Академический Документы

Профессиональный Документы

Культура Документы

Lasco Shower Pan Installation

Загружено:

Ken O'ConnellАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lasco Shower Pan Installation

Загружено:

Ken O'ConnellАвторское право:

Доступные форматы

CPAN_installation 11/23/05 9:51 AM Page 1

Installation Data

Shower Pans

3232-CPAN, 3636-CPAN, 4242-CPAN, 4834-CPAN, 6034-CPAN

Patent Pending

Fax on Demand # 2101, 2102, 2103, 2104, 2105

NOTICE: Please inspect the unit thoroughly before installation to make sure it has not been damaged during transportation. Under

no circumstances should a damaged pan be installed. Neither LASCO Bathware nor the distributor will be responsible for

removal or reinstallation costs should a replacement be necessary.

IMPORTANT! Before installation begins:

a. READ ALL INSTALLATION INSTRUCTIONS COMPLETELY. IMPROPER INSTALLATION WILL VOID THE WARRANTY.

b. Make sure that walls and floors meet fire safety requirements of local building code and/or FHA/HUD Minimum Property Standards.

c. All dimensions are nominal. The stud opening is +¹/₈" (3mm) - 0.

Pre Installation Requirements:

a. In remodeling, if necessary, add studs at each end to provide a vertical nailing surface for the side nailing flanges of bath fixture product.

b. To avoid obstruction during installation make sure that supply lines, spout pipe and valve plumbing do not project into alcove.

c. Shower pans require a 6" (150mm) diameter floor opening for 2" (50mm) IPS drain fitting connection. [See Chart 1 for location]

NOTE: Be sure floor opening location matches left-hand, right-hand or center bath fixture drain location.

d. Use of casting plaster/plaster of paris (foundation material) is mandatory for all construction applications (i.e. hotels, motels, dormitories,

health clubs, residential homes, apartments, etc.).

e. Locate rough plumbing/valving according to the manufacturer’s instructions. Do not install trim at this time.

Installation

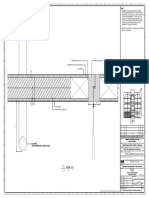

■ Make sure framed-in alcove is of proper size per LASCO dimensions, (See Chart 1. The stud opening is +¹/₈" (3mm) - 0), square, and plumb;

check floor for levelness.

■ Place pan in alcove with the front skirt firmly on the floor. The pan must be set level. To check, use a 3' (915mm) long (minimum) level on top

of the ledge on both ends of pan and on top of dam. [See Diagram 2]

■ After leveling pan, mark each stud (or concrete or block wall) immediately above the back horizontal flange. Remove pan from alcove.

■ Pre-drill and fasten flange above scribe line shown on pan. [See Diagram 2].

NOTE: Fasteners to wood framing - 1" (25mm) galvanized roofing nails or 1" (25mm) pan head screws; to steel studs - drill flanges and studs

with ³⁄₁₆" (5mm) carbide bit and fasten with #10 x 1" (25mm) sheet metal screws with washers; to concrete/block walls use 1" (25mm) concrete

nails with nailing tool or impacter. NOTE: Pre drilling flanges is required to prevent cracking of unit.

■ Apply sanitary drain assembly, per drain manufacturer’s recommendations to the pan.

■ Additional bottom support: Casting plaster/plaster of paris (herein referred as foundation materials), is mandatory for shower pans. The follow-

ing applies for foundation materials:

In a bucket, mix foundation material. Place three or four mounds of plaster on the subfloor around but away from drain hole. The mounds

should be placed high enough so that when the pan is set, it will cause the plaster to displace and spread. [See Diagram 2]

■ Place pan into alcove with front skirt firmly on floor and depress plaster mounds. Make certain that unit is level [See Diagram 2].

The pan must be set level.

a. Spot-fasten the four corners of the nailing flanges to studs above line on pan.

b. Nail fasten at each stud through the topside flanges; through back flange, at each stud (concrete; 16" (405mm) on center), working from

both ends toward back center. [See Diagram 2]

c. As an option, a large head nail may be driven into place above the tiling flange.

