Академический Документы

Профессиональный Документы

Культура Документы

7 Validation of LedaFlow-public

Загружено:

Wan Ah-LunАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7 Validation of LedaFlow-public

Загружено:

Wan Ah-LunАвторское право:

Доступные форматы

Bergen

Stavanger

Haugesund

Kristiansand

Oslo

Trondheim

Drammen

Bodo

Tromso

Vadso

Validation of LedaFlow

Contractor : SINTEF

Partners: Total, ConocoPhillips and SINTEF

Commercial Partner: KOGT

Content

General Information

LedaFlow

Validation Process

Example of Current Activities

in TEP NORGE

Way Forward for LedaFlow

2

4

2002 2004 11/2010 2005

Phase I:

Proof of

Concept

Phase II:

Fully working

Engineering Tool (SET)

I&C Phase:

Model improvements

and Functionalities

TechForum Participants :

Saudi Aramco ENI - Chevron- Shell Statoil

First Commercial Release of SET

June

2011

3/2012

Industrialization and

Commercialization

2009

Extensive Validation and Testing

Customer Acceptance Testing (CAT): 01/04 30/06/2010

LedaFlow

Current capabilities and Testing

Transient analysis for:

Normal conditions

Turndown

Shutdown

Start-up

Depressurization

Line packing

Terrain slugging

Liquid surges in gas condensate

systems

Gas lift impact on flow conditions

Thermal design of flowlines

Thermodynamic Inhibitor tracking

Compositional tracking

Pigging

Converging and diverging networks

5

We tested them all!

LedaFlow

Validation Process

6

7

Validation of LedaFlow

Validation of Leda 1D

Customer Acceptance Testing (CAT) was conducted from April 1st June 30th 2010

CoP and Total R&D and ECP (CAT) focus on accuracy

COAT (Commercial Acceptance Test): KOGT focus on robustness and speed

The purpose of CAT

to assess if the LedaFlow products satisfy customer acceptance criteria and to end the Phase II

The CAT performed on a frozen version of the LedaFlow Core software (version 2.23) released on

March 31 2010. This release includes:

LedaFlow Point Model v2.23

LedaFlow Steady-State Pre-Processor v2.23

LedaFlow 1D Transient v2.23

Q3D and compositional tracking were not tested

Main Conclusion from CAT

LedaFlow results are comparable to OLGA

pressure drop, liquid holdup, temperature

LedaFlow

predictions were compared to (depending on the availability):

Experimental data

Field data

OLGA predictions (OLGA versions 5.3.1 and 5.3.2)

Continuous Testing of Leda 1D and Q3D

LedaFlow Testing Experimental data

Tests performed on Point Model (on experimental data and field

measurements)

Tiller 2j database (3105 data points) in Stavanger and Paris

Porsgrunn 2j Gas-Condensate database (84 data points)

Porsgrunn 3j Gas-Condensate-Water database (83 data points)

Porsgrunn 3j Gas-Oil-Water database (288 data points)

Porsgrunn 2j Oil-Water database (121 data points)

Downward flow 2j database (130 data points)

Tiller database error distribution analysis

Point-model predictions compared to annular flow data

Boussens database presented in the BHRG conference in Cannes 2011 (blind test)

Steady state tests performed

Inclined Pipe (3 phase, 0.078 m)

Statistical Analysis and special methodology was developed by Total to assist in

processing such large amount of data

8

Tiller loop SINTEF

LedaFlow Testing Field data and with OLGA

only

Field data (steady state and/or transient data depending on the availability)

Miranda database (Multiphase line, 41 km, 12 (Bekapai), Oil dominated, 22 km, 3 (Pecorade ), etc)

Oil dominated in west Africa (Girassol)

Multiphase transport line, gas dominated in North Sea, 22, 150 km long (Huldra to Heimdal)

Two phase gas dominated, diameter: 32, Length: 80km (Middle East Case)

Oil well in West Africa (2 phase, 7 tubing, 1700 m long, deviated) (Dalia well)

Yemen LNG on-shore, single phase, 320 km long, pigging data

Shtokman

ECP Flow Tech library containing 8 field cases (Alwyn flowline (oil), Girassol (2 and 3 phase oil), Alwyn

to Dunbar (gas cond.), Carina (gas cond.), 32 gas condensate in Australia (gas cond.)

