Академический Документы

Профессиональный Документы

Культура Документы

Conveyor Belts

Загружено:

Thitikorn WassanarpheernphongАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Conveyor Belts

Загружено:

Thitikorn WassanarpheernphongАвторское право:

Доступные форматы

C

O

N

V

E

Y

O

R

B

E

L

T

S

CONVEYOR BELTS

CONTENTS

Company Profile and Locations

Conveyor Belt Construction

Selection of Carcass by Service Condition

Multi-Ply Fabric Conveyor Belt

Single-Ply Conveyor Belt

Jason Cover Compounds

Classification and Application of Conveyor Belt

Covers

Heat Resistant Conveyor Belt

Flame Resistant Conveyor Belt

Multi-Ply Recommended Min. Pulley Diameters

Bucket Elevator Belt

Cut Edge Transmission/Package Handling Belt

Sidewall Conveyor Belt

Rough Top Belt

Impression Belt

M-Shaped Conveyor Belt

Small Vee Corrugated Conveyor Belt

Raised Cleat Conveyor Belt

Silage Conveyor Belt

V-Guides Conveyor Belt

Flanged Conveyor Belt

Solid Woven Conveyor Belt

Starsteel

Chevron Conveyor Belt

Min. Pulley Diameters for Chevron Belt

6 Multi-V Conveyor Belt

Jason Specifications - Metric

Low Chevron Profile

Middle Chevron Profile

High Chevron Profile

Jason Product Catalogues

New Replacement Rollers

1 + 2

3

4

5

6

7

8

9

10

11

12

13

14

15 + 16

17

18

18

18

19

19

20

20

21

22

23

24

24

25

26 - 30

31

32 + 33

34

35

Distributors and customers have come to appreciate the value of doing business with Jason Industrial. Since 1958 Jason,

founded by Jacques Cohenca, has grown to become one of the leading suppliers of industrial rubber products and related

hardware in the western hemisphere. Our business model is simple - lean, responsive and being easy to do business with is our

corporate culture. We know that your opportunities are determined by quick, decisive action on your part, and we strive to

assist you in making those enquiries turn into orders.

Jason Industrial offers a complete range of industrial V-belts, neoprene and urethane synchronous belts, each provided in all

English and metric cross-sections or pitches. Our Industrial Hose and Couplings business offers solutions to the application

challenges of Agriculture, Construction, Food Processing, Mining and Wastewater to name a few.

Jason, built on customer services, is available to assist you with our team of well-trained sales professionals and engineers,

backed by domestic manufacturing facilities for all synchronous belt products. Our additional suppliers factories are

world-class facilities, which manufacture to both our and industry standard specifications.

Jason Industrial Inc. has replicated its Successful business practices with sales/distribution centres in Canada, Mexico and Brazil,

as well as the U.K. Acknowledged for providing single source solutions, Jason has recently expanded into Central America.

Taken as a whole, this global supply chain is your source for an imaginative offering of not only the products displayed within

this brochure, but rapid growth extensions in moulded goods, industrial drive components and speciality hoses.

Our Mission

To deliver the most complete selection of power transmission belts, hose, couplings and conveyor belts to a global marketplace

in a manner which promotes Jason Industrials identity as a responsive, value oriented supplier and partner.

CONVEYOR BELTS

COMPANY PROFILE AND LOCATIONS

1

62 Brunswick Street

Stockton-on-Tees

Cleveland TS18 1DR

Tel: 0044 (0) 845 053 9099

Fax: 0044 (0) 1642 601753

www.jasonindustrial.com

CONVEYOR BELTS

2

Jason Industrial

Canada, LTD

9135 Cote

De Liesse

Dorval,

Quebeb H9P-2N9

514-631-6781

Fax: 514-631-7408

Jason Industrial

Canada, LTD

4242 99th Street

Edmonton,

Alberta

T6E-5B3

780-461-4400

Fax: 780-461-1034

Jason Industrial

Canada, LTD

927 Matheson Blvd. East

Mississauga

Ontario

L4W-2R7

905 602-4400

Fax 905 602-4406

Jason do Brazil Ltda

Avenida, Armando

Panuzzio

Sorocaba- Sao Paulo

Brazil CEP 18050-000

011 55 15 222 00 07

Fax: 011 55 15 222 90 12

or 011 55 15 222 75 65

SJM Belting (Wuxi) Co. Ldt

Wuxi City

China 214101

Jason Industrial

S.De R.L. De C.V.

Azcapotzalco

Mexico D.F.

Corporate Warehouse

Jason Industrial, Inc.

340 Kaplan Drive

Fairfield, NJ 07004

973-227-4904

Fax: 973-227-1651

Jason Industrial Inc.

258 S.

Westgate Drive

Carol Stream,

IL 60188-2243

630-752-0600

Fax: 630-752-0680

Jason Industrial Inc.

3724 East

26th Street

Los Angeles,

CA 90023

323-265-8061

Fax: 323-265-0813

Jason Industrial Inc.

5120-B East

Adamo Drive

Tampa, FL

33619

813-241-4111

Fax: 813-241-4212

Jason Industrial Inc.

3236 Royalty Row

Irving

TX 75062

972 438-6992

Fax 972 721-9162

TBMC

Greenville

SC

Megadyne

America

Charlotte, NC

UNITED STATES OF AMERICA OTHER COUNTRIES

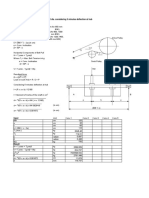

Conveyor Belts are generally composed of three main components:

1. Cover Rubber (Top Cover and Bottom Cover)

2. Carcass

3. Rubber Skim Coat

4. The reinforced breaker fabric is used for extra protection

1. Cover Rubber Covers of natural or synthetic rubber are used in conveyor belt construction in order to protect the base

carcass from wear, impact, deterioration and other injurious influences. They are compounded to meet particular service

conditions such as abrasion, oil, heat, flame, chemical resistant and antistatic, etc. Cover type, quality and thickness are

matched to the service life of the belt involved. A specific cover formulation used in an individual belt construction is

determined by the material to be carried and the environment in which the belt will operate.

2. Carcass Carcass consists of one or more plies of textile fabric with rubber on each side to give adhesion and flexibility.

The fabrics most commonly used are nylon, polyester and cotton, etc. The carcass of the belt provides the tensile strength

necessary to move the loaded belt and absorb the impact of the impinging material being loaded onto the conveyor belt.

3. Rubber Skim Coat An extra layer compound between plies is called skim coat. Skims are important contributors to

internal belt adhesions, impact resistance, and play a significant role in determining belt load support and troughability. The

proper skims increase flex life and create a more elastic link so that plies flex without separation; improper skims can adversely

affect belt performance and lead to ply separation.

4. Breaker Fabric A special woven fabric between the cover and the carcass

improves cushioning, the gouging and tear resistant properties of the cover rubber

and protects the carcass from impact damages. This construction is recommended

for use in belts handling primarily crushed and sized material which gives severe

impact to the belt when lumps drop at a loading point.

CONVEYOR BELTS

CONVEYOR BELT CONSTRUCTION

Top Cover

Carcass

Bottom Cover

Skim Coat

Here a breaker ply is laid over the

top fabric ply of the carcass

Fabric Plies Bottom Cover

3

Three Versatile Fabric Designs:

1. Nylon/Nylon (NN) Carcass This construction, utilizing all

Nylon, is flexible to adopt a small diameter pulley and is suitable for

transporting a variety of materials like ore, crushed stones, grain, sand,

etc., but has a rather weak point in being easily excessively stretched.

Features:

Excellent resistance to impact.

Superior in fastener holding ability.

Unaffected by alkali and weak acids.

Strong adhesion to rubber.

Great flexibility and excellent troughability.

Higher tensile strength compatible with low weight.

Advanced resistance to mildew, moisture and rotting.

2. Polyester/Nylon (EP) Carcass The EP fabric consists of polyester fibre as warp and polyamide (Nylon66) as the weft.

Besides having the advantages as listed for NN carcass, EP has the additional advantage of lower longitudinal elongation. The

stretch is much less than a belt using Nylon and makes take-up travel shorter. This belt is suitable for middle and long

distance transportation of higher load and speed.

3. Cotton/Cotton (CC) Carcass Excellent heat and bending resistance, low elongation, but with water absorption higher

than that of EP and NN.

CONVEYOR BELTS

SELECTION OF CARCASS BY SERVICE CONDITION

CODE

CONSTRUCTION

(Weave:Plain)

WARP

TENSILE STRENGTH

ALLOWABLE WORKING

TENSION

APPROX GAUGE PER PLY

with skim rubber

Warp Weft kg/cm-ply Ib/in-ply kg/cm-ply Ib/in-ply m/m inch

NN-100 Nylon-6 Nylon-6 100 560 10 56 1.0 0.039

NN-150 Nylon-6 Nylon-6 150 840 15 84 1.2 0.047

NN-200 Nylon-6 Nylon-6 200 1120 20 112 1.3 0.051

NN-250 Nylon-6 Nylon-6 250 1400 25 140 1.4 0.055

NN-300 Nylon-6 Nylon-6 300 1680 30 168 1.5 0.060

NN-400 Nylon-6 Nylon-6 400 2240 40 224 1.6 0.063

EP-100 Polyester Nylon-66 100 560 10 56 1.0 0.039

EP-125 Polyester Nylon-66 125 700 10 70 1.2 0.047

EP-150 Polyester Nylon-66 150 840 15 84 1.2 0.047

EP-200 Polyester Nylon-66 200 1120 20 112 1.3 0.051

EP-250 Polyester Nylon-66 250 1400 25 140 1.4 0.055

EP-300 Polyester Nylon-66 300 1680 30 168 1.5 0.060

EP-350 Polyester Nylon-66 350 2000 35 200 1.6 0.063

EP-400 Polyester Nylon-66 400 2240 40 224 1.7 0.067

EP-500 Polyester Nylon-66 500 2800 50 280 1.8 0.071

30OZ Cotton Cotton 55 308 5.5 30 1.4 0.055

32OZ Cotton Cotton 60 335 6.0 33 1.5 0.060

Fabric Specification

4

Multi-Ply Fabric Conveyor Belts have three or more

fabric plies in the carcass. The necessary strength

and stability is secured by using sufficient numbers

of fabric plies in the carcass.

