Академический Документы

Профессиональный Документы

Культура Документы

11V02 Acc SPC M 0001 V2 Part C

Загружено:

suparnabhose0 оценок0% нашли этот документ полезным (0 голосов)

61 просмотров39 страницspecification for air cooled condenser -instrumentation part

Оригинальное название

11V02-ACC-SPC-M-0001-V2-PART-C

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документspecification for air cooled condenser -instrumentation part

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

61 просмотров39 страниц11V02 Acc SPC M 0001 V2 Part C

Загружено:

suparnabhosespecification for air cooled condenser -instrumentation part

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 39

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 1 of 39

VOLUME-II

PART-C

CONTROL & INSTRUMENTATION

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 2 of 39

VOLUME-II, PART-C

CONTROL & INSTRUMENTATION

I N D E X

CLAUSE NO. DESCRIPTION

1.00.00 INTRODUCTION

2.00.00 CONTROL & INSTRUMENTATION SYSTEM

PHILOSOPHY

3.00.00 GENERAL TECHNICAL REQUIREMENTS

4.00.00 DATA SHEETS FOR FIELD INSTRUMENTS

AND CABLES

5.00.00 UTILITIES

6.00.00 CODES AND STANDARDS

7.00.00 INSTRUMENT INSTALLATION

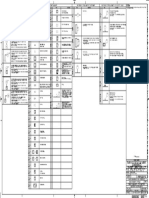

ANNEXURE-1 DRIVE CONTROL INTERFACE

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 3 of 39

VOLUME-II, PART-C

CONTROL & INSTRUMENTATION

1.00.00 INTRODUCTION

1.01.00 This specification is intended to cover all aspects of the design, engineering

manufacture, assembly, testing & inspection at manufacturer's works, delivery

at site and erection & commissioning of the complete Control &

Instrumentation System of Air cooled Condensor (ACC) package for 1 x 300

MW coal based thermal power plant at village - Bandakhar, Tehsil - Pali,

Korba district in state of Chhattisgarh.

1.02.00 The Control & Instrumentation for the unit shall comprise equipment

described and specified in this section and other part/section of this

specification document. In general only the major C & I systems and

conceptual guideline for the plant C & I have been indicated.

1.03.00 It is not the intent or purpose of this specification to give details of every

single item that might be required for completeness and/or proper integration

of the overall system. The bidder shall be responsible for providing all

materials, equipment and services, specified or otherwise which are required

to fulfill the intent of ensuring functional completeness, safety of plant and

personnel, operability, maintainability and reliability of the total work covered

under this specification, during any stage of execution of the contract and the

operating life of the plant; within the quoted price and without any further

commercial implication to the Purchaser/Owner.

1.04.00 In the event of any conflict between the requirements of any two (2) clauses

or documents forming a part of this contract the more stringent requirements

shall supply unless otherwise confirmed by the Owner in writing. The decision

of the Owner shall be final and binding in all such cases.

2.00.00 CONTROL & INSTRUMENTATION SYSTEM PHILOSOPHY

2.01.00 The Control & Instrumentation System shall mainly realize the following

functions in order to assist the operator to perform safe start up/shutdown and

normal/emergency operation of the plant.

1. Closed loop modulating control of parameters for optimized

operation of turbine, boiler and balance of the plant.

2. Open loop control for automatic sequential operation,

interlock and protection of various drives.

3. Continuous supervision of system parameters and equipment

operating conditions

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 4 of 39

2.02.00 State-of-the-art-practices prevailing in the field of Control & Instrumentation

shall be considered to ensure safe, efficient and smooth operation of the air

cooled condenser with minimum interference of the operating personnel

during normal working of the plant.

2.03.00 The system design shall be such that no single point failure will result in total

system paralysis under any operational eventuality. Redundancy shall be

provided at appropriate levels for critical control system functions.

2.04.00 In the event of loss of a major plant item, activities of binary and analog

controls shall be coordinated to ensure that the plant is automatically brought

to a safe holding condition consistent with maintaining maximum generation

permissible under reduced plant availability.

2.05.00 The C & I System shall be configured to perform the following basic functions:

-

a) Automatic sequencing of the start-up and shutdown of major

equipment and auxiliaries including group/plant level start-

up to minimize operators intervention under normal

operating conditions.

b) Regulation functions for various valves and dampers to

achieve guaranteed performance and to achieve the most

fuel-efficient operation.

c) Protection of plant equipment and monitoring of equipment

life.

d) Acquisition, display and archiving of plant data and

generation of reports.

2.06.00 The entire operation of the air cooled condenser system will be through DCS

from central control room.

Sequence control of ACC fan will be implemented in DCS. Bidder to optimise

the % of VFD fans required for operation of the power plant meeting design

performance and without under cooling for complete year operation at various

temperatures. This system shall enable the operator for cold/warm/hot start-

up and safe shutdown and carryout normal operation from control room.

Hotwell control & CEP minimum recirculation control will be implemented in

DCS by CWPC.

The signals required for operation of ACC fans and associated valves will be

cabled to DCS.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 5 of 39

Bidder shall consider all necessary field instruments, cable supply, cable

laying including cable trays and cable termination in DCS cabinet/DCS

remote I/O cabinets(supplied by BTG Vendor).

Bidder shall prepare I/O list, ACC logics and graphic screens for

implementation in DCS.

3.00.00 GENERAL TECHNICAL REQUIREMENTS

3.01.00 All equipment, system and associated accessories shall be from the latest

proven product range of qualified manufacturers. All materials and equipment

furnished for permanent installation shall conform to applicable local and

international codes and standards Specifications and shall be new, unused

and undamaged.

3.02.00 The equipment and systems shall be designed and constructed to meet

specification requirements, and shall perform accurately and safety under the

environmental and operating conditions described or implied in this

specification without undue heating, vibration, wear, corrosion or other

operating troubles during the continuous service life of the plant. It will be the

responsibility of bidder to fully acquaint himself with the functional

requirements and operating conditions for equipment, system/sub-system/

assemblies and accessories offered for this project. Additional features shall

be provided where required to meet service conditions, functional/descriptive

or parametric requirements for equipments/systems/assemblies/ accessories.

3.03.00 The design of the Control & Instrumentation system shall be such that

isolation of any piece of defective equipment/accessories should be possible

without shutting down the main equipment and should result in minimum

disturbance to the process.

3.04.00 The design of control systems and related equipment shall adhere to the

principle of fail safe operation at all system levels. Fail-safe Operation

means that loss of signal, loss of power supply/air supply or failure of any

component shall not cause a hazardous condition while at the same time

prevent occurrence of false trips.

The following types of failure as a minimum shall be taken into account:

a) Failure of sensors or transmitters, producing high or low signal.

b) Failure of controller during automatic operation.

c) Loss of motive power to final control element actuators.

d) Loss of control power.

e) Loss of instrument air supply.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 6 of 39

3.03.00 The instrument material specifications shall be consistent with the operating

parameters like temperature, pressure, corrosion conditions and other

process conditions. The instruments shall meet the brief technical

requirements as specified elsewhere.

3.06.00 To ensure safe operation of C & I equipments located in hazardous areas,

based on area classification requirement, transmitters shall be intrinsically

safe and JB/Switch shall have ex-proof enclosures.

3.07.00 Safety earthing and C & I system earthing shall be separate. Safety earthing

bus shall be connected to main plant earthing pit. Separate earth pits shall be

provided for C&I system earthing (electronic earth) to achieve less than 0.5

ohm resistance to ground. Separate earthing shall be provided for intrinsically

safe system.

3.08.00 All field mounted instruments shall have waterproof enclosures conforming to

IP-65. All panels/cabinets shall have protection class IP-54 in ventilated areas

and IP-42 in Air-conditioned area.

3.09.00 All field instruments shall be located in accessible/vibration free locations and

clearly visible range for all readable instruments. Access platforms with

ladders shall be provided for measuring instruments located at high or difficult

places.