■ Finished Wall Coverings:

a. For cultured marble walls - Bring water resistant wall board down to the top of the flange. Apply 100% silicone sealant with mildew resist-

ant properties between the gypsum board and nailing flange. Apply cultured marble over the gypsum board to the horizontal surface of

the unit, then seal the seams of the cultured marble. [See Diagram 3, Detail A]

b. For ceramic tile with cementitious backer board – Furring strips as thick as nailing flanges are recommended above the unit. Apply con-

crete backer board to leave at least a gap of ¹/₄" between the backer board and the horizontal surface of the pan. Apply 100% silicone

with mildew resistant properties between the backer board and the horizontal surface of the unit. Apply finished wall tiles, leaving the val-

ley detail on the pan clear of all materials to allow trapped water to escape. Finishing of other trades should be done in conformance

with applicable codes and generally accepted building practices. [See Diagram 3, Detail B]

c. For ceramic tile with traditional mortar bed – Apply the waterproof membrane overlapping the flange of the unit 1" min. Apply wire over

the flange to leave a gap of ¹/₄" between the wire and the horizontal surface of the pan. Apply the mortar bed to the second step of the

pan, leaving the third step clear for tile. Apply 100% silicone with mildew resistant properties, leaving the valley detail on the pan clear of

all materials to allow trapped water to escape. Finishing of trades should be done in conformance with applicable codes and generally

accepted building practices. [See Diagram 3, Detail C]

■ Door Enclosures: Use LASCO shower door model for an engineered fit, or refer to other door manufacturer’s installation instructions.

NOTE: Where local codes specify minimum door openings, shower stalls may require swing (not sliding) doors.

■ 3232-CPAN does not carry the UPC seal and is not approved by some municipal plumbing codes due to inside dimensions. Check local

building codes.

Printed in U.S.A. 1 © 2005 LASCO Bathware

CPAN_installation 11/23/05 9:51 AM Page 2

Clean-up

CAUTION: DO NOT USE heat, or solvent based cleaning fluids

NOTE: Do not remove adhered label. Warranty/User Maintenance Label must be left for occupant. (Required by ANSI Z124)

1. To prevent staining and/or blistering: Remove all construction debris before filling product for plumbing inspection. Drain and wipe clean

immediately after the inspection process. Use sponge with warm water and liquid detergent. Do not use abrasive cleaners, such as scouring

powders or pads, steel wool, scrapers, sandpapers or anything else that may scratch, mar or dull the finish. Roofing tar or paints may be

removed with turpentine, rubbing alcohol or paint thinner (not lacquer thinner).

2. Plaster may be removed by scraping with the edge of a piece of wood or rigid plastic. Do not use a metal scraper or utensil to remove plaster

or paint from finish.

3. Dulled areas can be restored to a high gloss with white or cream-colored automotive rubbing compound, followed by application of a coat of

good quality white automotive polish (or similar) and buff with a soft cloth. Do not polish or buff on the standing or floor areas of the pan.

4. Remove minor scratches with 600 grit wet/dry sandpaper, followed by Step #3 (above).

5. Major gouges require professional repair.

User Maintenance Instructions

IMPORTANT! Use only recommended cleaners and procedures described herein. Use of other materials and methods may damage

your bath fixture and void the warranty.

■ For normal cleaning: Never use abrasive cleaners such as scouring powders or pads, steel wool, scrapers, sandpaper or anything else that

could scratch or dull the surface of your LASCO unit. Instead, use warm water and liquid detergents or non-abrasive cleansers, especially

those bathroom cleaners recommended for cleaning fiberglass.

■ To keep your LASCO bath fixture sparkling clean: Apply a coat of good quality automotive paste wax or polish and buff to a high shine with a

soft cloth or towel. Repeat every six months for easier cleaning and long lasting protection.

NOTE: DO NOT WAX floor/bottom of unit, which could result in greater risk of slipping and personal injury.

■ To restore a scratched or dull unit: Use an automotive polishing compound applied with a clean cotton rag. Rub scratches and dull areas

vigorously. Wipe off residues. Follow with automotive wax treatment described above.

■ To remove adhesive: Try 3-M Natural Cleaner, De-Solv-It® or similar materials. If residues remain, saturate a small, white, cotton rag with nail

polish remover (naphtha or acetone) and rub vigorously until the adhesive dissolves and disappears. These solvents are highly flammable and

must be used sparingly and with caution. Do not smoke or permit others to do so. Make sure all nearby heating devices (including pilot lights)

are extinguished. Do not allow solvent to go down the drain. Make sure not to contact plastic drain grates or other synthetic materials.

■ Rubber Mats: If you use a rubber "anti-skid" mat, make sure to remove it from the unit after each use to avoid harm to the surface finish.