CITEPH fiche (Moho Bilondo)

Comparisons with OLGA

when field data or experimental data were not available (comparison of

steady state and transient results such as shutdown, restart and depressurization were compared)

Egina, CLOV, Block 32 field development study, oil dominated systems

Tight gas case in Algeria, Gas-condensate field with water (3-phase simulations), Onshore / climb a

crest before junction, Focus on low flow-rates

Multiphase Gathering Network: onshore-arctic gas field

Vega Pleyade (Total Austral)

9

In addition, CoP performed testing on large amount of experimental

and field data (Ekofisk field, Alaska wells, etc)

Testing of pigging functionality

Field Overview

Pig trap area

Terminal processing

area

The field produces low pressure oil and gas, and a high pressure gas stream.

The combined production flows about 41 km to shore through a 12 line.

The last kilometer of the line, from the shore pig receiver to the terminal is a 16

line.

The Experimental Campaign

The report includes measurements from four campaigns:

- Campaign 1: steady-state measurements

- Campaign 2: transient flow rate change experiment

- Campaign 3: pigging run with a foam type pig

- Campaign 4: pigging run with a cup type pig

Campaign 3:

Measurements were made before, during and after the pigging.

Steady-state conditions at the pig launching flowrate were ensured before

pigging.

These steady-state conditions are the same as for campaign 1.

The nominal operating conditions during the measurement campaign were:

Oil flowrate 1270 Sm3/d

Gas flowrate 820000 Sm3/d

GOR 640 Sm3/Sm3

Inlet Separator Pressure 11 bara

Pig position & velocity

2h27min

Measured pig travel time

: 2h47min

OLGA

and LedaFlow

seem to have slightly over-predicted the speed of the

pig (by 20 minutes).

The predicted values by OLGA

and LedaFlow

are very close, except for a

higher peak predicted by LedaFlow

just before the pig comes out.

Inlet pressure

Predicted :

Measured :

The maximum measured value was

34.5 bara.

Both OLGA

and LedaFlow

predicted lower maximums (32.0 bara,

respectively 32.9 bara).

After the arrival of the pig, the inlet

pressure dropped below the normal

conditions for a duration of

approximately three hours. This

seems to be well captured by both

simulators.

Outlet flow rates

Liquid

OLGA 5.3.2 and LedaFlow

predicted peaks were higher and

shorter in time than the peak of

liquid that was measured.

Return to the normal flowing

conditions occurred slightly earlier in

the simulations than in the field. This

could be due to the fact that the pig

travelled faster in the simulations.

Liquid Surge (kg)

Measured 140 000

OLGA 5.3.2 255 000

LEDA 2.31 180 000

Slight delay and higher

peak predicted

Outlet flow rates

High flow

fluctuations

There is a slight delay between what was

predicted and what was measured. This

could also be due to the fact that the pig

travelled faster in the simulations.

Gas

Higher and

thinner peak

predicted

Conclusions

Both codes provide comparable results to the field measurements.

LedaFlow

and OLGA 5.3.2 give similar accuracy to field data.

LedaFlow

is able to predict liquid surges more accurately than OLGA

5.3.2

Validation References

June

2011

BHRG

Cannes

Comparison of Commercial Multiphase Flow Simulators

with Experimental and Field Databases

R. Belt, E. Duret and D. Larrey, Total EP Paris, France; Biljana

Djoric, Sophia Kalali, Stavanger Research Centre, Total EP,

Norway.

May

2011

OTC

Houston

Testing and Qualification of a New Multiphase Flow

Simulator

T. J. Danielson and K. M. Bansal, ConocoPhillips, B. Djoric

and E. Duret, TOTAL, Stein Tore Johansen and yvind

Hellan, SINTEF.

