Академический Документы

Профессиональный Документы

Культура Документы

Mech 009

Загружено:

hasan_6764896160 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров2 страницыBBAE Method Statement is applicable to Welding of MS Pipe and Fittings. The srfaces to be welded shall be smooth, niform and free from laminations, tears, scale, slag, grease paint and other deleterios materials that might adversely affect the welding. The alignment of abtting ends shall minimi!e any offset. Cased by dimensional variations and will e!ally distri!e arond the circmference of the pipe any

Исходное описание:

Оригинальное название

Mech-009

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBBAE Method Statement is applicable to Welding of MS Pipe and Fittings. The srfaces to be welded shall be smooth, niform and free from laminations, tears, scale, slag, grease paint and other deleterios materials that might adversely affect the welding. The alignment of abtting ends shall minimi!e any offset. Cased by dimensional variations and will e!ally distri!e arond the circmference of the pipe any

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров2 страницыMech 009

Загружено:

hasan_676489616BBAE Method Statement is applicable to Welding of MS Pipe and Fittings. The srfaces to be welded shall be smooth, niform and free from laminations, tears, scale, slag, grease paint and other deleterios materials that might adversely affect the welding. The alignment of abtting ends shall minimi!e any offset. Cased by dimensional variations and will e!ally distri!e arond the circmference of the pipe any

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Project: Development of Palm Deira Client: NAKHEEL

Main Contractor: ZSML MEP Contractor: BBAE

METHOD STATEMENT O !ELD"N# P$OCED%$ES

Welding Procedure of CHW Pipelines

&'( SCOPE O !O$K

The Method Statement is applicable to Welding of MS Pipe & Fittings.

)'( $ESPONS"B"L"T*

Before commencement of any installation activity, the following procedres are re!ired to be carried ot.

".# $ll materials sed mst have an approved material sbmittal.

"." $ll wor%s shall be installed as per approved constrction drawings.

".& $ll wor%s shall be installed in a neat and tidy fashion.

+'( DESC$"PT"ON O !O$K

+'& Preparation !or, -. BBAE

# Measre length of pipe re!ired de allowance for any pipefittings to be sed. 't pipes to

measred length. (nsring that the ends are ct s!are.

" Prepare the end of pipe to be welded to the right angle of level and the si)e of the root face in

accordance with the procedre specification. The srfaces to be welded shall be smooth, niform

and free from laminations, tears, scale, slag, grease paint and other deleterios materials that might

adversely affect the welding. Power Tools of *and Tools will be sed for cleaning, grinding or

both.

& The prepared ends to be welded, pipe+to+pipe or pipe to fitting shall be aligned as accrately as is

practical and ensring that the spacing between the abtting ends is in accordance with the

procedre specification sed. The alignment of abtting ends shall minimi)e any offset between

the srfaces cased by dimensional variations and will e!ally distribte arond the circmference

of the pipe any sch offset. *ammering of the pipe to obtain proper line will be %ept to a

minimm.

, The two prepared end shall be tac% welded together in for positions at ninety degree. $fter

tac%ing, the alignment shall be chec%ed to confirm the integrity of the alignment has been

preserved. -ring the welding process the tac%s shall be removed by grinding.

. The welding process will commence, ensring that the correct filler metal, electrical crrent,

polarity, voltage, crrent and nmber of passes is in accordance with welding procedre. $ll slag

or foreign matter shall be removed from each pass of welding, inclding the repair of any visible

defects, sch as crac%s, cavities, etc., prior to commencing the scceeding passes. The removal of

any sch imprities will be by electrical grinder.

/ 0n completion of welding process the welders designated identification mar% will be placed

ad1acent to the weld.

2 The weld shall be visally inspected to chec% for inade!ate penetration e3cessive nderctting,

brn throgh, and to ensre the weld is free from crac%s.

4 5oints to be welded to $STM $"&, and *6$' code of practice T78. inclding of carbon steel pipe

wor%.

9 $ll welds to be wire brshed and painted with 7ed 03ide Paint when welds are completed.

/'( LABO%$0 PLANT 1 MATE$"AL $E2%"$EMENTS

,.# The material shall be of approved Manfactrer as per the material sbmittal.

,." S%illed technicians, in sfficient nmbers, shall carry ot the installation.

