Академический Документы

Профессиональный Документы

Культура Документы

Augusto 2001

Загружено:

Audry AriasИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Augusto 2001

Загружено:

Audry AriasАвторское право:

Доступные форматы

Design and Validation of Portable SPME Devic es

for Rapid Field Air Sampling and Diffusion-Based

Calibration

Fabio Augusto,

J ac ek Koziel,

and J anusz Pawliszyn*

Department of Chemistry, University of Waterloo, Waterloo, Ontario, Canada N2L 3G1

TheuseofSPME fiberscoatedwithporouspolymer solid

phases for quantitativepurposes is limitedduetoeffects

such as interanalyte displacement and competitive ad-

sorption. For air analysis, theseproblemscanbeaverted

byemployingshortexposuretimestoair samplesflowing

around the fiber. In these conditions, a simple math-

ematical model allows quantificationwithout theneedof

calibration curves. This work describes two portable

dynamic air sampling (PDAS) devices designed for ap-

plicationof this approachtononequilibriumSPME sam-

pling and determination of airborne volatile organic

compounds (VOCs). The use of a PDAS device resulted

in greater adsorbed VOC mass compared totheconven-

tional SPME extractioninstatic air for qualitativescreen-

ingof liveplant aromas and contaminants in indoor air.

For all studiedair samples, anincreaseinthenumber of

detected compounds and sensitivity was also observed.

Quantification of aromatic VOCs in indoor air was also

carried out using this approach and the PDAS/ SPME

device. MeasuredVOC concentrationswereinlowparts-

per-billion byvolumerangeusingonly30-s SPME fiber

exposureand werecomparableto thoseobtained with a

standardNIOSH method1501. TheuseofPDAS/ SPME

devices reducedthetotal air samplingandanalysis time

byseveral orders of magnitudecompared to theNIOSH

1501 method.

Sampling of air and related gas mixtures for chromatographic

analysis of contaminants has been performed using abroad range

of techniques. Sorbent adsorption, cryotrapping, and canister

sampling, followed by thermal desorption/ cryofocusing or solvent

desorption are the most employed procedures for air analysis.

1

However, most of these procedures have several serious draw-

backs, such as production of artifacts

2

and retention of large

amounts of water.

3

Techniques such as membrane extraction with

sorbent interface (MESI),

4

where the analytes present in asample

selectively permeate through a polymeric membrane and are

trapped in a sorbent interface for further desorption into a

chromatographic system, also had been suggested.

5

SPME is an attractive alternative to the aforementioned

techniques, considering features such as accuracy, cost, simplicity,

and speed,

6

and has been widely used in analysis of several

contaminants in air.

7-10

Many of these SPME methods reported

in the literature employ fibers coated with liquid polymeric phases,

such as poly(dimethylsiloxane) (PDMS) and polyacrylate. How-

ever, the use of fibers covered with mixed porous solid adsorptive

coatings, such as Carboxen/ PDMS and PDMS/ divinylbenzene

(PDMS/ DVB), seems to be especially interesting for analysis of

air contaminants. They are more efficient than the liquid-coated

fibers,

11

especially for extraction of analytes with low molecular

weight.

12

Both quantitative and qualitative applications of solid-

phase coated fibers have been described for analysis of food

contaminants,

13

fruit pulp volatiles,

14

and flavor compounds in

milk.

15

Adsorption is the physicochemical mechanism involved in

extractions using fibers coated with solid phases. Both the

theoretical foundations of the equilibrium

16

and the kinetics

17

of

adsorption by solid-phase coated fibers had already been ad-

dressed. These studies point to problems, e.g., competition

between the analytes for the adsorptive sites available in the fiber

and interanalyte displacement, as severe drawbacks to the ap-

plication of solid-phase coated fibers to quantitative analysis and

limiting the accuracy and precision of the results. However, in

recent work, Koziel et al.

18

presented an alternate methodological

approach to overcome these deleterious effects. According to the

* Corresponding author: (fax) (519) 746-0435; (e-mail) janusz@uwaterloo.ca.

Current address: Instituto de Qu mica, Unicamp, CP 6154-13083-970

Campinas, SP, Brazil.

Current address: Texas Agricultural Experiment Station, Amarillo, TX

79106.

(1) Dewulf, J.; Van Langenhove, H. J. Chromatogr., A 1999, 843, 163-177.

(2) Clausen, P. A.; Wolkoff, P. Atmos. Environ. 1997, 31, 715-725.

(3) Helmig, D.; Vierling, L. Anal. Chem. 1995, 67, 4380-4386.

(4) Yang, M. J.; Harms, S.; Luo, Y. Z.; Pawliszyn, J. Anal. Chem. 1994, 66,

1339-1346.

(5) Luo, Y. Z.; Pawliszyn, J. Anal. Chem. 2000, 72, 1064-1071.

(6) Pawliszyn, J. TrAC, Trends Anal. Chem. 1995, 14, 113-122.

(7) Chai, M.; Pawliszyn, J. Environ. Sci. Technol. 1995, 29, 693-701.