18

Complete list of the publications can be downloaded from KOGTs website

http://www.kongsberg.com/en/kogt/offerings/software/ledaflow/ledaflowpapers/

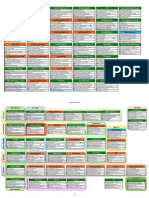

Major Advantages and Disadvantages of Leda Flow

19

OLGA

LEDA

Number of Functionalities -

Speed (Note 1) -

Robustness and Accuracy

(pressure, temperature, liquid holdup*)

Pigging Functionality

3 Energy Equation (gas, oil and water phase) -

Multi D (Note 2) -

Prediction of Instabilities (Note 3)

Slug Tracking (ST) fast and

robust but weak on slug initiation

Slower than OLGA ST but

can potentially give more

accurate predictions

Note 1 - Comparison depends on the type of case and OLGA version

Note 2 - Not validated yet, development and testing are on-going

Note 3 Difficult to compare. Slug Capturing in Leda - version is released

Example of Current Activities in TEP NORGE

20

Test pilot for Skirne on-line

system with LedaFlow

Participants: TEP NORGE

Contractor: KOGT

Stavanger Research Center in collaboration

with TEP Norge Operation Team

22

Skirne Field General Information

Scotland

Frigg

Dunbar

Heimdal

Oseberg

Tune

Huldra

Bruce

ByggveSkirne

MCP01

Vale

Alwyn

St.Fergus

Brae

Forties C

Cruden Bay

Kerse of Kinneil

Grane

Draupner

Vesterled

Statpipe

Krst

Skirne Field remotely operated

from Heimdal

120 m WD

Skirne Field Location

Block 25/5

Byggve well 16km east of Heimdal

Byggve reservoir discovered by exploration

well 25/5-4 in 1991

Skirne well 24 km east of Heimdal

Skirne reservoir discovered by exploration

well 25/5-3 in 1990

Production licence PL102

Ownership

Total E&P Norge

Statoil Petroleum

Centrica Resources Norge

Petoro

23

Skirne to Heimdal General Information

FAT was signed in week 38

SAT is scheduled in December

Extension to Atla are on-going:

real time reconciliation system

Fluid properties:

Gas Condensate field (3 phase)

MEG injection

Pipe properties:

Diameter: 12

Length: 25 km

Operating conditions:

separator pressure: 45 barg

Inlet fluid temperature: 65C

Byggve production will be replaced by Atla well

(fast track project in 2012)

Three main objectives for Skirne on-line

test pilot

Validate LedaFlow for on-line applications

Help operations in their daily work

Bring more competition to the OTS/PMS market

Atla

Byggve

Skirne

Skirne Byggve flowline

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

0 5000 10000 15000 20000 25000

X [m]

Z

[

m

]

Expansion of Skirne on-line system

The Atla field has different ownership

The well flow is not measured by MPFM

The fluids are commingled subsea. Commingled flow is measured at the outlet of the inlet separator at Heimdal.

The well flows are deduced by use of real-time flow algorithms which utilize pressure, temperature, choke opening and PVT data.

Subsea commingling - more challenging to acquire representative samples to calibrate the MPFM

The introduction of subsea multiphase flow meters often involves dedicated structures and dedicated

power/control (high cost).

Atla is the fast track project: X-tree had to be ordered on time

As a result partners have agreed that allocation should be performed by using an advanced real time flow

reconciliation system with LedaFlow.

The outcome is not only savings in both CAPEX and OPEX, but also has a positive effect on project execution

and complexity

24

Way forward for LedaFlow

25

Joint Leda Vision

Successfully establish a novel commercial multiphase flow

simulator that provides better foundation for decisions for the

global oil & gas community

Way Forward for LedaFlow

Continue Testing: 1D, functionalities, Wells, Q3D

Stavanger R&D, Paris ECP, Pau FP

Committed to continuous development

Total and CoP have committed to reinvest their royalties in R&D work for the next 10 years

Total provided a scientific support to Leda development since the begining of the project

Tail-end Activities (March 2012 - 2015) and New JIPs (March 2012 2015)

Use of SET for projects and LedaFlow for integrated systems

LedaFlow

will be included shortly in the Total list of approved software with some restirctions

Some design studies both with OLGA and Leda in parallel are currently on going (Slug distribution for

Egina for example)

Leda PM is now available/ implemented in PROII for design studies performed in ECP

Leda PM is available in PIPESIM

Additional Experiments and Field data

26

A new multiphase simulator has now been launched. The value of the additional

information from the different modelling approach can now be better judged.