,.& The wor%manship shall be maintained at all times.

3'( HEALTH AND SAET* $E2%"$EMENT

/.# (nsre wor% area is clear and tidy.

/." (nsre the wor% $rea is well ventilated.

/.& (nsre area is %ept clear while lifting is in progress.

/., 'hec% all lifting e!ipment for visal signs of damage.

/.. 'hec% electric drill and e3tension leads for visal signs of damage.

/./ Safety e!ipment :e3ample *ard hats, Safety shoes, 'overalls, ;loves, ;oggles when necessary etc.< to be

worn at all times.

4'( $EE$ENCE DOC%MENTS

5'& Dra6in78

#< Bloc%+$ ;#, ", & Floors, Bloc%+B and ' ;rond Floor #, " and &

"< 'hilled Water 7iser Schematic

5') Cali-ration Certificate8

#< Welders =alification 'ertificate.

5'( E2%"PMENT $E2%"$ED

2.# Metal $rc welding Machine.

2." (lectric $ngle ;rinder.

Prepare9 -.: K' Lin7anna $evie6e9 -.: Caner Tona, Approve9 -.: Caner Tona,

Si7nat:re: Si7nat:re: Si7nat:re:

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Method of Statement Piping Fab. ErectionДокумент22 страницыMethod of Statement Piping Fab. Erectionhasan_676489616Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- LNG Tank Dismantling MS RevCДокумент14 страницLNG Tank Dismantling MS RevChasan_676489616100% (1)

- Cross Cut TestДокумент1 страницаCross Cut Testhasan_676489616Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Delayed PWHTДокумент4 страницыDelayed PWHThasan_676489616Оценок пока нет

- Acid PipingДокумент1 страницаAcid Pipinghasan_676489616Оценок пока нет

- ITP For Piping WorksДокумент91 страницаITP For Piping Workshasan_676489616100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

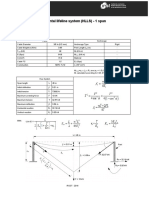

- Horizontal Life Line CalculationДокумент1 страницаHorizontal Life Line Calculationhasan_676489616100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

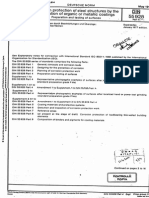

- E SN883Документ2 страницыE SN883hasan_676489616100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- E SN834Документ3 страницыE SN834hasan_676489616Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Steel Grades ComparisonДокумент14 страницSteel Grades Comparisonhasan_676489616Оценок пока нет

- Weld-On Pipe Coupling SN 789: Type ASДокумент1 страницаWeld-On Pipe Coupling SN 789: Type AShasan_676489616Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- ITP For Piping WorksДокумент91 страницаITP For Piping Workshasan_676489616100% (1)

- OSHA - 29CFR - Construction StandardsДокумент22 страницыOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Din 55928Документ16 страницDin 55928hasan_676489616Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- ASME B16.47 Series B FlangeДокумент4 страницыASME B16.47 Series B Flange41h189Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Din 17221Документ9 страницDin 17221hasan_676489616100% (1)

- Din 30678Документ6 страницDin 30678hasan_676489616Оценок пока нет

- Din 2614Документ11 страницDin 2614hasan_676489616Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Din en Iso 4014Документ16 страницDin en Iso 4014hasan_676489616100% (7)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- E SN752Документ3 страницыE SN752hasan_676489616Оценок пока нет

- E SN759Документ2 страницыE SN759hasan_676489616Оценок пока нет

- Din 17240Документ24 страницыDin 17240hasan_676489616100% (1)

- DIN2391 1EN10305 1 - 2003 02 - eДокумент27 страницDIN2391 1EN10305 1 - 2003 02 - ehasan_676489616Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- E SN753Документ2 страницыE SN753hasan_676489616Оценок пока нет

- Din 17155Документ16 страницDin 17155hasan_676489616Оценок пока нет

- Material Price ListДокумент43 страницыMaterial Price ListSathish RagavanОценок пока нет

- Biosorption of Heavy Metals: Department of Biotechnology and Environmental SciencesДокумент25 страницBiosorption of Heavy Metals: Department of Biotechnology and Environmental SciencesYen BumОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Mechanical Properties of MaterialsДокумент24 страницыMechanical Properties of MaterialsMohannad sehwailОценок пока нет