(8) Grote, C.; Pawliszyn, J. Anal. Chem. 1997, 69, 587-597.

(9) Martos, P. A.; Pawliszyn, J. Anal. Chem. 1997, 69, 206-215.

(10) Eisert, R.; Pawliszyn, J.; Barinshteyn, G.; Chambers, D. Anal. Commun.

1998, 35, 187-190.

(11) Mani, V. Properties of Commercial SPME Coatings. In Applicationsof Solid-

PhaseMicroextraction; Pawliszyn, J., Ed.; RSC.: Cornwall, UK, 1999; Chapter

5, pp 63-67.

(12) Gorecki, T. Solid versus Liquid Coatings. In Applications of Solid-Phase

Microextraction; Pawliszyn, J., Ed.; RSC.: Cornwall, UK, 1999; Chapter 7,

pp 92-108.

(13) Page, D. B.; Lacroix, G. J. Chromatogr., A 2000, 873, 79-94.

(14) Augusto, F.; Valente, A. L. P.; Tada, E. S.; Rivellino, S. R. J. Chromatogr., A

2000, 873, 117-127.

(15) Marsili, R. T. J. Chromatogr. Sci. 1999, 37, 17-26.

(16) Gorecki, T.; Yu, X.; Pawliszyn, J. Analyst 1999, 124, 643-649.

(17) Semenov, S.; Koziel, J.; Pawliszyn, J. J. Chromatogr., A 2000, 873, 39-51.

Anal. Chem. 2001, 73, 481-486

10.1021/ac000629k CCC: $20.00 2001 American Chemical Society Analytical Chemistry, Vol. 73, No. 3, February 1, 2001 481

Published on Web 12/30/2000

authors, when a fiber is exposed to a gaseous sample moving

perpendicularly to the fiber axis for aperiod of time much smaller

than the equilibration time, the coating behaves as a perfect sink

and all analyte molecules reaching the fiber surface are im-

mediately adsorbed. As alarge number of nonoccupied adsorptive

sites are available in these conditions, interanalyte competition

and displacement are minimized and can be disregarded. It can

be demonstrated that the extracted amount of an analyte n

depends only on its concentration in the gaseous matrix C

g

, its

diffusion coefficient in air D

g

, the fibers length and radius L and

b, respectively, the thickness of the effective static boundary layer

surrounding the fiber , and the sampling time t:

The extracted amount, n, can be calculated from the peak area

and from the detector response factor. Equation 1 holds true for

air speeds up to values between 4 and 10 cm s

-1

, depending on

the analyte. Further increase in the air velocity shows no effect

on the mass uptake rate, which becomes nearly constant and

limited by the diffusion of the analyte in the coating.

18

For practical

reasons, devices that allow extractions using air speeds superior

to this critical limit would be desirable because variations in air

velocity would not affect the mass uptake rate, ensuring better

analytical precision and accuracy.

Several models are available to estimate diffusion coefficients

in air needed for the use of eq 1 with the Fuller-Schettler-

Giddings

19

model being the most adequate for a large number of

analytes in normal air sampling conditions:

where T is the absolute temperature, M

air

is the air apparent

molecular weight (i.e., the weighted average of the molecular

weights of the components of air), M

voc

is the molecular weight

of the analyte, p is the ambient pressure, and V

air

and V

voc

are

respectively the molar volumes of air and of the analyte.

The thickness of the effective static boundary layer sur-

rounding the fiber can be calculated from eq 3, where Rerefers

to the Reynolds number (Re) 2ub/ j; u is the linear velocity of

the air and is the air kinematic viscosity) and Scto the Schmidt

number (Sc ) / D

g

).

Using these equations, the concentration of an analyte can be

directly estimated from the chromatographic peak area, given that

the sampling conditions (sampling time, air velocity, temperature,

and pressure) and constants (diffusion coefficient and fiber

dimensions) are known. For that reason, apart from the suppres-

sion of interanalyte effects, this methodology also allows quanti-

tation of analytes in air without construction of calibration curves.

Another benefit would be the increase of the extracted amounts

(and, therefore, of the sensitivity), when this approach is compared

to the traditional static SPME sampling (simple exposure of the

fiber to the air). It can be proved, from eqs 1 and 3, that increasing

the air speed also increases the fibers mass uptake, due to the

decrease of the boundary layer thickness. Under static conditions,

the extraction would depend on transport of the mass through a

boundary layer which would turn progressively thicker during the

process, due to the depletion of the analyte.

20

This, in turn, would

limit the amount extracted in short periods of fiber exposure to

the sample.

This work describes several portable devices designed to apply

the dynamic nonequilibrium sampling concept to analysis of

airborne chemicals. The suitability of this approach both for

qualitative analysis of living plant aroma compounds and for

volatile organic contaminants in indoor air was examined. Also,

quantitation of air contaminants using dynamic SPME sampling

was compared to results obtained using a standard air analysis

method.