Вам также может понравиться

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryОт EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryОценок пока нет

- Deepwater Sedimentary Systems: Science, Discovery, and ApplicationsОт EverandDeepwater Sedimentary Systems: Science, Discovery, and ApplicationsJon R. RotzienОценок пока нет

- Assisted History Matching for Unconventional ReservoirsОт EverandAssisted History Matching for Unconventional ReservoirsОценок пока нет

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsОт EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsОценок пока нет

- Banchmark Olga Vs LedaДокумент79 страницBanchmark Olga Vs Ledasri9987100% (1)

- Quantifying Uncertainty in Subsurface SystemsОт EverandQuantifying Uncertainty in Subsurface SystemsCéline ScheidtОценок пока нет

- An Efficient Tuning Strategy To Calibrate Cubic EOS For Compositional SimulationДокумент14 страницAn Efficient Tuning Strategy To Calibrate Cubic EOS For Compositional SimulationKARARОценок пока нет

- Tuv Nel - Evaluation of Roxar MPFM2600 Multiphase Flowmeter PDFДокумент23 страницыTuv Nel - Evaluation of Roxar MPFM2600 Multiphase Flowmeter PDFReza GhanavatiОценок пока нет

- Natural Gas Hydrates in Flow AssuranceОт EverandNatural Gas Hydrates in Flow AssuranceCarolyn Ann KohРейтинг: 5 из 5 звезд5/5 (1)

- Olga Dynamic Multiphase Flow SimulatorДокумент2 страницыOlga Dynamic Multiphase Flow SimulatorArif MokhtarОценок пока нет

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyОт EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyОценок пока нет

- Integrated Approach To Flow Assurance AnДокумент19 страницIntegrated Approach To Flow Assurance Anrezki eriyando100% (1)

- Pvtsim: The Olga 2000 Fluid Property PackageДокумент24 страницыPvtsim: The Olga 2000 Fluid Property Packagesterling100% (1)

- 2 Day Peep Class Slides - 2005Документ124 страницы2 Day Peep Class Slides - 2005warrior_2008100% (1)

- Reservoir Fluid Sampling (Lulav Saeed)Документ15 страницReservoir Fluid Sampling (Lulav Saeed)Lulav BarwaryОценок пока нет

- Print Able Olga 7 User ManualДокумент286 страницPrint Able Olga 7 User ManualAzira Nasir100% (1)

- Multiphase Flow 1995От EverandMultiphase Flow 1995A. SerizawaОценок пока нет

- SPT OLGA Drain RateДокумент69 страницSPT OLGA Drain RatecsharpplusОценок пока нет

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeОт EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeРейтинг: 4 из 5 звезд4/5 (2)

- C o U R S e N o - PENG 331 Reservoir EngineeringДокумент3 страницыC o U R S e N o - PENG 331 Reservoir Engineeringtassili17Оценок пока нет

- SPE-175877-MS EOS Tuning - Comparison Between Several Valid Approaches and New RecommendationsДокумент17 страницSPE-175877-MS EOS Tuning - Comparison Between Several Valid Approaches and New RecommendationsCamilo Benítez100% (1)

- SPE-28589 Merril and Hartman A Comparison of Equation of State Tuning MethodsДокумент16 страницSPE-28589 Merril and Hartman A Comparison of Equation of State Tuning MethodsSolenti D'nouОценок пока нет

- Choke Sizing & Propiedaes de Los FluidosДокумент149 страницChoke Sizing & Propiedaes de Los FluidosJose RojasОценок пока нет

- Application of Optimal Control Theory to Enhanced Oil RecoveryОт EverandApplication of Optimal Control Theory to Enhanced Oil RecoveryРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Flow Assurance Study: Wolfgang Böser, Stefan BelfroidДокумент13 страницFlow Assurance Study: Wolfgang Böser, Stefan BelfroidAhmed RamadanОценок пока нет

- Olga Mat LabДокумент54 страницыOlga Mat Labarun06msritОценок пока нет

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsОт EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsОценок пока нет

- 2011 What's New at CMG Event in Perth - Automated History-Matching & Optimization Using CMOSTДокумент48 страниц2011 What's New at CMG Event in Perth - Automated History-Matching & Optimization Using CMOSTtsar_philip2010Оценок пока нет

- 8 Dynamic Well SimulationsДокумент24 страницы8 Dynamic Well SimulationsBAGHFAY16Оценок пока нет

- CO2 Storage Projects in Europe Map 120919Документ10 страницCO2 Storage Projects in Europe Map 120919av1986362Оценок пока нет