3.10.00 Separate cable trays shall be provided for control cables and instrumentation

(signal) cables and separated from power cable trays by at least 600 mm.All

cable entry points to instruments, junction boxes of panel shall be provided

with suitable dust and watertight double compression type glands. All cables

from field to junction box shall be through flexible conduit upto main tray/sub-

tray.

3.12.00 Bidder to provide necessary provision in HT motors for vibration sensor as

per API 670

4.00.00 DATA SHEETS FOR FIELD INSTRUMENTS AND CABLES

4.01.00 PRESSURE GAUGE (PG)

01. Quantity : As per Service Requirement

02. Make : As per approved vendor list

03. Sensing Element : Bourdon Tube

04. MOC sensing & socket : AISI 316 SS

05. Movement material : AISI 304 SS

06. Case material : Stainless steel casing

bayonet type.

07. Accuracy : 1.0% of span or better.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 7 of 39

08. Dial size : 150mm

09. Adjustment : Micrometer screw of zero

adjustment. Internal micro

meter

screw for range adjustment

10. Scale : Black lettering on white

background in 270 arc

11. Window : Shatterproof toughened

glass

12. Process connection : NPTM, Bottom entry

13. Element connection : Argon welding

14. Safety device : Blow out disc/Diaphragm at

the back

15. Enclosure class : IP 65

16. Ambient temperature : 0 50 C

17. Over range protection : 130 % of max range by

internal stop.

18. Nameplate : Tag number, service

engraved in SS plate.

19. Application standard : IS 3624 / 1996

20. Accessories : a) Snubbers for

pulsating fluid

application

b) Syphons for steam

services

c) For viscous & corrosive

services, Remote Seal

with Silicon Oil Filled

diaphragm seal adapter

flanges with nuts, bolts and

gasket

4.02.00 PRESSURE SWITCH (PS)

01. Quantity : As per Service Requirement

02. Range & Set Pressure : As per Service Requirement

03. Make : As per approved vendor list

04. Type : Seal Diaphragm

05. Sensing element material : SS316 diaphragm

06. Case material : Die-cast aluminum with

neoprene gaskets.

07. Performance : a) Accuracy1.0%

b) Accuracy of setting

indicator of 1.5%

c) Repeatability 1%

of span

08. Over range : 150% of maximum

pressure

09. Switch configuration : Two (2) Nos. SPDT type

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 8 of 39

10. Switch type : Snap acting, shock &

vibration proof

11. Switch rating : 240 V, 5A AC / 220 V, 0.5A DC

12. Ambient temperature : 0- 50C

13. Adjustability : a) Set point adjustable over

span range

b) Differential adjustable by

10% span

14. Cable Entry : 3/4" ET

15. Enclosure class : IP 65

16. Process connection : 1/2 NPT (M) bottom connected.

17. Name plate : Tag number, service engraved in

SS tag plate

18. Accessories : a) Snubbers for pulsating fluid

application

b) For viscous & corrosive

services, Remote Seal with

Silicon Oil Filled diaphragm

Seal adapter flanges with

nuts, bolts and gasket

4.03.00 PRESSURE TRANSMITTER (PT)

01. Quantity : As per Service

Requirement

02. Make : As per approved vendor list

03. Principle : Smart

04. Type : 2 Wire Microprocessor

based Transmitter

05. Output signal : 4 20 mA DC with HART

Protocol

06. Signal processing : Silicon solid state electronic

circuitry

07. Measuring element : Diaphragm

08. Measuring element material : AISI 316 (Stainless steel)

Diaphragm

09. Static pressure : 150% of maximum span

continuously without

affecting the calibration.

10. Operating voltage : 24 V DC

11. Ambient temperature : 0-50 C

12. Performance

a) Accuracy : 0.1% of span or better

b) Repeatability : 0.1% of span or better

13. Turn-down ratio : Minimum 40:1

14. Load impedance : 600 Ohm min at 24V DC

15. Response Time : 100 msec or better

16. Span / zero adjustment : Locally adjustable, non-

interacting facility for

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 9 of 39

Elevation & Suppression

by 100%

17. Enclosure class : IP-65

18. Output Indicator : LCD type in % and

engineering unit.

19. Cable Entry : ET

20. Process Connection : NPT

21. Nameplate : Tag number, service engraved in

SS tag plate.

22. Body : Forged Carbon steel (SS for DM

Water).

23. Accessories : a) Universal mounting

bracket suitable for

2 pipe and wall mounting.

b) Condensate pot for Steam

services.

c) High tensile carbon steel U

bolts.

d) Installation accessories

e) 2 way SS manifold,

constructed from SS316

bar stock.

f) Reverse polarity protection

required.

4.04.00 DIFFERENTIAL PRESSURE SWITCH (DPS)

01. Quantity : As per Service Requirement

02. Make, Model : As per Approved Vendor List

03. Type : Sealed diaphragm, piston

actuated type for high pressure &

diaphragm bellow and torque tube

for low pressure.

04. Sensing element material : AISI SS-316 diaphragm / piston.

All other wetted part SS316.

05. Case material : Epoxy coated steel plate or die-

cast aluminum alloy with

neoprene gasket and clear glass

where applicable.

06. Scale : Black graduation on white linear

scale. 0 100% with red pointer

for set point.

07. Performance : a) Accuracy1.0%

b) Accuracy of setting

Indicator of 1.5%

08. Over range : Static pressure on any one side,

the other side being open to

atmosphere.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 10 of 39

09. Switch configuration : Two (2) Nos, SPDT type

10. Switch type : Snap acting, shock & vibration

proof

11. Switch rating : 240 V, 5A AC / 220, 0.5A V DC

12. Ambient temperature : 0 - 50C

13. Adjustability : a) Set point adjustable over

span range

b) Differential adjustable by

10% span

14. Cable connection : 3/4" ET compression gland

15. Enclosure class : IP 65

16. Process connection : 1/2 NPT (M) bottom connected.

17. Name plate : Tag number, service engraved is

SS tag plate

18. Accessories : a) Snubbers for pulsating fluid

application

b) Retention ring & screw for

surface mounting

c) 1/2" NPT 5-way valve SS-

316 manifold constructed

from bar stock.

d) 3/4" ET cable gland.

4.05.00 TEMPERATURE GAUGE (TG)

01. Quantity : As per Service Requirement

02. Range : As per Service Requirement

03. Make : As per approved vendor list

04. Type : Mercury filled, rigid stem type

05. Sensing element material : Bourdon AISI 316 SS

06. Movement material : AISI 304 SS

07. Bulb diameter and length : 11/70mm

08. Bulb material : AISI 316

09. Case material : Stainless steel casing bayonet

type

10. Accuracy : 1.0% of full scale deflection or

better.

11. Dial size : 150mm

12. Scale : Black lettering on white

background in 270 Arc

13. Window : Shatterproof toughened glass

14. Process connection : 1/2"NPT (M)

15. Mounting : Surface

16. Enclosure class : IP 65

17. Over range protection : 130 % of max range by internal

stop.

18. Zero Adjuster : Micro adjustable from front

19. Nameplate : Tag number, service engraved in

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 11 of 39

SS tag plate.

