Академический Документы

Профессиональный Документы

Культура Документы

Fastferry Nik

Загружено:

nikdbstttАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fastferry Nik

Загружено:

nikdbstttАвторское право:

Доступные форматы

Fast Ferries

&

Floating Production/Storage/Offloading

(FPSO) Vessels

Hauke Kite-Powell

October 2005

Fast Ferries: Outline

Technical Overview

Background and History

Present Market Conditions

Likely Developments

Financial and Risk Management

Considerations

Fast Ferries: State of the Art

large catamaran (Incat): 100 m, 500 dwt,

900 passengers/240 vehicles, 50 knots;

$44m

small catamaran: 30 m, 325 passengers,

40 knots; $15m

Italian monohull: 150 m, 1800

passengers/460 cars, 40 knots

Fast Ferries: Earlier

Approaches

hydrofoil

hovercraft

SWATH

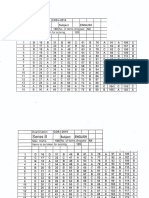

Fast Ferries: World Fleet

903 in 1990; 1218 in 1997; 12% growth

over 1000 are passenger-only

catamarans and monohulls growing

fastest

major regions: Greece (10%), China,

Indonesia, Scandinavia, Western Europe,

Turkey, Singapore, Australia, South

America

Fast Ferries: Leading Builders

Incat, Austal: Australian catamarans

Kvaerner Fjellstrand, FBM: Eurasian

catamarans

Fincantieri, Rodriquez Cantieri Navali:

Italian monohulls

Fast Ferries: Supply

Italian and N. European yards: largest

ferries

Australian yards: 40% of fast pass/vehicle

market

licensing of designs from Australia

Fast Ferries: Current Demand

passenger-only craft dominate

greatest current demand still from Europe

and the Asian Pacific Rim

Fast Ferries: Nearterm Growth

United States: metropolitan transport

systems

Greece: replacement of aging hydrofoils

Fast Ferries: Longterm Growth

Caribbean

Indonesia

Philippines

South America

Fast Ferries: Developments

size and speed

propulsion

reduced environmental impacts

rough sea operations

Fast Ferries: Size and Speed

gas turbines and composites: high speed

more economical; long open water routes

95 m/1000 t/65 knots freight catamaran on

offer

120-130 m/2000 t/50+ knots freight

catamaran being designed

flexible, modular designs

Fast Ferries: (Gas) Turbines

more kW/kg, but higher purchase price

fuel cost, maintenance cost coming down

inefficient at low power

four diesels is max. installation for

catamaran hull (30,000 kW)

Fast Ferries: Environment

wake wash

emissions

ship strikes on marine mammals

Fast Ferries: Rough Sea Ops

motion control systems (refinements)

SLICE: modified SWATH concept, focus

on Hawaiian islands

Fast Ferries: Risk Management

environmental and regulatory restrictions

inexperienced operators

secondary market

FPSOS and Fast Ferries:

Conclusions

growth in both markets areas

opportunities exist

cash flows, not asset values

examine deployment specifics

consider redeployment opportunities and

limitations

Floating Production, Storage,

and Offloading (FPSO)

Vessels

Outline

Technical Overview

Background and History

FPSO Market Development

Market Forecasts

Prospects for Conversions

Conclusions

Technical Overview

jackups

semisubmersibles

monohull FPSOs

Context

offshore production about 20% of world

production

mobile production about 10% of offshore

production

both fractions are increasing

Mobile Production Installations

FPSO newbuildings 22

FPSO conversions 46

semisubmersible newbuildings 4

semisubmersible conversions 31

jack-ups 19

total 122

History

first installation in Mediterranean

first substantial development in benign

waters of Far East, Australia

move to North Sea, South America, West

Africa

likely soon in U.S. Gulf of Mexico

Technology Development

flexible mooring to riser buoy

rigid mooring to riser buoy (detachable)

mooring turret in bow

mooring turret within length of vessel

dynamic positioning

Technology Development

water depth: 120 m (1977) to about 2500

m today

production (flow) rates: 15,000 b/d (1977)

to 200,000 b/d

Water Depth Trend

0

100

200

300

400

500

600

700

800

900

1,000

FPSO deployments, 1981-1998

w

a

t

e

r

d

e

p

t

h

(

m

)