EXPERIMENTAL SECTION

Materials. Chemicals and Supplies. All chemicals were of

analytical grade and used as supplied: benzene, toluene, ethyl-

benzene, o-xylene, p-xylene, and mesitylene (Sigma-Aldrich, Mis-

sissauga, ON, Canada) and carbon disulfide (BDH, Toronto, ON,

Canada). The SPME holder and 65-m PDMS/ DVB fibers were

obtained from Supelco (Oakville, ON, Canada); the fibers were

conditioned at 210 C for 8 h prior to their use. Supelco ORBO-

32 charcoal tubes and a model I.H. portable air pump (A.P. Buck,

Orlando, FL) wereemployed for thevalidation quantitativeanalysis

according to NIOSH method 1501.

21

All preparations involving CS

2

(flammable and toxic) and benzene (suspect carcinogen) were

carried out in a ventilated hood.

GasChromatography. Qualitative chromatographic analyses of

aromas were carried out in aSaturn IV GC-ITMSsystem (Varian

Associates, Sunnyvale, CA) fitted with a 30 m 0.25 mm 0.25

m HP-5 column (Hewlett-Packard, Avondale, PA) and a septum-

purged injector (SPI). The carrier gas was 1.5 mL min

-1

helium

at 12 psi. The SPI was kept at 210 C, and the column oven

temperature was ramped from 60 to 280 C at 5 C/ min. Profiles

of indoor air contaminants and quantitative data were obtained

using a Varian Star 3400 GC-FID chromatograph equipped with

a 30 m 0.25 mm 0.25 m Supelco SPB-5 column and SPI; 2.0

mL min

-1

helium at 20 psi was used as carrier gas. The

temperatures were set at 250 C for the FID and 210 C for the

SPI, and the column oven program for all injections was as

follows: 1 min hold at 60 C, followed by a 15 C/ min ramp until

ramped to 180 C, and hold there for 3 min.

Plant Sample. Aroma from juniper bushes (Juniperuscommu-

nis) from the University of Waterloo campus gardens was used

as a sample for the qualitative application in this work.

PortableDynamicAir SamplingDevices(PDAS) for SPME. Two

devices to perform air sampling under dynamic conditions were

(18) Koziel, J.; Jia, M.; Pawliszyn, J. Anal. Chem. 2000, 72, 5178-5186.

(19) Fuller, E. N.; Schettler, P. D.; Giddings, J. C. Ind. Eng. Chem. 1966, 58,

19-27.

(20) Pawliszyn, J. Solid-PhaseMicroextraction: Theoryand Practice; Wiley-VCH:

New York, 1997; pp 67-69.

(21) National Institute of Occupational Safety and Health. Manual of Analytical

Methods, 4th ed.; U.S. Department of Health and Human Services: Cincin-

nati, OH. 1994; Vol. I (Method 1501 (Hydrocarbons, Aromatic).

C

g

) n ln

(

b+

b

)

/ 2D

g

Lt (1)

D

g

)

0.001T

1.75

1

M

air

+

1

M

voc

p[ (

V

air

)

1/ 3

+ (

V

voc

)

1/ 3

]

2

(2)

) 9.52b/ Re

0.62

Sc

0.38

(3)

482 Analytical Chemistry, Vol. 73, No. 3, February 1, 2001

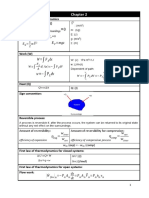

projected and built; the design concepts for these apparatus are

discussed in Results and Discussion. Figure 1 shows the schemat-

ics of the first device, built using a VS-513F household hair-dryer

(Helen of Troy, El Paso, TX) modified to revert the air flow

direction and to disable the internal heating coil. An aluminum

tube was machined and adapted to the front part of the modified

hair-dryer. Two plain cardboard sheets fixed to the opposite side

of the aluminum tubing creating a 3-mm slit; the modified hair-

dryer suction forces the passage of the ambient air through this

slit. PDAS-SPME sampling is performed by exposing the fiber

to the flowing air in front of the slit. The average air speed in

front of the slit was measured to be 1.5 m s

-1

with an HHF51

digital wire anemometer (Omega Engineering, Stamford, CT).

This value is greater than the critical air speeds mentioned in the

introduction. All datapresented in this work were collected using

this apparatus.

A different PDAS-SPME (sandwich design), shown in

Figure 2, was also projected and assembled. A portable air

sampling pump was used to force ambient air through the

rectangular orifice of the device; a small hole (diameter 0.6 mm)

in the Teflon spacer allowed exposure of the SPME fiber to the

ambient air flowing through the orifice. Using a Buck I.H. air

pump, it is possible to sample air flowing with controllable speeds

up to 1.38 m s

-1

. This device is presented here as an alternative

to that described above, and its use is currently being evaluated.

Methods. Screeningof LivingPlant Aromas. PDAS-SPME was

compared with conventional (static) SPME sampling for identifica-

tion of compounds found in the fragrance released by an aromatic

plant (juniper). Both for static SPME and for PDAS-SPME, the

SPME fiber was exposed to the air surrounding the living

specimen for 30 s, and the approximate distance between the

SPME fiber and the specimen was 5 cm. The extracted materials

were separated and identified by GC-ITMS. The desorption time

was 5 min. The time between sampling and chromatographic

analysis was kept lower than 20 min for all extractions performed

here and in the subsequent essays; under these conditions, loss

of sorbed materials can be assumed as negligible.