20. Compensation : Case compensation

21. Thermowell :

a. Standard : ASME - PTC 19.3

b. Body MOC : Stainless Steel - Barstock

c. Process Connection : M33 X 2 Screwed

d. Element Connection : NPTF

e. Extension length : As per Service Requirement

f. Insertion Length U : As per Service Requirement

22. Accessories : a) Installation accessories as

required.

b) Adjustable nipple union

nipple with thermo well

connection

4.06.00 THERMOCOUPLES (T/C)

01. Quantity : As per Service Requirement

02. Range : As per Service Requirement

03. Make : As per approved vendor list

04. Type : Duplex, ungrounded

05. Element : Type-K (Chromel / Alumel). 16

AWG Wire

06. Protecting Tube:

i) O.D : 8 mm (approx)

ii) Material : 316 SS Seamless

iii) Filling : Magnesium Oxide (Purity above

99.4%)

iv) Length : As per Service Requirement

07. Response time : < 20 seconds for measurement.

08. Head

i) Type : IP-65 universal screwed type

ii) Material : Die cast aluminum or better

iii) Terminal blocks : Nickel plated brass screw

type/silver plated

iv) Cable connection : 3/4" ET

v) Process Connection : NPTF

vi) Others : Terminal head cover with SS

chain and suitable gasket.

09. Standard : ANSI MC 94.1

10. Thermowell :

a. Standard : ASME - PTC 19.3

b. Body MOC : Stainless Steel - Barstock

c. Process Connection : M33 X 2 Screwed

d. Element Connection : NPTF

e. Extension length : As per Service Requirement

f. Insertion Length U : As per Service Requirement

11. Accessories : a) Adjustable nipple-union-

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 12 of 39

nipple with thermo well

connection

12. Nameplate : Tag number, service engraved in

SS tag plate

4.07.00 RESISTANCE TEMPERATURE DETECTOR (RTD)

01. Quantity : As per Service Requirement

02. Range : As per Service Requirement

03. Make : As per approved vendor list

04. Type : 3 wire, Duplex, ungrounded

05. Element : Pt-100 0.1/100 0hm at 0C,

06. Protecting Tube:

i) O.D : 8 mm

ii) Material : 316 SS Seamless

iii) Filling : Magnesium Oxide (Purity above

99.4%)

iv) Length : As per Service Requirement

07. Response time : < 20 seconds for measurement.

08. Head

i) Type : IP-65 universal screwed type

ii) Material : Die cast aluminum or better

iii) Terminal blocks : Nickel plated brass screw

type/silver plated

iv) Cable Entry : ET

v) Process Connection : NPTF

vi) Others : Terminal head cover with SS

chain and suitable gasket

09. Standard : Standard DIN 43760

10. Thermowell :

a. Standard : ASME - PTC 19.3

b. Body MOC : Stainless Steel Bar stock

c. Process Connection : M33 X 2 Screwed

d. Element Connection : NPTF

e. Extension length : As per Service Requirement

f. Insertion Length U : As per Service Requirement

11. Accessories : a) Adjustable nipple-union-

nipple with thermo well

connection

12. Nameplate : Tag number, service engraved in

SS tag plate

4.08.00 TEMPERATURE TRANSMITTER (TT)

01. Quantity : As per Service Requirement

02. Make : As per approved vendor list

03. Principle : Smart with HART Protocol

04. Type : 2 Wire

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 13 of 39

05. Input : Thermocouple / RTD

06. Range : As per Service Requirement

07. Output signal : 4 -20 mA DC with HART Protocol

08. Signal Processing circuitry : Microprocessor based solid state

electronic

09. Output indicator : LCD type

10. Body : Die Cast aluminum

11. Operating Voltage : 24 V DC

12. Ambient Temperature : 0 50 C

13. Performance :

a) Accuracy : 0.2% of span or better

b) Repeatability : 0.05% of span or better

c) Cold Junction

Compensation : Built-in

14. Load impedance : 600 Ohm min at 24V DC

15. Span / zero adjustment : Locally adjustable, non-

interacting

16. Calibration : As Per N.I.S.T Monograph 125

for T/C

16. Enclosure class : IP-65

17. Cable connection : 3/4 ET

18. Nameplate : Tag number, service engraved

on metallic tag plate rigidly fixed

to the body.

19. Accessories : a) Universal mounting

bracket suitable for 2

pipe and wall mounting.

b) High tensile carbon steel

U bolts.

4.09.00 TEMPERATURE SWITCH (TS)

01. Type : Mercury filled in

02. Sensing element material : Bellow / Bourdon AISI SS-316

03. Bulb Material : AISI SS 316

04. Capillary : Stainless steel armored

05. Movement Material : AISI SS - 304

06. Case Material : Epoxy coated steel plate or die-

cast aluminum alloy with

neoprene gasket and clear glass

where applicable conforming to

IP65.

07. Scale : Black lettering n white

background.

08. Over range protection : 120 %

09. Instrument connection : Bottom

10. Switch configuration : Two SPDT Lead wires (3+3

Nos.) are to be brought externally

to the male connector wherein

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 14 of 39

the female pug Connector will be

inserted to connect the control

room cables for easy removal &

re - calibration.

11. Switch rating : 240 V, 5A AC / 220, 0.5A V DC

12. Switch Type : Snap acting, shock & vibration

proof

13. Adjustability : a) Internal Set point

adjustable over span

range

b) Differential adjustable by

10% span (min)

14. Cable Connection : 3/4" ET compression gland

15. Compensation : a) Capillary compensation

with invar wire throughout

the capillary length.

b) Case compensation

16. Performance

i) Accuracy : 1.0% of full scale

ii) Repeatability : < 0.5% of full scale

iii) Response time : < 40 seconds with thermo well

17. Capillary length : 5 meters (local) /15 meters (local

panel)

18. Name plate : Tag number, service engraved is

SS tag plate

19. Accessories : a) Mounting accessories,

b) 3/4' ET cable gland.

4.10.00 LEVEL GAUGE (LG) FLOAT & BOARD

01. Make : As per approved vendor list

02. Service : As per Service requirement

03. Type : Float & Board type

04. Float material : SS-304 / 316

05. Float Wire : SS-304 / 316

06. Tank Height : As per Tank Height

08. Range : As per Tank Height

09. Scale : 4 broad Aluminium (in inches)

10. Accuracy : 2% of FSD

11. Bolts and nuts : Rust proof alloy steel

12. Process

a. Operating temperature: As per Service Requirement

b. Operating Pressure : As per Service Requirement

13. Accessories : a) Counter flange, nuts &

bolts,

suitable gasket etc.

b) Wire Rope, Nylon Roller,

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 15 of 39

Mounting brackets & all

other required fittings.

4.11.00 LEVEL GAUGE WITH SWITCH FLOAT & BOARD

01. Make : As per approved vendor list

02. Service : As per Process

03. Type : Float & Board Gauge with Low

Level Switch

04. Float & Wet material : SS-316

05. Float Wire : SS-316

06. Tank Height : As Required

07. Range : As Required

08. Scale : 4 broad Aluminium (in inches)

09. Accuracy : 2% of FSD

10. Bolts and nuts : Rust proof alloy steel

11. Process

a. Operating Temp. : As per Service Requirement

b. Operating Pressure : As per Service Requirement

12. Switch configuration : Micro, SPDT type (2 Nos.)

13. Switch type : Snap acting, 2 NO+ 2 NC

13. Switch rating : 240 V AC, 5A / 220, 0.5A V DC

14. Adjustability : Set point adjustable over span

range

15. Cable connection : 3/4" ET

16. Enclosure class : IP 65

17. Accessories : a) Counter flange, nuts &

bolts,

suitable gasket etc.

b) Wire Rope, Nylon Roller,

Mounting brackets & all

other required fittings.