■ Hard Water: Water in certain regions, if not wiped up after bathing/showering, may cause fading of some bath fixture colors. This is a natural

occurrence beyond LASCO's control. (See Warranty)

CAUTION: When using any cleaning or polishing materials, make sure to read and follow all package instructions carefully. Wear

rubber gloves at all times and avoid contact with eyes, skin, clothing, rugs and furnishings. Make sure all residues are rinsed

off thoroughly.

Printed in U.S.A. 2 © 2005 LASCO Bathware

CPAN_installation 11/23/05 9:51 AM Page 3

Rough-In Dimensions

OW OD OH DH RC DR/DC Fax-On-

RI Approx. Wt.

MODEL Overall Overall Overall Dam Rough- Drain Diamerter Demand

Rough-In lbs. (kg)

Width Depth Height Height Center Drian Clearance Doc. #

3232-CPAN 32" (810mm) 32" (810mm) 7¹/₁₆" (180mm) 6" (150mm) 15¹/₂" (395mm) 16" (405mm) 3¹/₄" / ³/₈" (80mm) / (10mm) 2101 21lbs. (8kg.)

3636-CPAN 36" (915mm) 36" (915mm) 7¹/₁₆" (180mm) 6" (150mm) 17¹/₂" (445mm) 18" (455mm) 3¹/₄" / ³/₈" (80mm) / (10mm) 2102 25lbs. (9kg.)

4242-CPAN 42" (1065mm) 42" (1065mm) 7¹/₁₆" (180mm) 6" (150mm) 20¹/₂" (520mm) 21" (535mm) 3¹/₄" / ³/₈" (80mm) / (10mm) 2103 33lbs. (13kg.)

4834-CPAN 48" (1220mm) 34" (865mm) 7¹/₁₆" (180mm) 6" (150mm) 16¹/₂" (420mm) 24" (610mm) 3¹/₄" / ³/₈" (80mm) / (10mm) 2104 33lbs. (13kg.)

6034-CPAN 60" (1525mm) 34" (865mm) 7¹/₁₆" (180mm) 6" (150mm) 16¹/₂" (420mm) 30" (760mm) 3¹/₄" / ³/₈" (80mm) / (10mm) 2105 38lbs. (15kg.)

Chart 1

I M P O RT A NT ! F A ST E N A B OV E L I N E

LEVEL

FRONT

TO BACK

(BOTH

SIDES) LEVEL LEFT

TO RIGHT

(BOTH

SIDES)

DR

OD RI

OW RC NAIL EXAMPLE OF

FASTENED CASTING

AT EACH PLASTER

STUD MOUND

ABOVE PATTERN

SCRIBE LINE

Diagram 1 Diagram 2

Printed in U.S.A. 3 © 2005 LASCO Bathware

CPAN_installation 11/23/05 9:51 AM Page 4

SECTION

DETAILS

A, B, C

Diagram 3

Customer Service/

Field Service/Repairs Sales Order

West Central North East Mid-Atlantic South East Customer Service/Sales Order

P.O. Box 310 40 Industrial Road 1100 Industrial Park Rd. 210 S. Harris St. Technical Services Department

Moapa, NV 89025 Conewago Industrial Park So. Boston, VA 24592 Cordele, GA 31015 C/O Skymark Tower

PH: 800-335-5151, 702-864-2100 Elizabethtown, PA 17022 PH: 800-444-0832 PH: 800-444-0926 1521 No. Cooper, Ste. 500

FAX: 800-799-2158 PH: 800-444-0781 FAX: 434-572-1794 FAX: 229-273-6838 Arlington, TX 76011

FAX: 717-367-4722 PH: 800-945-2726, 817-801-8300

FAX: 866-544-5353

North Central South West/South Central West Rocky Mtn./North West

888 W. Broadway 151 Industrial St. 3261 E. Miraloma Ave. 801 Northern Pacific

Three Rivers, MI 49093 Lancaster, TX 75134 Anaheim, CA 92806 Yelm, WA 98597

PH: 800-444-1426 PH: 800-876-3044 PH: 800-877-0464, 714-961-9735 PH: 800-444-5126

FAX: 269-273-3053 FAX: 972-227-0769 FAX: 800-328-6465 FAX: 360-458-3024

Printed in U.S.A. LAB-ID-CPAN-25M-11/05 © 2005 LASCO Bathware

Вам также может понравиться

- Always Check Your Local Building and Plumbing Code Requirements Before Starting Any Project. ThisДокумент4 страницыAlways Check Your Local Building and Plumbing Code Requirements Before Starting Any Project. ThisGiveme WhatiwantОценок пока нет