Belt Construction

Top Cover: Any thickness from 1/32 to 1

Carcass: 1 to 6 plies or more

Skim: From 1/32~

Bottom Cover: Any thickness from 1/32 to 1

(Bareback is also available)

Range of Production

Fabric: EP, NN or Cotton

Tensile Strength: 100~3000 kgf/cm

Belt Width: 300mm ~ 1600mm

No. of Ply: 1 ~ 6 plies

Overall Thickness: 3mm ~ 50mm

Edge: Cut or Moulded Edge

Max. Length: Roll Diameter not exceeding 2.6m

CONVEYOR BELTS

MULTI-PLY FABRIC CONVEYOR BELT

Product Application

1. General Purpose

2. Super Abrasion Resistance

3. Oil Resistance

4. Heat Resistance

5. Flame Resistance

6. Chemical Resistance

7. Anti-Static

Top Cover

Carcass

Bottom Cover

Skim Coat

Strength Class (kN/m) 2-PLY 3-PLY 4-PLY 5-PLY 6-PLY

160 160/2

200 200/2

250 250/2 250/3

315 315/2 315/3

400 400/2 400/3 400/4

500 500/3 500/4 500/5

630 630/3 630/4 630/5 630/6

800 800/3 800/4 800/5 800/6

1000 1000/3 1000/4 1000/5 1000/6

1250 1250/3 1250/4 1250/5 1250/6

1500 1500/4 1500/5 1500/6

1600 1600/4 1600/5 1600/6

1800 1800/5 1800/6

2000 2000/5 2000/6

2500 2500/6

3000 3000/6

Class of Material Example of Material Carried

Top Cover

Belt Length

Bottom Cover

Belt Length

<40m 40~150m >150m <40m 40~150m >150m

Non-Abrasive Wood Chips, Grain Chips, Fine Coal, Ash, Cement, etc. 1/8 1/16~1/8 1/16 1/16 1/16 1/32

Slightly-Abrasive Sand, Earth, Bituminous Coal, Salt, Clay, etc. 3/16 1/8~3/16 1/8 1/16 1/16 1/16

Moderately-Abrasive Limestone, Coke, Sinter, Crushed Stone, etc. 1/4 3/16~1/4 3/16 1/8 1/16~1/8 1/16

Very-Abrasive Copper, Ores, Slag Iron, Gravel, Coke, etc. 3/8 3/8~1/4 1/4 1/8~3/16 1/8 1/8

Extra-Abrasive Grass Cullet, Trap Rock, Quartz, Sharp Ore, etc. 1/2 3/8 3/8 3/16 3/16 1/8~3/16

Strength Classes and Number of Plies; Recommended Cover Thickness

5

Structure of Belt

Application:

Single-Ply Belting possesses a unique straight-warp carcass, unlike conventional crimp

weave fabrics. The carcass developed is a total departure from the traditional plied

belt concept and constructions. It is designed to carry a large capacity of material and

has a superior endurance performance in rugged environments.

Features:

The synthetic fibres yield a higher unit strength and exceptional resistance to abrasion,

cutting and snagging. The construction of single-ply increases resistance to flexural

fatigue and impacts. Its troughability is much better than a normal fabric. It provides

high-carrying capacity and very low stretch. The elongation is approx. 0% at 10% load,

hence the belt can be used for long distance conveyor lines.

CONVEYOR BELTS

SINGLE-PLY CONVEYOR BELT

Top Cover

Any Thickness

from 1/16 to 1

Carcass:

Single Unit

Bottom Cover

Any Thickness

from 1/16 to 1/2

Top Cover

Any Thickness

from 1/16 to 1

Carcass:

Double Unit

Bottom Cover

Any Thickness

from 1/16 to 1/2

Skim

Fabric

Type

Number

of plies

Tensile

Strength

Tension

Rating

10%

Strength

Carcass

Thickness

When 100%

Tension

Troughability

Angle 35

kg/cm/ply kg/cm/ply % mm Min. Pulley Dia. Min. Width

SW315 1 Min. 315 31 Max. 1.0 2.0 16 20

SW400 1 Min. 400 40 Max. 1.0 2.2 20 24

SW500 1 Min. 500 50 Max. 1.0 2.6 24 24

Belt width

Fabric Type

Belt Strength (N/mm)

No. of plies

Top cover thickness

Bottom cover thickness

Belt length

Grade of cover

1600mm x EP 500/3 x 5mm x 1.5mm x 200M Grade N

Filling

Binder warp

Basic Straight Warp

Single Ply Fabric Grade

Designation

Type: SW x 1

Type: SW x 2

It is available with various cover grade and gauges in accordance with customer requirements. Double plies of straight wrap fabrics also is available.

6

Operating conditions demand the right covers. The covers, which are vulcanized onto the

belt carcass, are designed for specific applications. Each cover is job-engineered using the

proper formula of chemically compounded natural and/or synthetic rubbers. Whether the

primary operational concern is abrasion, heat, oil, flame, etc., Jason has a wide range of cover

compounds designed specifically to meet with the most demanding operating requirements.

CONVEYOR BELTS

JASON COVER COMPOUNDS

General Service Covers

Grade S150 (General Light Duty Service)

The most economic type. Suitable for conveying moderately abrasive materials and small sized materials.

Grade S180 (RMA2, DIN-Y, N, BS-N17, AS-N, JIS-G)

This cover rubber grade is widely used for general conveyor belts with good resistance to abrasion, ozone, cutting and gouging.

Recommended for most above-ground abrasive material handling applications, such as coal, crushed ores and rock, slag,

limestone, bauxite, sand, aggregates and other abrasive materials.

Grade S240 (RMA1, DIN-X, M, BS-M24, AS-M, JIS-S)

Superior endurance against combined cutting, gouging and heavy impact plus superior abrasion resistance. Especially

recommended for the severest applications, such as heavy rock, slag, cullet, sharp stone, granite and other truly sharp and

heavy materials.

*General Service Cover *Super Abrasion Resistant Covers

*Oil Resistant Covers. *High Temperature Covers

*Flame Resistant Covers *Special Requirement Covers.

Cover Specifications

S150 General Purpose Resistance 150 2130 400 250

S180 High Strength & Abrasion Resistance 190 2700 450 200

S240 Super Strength & Abrasion Resistance 240 3410 500 120

SAR90 Super Abrasion Resistance 180 2560 400 90

OR Oil Resistance 140 1850 400 250

MOR Moderate Oil Resistance 155 2135 450 200

HR120 Heat Resistance (SBR) 180 2560 600 250

HR150 Heat Resistance (EPDM) 150 2130 500 300

HOR Heat & Oil Resistance 170 2410 450 300

FER Flame Resistance 140 1850 550 300

kg/cm Ibs/in % mm

Grade Characteristics

Min. Tensile Strength

Min. Elongation Max Abrasion Loss

2 2 3

7

General Abrasion Resistant Purpose

For general application, Jason sorts four kinds of grade for customers requirements. Firstly Grade S150, the most economic

one, is designed for those light duty applications, usually for conveying materials with moderate abrasion and small size.

Secondly, when considering heavy duty applications and good resistance to abrasion, ozone, cutting, and gouging, Grades S180

and S240 are the option for you. How to correctly choose one of either? Please refer to page 6 for full details. Finally, SAR90

is recommended for applications where severe abrasion is the primary concern, with materials that are heavy and sharp.

OIL RESISTANT CONVEYOR BELT

Application:

Oily material causes the ordinary rubber covers of the belt to swell and come off

easily, which usually results in a complete breakdown of the conveyor system.

In order to be able to put the right application in the right place, please refer to

the following information.

Chart of Comparision for Oil-Resistant Belts:

CONVEYOR BELTS

CLASSIFICATION AND APPLICATION OF CONVEYOR BELT

In addition, you should check the following important steps before ordering:

1. Check the type of oil.

2. Be aware of the approximate quantity of oil on the surface of the material carried.

3. Be aware of the temperature range that it may go to.

4. To understand the details of the belt used, the previous one.

Finally, be aware that mistakes will occur, should you not go through all as above.

