly until

the amount of freeplay specified at the beginning

of the "hapter is obtained at the centre of the

bottom run of the chain 1see illustrations/.

4ollowing chain adjustment, check that each

chain adjustment marker is in the same position

in relation to the marks on the swingarm 1see

illustrations2. 't is important each adjuster aligns

with the same notch if not, the rear wheel will be

out of alignment with the front. %ote) )! you need

to check wheel alignment re!er to -hapter :.

*6 'f there is a discrepancy in the chain adjuster

positions, adjust one of them so that its position

is e%actly the same as the other. "heck the chain

freeplay as described above and readjust if

necessary.

*8 Tighten the a%le nut to the tor,ue setting

specified at the beginning of the "hapter, then

tighten the adjuster locknuts securely 1see

?llustration2. -here removed, fit a new split pin

onto the a%le nut 1see illustration2. =n T05

models, tighten the brake caliper bracket bolt to

the specified tor,ue 1see illustration *.92.

Caution: $n models with a split pin securing

the a*le nut, if the groove in the nut does not

align with the hole in the a*le after the

specified tor.ue has been reached, tighten

the nut to align it / D$ !$+ loosen it.

0ubrication

*D 'f re,uired, wash the chain in paraffin

l.Hd .n TD an! XT3 mo!els; chec' the

relati,e "osition of the mar'er 1A2 an! the

notches 1/2 on each si!e

.kerosene/, then wipe it off and allow it to dry,

using compressed air if available. 'f the chain is

e%cessively dirty it should be removed from the

machine and allowed to soak in the paraffin .see

"hapter C/. Caution: Don1t use petrol, solvent

or other cleaning fluids which might damage

the internal sealing properties of the chain.

Don1t use high/pressure water. +he entire

process shouldn1t take longer than ten

minutes / if it does, the $/rings in the chain

rollers could be damaged. *0 4or routine

lubrication, the best time to lubricate the chain is

after the motorcycle has been ridden. -hen the

chain is warm, the lubricant will penetrate the

joints between the

*.**0 .n TRX mo!els; chec' the relati,e

"osition of the notches on the mar'er 1A2

an! the notches in the sBin&arm 1/2 on

each si!e

side plates better than when cold. %ote) %amaha

speci!ies +$. 4< to 8<> engine oil? you can use

an aerosol chain lube& but make sure that it is

suitable !or (-ring chains. Apply the oil to the

area where the side plates overlap # not the

middle of the rollers 1see illustration2.

centrifugal force will work the oil into

the chain when the bike is moving.

,fter appl)ing the lubricant, let it soak

in a few minutes before wiping off an)

eCcess.

*.*8a Ti&hten the aCle nut to the s"ecifie! torAue

>>.T>T8?

$

@@ly the oil to the top o!

Eh<?F? tne iower chain run& so

G?%T

*.*8b Ese a neB s"lit "in; Bhere a""ro"riate

*.*0 A""ly the oil to the o,erla" in the si!e "lates

Stane! by Stal'er

i.io $very 6??? miles .C??? km/ or C months

E,ery D000 miles 15000 'm2 or 5 months

6 S"ar' "lu&s #

check and adjustment P1j

8 5ake sure your spark plug socket is the

correct si&e .8> mm/ before attempting to remove

the plugs # a suitable one is supplied in the

motorcycle's tool kit which is stored under the

seat.

A =n 7TE models, remove the fuel tank and the

air filter housing .see "hapter 6/.

@ +sing compressed air if available, clean the

area around the base of the spark plugs to

prevent any dirt falling into the engine when the

plugs are removed.

6 "heck that the cylinder location is marked on

each plug lead, then pull the spark plug cap off

each spark plug 1see illustration2. +sing either

the plug tool supplied in the bike's toolkit or a

deep socket type wrench, unscrew the plugs from

the cylinder head 1see illustration2. Fay each

plug out in relation to its cylinder if either plug

shows up a problem it will then be easy to identify

the troublesome cylinder.

; 'nspect the electrodes for wear. *oth the

centre and side electrodes should have s,uare

edges and the side electrodes should be of

uniform thickness. Fook for e%cessive deposits

and evidence of a cracked or chipped insulator

around the centre electrode. "ompare your spark

plugs to the colour spark plug reading chart at

the end of this manual. "heck the threads, the

washer and the ceramic insulator body for cracks

and other damage.