FPSO Vessel Size Trend

0

50

100

150

200

250

300

FPSO deployments, 1981-1998

1

0

0

0

d

w

t

Production Capability Trend

0

20

40

60

80

100

120

140

160

180

200

FPSO deployments, 1981-1998

p

r

o

d

u

c

t

i

o

n

c

a

p

a

c

i

t

y

,

1

0

0

0

b

o

p

d

Geographic Regions

FPS installations

as of 1998

FPS installations

2003 (est.)

Europe 24 37

Africa 12 27

Middle East 1 1

Asia 13 15

Australia 4 7

North America 9 23

South America 12 25

Total 75 135

U.S. Gulf of Mexico

USCG, MMS share management

responsibility

FPSOs are tank vessels (OPA 90 etc.

apply)

stored oil is cargo

offloading is lightering

possibility of ISIS

EIS underway

gas flaring is illegal

Economics

structure cost insensitive to water depth

operating cost compares favorably to fixed

platforms

rapid deployment, redeployment

easy abandonment

(subsea tiebacks)

(semisubmersibles)

Conversion vs. Newbuild

2/3 to date are conversions

cost: factor of 10 (conversion costs $15-30

million)

availability of suitable tankers: 1970s and

1980s, 100 - 160,000 dwt

FPSO Deployment History

0

2

4

6

8

10

12

14

1981 1985 1986 1989 1990 1991 1993 1994 1995 1996 1997 1998

F

P

S

O

s

e

n

t

e

r

i

n

g

s

e

r

v

i

c

e

/

y

e

a

r

newbuilds

conversions

New vs. Convert: Vessel Size

0

2

4

6

8

10

12

14

16

0-50 51-100 101-150 151-200 201-250 251-300

dwt (1000s)

#

o

f

F

P

S

O

s

d

e

p

l

o

y

e

d

convert

newbuild

New vs. Convert: Production

Cap

0

5

10

15

20

25

0-50 51-100 101-150 151-200

production capability, 1000 bopd

#

o

f

F

P

S

O

s

d

e

p

l

o

y

e

d

convert

newbuild

New vs. Convert: Storage Cap.

0

2

4

6

8

10

12

0 to 5 5 to 10 10 to 15 15 to 20 20 to 25 >25

storage capacity, days at max. prod. rate

#

o

f

F

P

S

O

d

e

p

l

o

y

m

e

n

t

s

convert

newbuild

Indications for Newbuild

harsh environment (seas always head-on)

long field life or deployment prospects

Indications for Conversion

benign environment

short term deployment

Tank Vessels for Conversion

steel condition is paramount

turbo generator a plus

segregated ballast tanks (post-1980) a

plus

condition of piping does not matter

Demand Forecast

20+ deepwater fields/year being

developed

half of these to involve one or more FPSO:

10+ FPSOs/year

OOG Drivers

deepwater fields: 44% of reserves deeper

than 300 m

average field size decreasing

large new fields (West Africa, Brazil) are in

deep water

$44b in OOG development expenditures

forecast for next 5 years; 250 to 400

subsea completions per year

Effect of Oil Price

average deepwater finding/developing

cost is just above $4/barrel (range: $2.11

to $9.42)

deepwater development is relatively

insensitive to oil price above $10/barrel

Oil Price and U.S. OOG Activity

0

10

20

30

40

50

60

70

1

9

6

8

1

9

7

0

1

9

7

2

1

9

7

4

1

9

7

6

1

9

7

8

1

9

8

0

1

9

8

2

1

9

8

4

1

9

8

6

1

9

8

8

1

9

9

0

1

9

9

2

1

9

9

4

1

9

9

6

1

9

9

8

o

i

l

p

r

i

c

e

(

$

9

7

/

b

b

l

)

a

n

d

U

.