OR G E E E G G G E G G E G E -20C~60C

MOR F G G G F F F F F F F G F -30C~50C

M

a

t

e

r

i

a

l

Belt

Type A

n

i

m

a

l

F

a

t

s

V

e

g

e

t

a

b

l

e

O

i

l

s

W

o

o

d

O

i

l

W

o

o

d

C

h

i

p

P

i

n

e

O

i

l

P

e

a

n

u

t

O

i

l

O

l

i

v

e

O

i

l

M

i

n

e

r

a

l

O

i

l

C

o

r

n

O

i

l

C

o

t

t

o

n

S

e

e

d

O

i

l

D

i

e

s

e

l

O

i

l

H

y

d

r

a

u

l

i

c

O

i

l

P

e

t

r

o

l

e

u

m

O

i

l

Temp.

Range

Rating: F-Fair G-Good E-Excellent

8

Super Abrasion Resistant Covers

SAR90 (DIN-W)

Recommended for applications where heavy, continuous abrasion is the primary concern. Ideally suitable for crushed stone,

trap rock, copper or gold ore, sinter, coke, log handling, primary crushers and other abrasive materials. It provides increased

service life without increasing cover thickness and extends service life approx. 20% over that of Grade S180.

Oil Resistant Covers

OR (Oil Resistance)

Superior resistance to materials containing high concentrations of animal or vegetable fats, oily metal parts that cause swelling

and sponginess. The compound has abrasion, tear, ozone and weather resistance.

Recommended service temperatures max. +60C, min. -20C

MOR (Moderate Oil Resistance)

Designed to be used in moderately oily environments. Recommended for specialised service such as wood chips, waste

disposal, sewage, sludge, whole grains, and lightly oil treated materials.

Recommended service ambient temperature max. +50C, min. 30C.

High Temperature Covers

HR120 (Heat Resistance up to 120C)

For use in medium temperature range.

This grade heat resistant belt is the premium quality SBR rubber compound with excellent abrasion resistance and heat

resistance. Belt surface temperature allowed up to 120C. This grade belt is recommend for conveying hot material like coke,

sintered products, etc.

HR150 (Heat Resistance up to 150C)

For use in medium to high temperature range.

EPDM compound can withstand heat up to 150C for abrasive coarse lumps (2 inch+ / 50mm+) and 130C for abrasive fines

without cracking. It is used extensively in the cement and foundry industries for transporting cement, coke, sintered ores, soda

ash, fertilizer, etc.

HOR (Heat & Oil Resistance)

Used on systems handling hot and oily material, the covers are 100% Nitrile polymer, with no other type elastomer.

This grade is recommended for conveying hot asphalt with temperatures up to 150C (300F) where both oil and heat

resistance are required.

Flame Resistant Covers

FER (Flame Resistance & Antistatic)

Having fire resistant and antistatic properties, this grade is recommended for use where a fire hazard exists e.g. thermal plants,

underground mines.

CONVEYOR BELTS

COVERS

9

Application:

In general, it is economical to adopt a heat resistant belt if the temperature

of the conveying material exceeds 60C (140F). The proper selection of a

cover rubber is decided mainly on the temperature and size of transported

material. This belt is used for sintering plants, chemical plants, coking plants

and cement plants for transporting cement clinker, blast furnace clinker,

cokes, burnt lime, sinter, slag, and high-temperature powdery materials.

Selecting the right heat resistant belt:

In selecting the most suitable belt, it is important to consider carefully various

factors that may affect the belt, such as the temperature and lump or

particle size of material transported, belt surface temperature, time cycle

and other factors. Some examples of such temperatures are shown as follows:

CONVEYOR BELTS

HEAT RESISTANT CONVEYOR BELT

For high-temperature applications different types of belting are available: HR120, HR150 & HOR

ANTI-STATIC CONVEYOR BELT

With a specific rubber compound designed for excellent static conductivity, usually used for applications with a high risk of

igniting a fire by static spark, such as paper or textile mills.

Temp. resistant to 150C (300F) for abrasive coarse lumps 50mm+ (2+)

(e.g. sintered ores, coke) and 120C (250F) for abrasive fines

(e.g. cements, aluminium, carbon black, iron ore in pellets, etc.).

Recommended wherever a premium high temp. belt is required.

Provides max. service life on enclosed systems with high environmental temperatures.

EPDM compound can withstand up to 150C for abrasive

coarse lumps 50mm (2) and 130C for abrasive fines.

It is used extensively in the cement and foundry industries.

Excellent resistance to 150C temp. for coarse lumps 50mm+ (2+).

Recommended for conveying hot mixtures containing diesel oil as well as

kerosene, petroleum coke, hot asphalt, paving mixes, carbon pitch and in

other areas where moderate heat and extra oily conditions are present.

HR120

HR150

HOR

SPECIAL FEATURES Cover Grade

SBR

EPDM

NITRILE

Coke 100~200 70~100C 50~60C

Cements Powder 100~125C 80~90C

Clinker 10~30 100~220C 100~110C

Burnt Lime Powder 130~150C 100~130C

Sintered Ore 20~300 200~400C 130~150C

Return of Sintered Ore < 10 250~260C 150~200C

Moulding Sand < 2 270~280C 120~200C

Materials Carried Size (mm)

Temperature of

Materials Carried

Belt Surface

Temperature

Cover Rubber Regular Anti-Static

Electrostatic Resistance From 3 x 10 to 3 x 10 Less than 3 x 10

3 8 8

10

This belt is designed to prevent fire risks in coal mines where it is not easily accessible and to reduce maintenance of the

conveyors. The important characteristic is self-extinguishable cover rubber and meeting the drum friction test.

It is suitable for serving in the mining industry, power plants, electric utilities and coal cleaning plants.

CONVEYOR BELTS

FLAME RESISTANT CONVEYOR BELT

CHEMICAL RESISTANT CONVEYOR BELT

Application:

According to the nature of the materials or chemicals, acid-resistant or alkali-resistant cover rubbers may be selected.

All the information in this chart has been gathered from a number of resources. Each specific cover formulation used in

individual belt construction is determined by the materials to be carried and the environment in which it will be used.

Accordingly, Jason cannot guarantee the accuracy of the information presented. The chart should be used as a guide and

reference only, since the performance of any item in this chart could be affected by many factors. In order to avoid any

unexpected results, please make enquiries before making any decisions.

Rating: E: Excellent / G: Good / F: Fair / NR: Not Recommended

G NR NR G NR G NR NR G G E E F -30 ~ +120

NR G E E NR E G NR E E E E E -30 ~ +120

G G NR E F E NR NR E E F E G -10 ~ +200

E G G G NR E G E G NR E E G -18 ~ +120

E G NR E NR E G G G G G E E -30 ~ +120

E G NR E F E NR NR E G NR E E -54 ~ +150

Chemical

Polymer

Natural Gum

Urethane

EPDM

Nitrile

Neoprene

Butyl

A

l

c

o

h

o

l

s

A

n

i

m

a

l

F

a

t

s

A

s

p

h

a

l

t

H

o

t

C

a

l

c

i

u

m

S

u

l

p

h

i

d

e

C

h

r

o

m

i

c

A

c

i

d

C

o

p

p

e

r

S

u

l

p

h

a

t

e

F

a

t

t

y

A

c

i

d

L

a

t

e

x

A

d

h

e

s

i

v

e

s

O

x

y

g

e

n

O

z

o

n

e

S

e

w

a

g

e

S

o

d

a

A

s

h

S

u

n

l

i

g

h

t

Temp.

Range, C

Standard

JIS

CNS

Each less than 15 sec.

Total of 6 samples less

than 45 sec.

Each less than 15 sec.

Total of 6 samples less

than 45 sec.

Avr. less than 60 sec.

Avr. less than 10 sec.

Each less than 15 sec

Avr. less than 60 sec.

ISO

DIN

MSHA

AS

CSA

Flame

Laboratory Flame Test

Glow

Drum Friction

Test

Electric

Resistance

Other Items

None None

None None

None

None None

None

None

None

Avr. less than 180 sec.

Avr. less than 120 sec.

Each less than 180 sec.

Avr. less than 180 sec.

Less than 320C

on drum surface

and no glow

Less than 400C

on drum surface

and no glow

Oxygen index test in

accord with ISO 4589

gallery flame test

Less than 3 x 1O

Less than 3 x 1O

Less than 3 x 1O

Less than 3 x 1O

8

8

8

8

Flame Resistant Belt Standards by Country

11

Adhesion Range of Gauge ISO 252 Synthetic Fibres DIN 22102 BS 490

0.8 < T < 1.5mm 3.5 3.5 2.35

T > 1.5mm 3.9 4.5 2.8

Fabric/Fabric 5 5 5

When a belt travels around a pulley, the outer plies of the carcass traverse a greater distance than the inner plies. If the pulley

diameters are too small for the belt, the inner plies may be forced into compression resulting in ply separation and premature

failure of the belt.