22,23

QualitativeProfilesof Contaminantsin Indoor Air. Qualitative

profiles of the contaminants present in the air of the Motor Vehicle

Maintenance Shop of the University of Waterloo were obtained

using PDAS-SPME and conventional SPME. Extractions with a

fiber exposure time of 30 s were carried out simultaneously by

both methods. The SPME fibers were kept refrigerated under dry

ice and capped during their transportation to the laboratory and

storage. Several samples were collected during one workday to

show the variation of the air contamination profile during this time

span.

QuantitativeAnalysisof AromaticHydrocarbonsin Indoor Air.

PDAS-SPME was employed to quantify aromatic hydrocarbons

present in the air of several sites in the University of Waterloo.

These sites included two different locations in a chemical labora-

tory (close to a solvent storage cabinet and in an analytical

instrument room), the Motor Vehicle Maintenance Shop, and in

the Engineering Mechanical Shop. Replicate measurements

exposing the SPME fiber to the flowing air for 30 s were made.

Uncertainties were expressed as estimates of standard deviation

of replicates, i.e., vehicle and mechanical shop air analysis, three

replicates, and laboratory air analysis, eight replicates. Concentra-

tions of the aromatic hydrocarbons were calculated using eq 1

for nonequilibrium dynamic SPME extraction. It was assumed that

the thickness of the boundary layer did not significantly change

when air velocity was greater than 10 cm s

-1

. Thus, the threshold

air velocity of 10 cm s

-1

was used to estimate the thickness of

the boundary layer in eq 3.

For comparison purposes, vehicle and mechanical shop samples

were simultaneously analyzed using the NIOSH method 1501 for

aromatic hydrocarbons.

21

Air was pumped through ORBO-32

charcoal adsorption tubes with sampling times and flow rates

adjusted according to the level of contamination of each sample

(see Results below). Immediately after the sampling, both the

charcoal portion of the tube containing the extracted analytes and

the breakthrough control portion were transferred to separate

4-mL glass vials sealed with Teflon-coated silicone septa. Two

milliliters of CS

2

was added to each vial. After 1 h, 1 L of the

(22) Mu ller, L. Field Analysis by SPME. In Applications of Solid-Phase Micro-

extraction; Pawliszyn, J., Ed.; RSC.: Cornwall, UK, 1999; Chapter 20, pp 269-

283.

(23) Koziel, J.; Pawliszyn, J. J. Air WasteManag. Assoc., in press.

Figure 1. Side view (A) and front view (B) of the portable dynamic

air sampling device for SPME. (1) modified hair-dryer; (2) aluminum

tube; (3) 18 VDC power supply cable; (4) fixing brace; (5) cardboard

pieces; (6) 3-mm slit; (7) SPME holder and fiber.

Figure 2. Sandwich PDAS-SPME; (A) unassembled and (B)

assembled device. (1) 1-mm-thick stainless steel sheets; (2) 3-mm-

thick Teflon spacer; (3) 0.6-mm hole; (4) ) SPME holder and fiber;

(5) silicone tube.

Analytical Chemistry, Vol. 73, No. 3, February 1, 2001 483

CS

2

phase in the vials was injected into the GC-FID system using

the same operational conditions employed for the PDAS-SPME

analysis.

RESULTS AND DISCUSSION

Design Aspects of the PDAS-SPME. The PDAS-SPME

complements previously described devices for field SPME sam-

pling.

22

These already reported devices and the techniques used

extractions under analyte/ fiber equilibrium conditions, which

demands the use of calibration curves or quantitation based on

chromatographic retention data.

24

However, quantitation in pre-

equilibrium conditions, where the analyte uptake depends only

on its diffusion through the static boundary layer,

18

has several

advantages for field use. Since no calibration procedures are

needed for well-defined flow rates, the analytical process is

simplified. Also, the sampling time is noticeably shorter when

compared to the typical equilibrium times for airborne analytes,

resulting in faster analysis. The main design feature of the PDAS-

SPME project is to ensure aconstant and uniform air flow around

the fiber, consistent with the demands of diffusion-based extrac-

tion. These devices should also provide flow rates high enough

to have air speeds higher than the critical values mentioned in

the introduction, where the extraction rate is dependent mainly

on diffusion of the analyte through the adsorbent pores or through

the liquid coating film.

For the device shown in Figure 1, this was achieved by using

a modified dc-powered hair-dryer. The reversion of the direction

of the air flow was made to avoid contact of the fiber with potential

artifacts originated from the dryer body and motor. The device

shown in Figure 2 was intended to use with industrial hygiene

air sampling pumps, a resource already existent in several

laboratories, as a source of air motion. In addition to these

features, characteristics such as weight, cost, and handiness of

use were taken in account. An alternate version of this device

without the two cardboard sheets allows sampling of large volume

air samples, i.e., indoor air, under higher flow rates. In this case,

a special 1-in.-O.D. short tube is mounted perpendicularly to the

main aluminum tube to position the SPME holder and to allow

one-hand operation. A 1-mm hole was made in the aluminum tube

for insertion of the SPME needle and fiber in the sampled air

stream.