S

.

O

&

G

C

A

P

E

X

(

$

b

)

0

200

400

600

800

1000

1200

1400

1600

1800

2000

n

u

m

b

e

r

o

f

G

O

M

t

r

a

c

t

s

l

e

a

s

e

d

oil price

US O&G CAPEX

tracts leased

Likely Developments

Standardization -- not yet

connection technologies

gas production/disposal

Standardization

has not yet happened: too many one-off

conversions

shift to contractor ownership will help drive

standardization

production system components

Connection Technologies

subsurface buoys

riser connections

S-shaped risers

composite risers

synthetic rope moorings

Gas Production

conversion to methanol

liquefaction now proven

pipeline

reinjection

flaring

Conclusions

growth projection healthy

conversions now slowing

investment opportunities in newbuildings

Вам также может понравиться

- CDS I 15 EnglishДокумент4 страницыCDS I 15 Englishamitrathee09Оценок пока нет

- Dock and Lock Gates Royal HaskoningDHV BrochureДокумент16 страницDock and Lock Gates Royal HaskoningDHV BrochureJorge LafontantОценок пока нет

- The New Cds GK PaperДокумент4 страницыThe New Cds GK PapernikdbstttОценок пока нет

- Gases - Specific Heats and Individual Gas Constants (R)Документ2 страницыGases - Specific Heats and Individual Gas Constants (R)nikdbstttОценок пока нет

- War and PeaceДокумент2 882 страницыWar and PeacenikdbstttОценок пока нет

- Engg. MachanicsДокумент3 страницыEngg. MachanicsnikdbstttОценок пока нет

- Produced by An Autodesk Educational Product: NO.2 WBT (P)Документ1 страницаProduced by An Autodesk Educational Product: NO.2 WBT (P)nikdbstttОценок пока нет

- General Arrangement Lecture Notes - by Prof. S.C.Misra: 1.3 Frame SpacingДокумент14 страницGeneral Arrangement Lecture Notes - by Prof. S.C.Misra: 1.3 Frame SpacingnikdbstttОценок пока нет

- Wave LoadsДокумент8 страницWave LoadsnikdbstttОценок пока нет

- Hydromax ManualДокумент252 страницыHydromax Manualmanon160100% (1)

- Application GSLДокумент4 страницыApplication GSLnikdbstttОценок пока нет

- Theory of EverythingДокумент2 страницыTheory of EverythingnikdbstttОценок пока нет

- The Red SariДокумент417 страницThe Red Sarikharman10183% (6)

- Basic ElectronicsДокумент1 страницаBasic ElectronicsnikdbstttОценок пока нет

- Capacity CalculatioДокумент8 страницCapacity CalculationikdbstttОценок пока нет

- Delftship Tutorial - Using Background ImagesДокумент14 страницDelftship Tutorial - Using Background ImagesBSD141Оценок пока нет

- DELFTship TutorialДокумент2 страницыDELFTship TutorialnikdbstttОценок пока нет

- Hydrostatics MaxxДокумент1 страницаHydrostatics MaxxnikdbstttОценок пока нет

- AutoCAD Tutorial 002 PDFДокумент54 страницыAutoCAD Tutorial 002 PDFskannanmecОценок пока нет

- Preliminary Ship DesignДокумент44 страницыPreliminary Ship DesignSijish93% (27)

- Marine Material PaperДокумент3 страницыMarine Material PapernikdbstttОценок пока нет

- Project Work On Air Cushion VehicleДокумент3 страницыProject Work On Air Cushion VehiclenikdbstttОценок пока нет

- Hps Ship's DataДокумент4 страницыHps Ship's DatanikdbstttОценок пока нет

- Maxsurf Cheat SheetДокумент4 страницыMaxsurf Cheat SheetnikdbstttОценок пока нет

- Preliminary Ship DesignДокумент44 страницыPreliminary Ship DesignSijish93% (27)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Diesel Generator Crank Shaft Balance Weight Mounting Bolt BreakageДокумент2 страницыDiesel Generator Crank Shaft Balance Weight Mounting Bolt BreakageRani NoumanОценок пока нет