- Broodmare Assistance Purchase Program 2022Документ5 страницBroodmare Assistance Purchase Program 2022Julie JamiesonОценок пока нет

- LT32599 - 07 Fleetguard Products & Parts Technical Information Catalogue Water Filters PDFДокумент14 страницLT32599 - 07 Fleetguard Products & Parts Technical Information Catalogue Water Filters PDFRizal RaishedОценок пока нет

- MTH Sd70Mac Diesel Engine Operating Instructions: Electric TrainsДокумент36 страницMTH Sd70Mac Diesel Engine Operating Instructions: Electric TrainsBala RajuОценок пока нет

- Series Frequency Inverter: English ManualДокумент17 страницSeries Frequency Inverter: English ManualJun SantelicesОценок пока нет

- Fusion User Guide 4.1Документ166 страницFusion User Guide 4.1Ntibileng MoloiОценок пока нет

- 40420-99 GT - D - InstДокумент54 страницы40420-99 GT - D - InstLucia vicenteОценок пока нет

- Enduro Fork Seals: 36 Talas Rc2Документ23 страницыEnduro Fork Seals: 36 Talas Rc2Juan Manuel AcebedoОценок пока нет

- Ericsson WinFIOL OSS CommandsДокумент4 страницыEricsson WinFIOL OSS CommandsKash BDОценок пока нет

- Owners Manual WOC54EC0ASДокумент32 страницыOwners Manual WOC54EC0ASAlex WellmanОценок пока нет

- Wilton Drill PressДокумент20 страницWilton Drill Pressterry.defaut9764100% (1)

- MK8 SVMOD 0002 - PeripheralsДокумент48 страницMK8 SVMOD 0002 - Peripheralswillian eduardo santiago cardenasОценок пока нет

- Yanmar C50R-3CДокумент2 страницыYanmar C50R-3CYew Lim100% (1)

- SQL Account User GuideДокумент135 страницSQL Account User GuideZexie Carmelia SintiaОценок пока нет

- Expense Manager User GuideДокумент22 страницыExpense Manager User GuideStam AnОценок пока нет

- Manual Fox TalasДокумент23 страницыManual Fox TalasseantierryОценок пока нет

- Amano Pix 55 Time Clock User GuideДокумент8 страницAmano Pix 55 Time Clock User GuideMmmmmmmmm3Оценок пока нет

- Midiplus Manual Ed-9 Pro (z11) en v0.2Документ22 страницыMidiplus Manual Ed-9 Pro (z11) en v0.2Ian ChoongОценок пока нет

- HughesNet Installation Manual - AN6-074S - HN74R - RavenДокумент72 страницыHughesNet Installation Manual - AN6-074S - HN74R - RavenRamiro AgundisОценок пока нет

- Fairbanks Fb100Документ44 страницыFairbanks Fb100edefrtgОценок пока нет

- USER'S MANUAL Datalogging Option V2.0 for μ-blox GPS Receiver Modules (GPS G1-X-00011)Документ37 страницUSER'S MANUAL Datalogging Option V2.0 for μ-blox GPS Receiver Modules (GPS G1-X-00011)l4rrikin100% (1)

- Husqvarna - Drujbe PDFДокумент124 страницыHusqvarna - Drujbe PDFmsicoie1851100% (1)

- Expedition PDFДокумент376 страницExpedition PDFGary RobbinsОценок пока нет

- NMON Analyser User Guide v34Документ29 страницNMON Analyser User Guide v34Siva KumarОценок пока нет

- Dealer Technical Manual For Sea Tel Series 12 Ku-Band Broadband-At-sea Antenna SystemsДокумент496 страницDealer Technical Manual For Sea Tel Series 12 Ku-Band Broadband-At-sea Antenna SystemsGabi GabrielОценок пока нет

- Beamer User GuideДокумент130 страницBeamer User GuideAtropospОценок пока нет

- Emisora FT-757GX Technical Supplement 29 PaginasДокумент29 страницEmisora FT-757GX Technical Supplement 29 Paginasjavier_gonzalez_cid8060100% (1)