Screening of Living Plant Aroma. Figure 3 allows the

comparison of a selected section of GC-ITMS chromatograms

obtained with PDAS-SPME and conventional SPME for juniper

aroma. Three compoundsslimonene, 3-nonen-1-ol, and 2-decen-

1-olswere identified in this section of the PDAS-SPME chro-

matogram (Figure 3A). Peaks corresponding to the same com-

pounds in the static SPME chromatogram section were considerably

lower (Figure 3B). In addition, the 3-nonen-1-ol peak is not distinct

from the baseline noise and not detected with static SPME

sampling.

As shown by these results, the application of PDAS-SPME

produced a significant increase in the number of detectable

compounds in the analyzed samples, when compared to conven-

tional SPME. This observation agrees with the theory; i.e., the

air flow around the fiber increases the extracted amount of

analytes per unit of time due to the reduction of the effective

boundary layer thickness. The increase in the analyte uptake is

also reflected in the increase of the number of detected com-

pounds.

QualitativeProfilesofContaminantsinIndoor Air. Figure

4 shows the chromatographic data profiles obtained after extrac-

tion of the indoor air at the UW Vehicle Maintenance Shop, using

both PDAS-SPME and static conventional SPME sampling,

respectively. The signal scale for the chromatograms in both sets

was adjusted to the same value. Both the number of detectable

peaks and the peak intensities are considerably greater in the

chromatograms in the PDAS-SPME profile (Figure 4B), allowing

easier visual assessment of the correlation between the pattern

of air contamination in this environment and the activities taking

place there. For example, it can be seen that the intensity of the

peak attributed to toluene (large peak with t

R

) 2.6 min) decays

during the period between 9:15 a.m. (just after the beginning of

the work shift) and 12:15 p.m., becoming roughly constant after (24) Martos, P.; Pawliszyn, J. Anal. Chem. 1997, 69, 206-215.

Figure 3. Section of GC-ITMS chromatogram of living juniper

aroma. (A) PDAS-SPME; (B) static SPME; (C) fiber blank). Peak

identification: (1) limonene; (2) 3-nonen-1-ol; (3) 2-decen-1-ol.

Figure 4. Variation of the GC-FID chromatographic profiles of

contaminants in the UW Vehicle Maintenance Shop monitored in a

workday using conventional SPME (A) and PDAS-SPME (B) col-

lected during a work shift. Chromatograms: (1) 9:15 a.m.; (2) 9:55

a.m.; (3) 10:20 a.m.; (4) 11:10 a.m.; (5) 12:15 p.m.; (6) 12:55 p.m.;

(7) 1:55 p.m.; (8) 3:05 p.m. For peak identification see Results and

Discussion.

484 Analytical Chemistry, Vol. 73, No. 3, February 1, 2001

this time. This was credited to the residues of degreasing solvents

containing toluene that were left for overnight cleanup of motor

parts. The group of peaks with retention times between 4 and 8

min were found to be volatile hydrocarbons present in gasoline

and diesel fuels. The intensity of these peaks was found to be at

maximum around 12:55 p.m., which correlated to the admission

of several vehicles to the shop.

QuantitativeAnalysisofAromaticHydrocarbonsinIndoor

Air. Table 1 compares concentrations of several aromatic hydro-

carbons found after PDAS-SPME sampling, combined with

nonequilibrium diffusion-based quantification, with concentrations

obtained after simultaneous application of NIOSH 1501 standard

method to the same samples. For PDAS-SPME calculations, the

values for the needed constants were as follows: b) 0.0120 cm;

L ) 1 cm (both previously measured in the laboratory); M

air

)

28.97 g mol

-1

; V

air

) 20.1 mL, and ) 0.15 cm

2

s

-1

.

25

Values for

V

voc

needed for estimation of D

g

(eq 2) were calculated according

to the literature.

25

The sampling time and air flow rate for NIOSH

analysis was adjusted according to the expected concentrations

of contaminants in each sample, based on preliminary exploratory

extractions: 91 min for the vehicle shop air and 215 min for the

mechanical shop air, with a flow rate of 138 mL min

-1

(sampled

air volumes: 12.6 L for vehicle shop and 29.7 L for mechanical

shop). Under these conditions, no analyte breakthrough was

observed when the NIOSH method was applied. It should be

emphasized that the sampling time for the NIOSH-based sampling

was a few orders of magnitude greater than the sampling time

associated with PDAS-SPME. However, none of the existing

standard methods could be compared with the 30-s PDAS-SPME

sampling time.

The PDAS-SPME results obtained for the vehicle and me-

chanical shops were similar to those from NIOSH analysis, except

for the hydrocarbons with higher molecular weight in the set (o-

xylene and mesitylene), which are underestimated by the NIOSH

method. A possible cause for this could be associated with the

incomplete desorption of these analytes from the charcoal tubes

employed in the NIOSH method, when the recommended de-

sorption procedure was used. Another reason for the observed

discrepancies in measured concentrations could be due to the

widely different sampling times used in both methods. The

NIOSH-based concentration can be considered as atime-weighted

average sample over a long sampling period. In contrast, the

PDAS-SPME concentrations can be associated with spot or grab

30-s sampling. In addition, it was not possible to measure benzene

concentration in the evaluated samples using this method.