4.12.00 LEVEL SWITCH RF TYPE

01. Quantity : As per Service Requirement

02. Service : Coal Bunker

03. Height : As per Service Requirement

04. Make/Model : As per approved vendor list

05. Type : RF type

06. Mounting : Side mounted

07. Supply voltage : 230 V AC

08. Contact type : Snap acting, 2 NO+ 2 NC

09. Contact rating : 240 V AC, 5A / 220 V, 0.5A DC

10. Adjustability : Set point adjustable over span

range

11. Performance :

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 16 of 39

a. Accuracy : 5% of FSR

b. Dead band : 2% of FSR

12. Cable connection : 3/4" ET

13. Response time : less than 1 sec

14. Sensing element : SS 316

14. Coat guard shield : SS 316

15. Insulation : PTFE

4.13.00 RADAR LEVEL TRANSMITTER

01. a) Type : Guided wave Radar type

transmitter

b) Probe : Coaxial

c) Probe material : SS 316 / SS 316L

02. Calibration Range : As per application

03. Process medium : As per application

04. Process temperature : As per application

05. Static pressure : Capable of working in vacuum

also

06. Power supply : Range to be specified by the bid

(loop power Available =24V DC)

07. Reverse polarity protection : Required

08. Output : 4 to 20 mA, 2Wire & HART

09. Accuracy : 10mm or better

10. Stability : As per process application

11. Communication : Communication / configuration

shall be possible either through

integral key pad and display or

through hand communicator. If

integral key pad is not available,

one number hand held

communicator common for all the

transmitters shall be supplied

12. Load limitation : Max 600 ohm at 24V

13. Span & Zero : Adjustable

14. Flange Mounting : Yes

15. Environmental protection : IP 66 or better

16. Process connection : Traditional flange with - 18

NPT on flange with process

adapters

17. Electronic housing : Aluminum alloy

18. Electrical connection : Preferably : 14 NPT with

gland

4.14.00 ULTRASONIC LEVEL TRANSMITTER

01. Type of transmitter : Non contact Microprocessor

based 2 wire type, HART protocol

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 17 of 39

Compatible

02. Output Signal : Galvanically isolated 4 20 mA

DC

along with superimposed digital

signal (HART protocol)

03. Sensor Accuracy : 0.5% of calibrated span

04. Sensor Repeatability : 3 mm or better

05. Power Supply : 18 - 36V DC

06. Temperature Compensation : To be provided within transducer

07. Configuration : Sensor and electronic unit are

separate. Electronic unit all be

possible to mount on the

accessible location near the

transducer. All cables, weather

proof fittings for connection

between transducer and

electronic unit.

08. Housing : IP 55 with durable corrosion

resistant Epoxy coating

09. Calibration : Through HART communicator

10. Zero and Span adjustment : Continuous, Tamper proof,

Remote as well as manual

adjustability. Provision to

calibrate the instrument without

any level in the tank or sump etc.

11. Sensor Material : Corrosion resistant application to

suit the individual

12. False signal tolerance : Facility to be provided. Shall

have adjustable damping circuitry.

13. Range : To be decided during detail

Engineering, with a facility to take

care of frequency attenuation

due to different obstructions

(Surface, vapor)

14. Display : Minimum 4 character display with

integral key pad, access

protected features.

15. Diagnostics : Loss of echo alarm

16. Load impedance : 500 minimum or as per vendor

spec.

17. Electrical connection : Plug and socket

18. Accessories : Canopy for protection sunlight

and Rain Mounting hardwares

4.15.00 DISPLACER TYPE LEVEL TRANSMITTER

01. Type : Smart

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 18 of 39

02. Float movement : Vertical

03. Stages of operation : Continuous

04. Material

a) Displacer/Float : AISI 316 SS/304 S

b) Wire rope, sleeve pipe: AISI 304 SS/316 SS

c) Torque tube : AISI 304 SS/316 SS/ Inconel

05. Transmission : 2-wire

06. Output Signal : 4-20 mA Protocol HART

07. Signal processing : Solid-state electronic circuitry

08. Static/overload pressure : Maximum static pressure without

permanent deformation or loss of

accuracy.

09. Turn-down ratio : 100: 1 minimum

10. Zero & Span : Easily accessible (local zero &

span adjustment and non-

interactive type)

11. Zero Suppression / elevation : i) Suppression = 150 % of

span (min.)

ii) Elevation = 50 % of span

(min.).

12. Enclosure class : IP-65 (explosion proof for

NEC class-1)

13. Body/Cage : Forged Carbon Steel or Stainless

Steel depending upon fluid

condition

14. Output Indicator : LCD type

15. Output Ripple : < 0.25% of span

16. Operating voltage : 16 48 V DC

17. Nameplate : Tag number and service

engraved in SS tag plate

18. Ambient Temperature : 0 - 50C

19. Load Impedance : 600 Ohms at 24 Volts (minimum)

20. Process connection : 50 NB ANSI RF Companion

flange

with nuts, bolts and gaskets

21. Performance

a) Accuracy : 0.5 % of span or better

b) Repeatability : 0.05 % of span or better

c) Sensitivity : 0.1 % of span or better

d) Hysteresis : 0.05 5 of span or better

e) Temperature : < 0.5 % of span / 50C

regardless of rate of calibration

change.

f) Power supply effect : 0.005 % / volt

22. Accessories : i) ANSI RF Counter

Flange; rating as per

process pressure.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 19 of 39

Necessary nuts, bolts,

gaskets etc.

ii) Vent and drain plugs

iii) Stilling chamber

v) 3/4" ET cable gland

23. Preferred Features : a) Test plug connection and

cutout terminal physically

separated from other

electronics.

b) Electronic Damping

facility (adjustable)

4.16.00 DP TRANSMITTER (LT & FT)

01. Quantity : As per Service Requirement

02. Make : As per approved vendor list

03. Principle : Smart with HART Protocol

04. Type : 2 Wire Microprocessor based

Transmitter

05. Output signal : 4 20 mA DC with HART

Protocol

06. Signal processing : Silicon solid state electronic

circuitry

07. Measuring element : Diaphragm

08. Measuring element material : AISI 316 (Stainless steel)

Diaphragm

09. Static pressure : 150% of maximum span

continuously without affecting the

calibration.

10. Operating voltage : 24 V DC

11. Ambient temperature : 0-50 C

12. Performance

a) Accuracy : 0.05% of span or better

b) Repeatability : 0.05% of span or better

13. Turn-down ratio : 100:1

14. Load impedance : 600 Ohm min at 24V DC

15. Response Time : 100 msec or better

16. Span / zero adjustment : Locally adjustable, non-

interacting facility for Elevation &

Suppression by 100%

17. Enclosure class : IP-65

18. Output Indicator : LCD type in % and engineering

unit.

19. Cable Entry : ET

20. Process Connection : NPT

21. Nameplate : Tag number, service engraved in

SS tag plate.

22. Accessories : a) Universal mounting

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 20 of 39

bracket

suitable for 2 pipe and

wall

mounting.

b) High tensile carbon steel U

bolts.

c) Installation accessories

d) Condensate Pot for steam

service

e) 5 - way SS manifold,

constructed from SS316

bar stock.

f) Reverse polarity protection

required.

4.17.00 ROTAMETER

01. Quantity : As per Service Requirement

02. Type : Online Reading

03. Process Parameter : As per Service Requirement

04. Accuracy : 1% of FSD

05. Scale : Graduated-Engraved Black

lettering on white background, in

m/hr

06. Body : SS-316

07. Tube : Borosilicate glass

08. Float : SS-316

09. Stopper : SS-316

10. Gland packing : PTFE

11. End connection size/Type : As per Service / Flanged to ANSI

B16.5 CL150

12. Pressure drop : As per Requirement

13. Range : As per Requirement

4.18.00 FLOW ORIFICE

01. Quantity : As per Service Requirement

02. Service : Feed Water

03. Design Standard : BS- 1042

04. Flow element & type : Orifice / Concentric

05. Flow element material : SS 316

06. Flow element thickness : 3mm minimum

07. Pipe material : SA 106 GR B

08. Flange Material : SA 106 GR B

09. Type of tapping : Corner tapping

10. Number of tapings : Two pairs

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 21 of 39

11. Beta ratio : 0.4 to 0.7

12. Pressure loss (meter max) : 0.7 Kg/Cm2

13. Process Parameter : As per Table

14. Service : Feed Water

15. Flow Rate (Nor/ Max.) TPH : As per Service Requirement

16. Pressure (Kg/Cm

2

) : As per Service Requirement

17. Temperature C : As per Service Requirement

18. Density : 1

19. Pipe Size / MOC : As per Service Requirement

20. End Connection : As per Service Requirement

21. Accessories : SS316 Flanges, 1/2" root valves

(Globe), 1/2" Nipple (2 nos. of

Root valves if upstream pressure

>40 Kg/cm2)

Note:

The following Drawing / Document shall be submitted along with each

instrument.

