Академический Документы

Профессиональный Документы

Культура Документы

Heater Design Calculation

Загружено:

Muthukumar MuruganАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Heater Design Calculation

Загружено:

Muthukumar MuruganАвторское право:

Доступные форматы

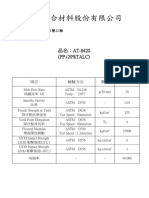

1.

2.

(YES/NO)

(kg/cm2G)

(kg/cm2G)

()

()

(kg/cm2G)

()

()

3.

4.CNS

5.

Insideradius(corroded) R 335.00 mm.

Do 1756.00 mm.

tm 40.000 mm.

Internalpressure P 45.00 kg/cm

2

G

Extermaldesignpressure Px 30.00 kg/cm

2

G

Staticheadpressure Phd 0.00 kg/cm

2

G

Designtemperature tem 110.00

Corrosionallowance CA 0.00 mm.

1 FULL

Jointefficiency E() 1

Shellmaterial

Shelllength L 4500

Max.allowablestress S 692 kg/cm

2

Modulusofelasticity@designtrmperture E 1765268 kg/cm

2

Pdoesnotexceed0.385SEP= 45.0 < 0.385SE= 266.42 Kg/cm

2

#OK#

Tdoesotexceed0.5RT= 40.0 < 0.5R= 167.50 mm. #OK#

CylindershavingDo/tvalues Do/t > Do/t= #FROME1#

Tr1 22.67 mm.

Tr2 22.67 mm.

Tr3 40.00 mm.

NOTE

Circumferential Shell or tube-CNS9789 5.2

43.9

Minimumrequiredthickness,Tt1=(P+Phd)R/(SE-0.6(P+Phd))

Minimumrequiredthickness(min.thickness>1.6mm)

Minimumrequiredthicknessforextemalpressure(assumed)

DESIGNDATA

OutsidediameterSHELLorTUBEofmoninalthickness

AssumeSHELLorTUBEthickness

Radiograpexamination(1=FULL/2=SPOT)

CALCULATION

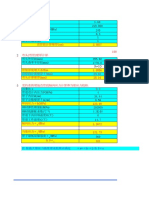

Exteral Shell5:39 AM9/5/2014 2

Ps 6 Kg/cm

2

g

Pt 13.58 Kg/cm

2

g

Temp.-SS

Temp.-TS

No. Description Material St(Kg/cm

2

) St/Sd

1 SA106-B 1202 1

2

3

4

5

6

S

Ph 7.50 Kg/cm

2

g

TEST Kg/cm

2

g

No. Description Material St(Kg/cm

2

) St/Sd

1 TUBESIDE SA312-312 1174 1

2

3

4

5

6

S

Ph 16.98 Kg/cm

2

g

TEST Kg/cm

2

g

NOTE

HYDOSTATICTESTPRESSUREFORSHEELSIDE=1.25PS 1.00

TUBESIDE-CNS978811.6.3(2)

Sd(Kg/cm

2

)

1174

HYDOSTATICTESTPRESSUREFORSHEELSIDE=1.25PS 1.00

St=Max.allowablestressattesttemperature

Sd=Max.allowablestressatdesgintemperature

SHELLSIDE-CNS978811.6.3(2)

Sd(Kg/cm

2

)

1202

Designpressure

SHELLSIDE

TUBESIDE

DesignTemperature

SHELLSIDE

TUBESIDE

PNEUMATIC TEST5:39 AM9/5/2014 3

1.CNS9788KEY

2.

DESIGNPRESSURE 16.8 kg/cm

2

g 10.5 kg/cm

2

g

DESIGNTEMPERATURE 165 280

MAX.OPERATINGPRESSURE 12.4 kg/cm

2

g 3.5 kg/cm

2

g

MAX.OPERATINGTEMPERATURE 135 146

HYDROSTATICTESTPRESSURE 25.2 kg/cm

2

g 15.75 kg/cm

2

g

335 mm. 335 mm.

RADIOGRAPHYEXAMIATION

JOINTEFFICIENCY

CORROSIONALLOWANCE 3 mm. 3 mm.

MIN.DESIGNMETALTEMPERATURE

IMPACTTEST

POSTWELDHEATTREATMENT

INSULATION

FLUID

NUMBEROFPASSES

EMPTYWEIGHT

FULLOFWATERWEIGHT

VOLUME 1.27 M

3

0.56 M

3

HEATINGSURFACE

LETHALDESIGN

Material St(Kg/cm

2

) Sd(Kg/cm

2

) St/Sd

SHELLS SA516-70 1230 1230 1.00

CHANNELS SA516-70 1230 1230 1.00

CAP --

TUBESHEETS SA516-70 1230 1230 1.00

CHANNELFLANGES SA105 1230 1230 1.00

TUBES SA179 1670 1670 1.00

NOZZLEFLANGES(Shellside)

NOZZLENECKS(Shellside)

NOZZLEFLANGES(Tubeside)

NOZZLENECKS(tubeside)

MATERIALSPECIFICATION

kg.

124 m

2

NA

kg.

