Академический Документы

Профессиональный Документы

Культура Документы

CH 22

Загружено:

ProfNDAcharya0 оценок0% нашли этот документ полезным (0 голосов)

32 просмотров5 страницProject Profiles For Small Enterprises - Mechanical Products

Оригинальное название

ch22

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документProject Profiles For Small Enterprises - Mechanical Products

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

32 просмотров5 страницCH 22

Загружено:

ProfNDAcharyaProject Profiles For Small Enterprises - Mechanical Products

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

INTRODUCTION

There are many types of Watch

Straps, made of Leather, Nylon, Stainless

Steel and Brass etc. Watch straps are

made in various designs including

ornamental one, being used by the

public now a days. In this Project Profile,

it is intended to manufacture stainless

steel watch straps out of stainless steel

sheet scrap and wire. Since the scrap

of required gauge is easily available from

the manufacturers of stainless steel

utensils, it is comparatively more

profitable than manufacturing these

items out of virgin stainless steel sheets

or coil.

MARKET POTENTIAL

Wrist watch has become necessity for

the present day life of human beings. It

is being used by people from all walks

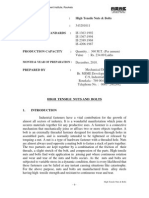

Watch Strap Metallic

PRODUCT CODE : 349906009

QUALITY AND STANDARDS : Buyers/Manufacturers own specifications

PRODUCTION CAPACITY : Qty. : 30,000 Nos. (per annum)

Value : Rs. 13,44,000

MONTH AND YEAR : April, 2003

OF PREPARATION

PREPARED BY : Small Industries Service Institute

22, Godown, Industrial Estate,

Jaipur-302006

(Rajasthan).

Phone Nos.: 212098, 213099

Fax No. : 0141-210553

E-mail: sisijpr@sancharnet.in

of life, male, female, educated,

uneducated, young and old etc. Watch

strap being an integral part of wrist

watch, it has a good market for supply

to meet original demand and in the

replacement market. Apart from the

large scale wrist watch manufacturers,

such as Titan, HMT, Maxima, Allwyn,

Timex etc., a good number of small

scale units in many States have also

come up with their phased production

programme for wrist watches. The

demand for the production of the item

is therefore likely to increase rapidly in

near future. Further, due to durability

of the product it is preferred over all

other types of straps.

Moreover, due to fast changes in the

design and liking of people, there is good

replacement prospects for the product

as well. Therefore, there is a good and

assured future for the product.

22

113

BASIS AND PRESUMPTIONS

(i) This report is worked out on 75%

capacity utilization, on single

shift and 300 working days per

year.

(ii) The machinery and equipment

are of standard make.

(iii) The cost of raw materials and

other expenditure is approximate

and based on current market

rates.

(iv) The period for achieving

envisaged capacity utilization

estimated to be one year after

commencement of trial production.

(v) Interest rate for fixed and working

capital has been calculated at

16% per annum.

(vi) Pay back period would

commence after a period of 12

months and the repayment period

is estimated as 3 years.

IMPLEMENTATION SCHEDULE

1. The entrepreneur has to arrive at

a decision in order to select this

product. The guiding factor in this

regard would be the market

potential, demand and supply

gap and availability of resources.

It may take 2 to 3 weeks.

2. After selecting the product, the

entrepreneur has to get

provisional registration from DIC,

so that he can apply for allotment

of land, power, etc.

3. In order to obtain financial

assistance from the financial

Institutions like Commercial

Banks or State Financial

Corporations, a detailed project

report is required to be prepared.

On the basi s of the report

financial Institutions may take 8

to 10 weeks time for sanctioning

and di sbursi ng the l oan.

Accordingly, orders for plant and

machinery may be finalized and

placed. Simultaneously, orders

for purchase of raw materials are

al so to be fi nal i zed and

recruitment of key staff is to be

done. This would require 3 to 4

weeks.

4. The pl ant and machi nery

received may be installed and

commissioned within 4 to 6

weeks time and the Workshop

staff should also be recruited.

The producti on may be

commenced after trial run of the

installed plant and machinery.

TECHNICAL ASPECTS

Process of Manufacture

The Metallic Watch Straps consist of

7 to 8 components according to its

design. These components are made by

balaking, piercing, and binding as per

the requirements, and then these

components are sent for assembly to

form a chain. These chain pieces are

grounded to size on a surface grinder.