GA drawing

Data Sheet

Flow orifice sizing calculation

Flow Vs Differential pressure curve

4.19.00 FLOW NOZZLE

01. Quantity : As per Service Requirement

02. Service : As per Service Requirement

03. Design Standard : BS-1042

04. Flow element & type : Flow Nozzle/ Long Radius

05. Flow element material : Alloy Steel

06. Pipe material : SA 335 P22

07. Pipe size : As per Service Requirement

08. End connection : Butt Weld

09. Type of tapping : D and D/2

10. Number of tapings : Two pairs

11. Beta ratio : 0.5 to 0.7

12. Pressure loss (meter max) : 0.4 Kg/Cm2

13. Service : As Required

14. Flow Rate : As per Service Requirement

15. Flow Rate (Nor/ Max.) TPH : As per Service Requirement

16. Pressure (Kg/Cm

2

) : As per Service Requirement

17. Temperature C : As per Service Requirement

18. Density : As per Service

19. Pipe Size / MOC : As per Service Requirement

20. End Connection : Butt Weld

21. Accessories : 1/2" root valves (Globe), 1/2"

Nipple

Test:

The Following test shall be carried out along with supply of instrument:

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 22 of 39

100% Radio graphic.

Hydro test.

Calibration test.

IBR test Certificate.

Note:

Drawing/ Document shall be submitted along with supply of instrument:

Fabrication & assembly drawing

Data Sheet

Flow Nozzle sizing Calculation

Flow Vs Differential pressure curve

4.20.00 FLOW SWITCHES (FS)

01. Type : Flapper

02. Material of sensing element : PP / Die Cast Aluminum, stoved,

enameled With anticorrosive

paint

03. Flow range and surge ratio : Later

04. Accuracy : 1 %

05. Contacts type, rating : Two (2) Nos, SPDT type with

snap

action

06. Enclosure class : IP 65

07. Connection Instrument/ : As per process requirements /

NPT (F) Conduit

08. Accessories : Isolation valve, drain and vent

plug on external cage, Bolt/Nut

and gaskets.

4.21.00 MASS FLOW METER

A. Sensor

01. Measuring principle : Coriolis Mass flow.

02. Primary Element : Flow tube of 316 SS or better

03. Heating Arrangement : Integral with Flow Element

04. Temp. control for heating : To be provided

05. Process connection : ANSI RF Flanged and rating as

per process required.

06. Drain : Self-draining facility

07. Accessories : Counter flanges, mounting nuts,

bolts, gaskets etc.

B. Transmitter

01. Measured quantities : Mass Flow rate, Total Mass

Flow, Density, Temperature as

minimum

02. Input Signal Processing : Digital processing

03. Display : Digital Display (LCD).

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 23 of 39

04. Output : 2 Nos. isolated output of 4-20mA

DC selectable from four

measured quantities.

05. Load : <750 ohms

06. Power supply : 240V AC, 50 HZ.

07. Turn Down : 100:1

08. Accuracy : 0.2% of measured value

09. Ambient Temperature : 85

10. Repeatability : 0.05%

11. Housing : IP 65(Explosion proof for NEC

Class-1)

12. Hazardous duty version : FM Standards.

13. Nameplate : Tag number, service engraved in

SS tag plate

14. Accessories : a) As required for field

mounting

b) Handheld configurator

c) Mounting U-bolts, nuts,

prefab cable etc.

d) ET cable gland.

4.22.00 MOTORISED VALVES

01. Quantity : As per Service Requirement

02. Valve service : Main Steam

03. Valve type : Gate Valve

04. Pipe size inlet / outlet : 250NB Sch 140 / 250NB Sch 140

05. Pipe MOC : SA-335 P22

06. Guiding : Later

07. Type of connection : Flanged

08. Material

i) Valve body : Later

ii) Stem : ANSI -316 SS

iii) Seat rings : ANSI -316 SS

iv) Plug : ANSI -316 SS

v) Bonnet gasket : Later

09. Port size : Later

10. Plug type : Later

11. Plug characteristic : Later

12. Differential pressure : Later

13. Maximum flow capacity :

a. Normal Flow in TPH : As per Service

b. Maximum Flow in TPH: As per Service

c. Operating Temp in

O

C : As per Service

d. Up steam Operating

Pressure in Kg/cm

2

:

As per Service

e. Down steam Operating

Pressure in Kg/cm

2

:

As per Service

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 24 of 39

14. Valve stem packing : Later

15. Type of actuator : Motor operated

16. Actuator make / model : Later

17. Signal range : Later

18. Integral Bypass Valve : 25NB Motorized Integral Valve

with All accessories

19. Accessories included : Electric motors, Position limit

switches & Torque limit switches,

Hand wheel, gear train,

mechanical position indicator,

internal wiring, integral starters

and terminal block etc.,

20. Noise ratio : < 85 db

21. Leakage class : Class IV

22. Minimum clearance required : As per standard for maintenance

purposes

23. Integral Bypass Valve : 25NB Motorized Integral Gate

Valve with all accessories

24. Make : As per approved vendor list.

4.23.00 CONTROL VALVE

01. Quantity : As per Service Requirement

02. Make : As per Approved Vendor List

03. Valve service : Later

04. Valve type & size : As per process requirement

05. Valve co-efficient : Later

06. Connection size inlet / outlet : As per process parameter

07. Guiding : Later

08. Type of connection : Later

09. Material

i) Valve body : Later

ii) Stem : ANSI -316 SS

iii) Seat rings : ANSI -316 SS

iv) Plug : ANSI -316 SS

v) Bonnet gasket : Later

10. Port size : Later

11. Plug type : Later

12. Plug characteristic : Later

13. Differential pressure : Later

14. Maximum flow capacity : Later

15. Valve stem packing : Later

16. Type of actuator : Pneumatic actuator

17. Actuator make & model : Later

18. Signal range : Later

19. Action on air failure : Fail to open or fail to close in a

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 25 of 39

direction safe for the process

20. Accessories included : Hand wheel, Limit switches, I/P

Converter, air lock relay, position

transmitter and JB etc.

21. Noise ratio : < 85 db

22. Leakage class : IV

23. Min. clearance required : As per standard for maintenance

purposes

24. Process Parameters:

a) Process Pressure : Later

b) Process Temperature : Later

c) Process Flow : Later

d) Line Size : Later

4.24.00 SOLENOID VALVE

01. Operating Principle : Electromagnetic (noiseless)

Latch

/ release coil shall be used in the

required application where the

safety is to be ensured.

02. Coil voltage rating : 240 V AC /110V AC / 24 V DC /

48

V DC / 220 V DC (As required).

03. Ways : 3 ways (NO + NC) [General],

other Depending on requirement

04. Port size : 1/2" NPT / as per site

requirement

05. Body : SS Bar Stock

06. Trim : AISI SS-316

07. Manual operator : In built

08. Duty : Suitable for continuous

energization

09. Sealing : Airtight and leak proof

10. Ambient temperature : 0 - 50

O

C

11. Fluid temperature : 0-150

O

C or as per application

12. Coil enclosure : Stainless Steel

13. Insulation : Class-H

14. Coil casing : IP-65 (Explosion proof for NEC

Class-1)

15. Mounting : On pipe or on panel

16. Cable connection : 3/4" ET Compression gland

17. Accessories : Mounting brackets, nuts and

bolts

18. Pressure Rating : As per application

19. Special feature : i) Temperature operated

fuse at explosion proof

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 26 of 39

enclosure.

ii) Solenoid valve directly

integral to actuator body

shall have NAMOOR

interface.