- Schedule 03Документ70 страницSchedule 03Tarek HassanОценок пока нет

- Pvtsim OlgaДокумент26 страницPvtsim OlgaBehnam Hosseinzadeh100% (1)

- Olga5 UsermanualДокумент453 страницыOlga5 Usermanualdavidrrg100% (1)

- Low Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsОт EverandLow Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsОценок пока нет

- Produced Water in Oil ReservoirДокумент12 страницProduced Water in Oil ReservoirGiovanni BenvegnaОценок пока нет

- Integrated Reservoir Asset Management: Principles and Best PracticesОт EverandIntegrated Reservoir Asset Management: Principles and Best PracticesРейтинг: 4 из 5 звезд4/5 (4)

- 1 Intro To MF Hydraulics UpdДокумент38 страниц1 Intro To MF Hydraulics UpdHoang Nguyen MinhОценок пока нет

- Enrtl-Rk Rate Based PZ ModelДокумент24 страницыEnrtl-Rk Rate Based PZ ModelsamandondonОценок пока нет

- How To Build A VFP Table For ECLIPSE Forecast Simulation - 4238270 - 01Документ7 страницHow To Build A VFP Table For ECLIPSE Forecast Simulation - 4238270 - 01ToufikNechОценок пока нет

- Guidelines For Well Model and Lift TableДокумент2 страницыGuidelines For Well Model and Lift TablemkwendeОценок пока нет

- PERFORM - Nodal Analysis by ExampleДокумент2 страницыPERFORM - Nodal Analysis by ExampleAlfonso R. ReyesОценок пока нет

- Basic Cash Formulas Manual April 2009 - 2.8Документ123 страницыBasic Cash Formulas Manual April 2009 - 2.8horns2034Оценок пока нет

- Microbial Enhancement of Oil Recovery - Recent AdvancesОт EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesОценок пока нет

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceОт EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceОценок пока нет

- PvtsimДокумент12 страницPvtsimogunbiyi temitayo100% (1)

- Multiphase Flow Metering: Principles and ApplicationsОт EverandMultiphase Flow Metering: Principles and ApplicationsРейтинг: 2.5 из 5 звезд2.5/5 (2)

- Tacite UgДокумент129 страницTacite Ugarmando0212-1Оценок пока нет

- Fluid Phase Behavior for Conventional and Unconventional Oil and Gas ReservoirsОт EverandFluid Phase Behavior for Conventional and Unconventional Oil and Gas ReservoirsРейтинг: 5 из 5 звезд5/5 (2)

- Upstream Process Engineering Course: 1. Hydrocarbon Phase BehaviourДокумент43 страницыUpstream Process Engineering Course: 1. Hydrocarbon Phase BehaviourMohamed Ali100% (1)

- PVTi REFERENCE MANUAL PDFДокумент448 страницPVTi REFERENCE MANUAL PDFJesse100% (1)

- OLGA For Wells Papers - 2012Документ7 страницOLGA For Wells Papers - 2012Ramdhan Ari Wibawa100% (1)

- Lectures On Well Testing 1AДокумент37 страницLectures On Well Testing 1APatrick KariukiОценок пока нет

- Entrepreneurial Investing Pre Release PDFДокумент180 страницEntrepreneurial Investing Pre Release PDFWan Ah-LunОценок пока нет

- 55194HMPPSplashzoneWhitepaper.5d8cbbf884bccДокумент3 страницы55194HMPPSplashzoneWhitepaper.5d8cbbf884bccWan Ah-LunОценок пока нет

- Developers Guide To Small Scale LNG Terminal PDFДокумент36 страницDevelopers Guide To Small Scale LNG Terminal PDFWan Ah-Lun100% (1)

- 0362-RT-0002-R2 Aviation Fuel Pipeline - Design Basis 29-01-15 PDFДокумент18 страниц0362-RT-0002-R2 Aviation Fuel Pipeline - Design Basis 29-01-15 PDFWan Ah-LunОценок пока нет

- Abbbdgget 155667Документ15 страницAbbbdgget 155667Wan Ah-LunОценок пока нет

- Whatever Is Updated and RevisedДокумент14 страницWhatever Is Updated and RevisedWan Ah-LunОценок пока нет