- MP6R 600x600VA Sonixs Manual - Mosca VersionДокумент184 страницыMP6R 600x600VA Sonixs Manual - Mosca VersionPablo SaavedraОценок пока нет

- STK 9310 Diagnostics User GuideДокумент206 страницSTK 9310 Diagnostics User GuidedcclancyОценок пока нет

- Lauda WK WKL ManualДокумент25 страницLauda WK WKL ManualAsistente MetrologiaОценок пока нет

- Vectrino Profiler User GuideДокумент36 страницVectrino Profiler User GuideAndresFelipePrietoAlarconОценок пока нет

- Accuriopress C3080/C3080P/C3070 Accurioprint C3070L: Quick GuideДокумент72 страницыAccuriopress C3080/C3080P/C3070 Accurioprint C3070L: Quick GuidehamiduОценок пока нет

- Bowland - BowlandX Bowler ConsoleДокумент27 страницBowland - BowlandX Bowler Consoletaner inevi100% (1)

- Hemispheregnss Pockletmax4 Userguide 875-0385-0 A1 PDFДокумент43 страницыHemispheregnss Pockletmax4 Userguide 875-0385-0 A1 PDFSergey LukinОценок пока нет

- 3850T V11Документ448 страниц3850T V11HendrickОценок пока нет

- Motor InstallationДокумент60 страницMotor InstallationhungОценок пока нет

- DS75 Folder Inserter User GuideДокумент61 страницаDS75 Folder Inserter User GuideGregОценок пока нет

- Automobilista User Guide (Basic)Документ14 страницAutomobilista User Guide (Basic)Odoru HiganbanaОценок пока нет

- User's Guide: Motorcycle Bluetooth Communication SystemДокумент60 страницUser's Guide: Motorcycle Bluetooth Communication SystemRoman Rajbhandari100% (1)

- FT 5 R2 Assembly Manual v1.45 SKR Pre ReleaseДокумент85 страницFT 5 R2 Assembly Manual v1.45 SKR Pre ReleaseredrickОценок пока нет

- PorterCable CatalogДокумент56 страницPorterCable CatalogAlejandro Antonio Alvarez BalveroОценок пока нет

- User Guide Stellarium Software PDFДокумент367 страницUser Guide Stellarium Software PDFAlfianardiwОценок пока нет

- Bullet LTE-NA Technical Manual - v1.2Документ172 страницыBullet LTE-NA Technical Manual - v1.2Dante FalconОценок пока нет

- Prison Break DuckДокумент1 страницаPrison Break Duckapi-3869362100% (1)

- Automation Interface User GuideДокумент118 страницAutomation Interface User GuideadamMonroehОценок пока нет

- ISDS205 User GuideДокумент9 страницISDS205 User GuideneneanaieОценок пока нет

- CD7416UB OR Owners ManualДокумент14 страницCD7416UB OR Owners ManualCésarОценок пока нет

- EcoTEC Installation and ServicingДокумент56 страницEcoTEC Installation and ServicingMaria Harris100% (1)

- Motorola - CM360 - User GuideДокумент56 страницMotorola - CM360 - User GuideLorenzoОценок пока нет

- PSTool - User GuideДокумент18 страницPSTool - User GuideStefanoViganóОценок пока нет

- Prominent ManualДокумент23 страницыProminent ManualCristobal Garcia GarciaОценок пока нет

- Squash Court Finish PDFДокумент5 страницSquash Court Finish PDFFrancis T. TolibasОценок пока нет

- Work Method Statemnet For Waterproofing WorkДокумент2 страницыWork Method Statemnet For Waterproofing WorkPunk GowthamanОценок пока нет

- OundingДокумент4 страницыOundingSyed Fawad Hasan100% (1)

- Installation ManualДокумент21 страницаInstallation ManualVarun H RaoОценок пока нет

- Technical Specifications MidsayapДокумент9 страницTechnical Specifications MidsayapDAP Ysabelle Marie FuentesОценок пока нет

- Septic Tank InstallationДокумент2 страницыSeptic Tank InstallationDianna LambertОценок пока нет

- Plastering Works Method StatementДокумент7 страницPlastering Works Method StatementYan Belarmino33% (6)

- Frameless Glass InstallationДокумент4 страницыFrameless Glass InstallationNita Jamnu60% (5)

- Ehs Risk RegisterДокумент4 страницыEhs Risk RegisterAhmed El SayedОценок пока нет