C 'f the electrodes are not e%cessively worn, and

if the deposits can be easily removed with a wire

brush, the plugs can be re#gapped and re#used .if

no cracks or chips are visible in the insulator/. 'f in

doubt concerning the condition of the plugs,

renew them, as the e%pense is minimal. :amaha

do not specify a renewal interval, but leave it to

the discretion of the owner.

B "leaning spark plugs by sandblasting is

permitted, provided you clean the plugs with a

high flash#point solvent afterwards.

> *efore installing the plugs, make sure they are

the correct type and heat range and check the

gap between the electrodes 1see illustrations2.

"ompare the gap to that specified and adjust as

necessary. 'f the gap must be adjusted, bend the

side electrode only and be very careful not to chip

or crack the insulator nose 1see illustration2.

5ake sure the washer is in place on the plug

before installing it.

9 1ince the cylinder head is made of aluminium,

which is soft and easily damaged, thread the

plugs into the heads turning the tool by hand

1see illustration2. =nce the

plugs are finger#tight, the job can be finished with

a spanner on the tool supplied or a socket drive

1see illustration *.Db2. 'f a tor,ue wrench can be

applied, tighten the spark plugs to the specified

tor,ue setting. =therwise tighten them by 8D6 to

8DA turn after they have been fully hand#tightened

and have seated. 0o not over#tighten them.

HTflflH88

#As the

plugs are Auite

G?%T

short length of hose over the end of the

plug to use as a tool to thread it into place.

+he hose will grip the plug well enough to

turn it, but will start to slip if the plug begins

to cross/thread in the hole / this will prevent

damaged threads.

8? (econnect the spark plug caps, making sure

they are securely connected to the correct

cylinder. 'nstall all other components previously

removed. .

#?>G>GS +tripped plug threads in the GE?ES>

cylinder head can be

GiT

6.Da Remo,e the s"ar' "lu& ca"...

*

recesse!; )ou can slip a

repaired with a Heli/Coil ' insert /

see +ools and 'orkshop +ips1 in the

"eference section.

6.Db ... then unscreB the s"ar' "lu&

6.8a Esin& a Bire ty"e &au&e to measure the s"ar' "lu& electro!e &a"

6.8b Esin& a feeler &au&e to measure the s"ar' "lu& electro!e &a"

6.8c A!<ust the electro!e &a" by ben!in& the si!e electro!e only

6.9 Threa! the "lu& in as far as "ossible by turnin& the tool by han!

Scane! by Stal'er

$very 6??? miles .C??? km/ or C months 8.8.8

8.8a ?!le s"ee! a!<uster screB 1arroBe!2

(TD mo!els

@ 'dle speed # QH

check and adjustment

* The idle speed should be checked and

adjusted before and after the carburettors are

synchronised .balanced/ and when it is obviously

too high or too low. *efore adjusting the idle

speed, make sure the valve clearances and

spark plug gaps are correct. Also, turn the

handlebars back#and#forth and see if the idle

speed changes as this is done. 'f it does, the

throttle cable may not be adjusted or routed

correctly, or may be worn out. This is a

dangerous condition that can cause loss of

control of the bike. *e sure to correct this

problem before proceeding.

6 The engine should be at normal operating

temperature, which is usually reached after 8? to

8; minutes of stop#and#go riding. 5ake sure the

transmission is in neutral, and place the

motorcycle on its sidestand.

8 =n T05 and T(7 models, the idle speed

adjuster is located on the left#hand side 1see

illustrations2. =n 7TE models, the adjuster is

located at the back of the carburettors between

the float chambers. -ith the engine idling, adjust

the idle speed by turning the adjuster screw until

the idle speed listed in this "hapter's

1pecifications is obtained. Turn the screw

clockwise to increase idle speed, and anti#

clockwise to decrease it.

8.8b ?!le s"ee! a!<uster screB 1arroBe!2

(TRX mo!els

D 1nap the throttle open and shut a few times,

then recheck the idle speed. 'f necessary, repeat

the adjustment procedure.

0 'f a smooth, steady idle can't be achieved, the

fuelDair mi%ture may be incorrect .check the pilot

screw settings # see "hapter 6/ or the

carburettors may need synchronising .see

1ection 6/. Also check the inlet manifold rubbers

for cracks which will cause an air leak, resulting in

a weak mi%ture.

