Академический Документы

Профессиональный Документы

Культура Документы

2.stress Strain

Загружено:

Raja RosenaniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2.stress Strain

Загружено:

Raja RosenaniАвторское право:

Доступные форматы

Mechanics of Solids (VDB1063)

Stress and Strain

Lecturer: Dr. Montasir O. Ahmed

Universiti Teknologi PETRONAS

Civil Engineering Department

To predict normal and shear stresses in a member.

To analyze and design simple members subjected to axial load

and direct shear.

To determine the normal and shear strain in members.

LEARNING OUTCOMES

LECTURE OUTLINES

Stress

Design of Simple Connections

Strain

Stress

The stress is defined as: the intensity of the internal force acting on specific plan

(area).

Normal Stress . Is the intensity of the force acting normal to

A.

= lim

A0

A

If the normal force/stress pulls on A, its referred to tensile

stress, whereas if it pushes on A it is called compressive

stress.

Shear Stress . Is the intensity of the force acting tangent to A.

= lim

A0

= lim

A0

A

The subscript notation z specifies the orientation of the area A and the x and y indicate the

axes along which each acts.

Stress

The average normal stress in an axially loaded bar, =

Units. In the international Standard system (SI), the magnitudes of both normal and shear

stress are specified in the basic units of newtons per square meter (N/m

2

). This unit is called

pascal (1 Pa= 1 N/m

2

)......and kilo, k (10

3

)/// mega, M(10

6

) /// giga, G (10

9

).

Stress

Section the member

perpendicular to its

longitudinal axis at the

point where the normal

stress is to be determined.

Draw the free body

diagram and apply the

equation of equilibrium

to obtain the internal force

P

Determine the cross-

sectional area at the

section and calculate

Procedure for predicting

Stress

Stress

The average shear stress,

Section the

member at the

point where the

average shear

stress is to be

determined.

Draw the free

body diagram and

apply the equation

of equilibrium to

obtain the shear

force V

Determine the

cross-sectional

area A and

calculate

Stress

Procedure for predicting

*The materials allowable stresses should be determined for design purpose.

F.S =

where

F.S = Factor of safety, which is selected based on experience OR obtained from

the appropriate design codes and engineering handbooks.

F

fail

= Failure load, which is found from experimental testing of materials.

F

allow

= Is the allowable load.

*The factor of safety can be expressed also as:

F.S =

OR F.S =

*In any of these equations, the F.S > 1.

Stress

Allowable Stresses

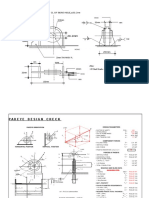

Design of Simple Connections

Equations =

and

can be used to analyze and design the simple connections or

mechanical elements.

If the member subjected to normal force at a section, its required area at the section is

determined from: =

If the section is subjected to an average shear force, its required area at the section is

determined from: =

Select the critical

section within the

member

Section the member

through the area

and draw the free

body diag. of the

segment.

The internal

resultant force is

determined using

the equation of

equilibrium.

Provide the

allowable stress is

known, determined

the required area by

using the previous

equations.

Design of Simple Connections

Design of Simple Connections

Strain

Normal strain: Is the change in length of a line per unit length.

Note: normal strain is a dimensionless quantity. For SI system, the basic unit for length is

meter (m). Ordinary for most engineering application strain () will be very small, so

measurement for strain is micrometers per meter (m/m), where 1m =10

-6

m. sometimes for

experimental work, stains is expressed as percent, e.g., 0.001 m/m = 0.1% . As an example, a

normal strain of 480(10

-6

) in./in., 480 m/m, or 0.048% OR simply 480 (480 micron)

Strain

s is the original length of AB along the

n axis

Strain

is the length of the deformed line A B,

therefore, the average normal strain (

avg

) can be

determined using the following equation:

avg

=

If (or

avg

) is positive the initial line will

elongate, whereas if is negative the line

contracts.

Strain

Shear strain : deformations not only cause line

segments to elongate or contract, but they also cause

them to change direction. If two line segments are

perpendicular to each other, then the change in angle

that occurs between them is referred to as shear

strain. This angle denoted by (gama) and is always

measured in radians (rad).

Strain

Shear strain can be calculated using the

following formula :

nt

= /2 -

If is smaller than /2, the shear strain is

positive. And if is larger than /2, the shear

strain is negative.

Strain

Small strain analysis: most engineering design involves applications for which only small

deformations are allowed and so the normal strain <<1. This assumption of small strain analysis

allows the calculations for normal strain to be simplified.