- Dwnload Full Engineering Mechanics Dynamics 13th Edition Hibbeler Solutions Manual PDFДокумент35 страницDwnload Full Engineering Mechanics Dynamics 13th Edition Hibbeler Solutions Manual PDFstrungrowett0m9ze100% (8)

- Q88 PropontisДокумент6 страницQ88 PropontisPadilaОценок пока нет

- MCA Stability BookletДокумент19 страницMCA Stability BookletBharatiyulam0% (1)

- 2 Fresh Water Allowance 2Документ52 страницы2 Fresh Water Allowance 2Secret files0% (1)

- Fender Application Design ManualДокумент86 страницFender Application Design ManualExaucée WONGAОценок пока нет

- ShipTheory Project 2Документ11 страницShipTheory Project 2Barış YükselОценок пока нет

- Buoyancy and StabilityДокумент56 страницBuoyancy and StabilityJuan Sebastian Varela SanabriaОценок пока нет

- Strength of Ships Transverse StrengthДокумент27 страницStrength of Ships Transverse Strengtharjungireesh789Оценок пока нет

- Chikyu SpecificationsДокумент1 страницаChikyu SpecificationstphsbОценок пока нет

- Port Info and Jetty BDM Smi Bahoropi Info. Bayu Shipping 2019Документ3 страницыPort Info and Jetty BDM Smi Bahoropi Info. Bayu Shipping 2019Agus Shofyan Taury IОценок пока нет

- FS14LS StudyДокумент6 страницFS14LS StudyAndréОценок пока нет

- Stability Lecture EngДокумент78 страницStability Lecture EngbranikОценок пока нет

- Who Takes The LeadДокумент6 страницWho Takes The LeadJulien CaponОценок пока нет

- Imo Ship Identification NumberДокумент7 страницImo Ship Identification NumberZin Maung Tun100% (1)

- Afra Laurel - Q88 (Oil) - 23apr2021Документ9 страницAfra Laurel - Q88 (Oil) - 23apr2021vimal sainiОценок пока нет

- Stresses On Ship StructureДокумент72 страницыStresses On Ship Structure187Ranjan Kumar100% (1)

- OCIMFДокумент36 страницOCIMFgeorgeОценок пока нет

- HVPQ5 v1 1 09Документ90 страницHVPQ5 v1 1 09Pavel ViktorОценок пока нет

- Eg01plan PDFДокумент24 страницыEg01plan PDFnaval consulОценок пока нет

- Emma Mærsk: Worlds Largest Container CarrierДокумент14 страницEmma Mærsk: Worlds Largest Container CarrierOleksiyОценок пока нет

- 2 - A General Description of A PortДокумент4 страницы2 - A General Description of A PortZuri MpowerОценок пока нет

- SEAMANSHIP (1 and 2)Документ11 страницSEAMANSHIP (1 and 2)Maria Kris Joaquin Capati100% (1)

- List of Registered Ships 13 November 2023Документ300 страницList of Registered Ships 13 November 2023arl06130905Оценок пока нет

- Bavaria 31 Cruiser: BootszubehörДокумент2 страницыBavaria 31 Cruiser: Bootszubehöruwestange61Оценок пока нет

- Stresses in Ship's Structure & Effect of LoadsДокумент6 страницStresses in Ship's Structure & Effect of LoadsGaurav ShresthОценок пока нет

- Ship Repair Services Logistic ServicesДокумент12 страницShip Repair Services Logistic ServicesVidyaОценок пока нет

- Grain Code Stability CriteriaДокумент9 страницGrain Code Stability Criteriashubham purohit100% (1)

- A.Nazarov - Small Patrol Boats - SelfRightingДокумент9 страницA.Nazarov - Small Patrol Boats - SelfRightingVladОценок пока нет

- 15 12 Calculating KB BM and Metacentric DiagramsДокумент8 страниц15 12 Calculating KB BM and Metacentric DiagramsPatrick ArancesОценок пока нет