Академический Документы

Профессиональный Документы

Культура Документы

CNCTS08 320

Загружено:

ג'ון ירוקАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CNCTS08 320

Загружено:

ג'ון ירוקАвторское право:

Доступные форматы

320

T

a

p

T

e

c

h

n

i

c

a

l

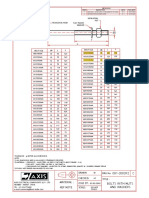

Taps: ISO Metric Screw Threads

Tolerance Position e

(large Allowance)

Tolerance Position g

(Small Allowance)

Tolerance Position h

(No Allowance)

Tolerance Position G

(Small Allowance)

Tolerance Position H

(No Allowance)

Internal Thread (Nuts) External Thread (Bolts)

ISO TOLERANCE SYSTEM

PREFERRED TOLERANCE CLASSES

Quality

Requirement

Length of Thread Engagement Length of Thread Engagement Length of Thread Engagement Length of Thread Engagement Length of Thread Engagement

Short Normal Long Short Normal Long Short Normal Long Short Normal Long Short

FINE

Close Fit

Applications

MEDIUM

General Purpose

Applications

COARSE

Difficult

Manufacturing

Applications

5g-6g 6g

8g

7g-6g

9g-8g

3h-4h

5h-6h

4h

6h

5h-4h

7h-6h 5G 6G

7G

7G

8G

4H

5H 6e 7e-6e

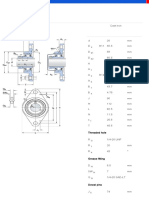

The ISO Metric Screw Thread Tolerance System provides for tolerance grades and tolerance positions (allowances) for the pitch diameter

and crest diameter

TOLERANCE GRADES

A series of numbers, 3 through 9, were established as

symbols, to reflect the size of the tolerance; the higher

the number the larger the tolerance.

FOR EXTERNAL THREADS

(lower case letter symbols)

Tolerance Position "e" has a large allowance. The upper limit is below basic by a large amount.

Tolerance Position "g" has a small allowance. The upper limit is below basic by a small amount.

Tolerance Position "h" has no allowance and the upper limit is basic.

FOR INTERNAL THREADS

(capital letter symbols)

Tolerance Position "G" has a small allowance. The lower limit is above basic by a small amount.

Tolerance Position "H" has no allowance and the lower limit is basic.

SELECTION OF TOLERANCE CLASSES

Two factors determine the selection of a suitable tolerance class:

1. Length of thread engagement (short, normal or long)

2. Quality requirement (fine, medium or coarse) See table below for preferred tolerance classes

NOTE: Tolerance Position "e" is not to be applied to pitches finer than 0.5 mm. Tolerance classes 6g and 6H are for commercial screw, bolt and nut threads.

Basic Designations: The letter "M" and the nominal size (basic major

diameter in millimeters) followed by "X" and the pitch in millimeters,

designates metric screw threads. For coarse series thread, the "X" and

pitch may be omitted.

Example: Coarse series threads; M6

other threads; M8 x 1

A complete designation comprises, in addition to the basic designation, the tolerance

class symbol separated by a dash. When the pitch and crest

diameter tolerance classes are identical, the symbol need only be given once.

Example: M20 x 26H

TOLERANCE POSITIONS

They define the maximum-material limits of the pitch and crest diam-

eters and indicate their relationship to the basic profile. For plating

requirements and ease of assembly, a series of tolerance positions

were established.

When the pitch and crest diameters have different tolerance classes, the pitch

diameter symbol is followed by the crest diameter symbol.

Example: M6 x 0.755g6g

To indicate a specified thread fit between mating parts, the internal thread toler-

ance class symbol is followed by that of the external thread,

separated by a slash.

Example: M20 x 26H/5g6g

When rounded root external threads are to be specified, the minimum root radius

value shall be added to the tolerance class designation.

Example: M65g 6g 0.100R

THREAD DESIGNATIONS

WWW.OSGCANADA.COM 800.263.4861

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Bearing Tolerances and Precision LevelsДокумент15 страницBearing Tolerances and Precision LevelsAbdul Junaedi100% (1)

- 01 Propeller TutorialДокумент22 страницы01 Propeller TutorialMirza CaticОценок пока нет

- Vehicle Inspection Form PDFДокумент6 страницVehicle Inspection Form PDFג'ון ירוק100% (1)

- Sizes For TappingДокумент1 страницаSizes For TappingsundyaОценок пока нет

- HP LP2465Документ9 страницHP LP2465ג'ון ירוקОценок пока нет

- Astm A395 PDFДокумент1 страницаAstm A395 PDFZouhair BoukriОценок пока нет

- Vehicle Inspection Form PDFДокумент6 страницVehicle Inspection Form PDFג'ון ירוק100% (1)

- 01 Propeller TutorialДокумент22 страницы01 Propeller TutorialMirza CaticОценок пока нет

- BMW Owners ManualДокумент87 страницBMW Owners Manualcrh8075Оценок пока нет

- DV07PUB5 Study GuideДокумент5 страницDV07PUB5 Study Guideantonio87Оценок пока нет

- Power SteeringДокумент100 страницPower Steeringג'ון ירוקОценок пока нет

- Prediction of Surface RoughnessДокумент6 страницPrediction of Surface Roughnessג'ון ירוקОценок пока нет

- Snap LatchesДокумент4 страницыSnap Latchesג'ון ירוקОценок пока нет

- Microsoft MathematicsДокумент6 страницMicrosoft MathematicsFrances0166Оценок пока нет

- BMW Owners ManualДокумент87 страницBMW Owners Manualcrh8075Оценок пока нет

- Metrology For Engineers - J.F.W. GalyerДокумент297 страницMetrology For Engineers - J.F.W. Galyerג'ון ירוקОценок пока нет