6 "arburettors # H

synchronisation H

'arning: 2etrol 3gasoline4 is

e*tremel) flammable, so take e*tra

precautions when )ou work on an)

part of the fuel s)stem. Don1t smoke or allow

open flames or bare light bulbs near the work

area, and don1t work in a garage where a

natural gas/t)pe appliance is present. &f )ou

spill an) fuel on )our skin, rinse it off

immediatel) with soap and water. 'hen )ou

perform an) kind of work on the fuel s)stem,

wear safet) glasses and have a fire

e*tinguisher suitable for a Class ( t)pe fire

3flammable li.uids4 on hand.

,

gauge take/off points on the intake

manifolds. Do not allow e*haust gases to

build up in the work area5 either perform the

check outside or use an e*haust gas

e*traction s)stem.

8 "arburettor synchronisation is simply the

process of adjusting the carburettors so they

pass the same amount of fuelDair mi%ture to each

cylinder. This is done by measuring the vacuum

produced in each cylinder. "arburettors that are

out of synchronisation will result in decreased

fuel mileage, increased engine temperature, less

than ideal throttle response and higher vibration

levels. *efore synchronising the carburettors,

make sure the valve clearances and idle speed

are properly set.

A To properly synchronise the carburettors you

will need a pair of vacuum gauges or a

manometer these instruments measure engine

vacuum and can be obtained from motorcycle

dealers or mail order parts suppliers. 'f you don't

have access to either of these instruments

entrust the work to a dealer.

@ 1tart the engine and let it run until it reaches

normal operating temperature, then shut it off.

6 (emove the fuel tank .see "hapter 6/.

; =n 8998 to 899> T05 models, release the

clamp securing the )o. 8 cylinder vacuum hose

to the fuel pump and detach the hose, then pull

the blanking plug out of the end of the )o. A

cylinder vacuum hose 1see illustrations2. 'f in

doubt, trace each hose from the take#off stub on

the top of each inlet manifold between the

carburettor and the cylinder head to make sure

you have the correct one. =n 8999 T05 models,

puil the blanking plug out of both vacuum hoses

situated down the right#hand side of the engine if

in doubt about their location, trace the hoses

from their take#off stubs on the inlet manifolds.

C =n T(7 models, release the clamp securing

the )o. A cylinder hose to the fuel pump and

detach the hose 1see illustration2. The )o. 8

cylinder vacuum hose has already been

detached from the fuel tap when removing the

fuel tank. 'f in doubt, trace each hose from the

take#off stub on the top of each intake

Stane! by Stal'er

D.0a .n TD mo!els; !etach the %o. *

,acuum hose 1arroBe!2 from the fuel

"um"...

D.0b ... an! remo,e the blan'in& "lu&

1arroBe!2 from the %o. 6 hose

D.5 .n TRX mo!els; !etach the %o. 6

,acuum hose 1arroBe!2 from the fuel

"um"

8.8A $very 6??? miles .C??? km/ or C months

D.4a .n XT3 mo!els; !etach the ,acuum hose 1arroBe!2.

D.4b ... an! remo,e the blan'in& "lu& 1arroBe!2

D.*6 9arburettor synchronisation screB

1arroBe!2 ( air filter housin& remo,e! for

clarity

manifold between the carburettor and the

cylinder head to make sure you have the correct

one. 'f access is not too restricted, the hoses can

be detached from the intake manifolds

themselves.

B =n 7TE models, release the clamps securing

the vacuum hose and the blanking plug to the

take#off stubs on the inlet manifolds between the

carburettor and the cylinder head and detach the

hose and plug 1see illustrations2.

> =n T05 and T(7 models, connect the gauges

to the vacuum hose ends. =n 7TE

models, connect the gauge hoses to the takeoff

stubs on the inlet manifolds. 5ake sure there are

no air leaks as false readings will result.

9 Arrange a temporary fuel supply, either by

using a small temporary tank or by using e%tra

long fuel pipes to the now remote fuel tank.

Alternatively, position the tank on a suitable

base on the motorcycle, taking care not to

scratch any paintwork, and making sure that

the tank is safely and securely supported. 'f

using the main tank, switch the tap to =) or

($1 on T05 and 7TE models, and to P(' on

T(7 models.

8? 1tart the engine and let it idle. 'f the gauges

are fitted with damping adjustment, set this so

that the needle flutter is just eliminated but so

that they can still respond to small changes in

pressure.