Strain

The intensity of the internal force at a point in the body is referred to as stress.

There are two types of stresses: normal stresses and shear stresses. This is depends upon the

orientation of the load with respect to the sectioned area.

Since there are many unknown factors that can influence the actual stress in a member, a

factor of safety is applied to obtain the allowable load the member can support.

There are two types of strains: normal strain (measure per unit length of the elongation or

contraction ) and shear strain (measure of the change of angle).

Most engineering materials undergo very small deformations ( 1).

Important Points in this Lecture

Tension and Compression Tests

The Stress-Strain Diagram

Hookes Law

Strain Energy

Poissons Ratio

Next Week / Class

Thank You

Вам также может понравиться

- 15 Chisel Criteria Vol.VДокумент2 страницы15 Chisel Criteria Vol.VSwamy Mani100% (1)

- PJHZ CD Masterlist - 19 January 2016Документ74 страницыPJHZ CD Masterlist - 19 January 2016Raja RosenaniОценок пока нет

- 10.1007 - s40098 017 0277 ZДокумент17 страниц10.1007 - s40098 017 0277 Zjacs127Оценок пока нет

- Foundation EngineeringДокумент4 страницыFoundation EngineeringRaja RosenaniОценок пока нет

- 1130-1135 Kohlbock PDFДокумент6 страниц1130-1135 Kohlbock PDFRaja RosenaniОценок пока нет

- Test 8 Softening PointДокумент2 страницыTest 8 Softening PointRaja RosenaniОценок пока нет

- Programming BeginДокумент25 страницProgramming BeginRaja RosenaniОценок пока нет

- Week3lab2 PDFДокумент1 страницаWeek3lab2 PDFRaja RosenaniОценок пока нет

- Repetition LoopingДокумент49 страницRepetition LoopingRaja RosenaniОценок пока нет

- Intro To Programming-InputOutputДокумент12 страницIntro To Programming-InputOutputRaja RosenaniОценок пока нет

- PROGRAMMING Chapter 1Документ46 страницPROGRAMMING Chapter 1Mohamad Izzulqhair FarisОценок пока нет

- PhoneticsДокумент8 страницPhoneticsRaja RosenaniОценок пока нет

- PSEUDOCODEДокумент33 страницыPSEUDOCODERaja Rosenani100% (1)

- SelectionДокумент21 страницаSelectionRaja RosenaniОценок пока нет

- Types of Resume: Chronological, Functional & CombinationДокумент19 страницTypes of Resume: Chronological, Functional & CombinationRaja RosenaniОценок пока нет

- ArrayДокумент37 страницArrayRaja RosenaniОценок пока нет

- Introduction To Pascal Programming Language: Arithmetic Expressions Logical/Boolean Expression Assignment StatementДокумент22 страницыIntroduction To Pascal Programming Language: Arithmetic Expressions Logical/Boolean Expression Assignment StatementHafiz OmarОценок пока нет

- Cover Letter AcadДокумент2 страницыCover Letter AcadRaja RosenaniОценок пока нет

- 1Документ1 страница1Raja RosenaniОценок пока нет

- AnswerrДокумент3 страницыAnswerrRaja RosenaniОценок пока нет

- SpeakingДокумент10 страницSpeakingRaja RosenaniОценок пока нет

- ReadingДокумент10 страницReadingRaja RosenaniОценок пока нет

- WritingДокумент7 страницWritingRaja RosenaniОценок пока нет

- FLOWCHARTДокумент17 страницFLOWCHARTRaja RosenaniОценок пока нет

- Note 5 MemosДокумент11 страницNote 5 MemosRaja RosenaniОценок пока нет

- Note 1 Linear To Non-LinearДокумент16 страницNote 1 Linear To Non-LinearRaja RosenaniОценок пока нет

- ListeningДокумент10 страницListeningRaja RosenaniОценок пока нет

- Stresses in Beams-Flexural FormulaДокумент15 страницStresses in Beams-Flexural FormulaRaja RosenaniОценок пока нет

- Barriers To Effective CommunicationДокумент9 страницBarriers To Effective CommunicationRaja RosenaniОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- 004 Foams PPT PresentationДокумент25 страниц004 Foams PPT PresentationPadmanaban BОценок пока нет

- Direction of Thermodynamic ProcessesДокумент26 страницDirection of Thermodynamic ProcessesJohn MagalongОценок пока нет

- Design of Cantilever BeamДокумент110 страницDesign of Cantilever BeamCONSTHURAG2012100% (3)