D = Driving Pulley T = Tall Pulley S = Snub Pulley

CONVEYOR BELTS

MULTI-PLY BELTS RECOMMENDED MIN. PULLEY DIAMETERS

2P 200/2 125 125 125 160 125 125 160 160 125

3P 315/3 160 160 160 200 160 160 200 200 160

4P 400/4 200 160 160 250 200 160 315 250 200

5P 500/5 250 200 200 315 250 200 400 315 250

2P 250/2 160 160 160 200 160 160 200 160 160

3P 400/3 200 160 160 250 200 160 315 250 200

4P 500/4 250 200 200 315 250 200 400 315 250

2P 315/2 160 160 160 200 160 160 250 200 160

3P 500/3 250 200 160 315 250 200 400 315 250

4P 630/4 315 250 200 400 315 250 500 400 315

5P 800/5 400 315 250 500 400 315 630 500 400

2P 400/2 200 200 160 250 200 160 315 250 200

3P 630/3 315 250 200 400 315 250 500 400 315

4P 800/4 400 315 250 500 400 315 630 500 400

5P 1000/5 500 400 315 630 500 400 800 630 500

3P 750/3 400 400 400 500 400 315 630 500 400

4P 1000/4 500 400 315 630 500 400 800 630 500

5P 1250/5 630 500 400 800 630 500 1000 800 630

3P 900/3 400 315 250 500 400 315 630 500 400

4P 1200/4 500 400 315 630 500 400 800 630 500

5P 1500/5 630 500 400 800 630 500 1000 800 630

3P 1000/3 500 400 315 630 500 400 800 630 500

4P 1250/4 630 500 400 800 630 500 1000 800 630

5P 1800/5 800 630 500 1000 800 630 1250 1000 800

3P 1200/3 500 400 315 630 500 400 800 630 500

4P 1600/4 630 500 400 800 630 500 1000 800 630

5P 2000/5 800 630 500 1000 800 630 1250 1000 800

3P 1500/3 630 500 400 800 630 500 1000 800 630

4P 2000/4 800 630 500 1000 800 630 1250 1000 800

5P 2500/5 1000 800 630 1250 1000 800 1600 1250 1000

H D L A M N S W X Y Z RMA1 RMA2 M24 N17

450 400 350 400 450 450 300 400 450 400 350 450 400 450 400

24 18 15 17 25 18 14 18 25 20 15 18 14 24 17

120 100 200 70 120 200 250 90 120 150 250 200 150

ISO 10247 AS1333 DIN22102, 1991 RMA BS 490

EP100

EP125

EP160

EP200

EP250

EP300

EP350

EP400

EP500

Fabric

Type

Number

of Plies

Strength

Classes

and

number of

plies

Utilisation of max. permissible belt tensile

Less 35%

MINIMUM DRUM

DIAMETER (mm)

MINIMUM DRUM

DIAMETER (mm)

MINIMUM DRUM

DIAMETER (mm)

35~65% 66~100%

D T S D T S D T S

Cover

Min. elongation at break (%)

Min. tensile strength (N/mm )

Min. wear loss (mm )

2

3

Cover/Fabric (N/mm)

Reference Value for Selection of Cover Compound of Belt

12

Application:

This is composed of rubber belt and elevator-bucket, which need a belt with high

strength and low elongation in service. The Bucket Elevator Conveyor Belt is applicable

to transport vertically loose powdery materials of usually not more than 50mm in

diameter, such as crushed limestone, sand, gravel, cement, grain etc.

Elevator Belt Tips:

They may be liable to break due to the bolt setting holes, distributed along the entire

belt length for fitting the buckets. In addition, these belts, different from ordinary belts,

are subject to various forces including lever action due to projection of the buckets

and the extracting force exercised by pulleys at the time of belt bending. So for

elevator service, you need to calculate the strength of the belt needed to support the

weight of the bucket and the material being conveyed.

CONVEYOR BELTS

BUCKET ELEVATOR BELT

Castings of enclosed construction, dust sealed

as required, in standard panels, including

removable inspection panels at head, tail and

intermediate points.

Bare-Backed Belts Application:

Used where the belts run on steel, wood or some other low-friction

surface (sliding bed), and for belts with low friction back and top cover.

These belts allow easy scraping-off of parcels, sacks and other items.

Standard Specification:

Carcass: EP or Cotton Duck

Tensile Strength: 100~2,400 N/mm

Max. Belt Width: ~1500mm or 60

Cover Rubber: Resistant to wear, oil,

heat and anti-static; also cover-less type (FS)

Feed Type:

SCOPE FEED FLY FEED

General Specification

Specification Belt Thickness

EP150 x 2P x 1/32 x 1/32 4.0mm

EP150 x 3P x 1/32 x 1/32 5.2mm

EP150 x 4P x 1/32 x 1/32 6.4mm

13

Commonly known as friction surface and/or transmission belting, this belt has long been a standard for a wide variety of

conveyor applications for both slider bed and roller applications. Construction is cotton or EP fabric plies bonded with resilient

rubber compounding. For light duty applications where rubber covers are not necessary or desirable. Standard also for heavy

duty power transmission drive, constructed of rugged silver hard duck fabrics with heavy skim coats between.

CONVEYOR BELTS

CUT EDGE TRANSMISSION/PACKAGE HANDLING BELT

1 3P x FS x FS 3.8 105 1050 3 48

2 4P x FS x FS 5 140 1400 4 48

3 5P x FS x FS 6.3 175 1750 6 48

4 4P x FS x FS 5.8 175 1750 5 48

5 5P x FS x FS 7.2 215 2150 8 48

6 6P x FS x FS 8.7 260 2600 12 48

7 EP135 2P x 1/32 x 1/32 4.8 150 1500 4 60

8 EP135 2P x 1/32 x Bare 3.9 150 1500 4 60

9 EP200 2P x Cover x Cover 2.8 220 2200 8 60

10 EP200 2P x Bare x Bare 3.2 220 2200 8 60

11 EP135 3P x Bare x Bare 4.8 225 2250 10 60

12 EP135 3P x 1/16 x Bare 6.3 225 2250 10 60

13 EP200 3P x 1/16 x Bare 6.9 330 3300 12 60

32oz

35oz

H.S.D

Tan

or

Cream

Black

Green

Red

Black

The most popular beltings

for converor / elevator /

tansmission uses

NO. CARCASS DESIGNATION

OAG

(mm)

COLOUR

WORKING

TENSION

PER INCH

WIDTH(Ibs)

BREAKING

TENSION

PER INCH

WIDTH(Ibs)

MIN.

PULLEY

DIA.

STAN-

DARD

WIDTH

APPLICATIONS

The most suitable bucket

elevator belting to be used

in grain and feed industries

Potato Belting

For general package handling

& agriculture application

Suited for parts assembling

lines in electronics industries

Usually used in aircraft

supply industries and other

lightweight conveying

Popular for carrying fruits,

plantation products and

general items.

2Ply 35oz. white FS x FS

Hot Silver Duck

30oz. white

Bare x Bare

4Ply Hot Stock and Water 3Ply Hot Stock and Water 5Ply 30oz. Tan FS x FS

Hot Silver Duck

EP-125 x 2P x 1/16 x 1/16

Green SBR

EP-125 x 2P x 1/16 x 1/16 EP-150 x 3P x FS x Bare EP-125 x 2P x 1/16 x

Green SBR x Bare

EP-150 x 2P x Bare x Bare

Specifications

14

Design

It is based on the following main components:

(1) Cross-Stabilised Base Belts (2) Sidewalls (3) Cleats

The Sidewall Conveyor Belt has been designed with two corrugated

sidewalls and cleats moulded to cross-rigid base belt and can carry

heavy product loads up to the inclined angle of 75. This belt is

popular where space is at a premium and steep incline angles are desired.

The Base Belt

The base belt is designed to bend efficiently in a longitudinal direction and

has greater rigidity in a transverse direction by utilising reinforced fabrics with

monofilament that creates a fabric carcass of high tension.

Base Belt Type:

TYPE: XE TYPE: XE+1 TYPE: XE+2

Belt Composition:

X = Cross-Stabilised Construction

E = Polyester Tension Plies

+1 = One Ply of Cross-Stabilised

+2 = Number of Separate Cross-Stabilising Plies

It can be deflected from the horizontal to an incline or vertical and back again without bowing or sagging. These deflection

points as well as the belt returning on free lateral space by snub idlers definitely require the cross-rigidity of the base belt. The

designed mono-filament fabrics provide better returnside support, no wear and tear of cleats and cover rubber is available with

various compounds such as abrasion resistance, oil, heat, and flame resistance.

CONVEYOR BELTS

SIDEWALL CONVEYOR BELT

Construction:

XE+2 : is a multiply construction with cut edges based

upon a carcass of EP fabric and one monofilament ply

on each side of the EP carcass integrated into the

upper and lower cover.

Rubber Grade

Belt Total Length (m)

Thickness of bottom cover rubber

Thickness of top cover rubber

Number of plies for mono-filament fabrics

Number of plies for simple EP fabrics

Tensile strength of belt (N/mm)

Belt width

1400mm wide, XE630/4 + 2P x 4mm + 2mm x 37m, MOR

15

CONVEYOR BELTS

SIDEWALL CONVEYOR BELT

Type H (mm) WB (mm) FB (mm)

L 60 60 45 50

L 80 80 45 50

L 100 100 45 50

L120 120 45 50

Type Type T Type C Type TC

Cleat Height 20mm-180mm 55mm-110mm 40mm-180mm

Cleats for transverse

The basic belt

Reinforcing mono-fabric

S-shape flange

Free Zone

EP Fabric carcass

SideWall :

SideWall :

S-type with taper bottom

Kind of Transverse Cleat

16

Application

The Rough Top Belt is designed for transporting lightweight goods, either

being inclined or horizontal, also suitable for transporting fragile or deformed

materials and packed goods, such as glass, papers, bags, boxes or cartons, to a

maximum of 35 degrees.