88 The vacuum readings for both cylinders

should be the same. 'f the vacuum readings

differ, proceed as follows.

8A The carburettors are adjusted by turning the

synchronising screw situated in#between the

carburettors, in the throttle linkage 1see

illustration2. %ote) *o not press down on the

screw whilst ad3usting it& otherwise a !alse

reading will be obtained. -hen the carburettors

are synchronised, open and close the throttle

,uickly a few times to settle

the linkage, and recheck the gauge readings,

readjusting if necessary.

8@ -hen the adjustment is complete, recheck

the vacuum readings, then adjust the idle speed

.see 1ection @/ until the speed listed in this

"hapter's 1pecifications is obtained. 0etach the

temporary fuel supply, then remove the gauges.

(efit the vacuum hoses andDor blanking plugs as

re,uired by your model .see 1teps 9, 8? and 88/.

86 'nstall the fuel tank .see "hapter 6/.

* (emove the fuel tank .see "hapter 6/. =n 7TE

models, also remove the air filter housing .see

"hapter 6/ it is possible to remove the covers

and elements with the housing in situ but access

to the screws is restricted and the screws are

easily dropped.

6 =n T05 and T(7 models remove the screws

securing the air filter cover to the filter housing,

then remove the cover and withdraw the filter

element from the housing 1see illustrations2.

8 =n 7TE models, there are two filter elements,

each fitted integral with its cover on the front of

the housing 1see illustrations2.

0.6a Remo,e the screBs 1arroBe!2 an! lift off

the co,er...

0.6b ..

then Bith!raB the element 1TD

shoBn2

0.8a Remo,e the screBs 1arroBe!2...

Scane! by Stal'er

$very 6??? miles .C??? km/ or C months *I*8

0.8b ... an! remo,e the co,er an! element toðer

DTap the element on a hard surface to dislodge any large particles of dirt, then if compressed air is available, use it to clean the element, directing the air from the

inside out 1see illustration2.

0"heck the element for signs of damage. 'f the element is torn or cannot be cleaned, or is obviously beyond further use, renew it.

5'nstall the filter element, making sure it is properly seated, and install the fuel tank .see "hapter 6/.

Caution: &f the machine is ridden in dust) conditions, the filter should be cleaned more fre.uentl).

'arning: 2etrol 3gasoline4 is e*tremel) flammable, so take e*tra precautions when )ou work on an) part of the fuel s)stem. Don1t smoke or

allow open flames or bare light bulbs near the work area, and don1t work in a garage where a natural gas/t)pe appliance is present. &f )ou spill an)

fuel on )our skin, rinse it off immediatel) with soap and water. 'hen )ou perform an) kind of work on the fuel s)stem, wear safet) glasses and

have a fire e*tinguisher suitable for a Class ( t)pe fire 3flammable li.uids4 on hand.

,

4.Da EnscreB the cran'case oil !rain "lu&

1arroBe!2...

0.D 9lean the element usin& com"resse! air if a,ailable

Check

8 (emove the fuel tank .see "hapter 6/ and check the tank, the fuel tap, the fuel pump and the fuel and vacuum hoses for signs of leakage, deterioration or damage

in particular check that there is no leakage from the fuel hoses. (enew any hoses which are cracked or deteriorated.

A 'f the fuel tap is leaking, tighten the assembly screws .see "hapter 6/. 'f leakage persists remove the screws and disassemble the tap, noting how the components

fit. 'nspect all components and renew any that are worn or damaged. 1ome components are available individually, though it may be necessary to renew the whole

tap, depending on your model.

@ 'f the carburettor gaskets are leaking, the carburettors should be disassembled and rebuilt using new gaskets and seals .see "hapter 6/.

6ilter cleaning

D "leaning or renewal of the fuel filter is advised after a particularly high mileage has been covered. 't is also necessary if fuel starvation is suspected.

0 =n T(7, 7TE and 8998 to 899> T05 models, the fuel filters are mounted in the tank. =n T05 models, the filters are integral with the fuel outlet assembly from the

tank. =n T(7 and 7TE models, the filters are integral with the fuel tap. =n 7TE models, each fuel tap has its own filter. (emove the

' '

:

-^^^tafc.- *m

mjrl

>--

1

Wr*^- A

m

\\

4.Db ... an! alloB the oil to !rain

0.5 a'e sure the element is correctly seate!

fuel tank and the fuel tap.s/ .see "hapter 6/. "lean the gau&e filter to remove all traces of dirt and fuel sediment. "heck the gau&e for holes. 'f any are found, a

new filter should be fitted .check for availability # it may be necessary to renew the whole tap/. "heck the condition of the =#ring and renew it if it is in any way

damaged or deteriorated. C =n 8999 T05 models and in#line fuel filter is fitted between the fuel tap and fuel pump. (efer to 1ection A@ for details.