- Types of FEA AnalysisДокумент5 страницTypes of FEA AnalysisRawendrraw KuriОценок пока нет

- Polymer: Deniz C. Tuncaboylu, Aslihan Argun, Melek Pamuk Algi, Oguz OkayДокумент8 страницPolymer: Deniz C. Tuncaboylu, Aslihan Argun, Melek Pamuk Algi, Oguz OkayНиколайШубинОценок пока нет

- Mechanical DesignДокумент141 страницаMechanical DesignAhmed EĻ-dawodyОценок пока нет

- The Theory of The Pressure Die Casting of Aluminium Alloys: Dilip Panjikar Consultant, PuneДокумент27 страницThe Theory of The Pressure Die Casting of Aluminium Alloys: Dilip Panjikar Consultant, Puneravindra191274Оценок пока нет

- VMGSim User Manual - Separators6Документ22 страницыVMGSim User Manual - Separators6overlord5555Оценок пока нет

- 21 Design of Leaf SpringsДокумент10 страниц21 Design of Leaf SpringsPRASAD326100% (1)

- Ductile LinkДокумент19 страницDuctile LinksuvraОценок пока нет

- 1984 JN Reddy A Refined Nonlinear Theory of Plates With Transverse Shear Deformation IJSS 20Документ16 страниц1984 JN Reddy A Refined Nonlinear Theory of Plates With Transverse Shear Deformation IJSS 20fritz2000Оценок пока нет

- Detailed - LESSON - PLAN - GRADE 10 DemonowДокумент5 страницDetailed - LESSON - PLAN - GRADE 10 DemonowShiela Ocho100% (3)

- Numerical Simulation of Seismic Slope Stability Analysis Based On Tension-Shear Failure MechanismДокумент12 страницNumerical Simulation of Seismic Slope Stability Analysis Based On Tension-Shear Failure MechanismPaul Pinedo VilcahuamánОценок пока нет

- Che522/Cpe523 (Transport Phenomena) Assignment 1Документ2 страницыChe522/Cpe523 (Transport Phenomena) Assignment 1Jaja TeukieОценок пока нет

- Calculation of Crack Width As Per Is:456-2000Документ4 страницыCalculation of Crack Width As Per Is:456-2000Gautam DuttaОценок пока нет

- PROJECT REPORT FinalДокумент43 страницыPROJECT REPORT Finaljustine paivaОценок пока нет

- Effect of High-Energy Shot-Peening On H13 Tool Steel Ion-NitridingДокумент5 страницEffect of High-Energy Shot-Peening On H13 Tool Steel Ion-NitridingkarimОценок пока нет

- 1 Nanomaterial Synthesis MethodsДокумент71 страница1 Nanomaterial Synthesis MethodsAhmad AliОценок пока нет

- Strength of Materials/Mechanics of Solids (CE-303/DCE-303) - Short Answer Questions-UIT-RGPV BHOPALДокумент4 страницыStrength of Materials/Mechanics of Solids (CE-303/DCE-303) - Short Answer Questions-UIT-RGPV BHOPALSantosh Kumar0% (1)

- Final Thesis PDFДокумент68 страницFinal Thesis PDFjnmanivannanОценок пока нет

- Phy331 L9Документ15 страницPhy331 L9Dharmesh SharmaОценок пока нет

- Padeye - SkidДокумент16 страницPadeye - SkidNaresh Kumar100% (1)

- Ce-424 Structure-V R.C.C DesignДокумент38 страницCe-424 Structure-V R.C.C Designstudio VIIОценок пока нет

- ASTM E1300-2 LEdge StressДокумент1 страницаASTM E1300-2 LEdge Stressahsan khanОценок пока нет

- Glassy Metals IIIДокумент265 страницGlassy Metals IIICristian HoreaОценок пока нет

- Jurnal Internasional Tentang Material FosforДокумент4 страницыJurnal Internasional Tentang Material FosforBebeh Wahid NuryadinОценок пока нет

- Ce 4413: Mechanics of Solids Ii: Principle Stresses Under A Given LoadingДокумент27 страницCe 4413: Mechanics of Solids Ii: Principle Stresses Under A Given LoadingUpload2739Оценок пока нет

- Exp-6 Creep TestДокумент6 страницExp-6 Creep TestHanamant HunashikattiОценок пока нет

- A Study of The Weld Heat-Affected Zone Toughness of 9% Nickel SteelДокумент7 страницA Study of The Weld Heat-Affected Zone Toughness of 9% Nickel Steelmp87_ing100% (1)