- Dokumen - Tips - Presentation On Industrial Training in Ultratech Cement Ratnagiri Narmada CementДокумент20 страницDokumen - Tips - Presentation On Industrial Training in Ultratech Cement Ratnagiri Narmada CementBanna bs ChouhanОценок пока нет

- Detail - C5 1: Key PlanДокумент1 страницаDetail - C5 1: Key PlanKumudu PereraОценок пока нет

- Brochure Reamers Type HДокумент5 страницBrochure Reamers Type HPatrizio MassaroОценок пока нет

- Inter Locking Bricks PresentationДокумент19 страницInter Locking Bricks PresentationSiddesh Naik100% (6)

- PR BuildingДокумент464 страницыPR Buildingmovies 123Оценок пока нет

- 11 Om Gupta Pre-Cast&FabricationДокумент11 страниц11 Om Gupta Pre-Cast&FabricationOm GuptaОценок пока нет

- Nilay Majumdar - Foundation EngineersДокумент3 страницыNilay Majumdar - Foundation EngineersPartha Pratim RoyОценок пока нет

- Modernsteel NasccissueДокумент132 страницыModernsteel NasccissueMinh Tâm TrầnОценок пока нет

- Oaa - WBSДокумент23 страницыOaa - WBSantonio angaritaОценок пока нет

- Progress Report - No. 35 DAWASA OFFGRID UP TO 1st November, 2022Документ12 страницProgress Report - No. 35 DAWASA OFFGRID UP TO 1st November, 2022tumuuОценок пока нет

- Road Work at 4.615%Документ91 страницаRoad Work at 4.615%charitha naiduОценок пока нет

- 1-Pre-Interview Candidate Blank FormДокумент1 страница1-Pre-Interview Candidate Blank Formengr.s.a.malik6424Оценок пока нет

- Brochure - Facade Cladding - Rheinzink - 2020Документ16 страницBrochure - Facade Cladding - Rheinzink - 2020Mateja Nosil MesicОценок пока нет

- Revised Quotation For Waterproofing Work To Basement, Superstructure & Terrace at MIT College, Kothrud, PuneДокумент2 страницыRevised Quotation For Waterproofing Work To Basement, Superstructure & Terrace at MIT College, Kothrud, PuneRushi Kadgaonkar50% (2)

- Fencing & Landscaping News - April 2009Документ88 страницFencing & Landscaping News - April 2009FencingNews100% (3)

- Pre-Construction Meeting Manual PDFДокумент21 страницаPre-Construction Meeting Manual PDFBambangShrОценок пока нет

- Demolition of Buildings Ib P Bc2014 039Документ7 страницDemolition of Buildings Ib P Bc2014 039Isaac MuiruriОценок пока нет

- For Information Only: Ec Type Examination CertificateДокумент5 страницFor Information Only: Ec Type Examination CertificateEmad ElazizОценок пока нет

- Method of Statement For Bus DuctДокумент11 страницMethod of Statement For Bus DuctTalha AltafОценок пока нет

- Gerab Corporate BrochureДокумент32 страницыGerab Corporate BrochureGourav SharmaОценок пока нет

- Service Information No: 981119: S Transfer Tubes With Clamped Switching ShaftДокумент2 страницыService Information No: 981119: S Transfer Tubes With Clamped Switching ShaftAndrei 26Оценок пока нет

- CA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21Документ7 страницCA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21sajanjoseОценок пока нет

- TENDER DOCUMENT InteriorДокумент61 страницаTENDER DOCUMENT InteriorScottОценок пока нет

- Ravi Kannaiyan: QC Inspection EngineerДокумент5 страницRavi Kannaiyan: QC Inspection EngineerVinoth BalaОценок пока нет

- Classified 20230709 1Документ5 страницClassified 20230709 1Qamar SikandarОценок пока нет

- Saic M 1033Документ7 страницSaic M 1033noor mohamedazeezОценок пока нет

- TITLE: Philippine Contractors Accreditation Board v. Manila WaterДокумент1 страницаTITLE: Philippine Contractors Accreditation Board v. Manila WaterGSSОценок пока нет

- DEC Infrastructure Projects India PVT LTD Sub Ledger of Depreciation 911 006714953Документ388 страницDEC Infrastructure Projects India PVT LTD Sub Ledger of Depreciation 911 006714953DEC InfraОценок пока нет

- BCA Coretrade GuidebookДокумент52 страницыBCA Coretrade GuidebookpostboxsgОценок пока нет