Mat finish on the straps can also be

given by using surface grinder. After

mating, straps may be polished on a

buffing lathe. Links, locks and barrels

are fitted to these pieces with the help

of spring loaded pins. Then these

assembled straps are cleaned in

kerosene oil to remove the luster

particles. Finally, the final buffing is

done to give polishing touch on straps.

These straps are packed suitably and

marketed.

WATCH STRAP METALLIC

114

Quality Control and Standards

Most of the watch manufacturers like

Titan, HMT, Alwyn, Maxima, Timex etc.,

have formulated their own specifications

and design for this product, and these

may be obtained from them for supply

to them. However, in view of

sophistication and individual liking the

appearance of the straps must be good

and have free link movement and

reliable locking system along with

appropriate polish.

Production Capacity (per annum)

Quantity 30,000 nos.

Value Rs. 13,44,000

Motive Power 15 HP.

Pollution Control

The activity does not create any

pollution. However, proper ventilation is

provided for safe working conditions.

Energy Conservation

General awareness is required for

energy conservation.

FINANCIAL ASPECTS

A. Fixed Capital

(i) Land and Building (In Rs.)

400 sq. meter (rented) 4,500

(ii) Machinery and Equipment

Sl. Description Ind/ Qty. Rate Total

No. Imp Nos. (Rs.) (In Rs.)

1. Inclinable Ind. 1 35,000 35,000

Power Press

10 Tonnes with

5 HP Motor

2. Power Press -do- 2 20,000 40,000

with 2 HP Motor

3. Bench Drill -do- 1 4,000 4,000

12 mm cap.

Sl. Description Ind/ Qty. Rate Total

No. Imp Nos. (Rs.) (In Rs.)

With 0.5 HP

motor.

4. Buffing lathe -do- 1 8,000 8,000

with 1 HP Motor.

5. Disc and Belt -do- 1 8,000 8,000

sand grinding

Machine,

1200 mm x

150 mm with

endless belt,

titling type table

and with 0.5

HP motor.

6. Pedestal -do- 1 4,000 4,000

grinder 200

mm wheel dia.

with 0.5 HP

motor.

7. Surface grinder, -do- 1 50,000 50,000

table size 550

mm x 200 mm

with 1 HP motor.

8. Work bench, -do- L.S. - 30,000

Vice, Hand tools,

Dies, Punches,

Measuring

tools etc.

9. Installation - - - 17,900

and Electrification

@ 10% of the

cost of Machines

10. Office furniture - - - 15,000

and equipments.

(iii)Pre-operative - - - 5,000

Expenses

Total 2,16,900

Say 2,17,000

B. Working Capital (per month)

(i) Personnel

Sl. Designation Nos. Salary Amount

No. (Rs.) (In Rs.)

1. Manager 1 4,000 4,000

2. Supervisor-Cum- 1 3,000 3,000

Inspector

3. Skilled Workers 4 2,500 10,000

4. Un-Skilled Workers 4 2,000 8,000

WATCH STRAP METALLIC

115

C. Total Capital Investment

(i) Fixed Capital Rs. 2,17,000

(ii) Working Capital (for 3 months) Rs. 2,48,000

Total Rs. 4,65,000

FINANCIAL ANALYSIS

(1) Cost of Production (per year) (In Rs.)

Recurring Expenditure 9,92,000

Depreciation on Machinery and

Equipments @ 10% 17,900

Depreciation on Office Furniture @ 20% 3,000

Interest on total capital investment @16% 74,400

Total 10,87,300

Say 10,87,000

(2) Turnover (per year)

Sl. Item Qty. Rate Total

No. (Rs.) (In Rs.)

1. Stainless Steel 30000 44 13,20,000

Watch Straps Nos. each

2. Sale of Scrap 2 MT 12000 24,000

Total 13,44,000

(3) Net Profit (per year) (Before Taxation)

Profit = Turnover - Cost of Production

= Rs. 13,44,000 - 10,87,000

= Rs. 2,57,000

(4) Net Profit Ratio

=

Net Profit per year 100

Turnover per year

=

257000 100

1344000

= 19.12%

(5) Rate of Return

=

Net Profit per year 100

Total Capital Investment

=

257000 100

4,65,000

= 55.26%

WATCH STRAP METALLIC

Sl. Designation Nos. Salary Amount

No. (Rs.) (In Rs.)