Features:

The bareback Rough Top Belt has a lower friction coefficient, suitable for

running over tables and flat panels. The design of the mesh-like pattern on

the top surface cover can generate the relief effect, absorbing any vibrations

and impacts exerted on the materials conveyed and simultaneously

preventing the materials from sliping.

Construction and Properties

2 or 3-ply construction with cut edges and a carcass of synthetic EP fabric. The surface texture resists the tendency for the

material to roll back down the conveyor. The black top cover is recommended for utility type incline service while the tan

cover is suggested for transporting packaged food products where an odourless, non-toxic, non-marking belt is a necessity.

Top cover is a full 1/8 thick SBR and the back is protected by either a durable friction surface bottom or a synthetic

bare-back for slider bed applications.

CONVEYOR BELTS

ROUGH TOP BELT

Permissible Inclined Angle

Materials Angle

Jute sacks (Bag) 35

Goods packed in paper 32

Wooden Case 30

Cartons 28

Salt or powder 27

Wheat (Bulk) 26

Boxes of synthetic material 25

Goods packed in plastics 22

Soy Bean (Bulk) 20

Type

No. of

ply

Top

Cover

Bottom

Cover

Standard

Length

Colour

Standard

Width

A 2 ply 1/8 R.T Bareback

B 2 ply 1/8 R.T 1/16

C 3 ply 1/8 R.T Bareback

D 3 ply 1/8 R.T 1/16

200m

Per Roll

Black

or

Tan

1350mm

~

1500mm

cut edge

Our R.T. Belt Standard Specification

Max. material temperature 80C

17

IMPRESSION BELT

CONVEYOR BELTS

M-SHAPED CONVEYOR BELT

The cross section of the top cover is formed into an M shape which is soft yet durable and will self clean as it goes around

pulleys. With this belt, loading or unloading can be performed easily from either side of the belt. This belt is recommended for

transporting comparatively heavier goods in bags, packages or boxes at angles from 15 to 20 degrees.

SMALL VEE CORRUGATED CONVEYOR BELT

The top surface features soft flexible parallel ribs which enable it to convey on steep inclines. The small Vee ribs are serrated to

form thousands of high-grip fingers that self clean. This belt is popular in the shoe industry.

Standard Specification

Max. Belt

width

Fabric Ply Top Cover

Bottom

Cover

Cleat

Height

1200mm EP150 2P~3P 1.5mm 1mm 2mm

Standard Specification

Max. Belt

width

Fabric Ply Top Cover

Bottom

Cover

Cleat

Height

Colour

1000mm EP150 2P 1.5mm Bareback 5.5mm Blue

1000mm EP150 3P 1.5mm 1.5mm 5.5mm Black

Belt cover with a textured pattern impressed, can be made on either the top cover or both covers depending on the customers

requirement. Suitable for material carried in the agricultural field or on light duty application.

18

Application:

This belt is suitable for transportation of firewood, hay, glass,

recycled materials, packaged goods and boxes at an inclined angle.

Cleats are hot vulcanized to the base belt for a bond the full width

of the cleats, making them an integral part of the belt top cover.

According to its operational requirement and lump size, the shape

and pitch of the rubber cleat can adequately be made.

CONVEYOR BELTS

RAISED CLEAT CONVEYOR BELT

SILAGE CONVEYOR BELT

This is used in cattle feeding machines in the agricultural business, mostly used in larger stables.

Type BW CW CP CH

SB-48 500~600 480 350 30

Type BW CW CP CH

T-25 300~800 250-650 300 25

T-50 350~1200 350-1200 300 50

Type T:

Unit:mm

Unit:mm

19

V-Guide Size

Type A B C Max. belt width

K15 15mm 8.5mm 9.5mm ~1160mm

K17 17mm 10mm 11mm ~880mm

Application:

The V-Guides are designed to keep belts always running in proper

alignment and to reduce tracking problems. The V-Guides ribs are

hot-vulcanized on the bottom of the belt to ensure the highest adhesion

levels possible. Standard sizes as follows:

CONVEYOR BELTS

V-GUIDES CONVEYOR BELT

FLANGED CONVEYOR BELT

Application:

These speciality belts are used mostly for coal burning units and weighted M/C in power stations, while many others are used

in cogeneration plants, cement manufacturing, etc.

Features:

1. The flanged structure prevents coal powder or

lumps from spilling over the edge during transportation.

2. Notching design enables a V-guided belt to operate in

smaller pulley diameters. The V-guide which fits into a

groove on pulleys reduces tracking problems.

Type Stock Belt Specification Cover

KF32 33wide NN150 x 2P x 2.8 + 2.8 (8mm T) RMA1

Type 1:

Type 2:

20

SOLID WOVEN CONVEYOR BELTS

CONVEYOR BELTS

Solid Woven Conveyor Belt:

This belt has many strong points in service, for example: no ply separation, small elongation, anti-impact, tear resistance and

good mechanical fastening property. It is mainly used in underground coal mines. The plastic type of solid woven conveyor

belt (PVC) is used in dry operation areas where the inclined angle is up to 16. The rubber covered solid woven

conveyor belt (PVG) is used in wet operation areas where the tilted angle is up to 20.

Standards:

PVC and PVG Solid Woven Belts conform to MT914 (Chinese), BS3289 (British).

The Type Series of Textile Reinforced Conveyor Belt (Solid Woven Type)

Solid Woven Type (PVC, PVG)

Identification of Conveyor Belt.

For Example:

Flame Resistant

PVG Solid Woven

Conveyor Belt

PVC Flame

Resistant Solid

Woven Belt

Type

Full Thickness Belt Tensile Strength N/mm Full Belt Elongation at Break % (not less than) Belt Width Length Per Reference Mass kg/m2

Longi. Transv. Longi. Transv. mm Roll m. PVC PVG

580S 580 245

680S 680 265 11.2 16.8

800S 800 280 12.0 17.1

1000S 1000 300 650 14.0 17.6

1250S 1250 350 15.5 19.6

1400S 1400 350 15 18 200 16.5 20.8

1600S 1600

1800S 1800 1400

2000S 2000

2240S 2240

2500S 2500

Type 580S 680S 800S 1000S 1250S 1400S 1600S 1800S 2000S 2240S 2500S

Min. Pulley Dia. mm 500 630 630 630 800 800 1000 1000 1250 1250 1400

MA S 1000 2+2 Rubber Six 9908 628

Safety Symbol Code for Flame Belt Strength Top. Bottom Trade Mark Production Date Code of Product

Retardent & Anti-Static Cover Thickness Qualified Certification

MA S 1000 Rubber Six 9908 628

Safety Symbol Code for Flame Belt Strength Trade Mark Production Date Code of Product

Retardent & Anti-Static Qualified Certification

21

Steel cord conveyor belts are chiefly used in long production lines that require high tensile strength. The addition of steel cords

to a carcass precisely adjusts the take-up stroke with a very low elongation of less than 0.3% under 100% working condition.

Jason STEELCORD is a top quality standard steel cord conveyor belt. It boasts excellent durability, and is made of

zinc-galvanised high carbon steel cords twisted alternately clockwise and counter-clockwise. It rarely deviates from a straight

line when in operation, and incorporates a double layer of rubber for extra protection. One rubber ply remains strongly adhered

to the cord, while the covering layer offers high tear resistance. Jason STEELCORD has proved its toughness and reliability in

heavy-duty sectors such as mines, power plants, cement factories and ironworks plants over the past 15 years.

CONVEYOR BELTS

STARSTEEL

Scope of Supply

Width: Ranging between 32 (813mm) and 84 (2134mm)

Top cover:

Any thickness from 5/32 to 1 (4mm to 25mm)

Steel Cord

Bottom cover :

Any thickness from 5/32

to 1/2 (4mm to 13mm)

Rubber layers

cover and bond securely

to steel cord

22

CHEVRON CONVEYOR BELT

CONVEYOR BELTS

Application:

Chevron conveyor belts are used to convey materials at angles that are so steep that load slip or roll back might otherwise

occur. Popular applications include sand and gravel, wood chip handling, minerals such as coal and ore, heavy-duty scrap metal,

road construction, waste management, also powdery materials such as sand, fine coal, grain, as well as materials in bags, along

angled routes.

Features:

1. Cleats and top cover rubber are integrally moulded.

This moulding process ensures that the cleats will not separate from the belting.

2. Cleats profile is in a highly abrasion resistant and elastic rubber compound.

3. Overlapping cleats design allows the belt to ride smoothly over return idlers.

4. It also increases conveyor capacity by quick pick-up at the loading point.

5. Variable cleat height and width lets you order belting to match your equipment.

Max. Angle of Inclination:

Angle of inclination is dependent on the internal friction of the material, loading conditions, distance between carrying idlers,

belt speed and construction of conveyor etc. Therefore the values are only recommendations:

Materials Angles

Sand (wet)...................................40~45

Sand...............................................30~35

Sacks, jute....................................35~40

Sacks, paper ................................30~35

Cement .........................................35

Salt<100mm..............................35

Fertilizer........................................35

Coal < 100mm..........................30

Potatoes .......................................30

Beets..............................................30

Grain (dry)...................................25

The Y shaped chevron belt is installed on the scraping equipment

which is used for scraping the asphalt pavement.