- EPM212 - Chapter 9 Slides GD T Handout PDFДокумент15 страницEPM212 - Chapter 9 Slides GD T Handout PDFג'ון ירוקОценок пока нет

- Nadella - Needle BearingsДокумент230 страницNadella - Needle Bearingsג'ון ירוקОценок пока нет

- Form-Fitting Aid - Plastic-Metal Press Fits PDFДокумент4 страницыForm-Fitting Aid - Plastic-Metal Press Fits PDFג'ון ירוקОценок пока нет

- Lecture 9 - Symmetry & Concentricity, Expanded Position TolerancingДокумент19 страницLecture 9 - Symmetry & Concentricity, Expanded Position Tolerancingג'ון ירוקОценок пока нет

- Design For Snapfit Revi-10 PDFДокумент26 страницDesign For Snapfit Revi-10 PDFDmitry ShelestОценок пока нет

- Timpuri EnglezaДокумент27 страницTimpuri Englezaג'ון ירוקОценок пока нет

- Ford Focus BrakeДокумент4 страницыFord Focus Brakelucianremus86Оценок пока нет

- Contraction of Aluminum Alloys During and After SolidificationДокумент11 страницContraction of Aluminum Alloys During and After Solidificationג'ון ירוקОценок пока нет

- Aluminium Hexagonal Bar PDFДокумент1 страницаAluminium Hexagonal Bar PDFג'ון ירוקОценок пока нет

- Beam Formulas With Shear and MomДокумент12 страницBeam Formulas With Shear and Momג'ון ירוקОценок пока нет

- EcoCAR NX6 Procedures and TipsДокумент25 страницEcoCAR NX6 Procedures and Tipsג'ון ירוקОценок пока нет

- Mechanism For Precise Linear and Angular AdjustmentДокумент12 страницMechanism For Precise Linear and Angular Adjustmentג'ון ירוקОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Bodywork - : XAS 137 StandardДокумент4 страницыBodywork - : XAS 137 StandardRichard EVОценок пока нет

- Conversion Tables, Inches - MM - Nordic Fastening Group ABДокумент1 страницаConversion Tables, Inches - MM - Nordic Fastening Group ABSudhakar KrishnamurthyОценок пока нет

- Shop Made Bandsaw Fence DrawingsДокумент2 страницыShop Made Bandsaw Fence DrawingsAnderson DanОценок пока нет

- Class 2B Internal ThreadsДокумент2 страницыClass 2B Internal ThreadsLaural MarshallОценок пока нет

- Juki AMS-205C, - 206CДокумент40 страницJuki AMS-205C, - 206Cbách hàОценок пока нет

- BS Au 050-3.4a-1980 (2000) Iso 4570-3-1980Документ8 страницBS Au 050-3.4a-1980 (2000) Iso 4570-3-1980amerОценок пока нет

- Trascabo 621 GДокумент2 страницыTrascabo 621 GJusaNadaОценок пока нет

- EtiketДокумент4 страницыEtiketyanuar ariОценок пока нет

- 2.thread GaugesДокумент28 страниц2.thread GaugesAshlin SreedharОценок пока нет

- RL425Документ25 страницRL425Zeljko SofijanicОценок пока нет

- Tap Drill SizesДокумент2 страницыTap Drill SizesManvendra KumarОценок пока нет

- Parts Catalogue Escorts Compactor EC5250 Water Cooled Rev-02-29.03.19Документ314 страницParts Catalogue Escorts Compactor EC5250 Water Cooled Rev-02-29.03.19ashish singh thakurОценок пока нет

- Juk Lu-562 563Документ24 страницыJuk Lu-562 563RHoskaОценок пока нет

- China Fastener Directory 2014 PLUS 2Документ106 страницChina Fastener Directory 2014 PLUS 2chinafastenerinfo60% (5)

- Fig.1350 Accelerator LinkageДокумент1 страницаFig.1350 Accelerator LinkageДмитрий ЗесковОценок пока нет

- Bill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoДокумент1 страницаBill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoRiyadiОценок пока нет

- Material: Ref Note: Rev # Description Appv. Rev DateДокумент1 страницаMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhОценок пока нет

- Mechanical Properties Metric Fasteners Jan 2016Документ2 страницыMechanical Properties Metric Fasteners Jan 2016Prashant KumarОценок пока нет

- Spalding Fasteners Product CatalogueДокумент95 страницSpalding Fasteners Product CatalogueMarco NiОценок пока нет

- ISO Metric Thread DimensionsДокумент29 страницISO Metric Thread Dimensionstorbenchr100% (2)

- Fed STD H28aДокумент11 страницFed STD H28amurphygtОценок пока нет

- 212 Ipb CH29 PDFДокумент66 страниц212 Ipb CH29 PDFsebastiandavid9100% (1)

- Screw Threads, Bolts and NutsДокумент10 страницScrew Threads, Bolts and NutsSayphone HoungbounyuangОценок пока нет

- SKF Bearing DrawingДокумент2 страницыSKF Bearing Drawingsanjay aОценок пока нет

- 914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationДокумент4 страницы914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationAsfiannur ade setiawanОценок пока нет

- Fastener Weight ChartДокумент9 страницFastener Weight ChartTricolor C AОценок пока нет

- Lamina 01 Roscas-WithworthДокумент1 страницаLamina 01 Roscas-WithworthAlvaro AlarconОценок пока нет

- Bolt Din 931Документ3 страницыBolt Din 931anОценок пока нет

- Omni CatalogДокумент28 страницOmni CatalogAhmet YilmazОценок пока нет