Benzene is a common and significant contaminant in the CS

2

solvent recommended for the desorption step in the NIOSH

method.

The method precision can be estimated from the uncertainties

presented in Table 1. VOCconcentration levels can be considered

typical of indoor air in occupational environments. Expressed as

estimates of relative standard deviations (s

R

), the precision of

PDAS-SPME results ranged from 13 to 28%, with an average

value of 20%. These results can be compared to those presented

in an extensive study of NIOSH charcoal tube collection methods

for airborne organics.

26

The s

R

values calculated from the data

presented in this study ranged from 0.4%to as much as 69%, with

an average of 15%(for xylene s

R

ranged from 5.2 to 22%, with an

average of 10%, and for benzene, from 4.3%to as much as 43%,

with an 15%average). Therefore, precision for the PDAS-SPME

method can be considered in the same order of magnitude (if

not better for some analytes) to the range of precision reported

for the NIOSH standard method.

An estimate of the detection limits of PDAS-SPME was

provided by thelaboratory air samples analysis. For sampling close

to the solvent cabinet 18 ( 6 ppbv benzene, 6 ( 3 ppbv toluene,

and 2 ( 1 ppbv p-xylene were detected, and for the air in the

instrument room, 3 ( 1 ppbv toluene and 2 ( 1 ppbv p-xylene;

other analytes were not detected. Those results show that the

detection limits for PDAS-SPME are in the low-ppbv range.

Comparison with the NIOSH method was not considered valid

here, since for the same samples no aromatic hydrocarbons were

detected with this method even extending the sampling volumes

to values up to 50 L, except for toluene in one of the samples.

For the sampling volumes employed in the vehicle and mechanical

shops analysis, the detection limits calculated according to data

provided in method 1501 would be in the range between 6 and

100 ppbv for mechanical shop air sampling and 15-230 ppbv for

vehicle shop air sampling, depending on the analyte in consider-

ation. Therefore, PDAS-SPME can be considered as more

sensitive than the standard NIOSH 1501 method.

CONCLUSIONS

This work demonstrated that the combination of SPME and

the simple and inexpensive (U.S. $10) PDAS-SPME device was

a powerful tool for both qualitative screening and quantitative

analysis of varied samples as aromas from living plants to

occupational air. When compared to SPME extraction with simple

static exposure of the fiber to the air, the application of PDAS-

SPME increased significantly the number of detectable analytes,

the adsorbed amounts, and the method sensitivities. Findings in

this work suggest that PDAS-SPME can provide more accurate

qualitative profiles of extremely diluted samples such as natural

aromas.

A few remarks should be made on the herein proposed

methodology. As it involves short sampling times, the assessment

(25) Tucker, W. A.; Nelken, L. H. Diffusion Coefficients in Air and Water. In

Handbookof Chemical PropertyEstimationMethods: Environmental Behaviour

of OrganicCompounds; Lyman, W. J., Reehl, W. F., Rosenblatt, D. H. Eds.;

McGraw-Hill: New York, 1982; Chapter 17, pp 17-1-17-25.

(26) Larkin, R. L.; Crable, J. V.; Catlett, L. R.; Seymour, M. J. Am. Ind. Hyg. Assoc.

J. 1977, 38, 543-554.

Table 1. Conc entrations in ppb v/v of Some Aromatic

Hydroc arbons in Indoor Air Measured by PDAS-SPME

and NIOSH Standard Method 1501

vehicle shop mechanical shop

SPME NIOSH SPME NIOSH

benzene 48 ( 10

a

b 17 ( 4 b

toluene 212 ( 43 215 62 ( 9 73

ethylbenzene 60 ( 8 48 nd

c

nd

p-xylene 189 ( 43 222 25 ( 5 nd

o-xylene 249 ( 35 137 18 ( 5 nd

mesitylene 202 ( 28 75 nd nd

a

Uncertainties expressed as estimates of standard deviation of

triplicates.

b

Not quantifiable (see text).

c

nd, not detected.

Analytical Chemistry, Vol. 73, No. 3, February 1, 2001 485

of long-term exposure of contaminants in indoor air, which is

frequently necessary, would require averaging several measure-

ments made during a period of time. For these cases, procedures

such as standard NIOSH methods, time-weighted average SPME

mode, or similar alternatives would be more adequate. Since the

sampling time is one of the variables needed to calculate the

concentration, errors in its measurement would reflect in the

accuracy and precision of results. Such errors could be significant

considering that these short exposure times should be manually

measured. Another possible handicap of the method is the

dependence of the results on dimensional parameters of the fibers

(their radius and length, which are constants in the models

equations). Fibers should be checked in respect to their real

dimensions to ensure accurate measurements, as well as the

integrity of the coating.