23

EP200/2 3+1.5mm 6.5 250 200 160

EP315/3 3+1.5 7.5 250 250 200

EP400/4 3+1.5 8.5 315 250 200

EP200/2 3+1.5 6.5 200 200 200

EP250/2 3+1.5 6.9 250 200 200

EP315/3 3+1.5 7.5 250 250 200

EP400/3 3+1.5 7.8 315 250 200

EP200/2 3+1.5 6.5 315 250 200

EP315/3 3+1.5 7.5 315 250 250

EP400/3 3+1.5 7.8 315 315 250

EP400/3 4+2 9.3 400 315 250

EP500/3 4+2 9.6 400 315 250

EP630/4 5+1.5 11.3 500 400 315

EP400/3 3+1.5 7.8 400 315 250

EP400/3 4+2 9.3 500 400 315

EP500/3 4+2 9.6 500 400 315

EP500/3 5+1.5 10.1 500 400 315

MINIMUM PULLEY DIAMETERS FOR CHEVRON BELT

CONVEYOR BELTS

6 MULTI-V CONVEYOR BELT

The patterns are designed to aggressively transfer free-flowing materials. The slittable cleated belts have integrally moulded

cleats. Overlapping 6 width cleats maintain a smooth travel over return idlers. Typical applications include aggregate, fertilizer,

grains, sand, bark and wood chip.

Standard Spec.: (cut edge)

* 48 Wide, EP160 x 2P x 1/8 x 1/16, RMA2

* 48 Wide, EP160 x 3P x 1/8 x Bare, RMA2

* 48 Wide, EP160 x 3P x 1/8 x 1/16, MOR

RIB TYPE RATING

C5~C10

C15~C17

C20~C25

Y32~C32

THICKNESS MINIMUM DRUM DIAMETER

O/A (mm)

HEAD

(mm)

TAIL

(mm)

SNUB

(mm)

BW CW CP PA CH

48 47.5 0.25 0.25 0.25

24

Fabric Style 330 440 550 660 800

Belt Style 1-330 1-440 1-550 1-660 1-800

Working Strength (KN/m) 58 77 96 116 140

Number of Plies 1 1 1 1 1

Approximate Carcass Thickness (mm) 2.5 3.3 3.5 4.3 4.9

Approximate Carcass Weight (kg/sq.m) 1.65 2.40 2.65 3.40 4.00

Estimate Maximum Impact Rating (N-m) * 1153 1425 1764 2374 2714

Recommended minimum pulley diameters inches % of rated belt tension (mm)

81~100 400 450 500 550 650

61~80 350 400 450 500 550

Up to 60 300 350 350 400 450

Minimum belt width for empty troughing (mm)

Idler type

20 450 450 600 750 750

35 600 600 750 800 800

45 600 600 900 900 900

Maximum belt width for load support (mm)

20 Idlers 0~640 kg/m3 1800 1800 1800 2100 2100

641~1280 kg/m3 1650 1800 1800 1800 2100

1281~1920 kg/m3 1500 1650 1800 1650 1800

Over 1920 kg/m3 1200 1350 1500 1500 1650

35 Idlers 0~640 kg/m3 1650 1800 1800 2100 2100

641~1280 kg/m3 1500 1650 1650 1800 2100

1281~1920 kg/m3 1350 1500 1650 1650 1800

Over 1920 kg/m3 1050 1350 1500 1500 1650

45 Idlers 0~640 kg/m3 1500 1650 1800 2100 2100

641~1280 kg/m3 1350 1500 1500 1650 1800

1281~1920 kg/m3 1200 1350 1500 1650 1800

Over 1920 kg/m3 900 1050 1350 1500 1650

JASON SPECIFICATIONS - METRIC

CONVEYOR BELTS

25

Rib Type

CLOSED V

C5

Rib Type

CLOSED V

C10

Belt Width Cleat Width Cleat Pitch Plain Area Cleat Height

Unit:mm

Rib Type

CLOSED V

C15

LOW CHEVRON PROFILE

CONVEYOR BELTS

500~1200 150 0~200 10

full width

or

appointed width

Belt Width Cleat Width Cleat Pitch Plain Area Cleat Height

Unit:mm

300~1200 100 0~200 5

full width

or

appointed width

Belt Width Cleat Width Cleat Pitch Plain Area Cleat Height

Unit:mm

500~1200 200 0~200 15

full width

or

appointed width

26

Rib Type

CLOSED V

C15V330

B.W. C.W. C.P. P.A. C.H.

400 330 250 35 15

450 330 250 60 15

500 330 250 85 15

600 330 250 135 15

650 330 250 160 15

Unit:mm

Rib Type

CLOSED V

C15V450

B.W. C.W. C.P. P.A. C.H.

600 450 250 75 15

650 450 250 100 15

700 450 250 125 15

Unit:mm

Rib Type

OPEN V

C15P380

LOW CHEVRON PROFILE

CONVEYOR BELTS

B.W. C.W. C.P. P.A. C.H.

450 380 250 35 15

500 380 250 60 15

600 380 250 110 15

650 380 250 135 15

800 380 250 210 15

Unit:mm

27

Rib Type

OPEN V

C15P600

B.W. C.W. C.P. P.A. C.H.

750 600 250 75 15

800 600 250 100 15

900 600 250 150 15

Unit:mm

Rib Type

OPEN V

C15P740

B.W. C.W. C.P. P.A. C.H.

900 740 250 80 15

1000 740 250 130 15

1050 740 250 155 15

1200 740 250 230 15

Unit:mm

Rib Type

CLOSED V

C127P-8509

B.W. C.W. C.P. P.A. C.H.

1000 850 295 75 12.7

1200 850 295 175 12.7

1400 850 295 275 12.7

1500 850 295 325 12.7

Unit:mm

LOW CHEVRON PROFILE

CONVEYOR BELTS

28

Rib Type

LONGHORN

C17L300

B.W. C.W. C.P. P.A. C.H.

350 300 330 25 17

400 300 330 50 17

450 300 330 75 17

500 300 330 100 17

Unit:mm

Rib Type

DEERHORN

C17L440

B.W. C.W. C.P. P.A. C.H.

500 440 330 30 17

600 440 330 80 17

650 440 330 105 17

Unit:mm

Rib Type

DEERHORN

C17L550

B.W. C.W. C.P. P.A. C.H.

600 550 330 25 17

650 550 330 50 17

700 550 330 75 17

Unit:mm

LOW CHEVRON PROFILE

CONVEYOR BELTS

29

Rib Type

DEERHORN

C17L630

B.W. C.W. C.P. P.A. C.H.

650 630 330 10 17

750 630 330 60 17

800 630 330 85 17

900 630 330 135 17

Unit:mm

Rib Type

DEERHORN

C17L750

B.W. C.W. C.P. P.A. C.H.

800 750 330 25 17

1000 750 330 150 17

1200 750 330 225 17

Unit:mm

Rib Type

DEERHORN

C17L950

B.W. C.W. C.P. P.A. C.H.

1000 950 330 25 17

1050 950 330 50 17

1200 950 330 125 17

Unit:mm

LOW CHEVRON PROFILE

CONVEYOR BELTS

30

Rib Type

BULL HORN

C25P550

B.W. C.W. C.P. P.A. C.H.

600 550 250 25 25

650 550 250 50 25

750 550 250 100 25

800 550 250 125 25

Unit:mm

Rib Type

BULL HORN

C25P750

B.W. C.W. C.P. P.A. C.H.

900 750 330 75 25

1000 750 330 125 25

1050 750 330 150 25

1200 750 330 225 25

Unit:mm

Rib Type

BULL HORN

C25P450

B.W. C.W. C.P. P.A. C.H.

500 450 250 25 25

600 450 250 75 25

650 450 250 100 25

700 450 250 125 25

Unit:mm

MIDDLE CHEVRON PROFILE

CONVEYOR BELTS

31

Rib Type

CLOSED Y

Y32P600

B.W. C.W. C.P. P.A. C.H.

650 600 300 25 32

800 600 300 100 32

900 600 300 150 32

1000 600 300 200 32

Unit:mm

Rib Type

OPEN Y

Y32P800

B.W. C.W. C.P. P.A. C.H.

900 800 333 50 32

1000 800 333 100 32

1050 800 333 125 32

1200 800 333 200 32

Unit:mm

Rib Type

H TYPE

C32H460

B.W. C.W. C.P. P.A. C.H.

500 460 330 20 32

600 460 330 70 32

650 460 330 95 32

Unit:mm

HIGH CHEVRON PROFILE

CONVEYOR BELTS

32

32

32

Rib Type

H TYPE

C32H580

B.W. C.W. C.P. P.A. C.H.

600 580 333 10 32

650 580 333 35 32

750 580 333 85 32

800 580 333 110 32

Unit:mm

Rib Type

H TYPE

C32H630

B.W. C.W. C.P. P.A. C.H.

650 630 330 10 32

750 630 330 60 32

800 630 330 85 32

900 630 330 135 32

Unit:mm

Rib Type

H TYPE

C32H750

B.W. C.W. C.P. P.A. C.H.