1.00 1.00

NO

NA

DESIGNDATA

DESIGNCODECNS9788

SHELLSIDE TUBESIDE

INSIDERADIUS(corroded)R

FULL FULL

R 335.00 mm.

Nominalthickness tm 12.00 mm.

Designpressure P 16.80 kg/cm

2

Staticheadpressure Phd 0.00 kg/cm

2

Designtemperature tem 165

Corrosionallowance CA 3.00 mm.

1

Jointefficiency E() 1

Shellmaterial

Max.allowablestress S 1230 Kg/cm

2

Pdoesnotexceed0.385SEP=16.8 < 0.384SE= 473.55 Kg/cm

2

#OK#

Tdoesotexceed0.5RT= 12.0 < 0.5R= 167.50 mm. #OK#

Tr1 4.61 mm.

Tr2 4.61 mm.

Tr 4.61 mm.

Td 7.61 mm.

MAWP 20.72 Kg/cm

2

CONCLUSTION

7.61 mm.

12.00 mm.

Pdoesnotexceed0.665SEP=16.8 < 0.665SE= 817.95 Kg/cm

2

#OK#

Tdoesotexceed0.356RT= 12.0 < 0.356R= 119.26 mm. #OK#

Tr1 2.28 mm.

Tr2 2.28 mm.

Tr 2.28 mm.

Td 5.28 mm.

MAWP 65.74 kg/cm

2

G

CONCLUSTION

5.28 mm.

12.00 mm.

NOTE

#SUFFICIENT#

Minimumrequiredthickness(min.thickness>1.6mm)

Minimumrequiredthickness,Tr=Maxof{Tr1,Tr2}

Designthickness,Td=Tr+CA

MAWP=(tm-CA)2SE/(R+0.2(tm-CA))-Phd

Thedesignshellthicknessof

Selectingthenomialthicknessof

Thedesignshellthicknessof

Selectingthenomialthicknessof

#SUFFICIENT#

SphericalShellsCNS97893.3

Minimumrequiredthickness,Tt1=(P+Phd)R/(2SE+0.4(P+Phd))

CircumferentialShellortubeCNS97893.2

Minimumrequiredthickness,Tt1=(P+Phd)R/(S*E-0.6(P+Phd))

Minimumrequiredthickness(min.thickness>1.6mm)

Minimumrequiredthickness,Tr=Maxof{Tr1,Tr2}

Designthickness,Td=Tr+CA

MAWP=(tm-CA)SE/(R+0.6(tm-CA))-Phd

DESIGN DATA

Inside radius(corroded)

Radiograpexamination(1=FULL/2=SPOT) FULL

SA516-70

CALCULATION

Shell5:39 AM9/5/2014 CNS calculation 5

R 335.00 mm.

Nominalthickness tm 10.44 mm.

Internalpressure P 16.80 Kg/cm

2

G

Staticheadpressure Phd 0.00 Kg/cm

2

G

Designtemperature tem 165.00

Corrosionallowance CA 3.00 mm.

Typeofhead(1=Ellipsidal/2=Torispherical) 1

2

Jointefficiency E() 1

Shellmaterial

Max.allowablestress S 1230 Kg/cm

2

Tr1 2.29 mm.

Tr2 2.29 mm.

Tr 5.29 mm.

15.00 %

8.82 mm.

Finalcenterlineradius Rf 35.00 mm.

Originalcenterlineradius=infinityforflatplate Re infinity mm.

%Extremefiberelongation=(75*tm(1-Rf/Re))/Rf 0.2237143 > 0.05 #OK#

MAWP 45.60 Kg/cm

2

G

CONCLUSTION

Thedesignshellthicknessof 5.29 mm.

Selectingthenomialthicknessof 10.44 mm.

Tr1 4.04 mm.

Tr2 4.04 mm.

Tr 7.04 mm.

15.00 %

7.10 mm.

Finalcenterlineradius Rf 35.00 mm.

Originalcenterlineradius=infinityforflatplate Re infinity mm.

%Extremefiberelongation=(75*tm(1-Rf/Re))/Rf 0.2237143 > 0.05 #OK#

MAWP 30.79 kg/cm

2

G

CONCLUSTION

Designthicknessshallnotexceedthicknessafterformin #SATISFACTORY#

CheckextremefibereiongationforexemptionofheattreatmentafterformingCNS97888.6(7)

MAWP=(tm-CA)2SE/(1.77Di+0.2(tm-CA))-Phd

TorisphericalCNS97894.2

Minimumrequiredthickness,Tt1=1.77(P+Phd)Di/(2SE+0.2(P+Phd))

Minimumrequiredthickness(min.thickness>1.6mm)

Designthickness,Tr=Max.{Tr1,Tr2}+CA

%Reductionafterforming=>Assumetobe

Thicknessafterforming=Tr+CA/(1-%)

Thicknessafterforming=Tr+CA/(1-%)

Designthicknessshallnotexceedthicknessafterformin #SATISFACTORY#

CheckextremefibereiongationforexemptionofheattreatmentafterformingCNS97888.6(7)

MAWP=(tm-CA)2SE/(Di+0.2(tm-CA))-Phd

#SUFFICIENT#

CALCULATION

EllipsoidalHeadCNS97894.3

Minimumrequiredthickness,Tt1=(P+Phd)Di/(2SE-0.2(P+Phd))

Minimumrequiredthickness(min.thickness>1.6mm)

Designthickness,Tr=Max.{Tr1,Tr2}+CA

%Reductionafterforming=>Assumetobe

DESIGN DATA

Insideradius(corroded)

ELLIPSOIDAL HEAD 2:1

Radiograpexamination(1=FULL/2=SPOT) SPOT

Head5:39 AM9/5/2014 CNS calculation 6

Thedesignshellthicknessof 7.04 mm.