4.25.00 ELECTRO-PNEUMATIC CONVERTER (I/P)

01. Quantity : As per Service Requirement

02. Make : As per approved vendor list.

3. Type : Electro-Pneumatic Input

4. Input : 4-20 mA DC

5. Output : 0.2 to 1.0 kg/cm

6. Direct/reverse action : Provided

7. Enclosure class : IP 65

8. Mounting : Field (Pipe& wall) mounting

9. Air filter regulator : Sintered bronze, 5 Microns,

10Kg/cm

10. Output gauge : Provided

11. Connections : ET / NPT (Electrical/

Pneumatic)

4.26.00 AIR FILTER REGULATOR

01. Quantity : As per Service Requirement

02. Make : As per Approved Vendor List

03. Filter element : Sintered Bronze

04. Filter size : 5 microns

05. Input air : 10.0 Kg/Sq.cm (maximum)

06. Output : Adjustable from 0- 2.0 Kg / cm or

0 7.0 Kg/Sq.cm (continuous) as

applicable.

07. Effect of supply : Maximum 0.002 Kg/Sq. cm for a

change pressure variation in

supply pressure of Kg / Sq.cm

08. Bowl material : Metallic cover around high

Temperature Area / clear

transparent polycarbonate with

metallic cover for ordinary

applications.

09. Accessories : 2" dial size output pressure

gauge

10. Desirable feature : No perceptible drop of pressure

on opening the drain port.

4.27.00 JUNCTION BOX

01. Quantity : As per Service Requirement

02. Make : As per Approved Vendor list

03. Type : Flame proof/weather proof

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 27 of 39

04. Enclosure : IP-65

05. Material : Die cast aluminum with

protective coating

06. Cable entry : Bottom

07. Cable glands : Double compression type

Nickel plated brass with PVC

hoods.

08. Mounting : Outdoor

09. No. of terminals : As required with standardization

10. Terminals : Phoenix/Wagon

11. Grounding : Two terminals for body and

shield

ground

12. Door : Hinged, lockable type.

4.28.00 POSITIONER

01. Stroke Adjustment : Shall be possible.

02. Gauges : Supply, signal, output

03. Travel time of valve : < 10 seconds

04. Hysteresis : 0.5% of F.S.

05. Linearity : 1.0% of F.S.

06. Dead Band : 0.5% of F.S.

4.29.00 LIMIT SWITCH (LS)

01. Type : Dust proof momentary spring

return

02. Operating head : Adjustable roller Lever (32-82.5

mm) with 19 mm Dia and 8 mm

Dia Vide metal Roller.

03. Accuracy and differential : 0.2% of full scale

04. Differentialfixed/ adjustable : Adjustable

05. Contact Arrangement : SNAP Action

06. Number of contacts : 2 Normally Open (NO) & 2

Normally Closed (NC)

07. Contact rating : 5A, 240V/0.25A, 220V DC

08. Outlet Pressure gauge range : 50 mm diameter Range (0 -10)

09. Operating temperature range : Later

10. Cable Entry : 3/4" Double compression cable

gland

11. Enclosure class : IP 65

13. Accessories : Isolation valve, drain and vent

plug on external cage

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 28 of 39

4.30.00 Control &Instrumentation Cables

4.30.01 600V GRADE SINGLE PAIR TWISTED INSTRUMENTATION SIGNAL

CABLE

CONSTRUCTION

a) Conductor: Each core shall be seven stranded annealed

copper electrolyte grade conductor of cross

section 1.0 mm2 generally complying to IS-8130.

b) Insulation: Each core shall be provided with extruded HR

PVC conforming to IS:5831 Type 'C'.

Insulation thickness shall be >=0.8 mm and shall

conform to relevant IS/other standard. Color of

insulation shall be white and black in a pair.

c) Twist: Every 2 core shall be twisted to form a pair and

number of twist shall be 20 twist per meter.

d) Shielding: The individual pair shall be shielded. Shield

shall be Aluminium backed by Mylar tape bonded

together side down helically applied with either

side 25% overlap and 100% coverage. Minimum

shield thickness shall be 0.05mm Drain wire

shall be 0.5 sq mm multi stranded bare tinned

annealed copper conductor. The drain wire shall

be in continuous contact with aluminium side of

the shield.

e) Inner sheath: Cables shall be provided with extruded HR PVC

inner sheath as per IS 5831 type ST1. The

color shall be black and minimum

thickness shall be >= 0.4 mm.

f) Armouring: Armouring applied over inner sheath shall be of

galvanised steel wire 1.4 mm dia as per IS 1554

part I and IS 3975.

g) Overall sheathing: The cable shall be sheathed with extruded HR

PVC type ST1 as per IS 5831 Color of sheath

be Black. Thickness of the sheath shall be as per

IS 1554 Part. I and >= 1.24 mm. FRLS PVC outer

sheath shall be provided.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 29 of 39

4.30.02 600V GRADE MULTIPAIR TWISTED INSTRUMENTATION SIGNAL

CABLES

GENERAL

Multi pair twisted instrumentation cables shall be same as Single pair

shielded cable.

Following additional features shall be applicable: -

a) Conductor: Each core shall be seven stranded annealed

copper electrolyte grade conductor of cross

section 0.75 mm2 generally complying to IS-8130.

b) Shielding: In addition to individual shielding of pair, overall

shielding shall be provided. Overall shield shall be

Aluminium backed mylar tape helically applied with

metallic side down either side 25% overlap and

100% coverage. Shield thickness shall be 0.075

mm. Drain wire shall be similar to individual pair drain

wire and shall be in continuous contact with the

Aluminium side of the overall shield.

b) Twist: Overall twist of all pair shall be as per

manufacturer standard

c) Pair-Identification : Pairs shall be identified by printing pair

numbers by black indelible ink on the white core

at interval not more than 250 mm. Conductor

insulation shall be black and white for each

pair.

4.30.03 600V GRADE SINGLE TRIAD SHIELDED CABLE

600V grade single triad cable shall be same as Single pair shielded cable.

4.30.04 600 GRADE MULTI TRIAD SHIELDED CABLE

600V grade multi triad cable shall be same as Multi triad shielded cable.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 30 of 39

4.30.05 1100V GRADE 2 CORE CONTROL CABLE

CONSTRUCTION

a) Conductor: Each core shall be seven stranded annealed tinned

copper conductor of cross section 1.5 mm2 generally

complying to IS 8130.

b) Insulation: Each core shall be provided with extruded HR PVC

insulation conforming to IS 5831 Type 'C'.

Insulation thickness shall be >= 0.8 mm. Color of core

insulation shall be black with core numbers printed in

white indelible ink at max. 150mm apart on each

conductor.

c) Inner sheath: Cables shall be provided with extruded HR PVC

inner sheath as per IS 5831 type ST1. The color shall

be black. Thickness of sheath shall be >= 0.3 mm.

d) Armouring : Armouring applied over inner sheath shall be of

galvanised steel wire 1.4 mm dia. as per IS 1554 part

I and IS 3975.

e) Overall : The cable shall be sheathed with extruded HR PVC

sheathing type ST1 as per IS 5831. Colour of

sheath shall be black. Thickness of the sheath shall

be >= 1.24 mm as per IS 1554 part-I. FRLS PVC

outer sheath shall be provided.

4.30.06 1100V GRADE Multi core control cables

Multi core control cables shall be same as two core control cable except for

the following features.

a) Conductor: Each core shall be seven stranded annealed tinned

copper conductor of cross section 0.75 mm2 generally

complying to IS 8130.