5. Clerk-cum-Accountant 1 2,500 2,500

6. Peon 1 2,000 2,000

7. Chowkidar/Watchman 1 2,000 2,000

Total 31,500

Additional perquisites @ 15% 4,725

Total 36,225

Say 36,200

(ii) Raw Materials

Sl. Description Qty. Rate Amount

No. (Rs.) (In Rs.)

1. Stainless Steel/Scrap 0.9 34,000 30,600

16/20/26/28/30 MT

SWG

2. Spring Bars and Link 108 40 4,320

Bars

3. Packaging Material L.S. - 1,080

Total 36,000

(iii) Utilities (In Rs.)

Electric Power @ 4 per unit 2,500

Water Charges L.S. 350

Total 2,850

(iv) Other Contingent Expenses (Rs.)

Rent 4,500

Transport and Cartage Charges 500

Postage and Stationery 300

Telephone 1,000

Publicity 300

Insurance/Taxes 100

Repair and Maintenance 400

Miscellaneous Expenses 500

Total 7,600

(v) Total Recurring Expenditure (per month)

[(i) + (ii) + (iii) + (iv)] = Rs. 82,650

(vi) Total Working Capital for 3 Months

3 82650 = Rs. 2,47,950

Say 2,48,000

116

(6) Break-even Point

Fixed Cost (In Rs.)

Rent 54,000

Depreciation on Machinery 17,900

Depreciation on office furniture 3,000

Interest on total capital investment 74,400

40% of Salary and Wages 1,73,760

40% of other contingent expenses 14,880

(excluding rent)

Total 3,37,940

Say 3,38,000

B.E.P.

=

Fixed Cost 100

Fixed Cost + Profit

=

338000 100

338000 + 257000

=

338000 100

595000

= 56.8%

Addresses of Machinery Equipment

Suppliers

1. M/s. SARB Presses Pvt. Ltd.

P. No. 52, Sector24,

Faridabad-121001 (Haryana)

2. M/s. Gurusharan Industries

920, New Colony,

Opp. Railway Station (Old),

Faridabad121001 (Haryana).

3. M/s. Lefoot Machines Pvt. Ltd.

110 (N.P.), SIDCO Industrial

Estate, Ambattur,

Chennai - 98.

4. M/s. Imperial Products of India

414A, Industrial Area - II,

Chandigarh - 160002.

5. M/s. Atlas Works Pvt. Ltd.

S. No. 119,

Ribbon Street,

Kolkata.

6. M/s. International Machine Tools

Corporation

5 Bank Street,

P.O. Box No. 799,

Behind State Bank,

Fort, Mumbai - 400023.

Raw Materials Available in the Local

Market.

WATCH STRAP METALLIC

Вам также может понравиться

- Engineering Applications: A Project Resource BookОт EverandEngineering Applications: A Project Resource BookРейтинг: 2.5 из 5 звезд2.5/5 (1)

- Ice Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiДокумент9 страницIce Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiBunty RathoreОценок пока нет

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningОт EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningОценок пока нет

- CH 25Документ19 страницCH 25Shanawar AzamОценок пока нет

- Industrial Machinery World Summary: Market Values & Financials by CountryОт EverandIndustrial Machinery World Summary: Market Values & Financials by CountryОценок пока нет

- Design Handbook MAchine DesignДокумент5 страницDesign Handbook MAchine DesignsouravОценок пока нет

- Takt Time: A Guide to the Very Basic Lean CalculationОт EverandTakt Time: A Guide to the Very Basic Lean CalculationРейтинг: 5 из 5 звезд5/5 (2)

- Project of Rexin BagДокумент11 страницProject of Rexin BagShayan Pitruja100% (1)

- Hand Gloves Project EportДокумент4 страницыHand Gloves Project Eportktgururaj0% (1)

- Gents T-Shirts: NtroductionДокумент8 страницGents T-Shirts: Ntroductionharish_kavetiОценок пока нет

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- A Project Profile On Saddlery & Harness: Dcdi-Agra@dcmsme - Gov.inДокумент8 страницA Project Profile On Saddlery & Harness: Dcdi-Agra@dcmsme - Gov.inroufzargarОценок пока нет

- Automotive Chain Motorcycle ChainДокумент6 страницAutomotive Chain Motorcycle ChainAshish KumarОценок пока нет

- Project Profile - Magnetic ButtonsДокумент7 страницProject Profile - Magnetic ButtonsSai PrashanthОценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Almirah Enterprenuership Project 2Документ11 страницAlmirah Enterprenuership Project 2Debadatta Ratha50% (6)