A 'arning: (e careful when draining the oil, as the e*haust pipes, the engine, and the oil itself can cause severe burns.

8 "onsistent routine oil and filter changes are

the single most important maintenance

procedure you can perform on a motorcycle.

The oil not only lubricates the internal parts of 6

the engine, transmission and clutch, but it

also acts as a coolant, a cleaner, a sealant,

and a protectant. *ecause of these demands,

the oil takes a terrific amount of abuse and should be changed often with new oil of the recommended grade and type. 1aving a little money on the difference in

cost between a good oil and a cheap oil won't pay off if the engine is damaged. The oil filter should be changed with every second oil change.

A *efore changing the oil, warm up the engine so the oil will drain easily.

@ Put the motorcycle on its sidestand, and position a clean drain tray below the engine. =n 8998 to 899; T05 models remove the seat, and on 7TE models

remove the right#hand side cover .see "hapter >/. +nscrew the oil filler cap from the oil tank to vent it and to act as a reminder that there is no oil in the en&ine

1see Dail) 3pre/ride4 checks4.

6 4irst unscrew the oil drain plug from the crankcase and allow the oil to flow into the drain tray 1see illustrations2. )e%t unscrew the oil drain plug from the oil

filter housing and

Scane! by Stal'er

8.86 $very 6??? miles .C??? km/ or C months

4.Dc EnscreB the oil filter housin& !rain 4.D!

"lu& 1arroBe!2...

allow the oil to flow into the drain tray 1see

illustrations2. "heck the condition of the sealing

washers on the drain plugs and discard them if

they are in any way damaged or worn. =n 899C#

on T05 and T(7 models, :amaha specify using

new ones as a matter of course.

; -hen the oil has completely drained, fit the

plugs to the crankcase and oil filter housing,

using new sealing washers if re,uired, and

tighten them to the tor,ue settings specified at

the beginning of the "hapter. Avoid

overtightening, as damage to the crankcase will

result.

C (efill the oil tank to the proper level using the recommended type and

amount of oil .see *aily (pre-ride) checks and this chapter's specifications/.

-ith the motorcycle vertical, the oil level should lie between the ma%imum

and minimum level lines on the dipstick or inspection window .according to

model/ .see *aily (pre-ride) checks). 'nstall the filler cap. 1tart the engine

and let it run for two or three minutes. 't is advisable to perform an oil

pressure check .see 1ection @A/. 1top the engine, wait a few minutes, then

check the oil level. 'f necessary, add more oil to bring the level up to the

ma%imum level line on the dipstick or window. "heck around the drain plugs

for leaks. RRRRRRRRR.#########R

B The old oil drained from the engine cannot ?>?? CC @@ CC

8 $ach brake pad has wear indicators that can

be viewed without removing the pads from the

caliper.

A =n T05 and T(7 models, the turned#in

corners of the brake pad backing material form

the wear indicators # when they are almost

contacting the disc itself the pads must be

renewed. The indicators are visible by looking at

the bottom corner of the pads 1see illustration2.

Caution: Do not allow the pads to wear to

the e*tent that the indicators contact the

disc itself as the disc will be damaged.

8 =n 7TE models, the indicators are in the form

of grooves in the brake pad friction material #

when the pads are worn so that the grooves are

only just visible the pads must be renewed 1see

illustration2.

D 'f the pads are worn to or beyond the

indicators, they must be renewed. 'f the pads are

dirty or if you are in doubt as to the amount of

friction material remaining, remove them and

measure the amount of friction material .see

"hapter B/. %ote) +ome a!ter-market pads may

use di!!erent indicators to those on the original

eAuipment as shown.

0 (efer to "hapter B for details of pad renewal.

5 *ikes used in the +< and anywhere where salt

is used on the roads are referred to "hapter B,

1ection A, 1tep 9 for details of brake pad and

caliper lubrication to prevent

8 A routine general check of the brake system will

ensure that any problems are discovered and