The core identification can be done by numbers. In that case, the

insulation of cores shall be of same color and number sequentially sorting

with number 1 for inner layer. The number shall be printed in Hindu Arabic

numerals on the outer surface of the cores. (All the numbers shall be of

same color which shall contrast with the color of the insulation. The

numerals shall be 1 eligible. Bidder may alternately offer color coded

conductors).

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 31 of 39

4.30.07 Fibre Optic Cable (Mono type)

i. Cable Type : Mono-mode with minimum 4

fibers

ii. Wavelength band optimized : 850nm / 1300nm / 1550nm

iii. Mode field diameter : 9-10m + 10% of nominal

value

iv. Cladding diameter : 125m + 3

Non-concentricity core

/ Cladding : not more than 2m

Non-circularity of cladding : not more than 3m

vii. Cut-off wavelength : 1200nm

viii. Attenuation : 1. less than 0.3-0.4 dB/km at 1300nm

2. less than 0.15-0.25 dB/km

at 1550nm

Fibre optic cables shall be Rodent proof type and shall be laid through 30 mm dia

HDPE conduit

4.30.08 Fibre Optic Cable (Multi type)

i. Cable Type : Multi-mode with minimum 4

fibers

ii. Core / cladding diameter : 62.5 / 125 m

iii. Jacketing Material : Halogen Free, Flame

Retardant, Low Toxicity

iv. Attenuation @ 850 nm : Length (m) x 0.0035

db/m+2db maximum

v. Outside Diameter : 8.10 mm (0.324 in)

vi. Minimum Bend Radius : 12.5 cm (5 in)

vii. Minimum Bend Radius : 7.5 cm (3 in) (Long term)

viii. Cable Assembly : Tensile Load for attenuation

increase <0.5 db: 300 N

(66 lb) maximum

ix. Tensile Load at Installation : 1776 N (400 lb) max.

x. Connector Tensile Load MIC : 133 N (30lb)

xi. Minimum Crush Resistance : 46 N /cm (250 lb /in)

Fibre optic cables shall be Rodent proof type and will be laid through 30 mm

dia HDPE conduit

5.00.00 CODES & STANDARDS

5.01.00 GENERAL

5.02.00 All equipment, systems and works covered under the Bidders scope shall

comply with all statutory regulations and safety codes as applicable

internationally and in locality where the equipment will be installed.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 32 of 39

5.03.00 The Bidders scope of supply shall include some items such as thermowells,

control valves and other in-line devices for main steam, feedwater system,

falling under the purview of Indian Boiler Regulation (IBR) Act. It shall be the

responsibility of the Bidder to obtain the necessary approval of the concerned

Inspecting Authority/Chief Inspector of Boilers for the design and design

calculations, manufacturing and erection procedures as called for under the

Indian Boiler Regulations Act.

5.04.00 The design, manufacture, inspection, testing and erection of the equipment

covered under this Specification shall conform to the standards and codes

(latest editions) including but not be limited to those mentioned below.

Contractor shall refer to the latest revision of all codes and standards.

Bidder shall however, follow sound Engg. practice throughout.

Temperature Measurement -ASME PTC 19.3

ANSI MC 96.1

IEC 751, IEC584.2

BS 1401

IS 2806

Pressure Measurement -ASME PTC 19.2

IEC 381

IS 3624

Flow Measurement -ASME PTC 19.5

BS 1042/ ISO 5167

Control Valves - ISA S 75.01-75.05

ANSI B16.34

ANSI B16.10

Sampling System -ASME PTC 19.11

ASTM D1198

ASTM A 269

Enclosures -IEC 529

IEC 79 (Hazardous)

IS 2147/IS 13947

Annunciator - ISA S 19.1

Boiler Safety Interlocks - NFPA Section 85B/D/E/F/G

Instrument Tubing, - ANSI B 16.11/B 31.1

Fitting

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 33 of 39

Cables - IEEE 383 BS 6746 IS 5831

BS 5308 BS 6346 IS 10810

IS 1554 BS 6360 IS 694

IS 8130 BS 6500

6.00.00 INSTRUMENT INSTALLATION

6.01.00 General

a) Instrument process tubing and instrument air tubing to be designed in

accordance with the instrument installation drawings.

b) All instruments, process connections, including isolation valves and

associated devices, shall be located in easily accessible locations for

maintenance, calibration and replacement. All maintenance, calibration

and replacement operations on a given device must be possible without

interruption of service to adjacent equipment.

c) Instrument mounting height shall 4 - 6 above equipment base or

platform.

d) Instrument tubing installation are designed in accordance with ANSI

B31.1 Power Piping.

6.02.00 Instrument Sensing Lines

a) All impulse pipe shall be of seamless type conforming to ANSI B36.10

for schedule numbers, sizes and dimensions etc

b) Minimum bending radius of instrument sensing lines 3 times the tube

diameter.

c) Instrument sensing lines are sloped in their horizontal runs, a minimum

of 1/2 per foot. In general, liquid and steam lines slope from their

process tap connection down to the instrument. In general, gas and

non-condensing vapor lines slope from their process tap connection

upto the instrument.

d) Instrument sensing lines shall be routed as directly as practicable from

the process root valve to the instrument. The length of instrument tubing

from the root valve to the instrument shall be limited to maximum of 12

meters for compressible fluids and 15 meters for non-compressible

fluids.

e) Instrument sensing lines are grouped together as much as possible to

benefit from the use of common support members and to present a

finished installation that is routed in a neat and orderly manner. Care is

exercised to assure that spacing between adjacent tubes in the same

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 34 of 39

group is maintained uniform and that tubes do not cross under or over

one another at any point. Changes in direction of tubing is done by the

use of tube bends and not tube fittings.

f) For connection to gauge or transmitter or switch compression tube

fittings will be used.

g) A single blow down valve or double blow down valves (if the process

root valves are doubled) shall be installed to the sensing lines of all

pressure transmitters that are tapped off liquid or steam process

systems. These valves shall be located at the instrument and may be

brought together to the header.

h) The maximum process temperature for all transmitters shall be limited to

80

o

C. To dissipate the excess heat, a maximum of 1 meter of tubing for

each 30

o

C of excess heat shall be installed to isolate the process media

from the instrument. An additional isolation valve shall be used at the

instrument for isolation on those instruments without valve manifolds.

6.03.00 Instrument Air Lines

a) Instrument air lines shall be of stainless steel..

b) Minimum bending radius of instrument air line tubing is 3 times the tube

diameter.

c) All branch lines from the instrument air line header are made from the

top of the air header and shall not be smaller than 1/2 inch. Branch lines

have a root valve at the process connection.

d) In areas with multiple air users, an instrument air manifold is used. The

branch from the air header to manifold is 1 inch, with a 1-inch isolation

valve at the manifold. The manifold consists of a 3 inch pipe with a caps,

3/8 inch air takeoff connections with 3/8 inch shutoff valves, and a 1/2

drain valve. A six and eight air user, manifold design, will be used.

6.04.00 Instrument Mounting

a) Instrument mounting shall be in accordance to standard hook-up details

and mounting details.

b) Spacing between multiple instruments mounted on the same support

shall be sufficient to allow ample clearance area in order to perform

service, maintenance, calibration and testing.

6.05.00 Instrument Wiring

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 35 of 39

6.05.01 General

The two-wire system shall be employed for transmission of signals from

electronic transmitting instruments. Electronic instrument wiring shall be done

as per manufacturers standards and multicore cables shall be used wherever

practical. Special, screened, shielded or co-axial cables shall be used as

required and as such, these special cables shall be supplied by the

Contractor.

6.05.02 Conduit

Compensating and screened cable shall, in general, be installed in rigid

conduit. All special cable including compensating cables required for the plant

shall be included in Contractors scope.

6.05.03 Terminal Box

Except for thermocouple cables terminal/junction boxes shall be used for the

interconnection of control wiring and instrument signal wiring. Terminal boxes

of a type approved for area classification shall be provided for terminating

multicore control wiring. NEMA-3 standard type of better enclosures shall be

used for junction boxes. 20 % spare terminals shall be provided in the

junction box.