900 750 330 75 32

1000 750 330 125 32

1050 750 330 150 32

1200 750 330 225 32

Unit:mm

HIGH CHEVRON PROFILE

CONVEYOR BELTS

33

34

PLEASE ASK FOR THE JASON PRODUCT CATALOGUES

CONVEYOR BELTS

Power Transmission Belts

Catalogue JB-7

Urethane Power

Transmission Belts

Catalogue UB-4

Industrial Hose &

Couplings

Catalogue HC-7

Accu-Link Belts

Catalogue AL-4

Air Conditioning

Refrigeration

Catalogue SW1001-10

Lawn & Garden

Catalogue LG1007

Synchronous Belt

Technical Manual TM-2

Appliance & HVAC

Replacement Parts

Catalogue APPL-1

Sheaves,

Timing Pulleys & Bushings

Catalogue JI-3

35

CONVEYOR BELTS

NEW REPLACEMENT ROLLERS

62 Brunswick Street

Stockton-on-Tees

Cleveland TS18 1DR

Tel: 0044 (0) 845 053 9099

Fax: 0044 (0) 1642 601753

www.jasonindustrial.com

Вам также может понравиться

- Dunlop Conveyor Belt Design Manual - HTMLДокумент38 страницDunlop Conveyor Belt Design Manual - HTMLForbes KambaОценок пока нет

- Preventive Maintenance ManualДокумент60 страницPreventive Maintenance ManualAlfredo LopezОценок пока нет

- Structural Design and Erection: General RequirementsДокумент15 страницStructural Design and Erection: General RequirementsMKPashaPashaОценок пока нет

- Fine Material Washer SPLT1047ENPR 01Документ6 страницFine Material Washer SPLT1047ENPR 01NarvaxisОценок пока нет

- Impact CrusherДокумент8 страницImpact CrusherSharath MenonОценок пока нет

- Conveyor Belt Splicing GuideДокумент41 страницаConveyor Belt Splicing GuideFelipe MascayanoОценок пока нет

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Документ1 страницаEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnОценок пока нет

- MS 300 Belt Selection FactorsДокумент22 страницыMS 300 Belt Selection FactorsaldoarthoОценок пока нет

- S3 Product Range - EnglishДокумент35 страницS3 Product Range - EnglishJuan Esteban Luque ZegarraОценок пока нет

- F Class Tech SpecsДокумент8 страницF Class Tech SpecskosmcОценок пока нет

- How to analyze gear failuresДокумент15 страницHow to analyze gear failuresJorgОценок пока нет

- CA3000BДокумент756 страницCA3000BAlejandro Hernandez100% (2)

- Belt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationДокумент8 страницBelt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationKenji LacambraОценок пока нет

- The Rhodax® Process For Dry Mix Preparation in Anodes PlantsДокумент37 страницThe Rhodax® Process For Dry Mix Preparation in Anodes PlantsGupta AnacoolzОценок пока нет

- The Evolution of the Pipe-ConveyorДокумент9 страницThe Evolution of the Pipe-ConveyorJohnjun ChenОценок пока нет

- Install, Operate and Maintain SAM Turbo PumpДокумент40 страницInstall, Operate and Maintain SAM Turbo Pumpsanjayagrawal70-1Оценок пока нет

- 004 HFO Forwarding PumpДокумент7 страниц004 HFO Forwarding PumpSantoshkumar GuptaОценок пока нет

- Manejo de Catalogo Reductores Montados Sobre Eje DODGEДокумент56 страницManejo de Catalogo Reductores Montados Sobre Eje DODGEPedro Julio PérezОценок пока нет

- Non-Linear Dynamics Belt ConveyorsДокумент6 страницNon-Linear Dynamics Belt ConveyorsAndrew PeterОценок пока нет

- Bucket Elevators: Installation and Operation ManualДокумент20 страницBucket Elevators: Installation and Operation Manualboyka yuriОценок пока нет

- Apron Feeders: High Return On Investment Low Maintenance Costs Low Production CostsДокумент8 страницApron Feeders: High Return On Investment Low Maintenance Costs Low Production CostsarsanioseОценок пока нет

- Plant Mass Flow The Component PDFДокумент6 страницPlant Mass Flow The Component PDFAnonymous RCvLlKoSom100% (1)

- Designing of Screw ConveyorДокумент6 страницDesigning of Screw ConveyorErickk RoqueeОценок пока нет

- Comminution 2Документ159 страницComminution 2Kumar RajeshОценок пока нет

- Structural Health MonitoringОт EverandStructural Health MonitoringDaniel BalageasОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Running Insp Sheet NewДокумент20 страницRunning Insp Sheet NewSafrin SangiaОценок пока нет

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Shanghai Horizons Technology Limited Stone Crusher and Grinding Mill GuideДокумент24 страницыShanghai Horizons Technology Limited Stone Crusher and Grinding Mill Guidesaleem2412100% (1)

- Brochure-Filter Press.-TOROДокумент12 страницBrochure-Filter Press.-TOROSebastian Gomez BetancourtОценок пока нет

- Dodge Saf Pillow BlocksДокумент6 страницDodge Saf Pillow BlocksjvalkenburgОценок пока нет

- Fabric Filter Pulse CleanДокумент15 страницFabric Filter Pulse CleanmjbotelhoОценок пока нет

- Belt Cleaner: Head PulleyДокумент7 страницBelt Cleaner: Head PulleyAgung Pandega PutraОценок пока нет

- Kuri CONQUERORДокумент16 страницKuri CONQUERORJosh WhiteОценок пока нет

- 20 TPH Bucket ElevatorДокумент4 страницы20 TPH Bucket ElevatorAlok NayakОценок пока нет

- Drive-Non Drive Pulley Shaft Dia Calculation of Belt Feeder - IS 11592Документ1 страницаDrive-Non Drive Pulley Shaft Dia Calculation of Belt Feeder - IS 11592BISWAJIT DASОценок пока нет

- Hyponic Savings Calculator: Name: Company: Quote #Документ6 страницHyponic Savings Calculator: Name: Company: Quote #Ceric AdiОценок пока нет

- Evaluation of The Can Velocity Effect On A Bag Filter: Powder Technology August 2017Документ5 страницEvaluation of The Can Velocity Effect On A Bag Filter: Powder Technology August 2017Satrio FebriansyahОценок пока нет

- Terex Jaques Apron FeederДокумент12 страницTerex Jaques Apron FeederiranbodОценок пока нет

- Pdfcoffeecom Vibrating Screens Training For Maint 230601 225223Документ18 страницPdfcoffeecom Vibrating Screens Training For Maint 230601 225223khaled saadnehОценок пока нет

- Sturt Air ClassifierДокумент6 страницSturt Air ClassifierHenry Vladimir VianchaОценок пока нет

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityДокумент19 страницBelt Conveyors: Mechanical Engineering Department Carlos III UniversityAlfredo VelasquezОценок пока нет

- 15 X 21 Batch Ball MillДокумент12 страниц15 X 21 Batch Ball MillAnil Kumar KnОценок пока нет

- Splice ManualДокумент66 страницSplice Manualluis martinezОценок пока нет

- Hydraulic Cylinder Maintenance ChecklistДокумент10 страницHydraulic Cylinder Maintenance Checklisthaziq100% (1)

- Fan selection factors and curvesДокумент16 страницFan selection factors and curvesPhanhai KakaОценок пока нет

- Capacities and performance characteristics of jaw crushersДокумент7 страницCapacities and performance characteristics of jaw crushersvaper123Оценок пока нет

- Ypt Paletli Brosur 3 PDFДокумент4 страницыYpt Paletli Brosur 3 PDFarsanioseОценок пока нет

- Heavy Duty Conveyor Pulley CatalogДокумент100 страницHeavy Duty Conveyor Pulley Catalogkosmc123Оценок пока нет

- Exciter Vibrating Screen Rs TipДокумент1 страницаExciter Vibrating Screen Rs TipchrisОценок пока нет

- Chute Calculation ExampleДокумент1 страницаChute Calculation ExampleBimal DeyОценок пока нет

- Bucket ElevatorДокумент9 страницBucket Elevatorkoripella_prasadОценок пока нет

- Based On Leaf Test Data For Moisture, Cake and Cloth ResistanceДокумент2 страницыBased On Leaf Test Data For Moisture, Cake and Cloth ResistanceMiguel OrtizОценок пока нет

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsДокумент1 страницаRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanОценок пока нет

- Trojosky2019 PDFДокумент21 страницаTrojosky2019 PDFHector CabezasОценок пока нет

- Mechanical Centrifugal Air ClassifiersДокумент3 страницыMechanical Centrifugal Air ClassifiersBramJanssen76Оценок пока нет

- Aggregate ScreeningДокумент38 страницAggregate Screeningssmith2007Оценок пока нет

- Survey of Conveyor BeltДокумент5 страницSurvey of Conveyor BeltAashish LambaОценок пока нет

- Conveyer Belt TechnologyДокумент13 страницConveyer Belt Technologydebendra naikОценок пока нет

- BДокумент2 страницыBharshОценок пока нет

- Pamphlet 60 - Edition 8 - September 2019Документ28 страницPamphlet 60 - Edition 8 - September 2019Thitikorn Wassanarpheernphong100% (1)

- v63 121 PDFДокумент11 страницv63 121 PDFThitikorn WassanarpheernphongОценок пока нет

- Syphons and Connecting Pipes For Pressure Measuring Instruments Model 910.15Документ7 страницSyphons and Connecting Pipes For Pressure Measuring Instruments Model 910.15ghangОценок пока нет