- CH 21Документ5 страницCH 21Kader Kunju RizwanОценок пока нет

- Hacksaw BladeДокумент12 страницHacksaw BladeShankar GОценок пока нет

- Shuttle CockДокумент5 страницShuttle Cockpradip_kumarОценок пока нет

- Fastener ProjectДокумент10 страницFastener ProjectParam Saxena0% (1)

- Portfolio BagДокумент5 страницPortfolio Bagpradip_kumarОценок пока нет

- Project Profile - LAP TOP BAGДокумент8 страницProject Profile - LAP TOP BAGAjay PrajapatiОценок пока нет

- Project Profile On Gent's ShirtsДокумент12 страницProject Profile On Gent's ShirtsNidhin ChandranОценок пока нет

- ch22 PDFДокумент5 страницch22 PDFSumeet Singh KohliОценок пока нет

- CH 22Документ5 страницCH 22alkaОценок пока нет

- Men's Readymade GarmentsДокумент5 страницMen's Readymade Garmentsmorshed.mahamudОценок пока нет

- Bolt Nuts MFG ProcessДокумент5 страницBolt Nuts MFG ProcessscribddaduОценок пока нет

- Ajustable Hospital Beds PsДокумент11 страницAjustable Hospital Beds PsManish PoddarОценок пока нет

- Gent Shirt and Trouser UnitsДокумент10 страницGent Shirt and Trouser Unitsmurali muraliОценок пока нет

- High Tensile Nuts BoltsДокумент10 страницHigh Tensile Nuts BoltssagarhalappaОценок пока нет

- Disposable SyringeДокумент5 страницDisposable SyringePrabhu KoppalОценок пока нет

- Project Profile On Repair & Servicing of Electrical AppДокумент11 страницProject Profile On Repair & Servicing of Electrical AppKavi RehabianОценок пока нет

- Ready Made GarmentsДокумент8 страницReady Made Garmentsarmk_0073141Оценок пока нет

- Msme-Development INSTITUTE, 107, Industrial: Estate, Kanpur - 208012Документ10 страницMsme-Development INSTITUTE, 107, Industrial: Estate, Kanpur - 208012Sethu SparkОценок пока нет

- Auto Pistons: NtroductionДокумент5 страницAuto Pistons: NtroductionProfNDAcharyaОценок пока нет

- PVC Bag Making Unit (Hdpe)Документ12 страницPVC Bag Making Unit (Hdpe)Golden Shower தமிழ்Оценок пока нет

- Detailed Project Report On Clock and Watch Unit: Project Management Assignment Group No: 9Документ18 страницDetailed Project Report On Clock and Watch Unit: Project Management Assignment Group No: 9James IshakuОценок пока нет

- Investment Casting CalculationsДокумент7 страницInvestment Casting CalculationsRawendrraw KuriОценок пока нет

- Plaster of ParisДокумент5 страницPlaster of ParisAniket Salvi100% (1)

- CH 21Документ5 страницCH 21ProfNDAcharyaОценок пока нет

- Auto Leaf SpringДокумент11 страницAuto Leaf SpringVijayKrishnaAmaraneniОценок пока нет

- MSME Project ReportДокумент8 страницMSME Project Reportchaudhary1604Оценок пока нет

- Project Profile On Leather ShoesДокумент5 страницProject Profile On Leather ShoesSadrul Jamil100% (1)

- Leather BeltДокумент4 страницыLeather Beltpradip_kumarОценок пока нет

- Cement Concrete Tiles and Paving Blocks: NtroductionДокумент6 страницCement Concrete Tiles and Paving Blocks: NtroductionKeyur GajjarОценок пока нет

- Monolithic RefractoriesДокумент11 страницMonolithic RefractoriesZafr Cetn100% (1)

- Full PVC FootwearДокумент5 страницFull PVC Footwearpradip_kumarОценок пока нет

- Mech - Piston Ring - Sunil PDFДокумент7 страницMech - Piston Ring - Sunil PDFBrahmpal BhardwajОценок пока нет

- Presentation On Tennis Balls ManufacturingДокумент8 страницPresentation On Tennis Balls Manufacturingadiall4uОценок пока нет