The use of PDAS-SPME also allowed the application of

nonequilibrium diffusion-based quantification to air samples using

fibers coated with solid (porous) polymers. The use of short

sampling time minimized the effects of interanalyte displacement

that in the past prevented the use of these fibers for accurate

quantitativeair analysis. Also, this nonequilibrium model can result

in quantitativeanalysis without need of calibration curves, provided

that some constants, e.g., analyte diffusion coefficient in air and

the detector response factor, are known. When compared to

standard methodologies, a 30-s sampling using PDAS-SPME

allowed measurement of VOC concentrations that where not

detected by the NIOSH standard method, even after several hours

of extraction using expensive (air sampling pumps) and nonreus-

able (charcoal tubes) materials.

ACKNOWLEDGMENT

The authors acknowledge the Fundac a o de Amparo a` Pesquisa

do Estado de Sa o Paulo (FAPESP) for the scholarship provided

to F.A. and also thank NSERC(Natural Sciences and Engineering

Research Council of Canada) for funding this study.

Received for review June 1, 2000. Accepted November 8,

2000.

AC000629K

486 Analytical Chemistry, Vol. 73, No. 3, February 1, 2001

Вам также может понравиться

- Ref # 1Документ9 страницRef # 1Audry AriasОценок пока нет

- Ref # 2Документ6 страницRef # 2Audry AriasОценок пока нет

- Nanoscale Analysis of Photodegraded Polyester Fibers by AFM-IR DДокумент37 страницNanoscale Analysis of Photodegraded Polyester Fibers by AFM-IR DAudry AriasОценок пока нет

- TortricidaeДокумент9 страницTortricidaeAudry AriasОценок пока нет

- Eustaquio 1999Документ8 страницEustaquio 1999Audry AriasОценок пока нет

- Miyamoto 1998Документ5 страницMiyamoto 1998Audry AriasОценок пока нет

- Near Infrared TransmissionДокумент7 страницNear Infrared TransmissionAudry AriasОценок пока нет

- Xiao 2013Документ4 страницыXiao 2013Audry AriasОценок пока нет

- Monitoramento de Ecdytolopha Aurantiana (Lima) em Laranjeira Valência Com Feromônio SexualДокумент6 страницMonitoramento de Ecdytolopha Aurantiana (Lima) em Laranjeira Valência Com Feromônio SexualAudry AriasОценок пока нет

- Smith 2011Документ15 страницSmith 2011Audry AriasОценок пока нет

- Identification, Synthesis, and Field Evaluation of The Sex Pheromone of The Citrus Fruit BorerДокумент11 страницIdentification, Synthesis, and Field Evaluation of The Sex Pheromone of The Citrus Fruit BorerAudry AriasОценок пока нет

- Vapor Pressures of Moth Sex Pheromone ComponentsДокумент11 страницVapor Pressures of Moth Sex Pheromone ComponentsAudry AriasОценок пока нет

- EcdytolophaДокумент6 страницEcdytolophaAudry AriasОценок пока нет

- Sexual Behavior and Diel Activity of Citrus FRUIT BORER Ecdytolopha AurantianaДокумент13 страницSexual Behavior and Diel Activity of Citrus FRUIT BORER Ecdytolopha AurantianaAudry AriasОценок пока нет

- Identification, Synthesis, and Field Evaluation of The Sex Pheromone of The Citrus Fruit BorerДокумент11 страницIdentification, Synthesis, and Field Evaluation of The Sex Pheromone of The Citrus Fruit BorerAudry AriasОценок пока нет

- Vapor Pressures of Moth Sex Pheromone ComponentsДокумент11 страницVapor Pressures of Moth Sex Pheromone ComponentsAudry AriasОценок пока нет

- Turill Azzi 2002Документ7 страницTurill Azzi 2002Audry AriasОценок пока нет

- 5988 4373enДокумент10 страниц5988 4373enAudry AriasОценок пока нет

- ChromatographyДокумент44 страницыChromatographyAravind KanthОценок пока нет

- Addressing The Complexity and Diversity of Agricultural Plant Volatiles: A Call For The Integration of Laboratory-And Field-Based AnalysesДокумент5 страницAddressing The Complexity and Diversity of Agricultural Plant Volatiles: A Call For The Integration of Laboratory-And Field-Based AnalysesAudry AriasОценок пока нет

- 2010 Article 9831Документ10 страниц2010 Article 9831Audry AriasОценок пока нет

- Journal of Chromatography A, 985 (2003) 3-10Документ8 страницJournal of Chromatography A, 985 (2003) 3-10Audry AriasОценок пока нет

- Past Eels 1983Документ27 страницPast Eels 1983Audry AriasОценок пока нет

- QuimicaДокумент19 страницQuimicaAudry AriasОценок пока нет

- Environmental Analysis: Ray E. Clement and Paul W. YangДокумент30 страницEnvironmental Analysis: Ray E. Clement and Paul W. YangAudry AriasОценок пока нет

- TD DraftДокумент4 страницыTD DraftAudry AriasОценок пока нет

- Cephalotes Clypeatus Fabricius (Hymenoptera: Formicidae) : Hábitos deДокумент4 страницыCephalotes Clypeatus Fabricius (Hymenoptera: Formicidae) : Hábitos deAudry AriasОценок пока нет