- Chapter 2 Feasibility Study and Literature SurveyДокумент9 страницChapter 2 Feasibility Study and Literature SurveyAq AidilОценок пока нет

- Project Report On Wire RodДокумент9 страницProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- Iso 13734 2013 (E)Документ18 страницIso 13734 2013 (E)Freddy Santiago Cabarcas LandinezОценок пока нет

- 科莱恩塑料颜料宝旭化工Документ12 страниц科莱恩塑料颜料宝旭化工Ashesh ShahОценок пока нет

- Experimental - Investigation - of - Crude Oil DesaltingДокумент19 страницExperimental - Investigation - of - Crude Oil DesaltingElbahi DjaalabОценок пока нет

- Heating Catalogue 2019Документ44 страницыHeating Catalogue 2019Zoran SimanicОценок пока нет

- Casing and Cementing HardwareДокумент4 страницыCasing and Cementing Hardwarezapspaz100% (1)

- Sodium Chloride - CrystallizationДокумент8 страницSodium Chloride - CrystallizationVatra ReksaОценок пока нет

- Hempadur 15130Документ2 страницыHempadur 15130MuthuKumarОценок пока нет

- Xliil-On J. Brown. My: An Acetic Ferment Which Form CelluloseДокумент8 страницXliil-On J. Brown. My: An Acetic Ferment Which Form CelluloseFiqa SuccessОценок пока нет

- An Improved Isolation of Trimyristin From Myristica Fragrans As A Renewable Feedstock With The Assistance of Novel Cationic Gemini SurfactantДокумент16 страницAn Improved Isolation of Trimyristin From Myristica Fragrans As A Renewable Feedstock With The Assistance of Novel Cationic Gemini SurfactantNabila PutriОценок пока нет

- Rsia Artha Mahinrus: Jl. Pasar 3 No. 151 - Terusan Tuasan, 20237Документ15 страницRsia Artha Mahinrus: Jl. Pasar 3 No. 151 - Terusan Tuasan, 20237Rabyatul Maulida NasutionОценок пока нет

- Bs 16105Документ14 страницBs 16105Mohammad MiyanОценок пока нет

- FastenersДокумент178 страницFastenersthulasi_krishna100% (6)

- Sources of Drugs 2015Документ33 страницыSources of Drugs 2015Rafael Paulino RimoldiОценок пока нет

- Sist Iso 293 1996Документ8 страницSist Iso 293 1996rtplemat lemat100% (1)

- Casting DefectsДокумент24 страницыCasting DefectsMohamedSabryОценок пока нет

- Kandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyДокумент8 страницKandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyProf. Prithvi Singh KandhalОценок пока нет

- Protocol Hybridization Capture of Dna Libraries Using Xgen Lockdown Probes and Reagents Version 3Документ16 страницProtocol Hybridization Capture of Dna Libraries Using Xgen Lockdown Probes and Reagents Version 3Rodger12Оценок пока нет

- ACD/Percepta: Overview of The ModulesДокумент91 страницаACD/Percepta: Overview of The ModulesTinto J AlencherryОценок пока нет

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumДокумент1 страницаPlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoОценок пока нет

- Corrosion New Jul20Документ66 страницCorrosion New Jul20hafiz aimanОценок пока нет

- Presentation On Colorants of BeveragesДокумент12 страницPresentation On Colorants of BeveragesNISHANTОценок пока нет

- Drytec Aluminium Range Fine FiltersДокумент4 страницыDrytec Aluminium Range Fine FiltersDragoslav DzolicОценок пока нет

- 3.1 WeatheringДокумент25 страниц3.1 WeatheringSipu GiriОценок пока нет

- Pra Un Ing 2013-Paket 7Документ14 страницPra Un Ing 2013-Paket 7adela_97lineОценок пока нет

- Synthesis of New Kind of Macroporous Polyvinyl-Alcohol Formaldehyde Based Sponges and Its Water Superabsorption PerformanceДокумент11 страницSynthesis of New Kind of Macroporous Polyvinyl-Alcohol Formaldehyde Based Sponges and Its Water Superabsorption PerformanceJohan SukweenadhiОценок пока нет

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsОт EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsРейтинг: 4 из 5 звезд4/5 (16)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresОт EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresРейтинг: 1 из 5 звезд1/5 (2)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (18)