- NEvereverever PDFДокумент15 страницNEvereverever PDFWan Ah-LunОценок пока нет

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHДокумент28 страницInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunОценок пока нет

- Pipeline Buckling Caused by Axial Loads PDFДокумент9 страницPipeline Buckling Caused by Axial Loads PDFWan Ah-LunОценок пока нет

- Sompo - Authorised WorkshopsДокумент2 страницыSompo - Authorised WorkshopsWan Ah-LunОценок пока нет

- List of Training Organisations Suspended From SSG Funding 20171226 IBSD V01FinalДокумент2 страницыList of Training Organisations Suspended From SSG Funding 20171226 IBSD V01FinalWan Ah-LunОценок пока нет

- Ta200 Owner ManualДокумент54 страницыTa200 Owner ManualWan Ah-LunОценок пока нет

- Gases AnswersДокумент8 страницGases AnswersSayОценок пока нет

- FaienceДокумент15 страницFaienceRenata TatomirОценок пока нет

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsДокумент36 страницEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- HILTI ExBar Rebar Design Soft WareДокумент30 страницHILTI ExBar Rebar Design Soft WareAline Tabet Abi SaadОценок пока нет

- Henderson PDFДокумент4 страницыHenderson PDFtary_nuryanaОценок пока нет

- TankJet 65 Tank Cleaning CatalogДокумент2 страницыTankJet 65 Tank Cleaning Catalogvalerian1988Оценок пока нет

- University Malaya: KKEK 3156 Plant EngineeringДокумент10 страницUniversity Malaya: KKEK 3156 Plant EngineeringJoeОценок пока нет

- 2.Pv Semisolid FDAДокумент37 страниц2.Pv Semisolid FDARahayu Maulida RОценок пока нет

- BTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Документ8 страницBTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Akshat GargОценок пока нет

- XII PhysicsДокумент55 страницXII PhysicsCharu BhanotОценок пока нет

- Chemical Bonding ModuleДокумент35 страницChemical Bonding ModuleMark Paul Lipata Benitez100% (2)

- AlloysДокумент4 страницыAlloyslinguy007Оценок пока нет

- Amylose Content in PotatoesДокумент5 страницAmylose Content in PotatoesChinkee Illanza LimОценок пока нет

- Doc316 53 01223Документ6 страницDoc316 53 01223Abdul GhafoorОценок пока нет

- Hydrothermal Biomass GasificationДокумент9 страницHydrothermal Biomass GasificationCevdet demirtaşОценок пока нет

- OuchterlonyДокумент4 страницыOuchterlonyd_caasi100% (1)

- Astm C 171-07Документ2 страницыAstm C 171-07jun floresОценок пока нет

- Effect of Carrageenan Concentration On The Physicochemical and Sensory Properties of Papaya Jelly DrinkДокумент6 страницEffect of Carrageenan Concentration On The Physicochemical and Sensory Properties of Papaya Jelly DrinkrinrinmaudyОценок пока нет

- 5990 7413enДокумент20 страниц5990 7413enG_ASantosОценок пока нет

- Limnologica: Wojciech Ejankowski, Tomasz LenardДокумент8 страницLimnologica: Wojciech Ejankowski, Tomasz LenardMoltimer Folchart CrawОценок пока нет

- Proceedings of ICBC 2019Документ499 страницProceedings of ICBC 2019Mohanraj TОценок пока нет

- HPTLCДокумент46 страницHPTLCVedha K Chalam100% (1)

- Analytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaДокумент12 страницAnalytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaAzhan HassanОценок пока нет

- Concrete ExamДокумент26 страницConcrete ExamKyra AlesonОценок пока нет

- 99ebook Com Msg00388 PDFДокумент15 страниц99ebook Com Msg00388 PDFM Sarmad KhanОценок пока нет

- SPE-10489-PA PVT y Scal PDFДокумент9 страницSPE-10489-PA PVT y Scal PDF'Andres TorregrosaОценок пока нет

- Chemguard c333 Ar-Afff 3% MsdsДокумент7 страницChemguard c333 Ar-Afff 3% MsdsrendydunОценок пока нет

- DEGASSING AGENT AF 100 - Ind1 - AngДокумент1 страницаDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- Industrial Microbiology Lec 10Документ41 страницаIndustrial Microbiology Lec 10Louella ArtatesОценок пока нет