6.06.00 Wiring Practices

6.06.01 The signal cable shield shall not be used as a signal conductor. The signal

cable shall not be spliced. The cable shield shall be maintained at a fixed

potential with respect to the circuit being protected.

6.06.02 Low level signal cable shall be terminated with short untwisted length of wire,

which should have as minimum area as practicable to be exposed for

inductive pick-up. Low level signal cables should be separated (isolated) from

noisy & power circuits by practicable large distance. Signal cables should not

cross each others, if at all required, crossing shall be at right angles, and at a

large practical distance.

6.06.03 Instrument cubicle/panel wiring shall be such that minimum crossing of signal

cables are encountered. Instrument/device located in left (and right) hand

side of panel/cubicle should be terminated in left (& right) side terminal block

respectively so as to minimise intercrossing of wires in panel/cubicles.

6.06.04 Unused shielded conductors in a low level signal cable shall be single end

grounded at the opposite end.

6.06.05 Earthing plate for all electronic instruments shall be away from common

electrical earthing point. A signal circuit shall be grounded either at the

transmitter end or at the instrument end.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 36 of 39

6.06.06 All Cables to be terminated in Junction Box/Panel shall be through cable

glands.

6.06.07 All instrument cables like signal cable, communication cable, supply cable

should have separate color code and cables should be distinguished from

electrical cables. Signal cables and control cables should be put in cable trays

separate from that of power cables.

6.06.08 All cables should have traceability from field to JB and JB to DCS/Panel with

identification ferrules. The cabling should be documented properly so that it

can be useful for future maintenance.

7.00.00 DATA AND DOCUMENTS TO BE FURNISHED BY THE BIDDER ALONG

WITH BID

Bidder shall furnish all required information/data sheet/drawing/document

required to facilitate full appreciation of bid which shall include but not limited

to following :-

a) Proposed control philosophy along with Control system

configuration diagram.

a) Filled up Technical Particular Sheets/Schedules.

b) Details of C & I and PLC System offered

c) Tentative I/O counts

d) Details of hardwired controls and indication (if any).

e) List of deviation from Specification document.

f) Vendor list of instrumentation items.

DATA AND DOCUMENTS TO BE FURNISHED BY THE CONTRACTOR

a) Operational Philosophy.

b) Control system configuration diagram.

c) Description and write-up of control scheme and interlocking

system.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 37 of 39

d) Complete Local Control room layout drawings with foundation,

GA details of all panels, desks and consoles, wherever

applicable.

e) Interconnection cable schedule (ICS) and cable schedule

between instruments JBs & I/O cabinets.

f) Cabinet / Panel wiring diagrams and internal layout drawings

g) Cabinet / Panel terminal details

h) Wiring diagrams for panel, local panel, junction boxes,

actuators,etc

i) Proposed Graphics/Mimic displays and logs.

j) Control schemes/logic diagram.

k) Flow element and Control valve sizing calculations and

dimensional drawings.

l) Interconnection Diagram of different PLCs / C & I systems and

the DCS showing all hardware details.

m) Complete Instrument Schedule.

n) Junction Box Schedule

o) FAT procedure

p) Heat load, Power consumption and air consumption data

q) Calibration test & quality assurance test procedure and test

certificates.

r) Shop and site Test Records.

s) Manuals & technical literature for instruments/ equipments.

t) Instrument installation diagram showing all erection hardware.

u) Power supply arrangement for field mounted

instruments/panels/sub systems.

v) 'As built' status drawings.

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 38 of 39

ANNEXURE-I-DRIVE CONTROL PHILOSOPHY

Drive Control Philosophy: Control philosophy for interfacing of MCC/SWGR./Actuator with

PLC/DCS is as follow:

a. Bi-directional drives (inching or open/close) -

All Motor operated valves/dampers are integral type. The following interface between

PLC and valve integral starter:

i. Potential free On-Off commands from PLC to integral starter.

ii. Speed output (For VFD Drives)

Feed backs from integral starter to PLC shall include:

i. Open limit switch feedback

ii. Close limit switch feedback

iii. Open torque switch feedback

iv. Close torque switch feedback

v. Integral Starter Disturbed (Loss of power/control supply, thermostat trip,

Thermal O/L, Torque open/close, Local/off/Remote S/S in Local or Off mode

etc.)

vi. Position Transmitter Feedback (For Inching Type drive)

b. Unidirectional LT Drives

LT drives like Pumps and Fans shall have the following interface with PLC and MCC:

i. Potential free On-Off commands from PLC to MCC.

ii. Speed output (For VFD Drives)

Feed backs from MCC to PLC shall include:

i. On/Running

ii. Off/stop

iii. Switchgear/MCC Disturbance (when Thermal O/L, control power supply fails,

MCC power supply is isolated, EPB OPTD, S/S not in Remote).

iv. Current Feedback for motor rated >30KW

v. Speed (For VFD drives)

c. Unidirectional HT Drives

HT Drives like pumps and fans shall have the following interface with PLC and MCC:

i. Potential free On-Off commands from DCS to MCC.

ii. Speed output (in case of VFD)

SPECFICATION FOR

AIR COOLED CONDENSER

PROJECT

1 x 300 MW COAL BASED THERMAL

POWER PLANT, CHHATTISGARH, INDIA

Doc. No. 11V02-201-SPC-M-0001, REV.R0

Date: 04-11-2011 VOL-II PART-C Page 39 of 39

Feed backs from MCC to PLC shall include:

i. On/Running

ii. Off/Stop

iii. Switchgear/MCC Disturbance (Overload relay operated, control supply fail,

Emergency LPBS operated)

iv. Switchgear/MCC Available (Breaker in service position, Switchgear in remote

& breaker spring charged, lockout relay reset)

v. Breaker in test position

vi. Current Feedback

vii. Speed Feedback (in case of VFD)

d. Solenoid Drives

Solenoid operated drives shall have the following interface with PLC:

i. Energize

ii. De-energize

iii. Open limit switch feedback

iv. Close limit switch feedback

e. Pneumatic Drive

Pneumatic operated drives shall have the following interface with PLC:

i. Command to I/P converter

ii. Position Transmitter Feedback

iii. Open limit switch feedback

iv. Close limit switch feedback

v. Command to solenoid valve (Wherever Applicable)

Вам также может понравиться

- Recommended Noise CriterionДокумент4 страницыRecommended Noise CriterionsuparnabhoseОценок пока нет

- M574LEA7 - Mandatory Spares BTGДокумент23 страницыM574LEA7 - Mandatory Spares BTGsuparnabhoseОценок пока нет

- REL-DBR Mech-R1.Документ17 страницREL-DBR Mech-R1.suparnabhoseОценок пока нет

- k8v07 Raikheda CHH GlanceДокумент4 страницыk8v07 Raikheda CHH GlancesuparnabhoseОценок пока нет

- Boiler Performance Test ProcedureДокумент16 страницBoiler Performance Test ProceduresuparnabhoseОценок пока нет

- Volume - Ii Section - M0 Technical Specification: Specification For Compressed Air System GMR Energy LimitedДокумент50 страницVolume - Ii Section - M0 Technical Specification: Specification For Compressed Air System GMR Energy LimitedsuparnabhoseОценок пока нет

- Cooling Water Treatment NoteДокумент13 страницCooling Water Treatment Notesuparnabhose100% (1)

- Design Memorandum For LP Chemcial Dosing System (Rev-1)Документ12 страницDesign Memorandum For LP Chemcial Dosing System (Rev-1)suparnabhoseОценок пока нет

- 11V02 Acc SPC M 0001 V2 Part AДокумент182 страницы11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- Coal Feeder Catalog (Color)Документ10 страницCoal Feeder Catalog (Color)suparnabhoseОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)