- Bleaching and Dyeing of Cotton Knitted Fabric: NtroductionДокумент5 страницBleaching and Dyeing of Cotton Knitted Fabric: NtroductionPRATEEKMAHAJAN02Оценок пока нет

- Manufacture of Shirt (Top) and Skirts: Ntroduction Arket OtentialДокумент5 страницManufacture of Shirt (Top) and Skirts: Ntroduction Arket OtentialAnurag PalОценок пока нет

- Ms High Tensile Nuts and BoltsДокумент11 страницMs High Tensile Nuts and Boltsmax_ashi100% (1)

- Cotton Knitted Undergarments (Briefs, Panties, Vests) : 1. Procurement of Knitted FabricДокумент6 страницCotton Knitted Undergarments (Briefs, Panties, Vests) : 1. Procurement of Knitted FabricPaka ManojОценок пока нет

- Electronic Weighing ScaleДокумент17 страницElectronic Weighing ScaleVicky KaloniaОценок пока нет

- Gentsshirtsandtrousers PDFДокумент12 страницGentsshirtsandtrousers PDFwwwaqarОценок пока нет

- Offset Printing Press (Job Work) : NtroductionДокумент4 страницыOffset Printing Press (Job Work) : NtroductionMMjagpreetОценок пока нет

- Public Health Engineering Organization: Tender Document For The WorkДокумент27 страницPublic Health Engineering Organization: Tender Document For The WorkProfNDAcharyaОценок пока нет

- Is 6531 1994Документ16 страницIs 6531 1994ProfNDAcharyaОценок пока нет

- Hydraulic Structures - 2Документ34 страницыHydraulic Structures - 2Manmohit SinghОценок пока нет

- Hydraulic Structures - Course WebsiteДокумент10 страницHydraulic Structures - Course WebsiteProfNDAcharyaОценок пока нет

- 2012 CE404 Quiz 1 Solution QДокумент5 страниц2012 CE404 Quiz 1 Solution QProfNDAcharyaОценок пока нет

- Gujarat Technological University (Established Under Gujarat Act No. 20 of 2007)Документ1 страницаGujarat Technological University (Established Under Gujarat Act No. 20 of 2007)ProfNDAcharyaОценок пока нет

- Diversion Headworks: CEL351: Design of Hydraulic StructuresДокумент78 страницDiversion Headworks: CEL351: Design of Hydraulic StructuresAlvaro Rodrigo Chavez Viveros100% (1)

- Irrigation Structures - 1Документ13 страницIrrigation Structures - 1lakumas15Оценок пока нет

- 2.2 2.3 Hydraulic and Structure DesignДокумент144 страницы2.2 2.3 Hydraulic and Structure DesignSriram Nambi100% (1)

- Project Profiles For Small Enterprises - Mechanical Products-ForewardДокумент2 страницыProject Profiles For Small Enterprises - Mechanical Products-ForewardProfNDAcharyaОценок пока нет

- Barrages PresentationДокумент109 страницBarrages PresentationFaisal RashidОценок пока нет

- Project Profiles For Small Enterprises - Mechanical Products PDFДокумент2 страницыProject Profiles For Small Enterprises - Mechanical Products PDFProfNDAcharyaОценок пока нет

- 0838 Bhavnagar Port 2Документ1 страница0838 Bhavnagar Port 2ProfNDAcharyaОценок пока нет

- Project Profiles For Small Enterprises - Mechanical Products-Ch24Документ4 страницыProject Profiles For Small Enterprises - Mechanical Products-Ch24ProfNDAcharyaОценок пока нет

- CH 17Документ7 страницCH 17ProfNDAcharyaОценок пока нет

- Project Profiles For Small Enterprises - Mechanical Products-Ch25Документ6 страницProject Profiles For Small Enterprises - Mechanical Products-Ch25ProfNDAcharyaОценок пока нет

- CH 21Документ5 страницCH 21ProfNDAcharyaОценок пока нет

- CH 20Документ5 страницCH 20ProfNDAcharyaОценок пока нет

- Domestic Pressure Cookers: NtroductionДокумент5 страницDomestic Pressure Cookers: NtroductionKumar PhanishwarОценок пока нет

- Project Profiles For Small Enterprises - Mechanical Products-Ch23Документ4 страницыProject Profiles For Small Enterprises - Mechanical Products-Ch23ProfNDAcharyaОценок пока нет

- Offset Printing Press (Job Work) : NtroductionДокумент4 страницыOffset Printing Press (Job Work) : NtroductionMMjagpreetОценок пока нет