- IsolistДокумент4 страницыIsolistThitikorn WassanarpheernphongОценок пока нет

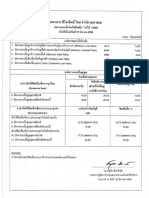

- Rate-Loan No1 2558 THДокумент1 страницаRate-Loan No1 2558 THThitikorn WassanarpheernphongОценок пока нет

- (2005) Identification of Caprolactam Oligomers and Related Compounds in Aqueous Extracts of Nylon-6Документ13 страниц(2005) Identification of Caprolactam Oligomers and Related Compounds in Aqueous Extracts of Nylon-6Thitikorn WassanarpheernphongОценок пока нет

- (2014) Hydrolytic Caprolactam Polymerization - Progress in Dynamic Simulation. Macromolecular Reaction EngineeringДокумент8 страниц(2014) Hydrolytic Caprolactam Polymerization - Progress in Dynamic Simulation. Macromolecular Reaction EngineeringThitikorn WassanarpheernphongОценок пока нет

- Pamphlet 165 - Edition 3 - January 2017Документ28 страницPamphlet 165 - Edition 3 - January 2017Thitikorn WassanarpheernphongОценок пока нет

- (2012) US8231765 Process For The Purification of LactamsДокумент9 страниц(2012) US8231765 Process For The Purification of LactamsThitikorn WassanarpheernphongОценок пока нет

- Optimizing Caprolactam Recovery Using Green DesignДокумент10 страницOptimizing Caprolactam Recovery Using Green DesignThitikorn WassanarpheernphongОценок пока нет

- (2005) US20050029086A1 Process For Distilling Alkaline Caprolactam Product at Reduced PressureДокумент5 страниц(2005) US20050029086A1 Process For Distilling Alkaline Caprolactam Product at Reduced PressureThitikorn WassanarpheernphongОценок пока нет

- Article DampersДокумент4 страницыArticle Dampersverat81Оценок пока нет

- (2009) Caprolactam Recovery by A Column Packed With PolysulfoneДокумент7 страниц(2009) Caprolactam Recovery by A Column Packed With PolysulfoneThitikorn WassanarpheernphongОценок пока нет

- (2009) US7501047 Methode For Purifying CaprolactamДокумент11 страниц(2009) US7501047 Methode For Purifying CaprolactamThitikorn WassanarpheernphongОценок пока нет

- (2014) US8841445 Process For Preparing Purified Caprolactam From The Beckmann RearrangementДокумент6 страниц(2014) US8841445 Process For Preparing Purified Caprolactam From The Beckmann RearrangementThitikorn WassanarpheernphongОценок пока нет

- (2016) Isolation and Quantification of Polyamide Cyclic OligomersДокумент15 страниц(2016) Isolation and Quantification of Polyamide Cyclic OligomersThitikorn WassanarpheernphongОценок пока нет

- Introduction MCC Oxo ProcessДокумент5 страницIntroduction MCC Oxo ProcessDeep PatelОценок пока нет

- Vafsa Qa 1Документ7 страницVafsa Qa 1Thitikorn WassanarpheernphongОценок пока нет

- Reduce Steam Loss and Energy Costs with Steam Z High Efficiency Condensate Drain SystemДокумент24 страницыReduce Steam Loss and Energy Costs with Steam Z High Efficiency Condensate Drain SystemThitikorn WassanarpheernphongОценок пока нет

- Is Wood Pellet-Based Electricity Less Carbon-IntenДокумент10 страницIs Wood Pellet-Based Electricity Less Carbon-IntenThitikorn WassanarpheernphongОценок пока нет

- Case Study: Global 500 Energy & Utilities CompanyДокумент1 страницаCase Study: Global 500 Energy & Utilities CompanyThitikorn WassanarpheernphongОценок пока нет

- Shell and Tube Heat Exchangers Using Coo PDFДокумент20 страницShell and Tube Heat Exchangers Using Coo PDFThitikorn WassanarpheernphongОценок пока нет

- Utilization of LNG Cryogenic Energy in A Proposed Method For Inlet Air Cooling To Improve The Performance of A Combined CycleДокумент5 страницUtilization of LNG Cryogenic Energy in A Proposed Method For Inlet Air Cooling To Improve The Performance of A Combined CycleThitikorn WassanarpheernphongОценок пока нет

- Guide To Safe Delivery of Bitumen (2011)Документ36 страницGuide To Safe Delivery of Bitumen (2011)Thitikorn WassanarpheernphongОценок пока нет

- Utilization of LNG Cryogenic Energy in A Proposed Method For Inlet Air Cooling To Improve The Performance of A Combined CycleДокумент5 страницUtilization of LNG Cryogenic Energy in A Proposed Method For Inlet Air Cooling To Improve The Performance of A Combined CycleThitikorn WassanarpheernphongОценок пока нет

- Case Study: Global 500 Energy & Utilities CompanyДокумент1 страницаCase Study: Global 500 Energy & Utilities CompanyThitikorn WassanarpheernphongОценок пока нет

- Computer Aided Design For The Recovery of Boil-Off Gas From LNG PlantДокумент17 страницComputer Aided Design For The Recovery of Boil-Off Gas From LNG PlantThitikorn WassanarpheernphongОценок пока нет

- Fix Frames Around Text in PDFs from AutoCADДокумент1 страницаFix Frames Around Text in PDFs from AutoCADThitikorn WassanarpheernphongОценок пока нет

- Sod PhosДокумент78 страницSod PhosThitikorn WassanarpheernphongОценок пока нет

- 2019-01 Future Outlook For Myanma Petrochemical Enterprise (MPE)Документ16 страниц2019-01 Future Outlook For Myanma Petrochemical Enterprise (MPE)Thitikorn Wassanarpheernphong0% (1)

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Документ20 страницUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniОценок пока нет

- LG AC Service ManualДокумент80 страницLG AC Service ManualFrengky RmОценок пока нет

- Tcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaДокумент20 страницTcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaEugene Santiago PadillaОценок пока нет

- Syllabus of MVSIДокумент3 страницыSyllabus of MVSIKashan Khan0% (1)

- Underground Cables - 010954Документ23 страницыUnderground Cables - 010954lawrence momanyiОценок пока нет

- Correction of Service Manual Si-18 M-11011Документ18 страницCorrection of Service Manual Si-18 M-11011Ahmed AzadОценок пока нет

- Dyneon PTFE BrochureДокумент0 страницDyneon PTFE BrochureXray UandОценок пока нет

- Kema Ageing Test 5000 Hrs.Документ12 страницKema Ageing Test 5000 Hrs.Tarun AggarwalОценок пока нет

- R5000 PriceInfoSheetДокумент2 страницыR5000 PriceInfoSheetDominique OnealОценок пока нет

- Drag CoefficientДокумент7 страницDrag CoefficientAdrian John Soe Myint100% (1)

- 6001 FluorescentLightFittings EK00 III en PDFДокумент9 страниц6001 FluorescentLightFittings EK00 III en PDFarturonc100% (1)

- API 650 Tank Design CalculationДокумент9 страницAPI 650 Tank Design CalculationSunday PaulОценок пока нет

- Rivera Jerahmae D. NSTP-CWTS Project ProposalДокумент8 страницRivera Jerahmae D. NSTP-CWTS Project ProposalRichard Culaton IIIОценок пока нет

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsДокумент4 страницыVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshОценок пока нет

- Building material thermal properties tableДокумент19 страницBuilding material thermal properties tablehansleyОценок пока нет

- PivsuexДокумент7 страницPivsuextthenryОценок пока нет

- Siemens Syngas Capable TurbinesДокумент8 страницSiemens Syngas Capable TurbinesAlasdair McLeodОценок пока нет

- Aesthetic FinishesДокумент5 страницAesthetic FinishesAnonymous dOdHWHg4Оценок пока нет

- Technical Data Sheet Baltoflake EcolifeДокумент5 страницTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadОценок пока нет

- Rate Analysis-KalikaДокумент35 страницRate Analysis-KalikaPujan Amit Gurung100% (1)

- Flocculation: IupacДокумент23 страницыFlocculation: IupacpraveenОценок пока нет

- Volvo EW145B Wheeled ExcavatorДокумент48 страницVolvo EW145B Wheeled ExcavatorHai Van100% (9)

- Enthalpy of FormationДокумент11 страницEnthalpy of FormationRONIBAEL CORDOVAОценок пока нет

- PumpДокумент14 страницPumpdhineshpОценок пока нет

- Report About: Classification of CompressorДокумент9 страницReport About: Classification of Compressornabaz muhamadОценок пока нет

- Tunnel Operations, Maintenance, Inspection and Evaluation (Tomie) ManualДокумент398 страницTunnel Operations, Maintenance, Inspection and Evaluation (Tomie) ManualGiuseppe Gentile100% (1)

- 2sc-Pco - Dual Solenoid Control ValveДокумент3 страницы2sc-Pco - Dual Solenoid Control Valveshan07011984Оценок пока нет

- Ie 12 Lec Act IiiДокумент2 страницыIe 12 Lec Act IiiLance JayomaОценок пока нет

- Industrial Materials ClassificationДокумент32 страницыIndustrial Materials ClassificationShakeel AhmadОценок пока нет

- MIDEL 7131 Technical Information Pack USДокумент15 страницMIDEL 7131 Technical Information Pack USkatherine100% (1)