- Fundamental Numerical Methods and Data Analysis - CollinsДокумент284 страницыFundamental Numerical Methods and Data Analysis - Collinssebarm86100% (1)

- Solid Phase Microextraction: GC Injectors SPME InjectionДокумент2 страницыSolid Phase Microextraction: GC Injectors SPME InjectionAudry AriasОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Commercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryДокумент15 страницCommercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryOwais AhmedОценок пока нет

- HDPE 2035 Bapolene PDFДокумент1 страницаHDPE 2035 Bapolene PDFAleexis FunezОценок пока нет

- Lactate PhysiologyДокумент5 страницLactate PhysiologyLee June LyngОценок пока нет

- Chapter 2 FormulasДокумент6 страницChapter 2 FormulasShellyОценок пока нет

- Refrigeration - Mechanical Engineering ReviewДокумент402 страницыRefrigeration - Mechanical Engineering Reviewanon_990889030% (2)

- 10 1016@j Powtec 2020 01 073Документ46 страниц10 1016@j Powtec 2020 01 073Angelique TaiebОценок пока нет

- Astm D6581 18Документ10 страницAstm D6581 18Salma ElrayahОценок пока нет

- Atomic Structure and Gaseous State ModuleДокумент122 страницыAtomic Structure and Gaseous State Moduleruchir angraОценок пока нет

- Mapei - 141-Kerapoxy-G9 PDFДокумент6 страницMapei - 141-Kerapoxy-G9 PDFLee WenjianОценок пока нет

- Modules 7 12 HistopathologyДокумент9 страницModules 7 12 HistopathologyKrystelle Anne PenaflorОценок пока нет

- Distillation Lewis 1932Документ3 страницыDistillation Lewis 1932Csaba AndrásОценок пока нет

- Szabo articolChemicalPapersДокумент4 страницыSzabo articolChemicalPapersTaufik HidayatullohОценок пока нет

- Design of Low Cost Radiotherapy FacilitiesДокумент162 страницыDesign of Low Cost Radiotherapy Facilitiesanwar01726100% (1)

- Penetrant Testing Process Guide Methods A B C DДокумент1 страницаPenetrant Testing Process Guide Methods A B C DNos GoteОценок пока нет

- Extract Pages From 7708D - C08 - 442-532 PDFДокумент1 страницаExtract Pages From 7708D - C08 - 442-532 PDFDeny Bayu SaefudinОценок пока нет

- The basics of geotextilesДокумент9 страницThe basics of geotextilesShamima akterОценок пока нет

- Mass Balance Practice Problems Algae ConcentrationДокумент1 страницаMass Balance Practice Problems Algae ConcentrationKZS1996Оценок пока нет

- Byjus Notes Sorting MaterialsДокумент4 страницыByjus Notes Sorting MaterialsNirali MehtaОценок пока нет

- Oral Dispersible Tablets - A ReviewДокумент8 страницOral Dispersible Tablets - A ReviewSriram NagarajanОценок пока нет

- Synthesis of New Kind of Macroporous Polyvinyl-Alcohol Formaldehyde Based Sponges and Its Water Superabsorption PerformanceДокумент11 страницSynthesis of New Kind of Macroporous Polyvinyl-Alcohol Formaldehyde Based Sponges and Its Water Superabsorption PerformanceJohan SukweenadhiОценок пока нет

- 217ME5258Документ16 страниц217ME5258jayОценок пока нет

- Competitive Exams Pharmacy MCQs Practice Test 19Документ4 страницыCompetitive Exams Pharmacy MCQs Practice Test 19safa_sabaОценок пока нет

- Hyperdesmo Polyurea 2K HCДокумент3 страницыHyperdesmo Polyurea 2K HCmeena nachiyarОценок пока нет

- Chapter 19 - Nuclear Chemistry 19.1 Nuclear Stability and Radioactive DecayДокумент14 страницChapter 19 - Nuclear Chemistry 19.1 Nuclear Stability and Radioactive Decaykaushik247Оценок пока нет

- Test Bank For Organic Chemistry With Biological Topics 6th Edition Janice Smith 2Документ35 страницTest Bank For Organic Chemistry With Biological Topics 6th Edition Janice Smith 2Harold Welborn100% (31)

- Engine Block Cleaning ProcedureДокумент7 страницEngine Block Cleaning ProcedureKamal PakdamanОценок пока нет

- Nitric Acid Power PointДокумент20 страницNitric Acid Power Pointعلی محمد قادر خضرОценок пока нет

- Plastick WeldДокумент35 страницPlastick WeldsuronocaturatmojoОценок пока нет

- Deformation of Solids Compiled by: Sir Sumair May 02Документ4 страницыDeformation of Solids Compiled by: Sir Sumair May 02Coolman PoonОценок пока нет

- Amino Acids Metabol Synth of UreaДокумент32 страницыAmino Acids Metabol Synth of UreaAnastasiafynn100% (1)