- CH 16Документ4 страницыCH 16ProfNDAcharyaОценок пока нет

- Bolt Nuts MFG ProcessДокумент5 страницBolt Nuts MFG ProcessscribddaduОценок пока нет

- CH 15Документ4 страницыCH 15ProfNDAcharyaОценок пока нет

- CH 11Документ7 страницCH 11ProfNDAcharyaОценок пока нет

- CH 10Документ5 страницCH 10ProfNDAcharyaОценок пока нет

- CH 12Документ4 страницыCH 12Vijay KiranОценок пока нет

- CH 13Документ6 страницCH 13ProfNDAcharyaОценок пока нет

- CH 9Документ5 страницCH 9ProfNDAcharyaОценок пока нет

- Lecture 2Документ30 страницLecture 2hayelomОценок пока нет

- Oracle INV Setups 0411Документ72 страницыOracle INV Setups 0411PraWinОценок пока нет

- Tanker BodyДокумент5 страницTanker BodyAghil BuddyОценок пока нет

- Powder Metallurgy SintekДокумент4 страницыPowder Metallurgy SintekKatina PrattОценок пока нет

- Daimlerfinalpresentationpdf 111122092224 Phpapp02Документ39 страницDaimlerfinalpresentationpdf 111122092224 Phpapp02Marius CiuculanОценок пока нет

- Astm A514 1977Документ6 страницAstm A514 1977Elumalai Srinivasan100% (1)

- RivetingДокумент7 страницRivetingAhmadFaisalОценок пока нет

- Foundry Manual - Part 3Документ49 страницFoundry Manual - Part 3Khin Aung ShweОценок пока нет

- SikaDur 53Документ2 страницыSikaDur 53pnОценок пока нет

- API Standards For Safe Offshore Operations BrochureДокумент1 страницаAPI Standards For Safe Offshore Operations BrochureAnonymous 70lCzDJvОценок пока нет

- KAMCOДокумент16 страницKAMCOArun Krishnan100% (1)

- Logistics and Supply Chain ManagementДокумент2 страницыLogistics and Supply Chain ManagementDr. Iqbal Ahmad HakimОценок пока нет

- Chapter 1Документ94 страницыChapter 1rethinamkОценок пока нет

- Metal FormingДокумент33 страницыMetal FormingSamir KhОценок пока нет

- Project Report On Logistic System in DHLДокумент57 страницProject Report On Logistic System in DHLManas Khanna77% (13)

- PWHTДокумент79 страницPWHTnguyenОценок пока нет

- HARDOX - OznakebДокумент24 страницыHARDOX - OznakebPuđa TomicaОценок пока нет

- Top 25 Lean ToolsДокумент2 страницыTop 25 Lean ToolsAnonymous dv2IR074100% (1)

- Reflo Brochure LUB2377EДокумент8 страницReflo Brochure LUB2377EEber.CVОценок пока нет

- Resume ManiДокумент3 страницыResume ManiMANIKANDARAJAgОценок пока нет

- Classification of AggregatesДокумент3 страницыClassification of Aggregatespaddy11234Оценок пока нет

- Westerman TableДокумент86 страницWesterman TableDipak88% (17)

- Los Grandes Problemas NacionalesДокумент409 страницLos Grandes Problemas NacionalesRamses Arturo ArenasОценок пока нет

- Stronger, Faster: by Mar Tin S. McgovernДокумент3 страницыStronger, Faster: by Mar Tin S. McgovernVijay KumarОценок пока нет

- Form Ability Od A8011 Aluminium Alloy SheetДокумент6 страницForm Ability Od A8011 Aluminium Alloy SheetwojciechsciezorОценок пока нет

- Master Production ScheduleДокумент9 страницMaster Production ScheduleglamboyzОценок пока нет

- Supply Chain Frameworks For The Service Industry: A Review of The LiteratureДокумент13 страницSupply Chain Frameworks For The Service Industry: A Review of The LiteratureSa Be MirОценок пока нет

- Influence of Surface Finish On Cavitation ErosionДокумент9 страницInfluence of Surface Finish On Cavitation ErosionJason BarrentineОценок пока нет

- CV Tauarai CVДокумент5 страницCV Tauarai CVgeorgiaОценок пока нет

- Black Knight 1000 BrochureДокумент2 страницыBlack Knight 1000 BrochureAdamMitchellОценок пока нет