Selectingthenomialthicknessof 10.44 mm.

NOTE

#SUFFICIENT#

Head5:39 AM9/5/2014 CNS calculation 7

DESIGNDATA

Shellsideinternalpressure(negatibesignifvacuum) Ps 16.8 kg/cm

2

G

Tubesideinternalpressure(negatibesignifvacuum) Pt 10.5 kg/cm

2

G

ShellsideinternaldesignTem. Temp-S 165

TubesideinternaldesignTem. Temp-T 280

Shelloutsidediameter Ds(Do) 694 mm.

Shellthickness Ts(ts) 12 mm.

Shellinsidediameter(corrodedcodition) Di(G) 670 mm.

Insidecorrosionallowanceofshell Cas 3 mm.

Tubeoutsidediameter Dt 19.05 mm.

Tubethickness Tt 2.11 mm.

Tubepitch Pit 25.4 mm.

Tubelength L 4800 mm.

Numberoftube N 207

Tubepatter(2=Square/1=Triangular) 2

Outsidediameterofthetubesheet A 830 mm.

Corrosionallowanceoftubesheet Cats 3 mm.

Nominalthicknessoftubesheet h 80 mm.

Assumetubesheetthickness Tass 58 mm.

MATERIALSPECIFICATION

TUBESHEETMaterial

Max.allowablestressatdesignmetaltemperature Sts 1670 kg/cm

2

Elasticmodulusoftubesheetatmetaltemperature E 2070000 kg/cm

2

SHELLMaterial

Elasticmodulusofshellatmeanmetaltemperature Es 2070000 kg/cm

2

TUBEMaterial

Elasticmodulusoftubeatmeanmetaltemperature Et 2070000 kg/cm

2

CALCULATION

K=EsTs(Ds-Ts)/(EtTtN(Dt-Tt)) K 1.106

Fq=0.25+(F-0.6)(300TsEs/(KLE)(Di/Tass)

3

)

0.25

Fq(Fg) 2.524

F=(17-100(TsDi))/15(Max1-Min8) F 1.000

J=1forshellwithoutexpansionjoint J 1

s=coefficientofthermalexpansionoftheshell s 6.513E-06 (1/)

t=coefficientofthermalexpansionofthetubes t 6.698E-06 (1/)

Tm=shellmeanmetaltemperature Tm 165

tm=tubemeanmetaltemperature tm 280

Differentialmetalgrowth,dL=L(tes(Tm-70)-tet(tm-70)) dl -3.782 mm

Pd=4JEsTs(dl/Lt)/((Ds-3Ts)(1+JKFq) Pd(Pe) -31.90 kg/cm

2

Mo=Totalmomentactingunderoperatingconditions Mo 20961804.7 kg-mm

Mg=Totalmometactingunderbolting-upconditions Mg 10169837.3 kg-mm

Pbt=620Mo/(F

2

Di

3

) Pbt 43.21 kg/cm

2

Pbs=620Mg/(F

2

Di

3

) Pbs 20.96 kg/cm

2

SA516-70

SA516-70

SA179

1.FACTOR

2.EQUIVALENTDIFFERENTIALEXPANSIONPRESSURECNS9792-5.5(1)

3.EQUIVALENTBOLTINGPRESSURECNS9792-5.5(2)

Tubesheet5:39 AM9/5/2014 CNS calculation 8

fs=1-N(Dt/Di)2 fs 0.8327

Ps'=Ps(0.4J(1.5+K(1.5+fs/(1+KFq))) Ps' 8.23 kg/cm

2

1.1P=(Ps'-Pd)/2 20.07 kg/cm

2

1.2P=Ps' 8.23 kg/cm

2

1.3P=Pbs 20.96 kg/cm

2

1.4P=(Ps'-Pd-Pbs)/2 9.58 kg/cm

2

1.5P=(Pbs+Pd)/2 -5.47 kg/cm

2

1.6P=(Ps'-Pbs) -12.73 kg/cm

2

ft=1-N((Dt-2Tt)/Di)

2

ft 0.8985848

Pt'=Pt(1+0.4JK(1.5+ft)/(1+JKFq) Pt' 4.75 kg/cm

2

2.1P=(Pt'+Pbt+Pd)/2 8.02911888 kg/cm

2

2.2P=Pt'+Pbt 47.96 kg/cm

2

3.1P=Pt'-Ps'+Pbt 39.73 kg/cm

2

3.2P=(Pt'-Ps'+Pbt+Pd)/2 3.91411888 kg/cm

2

3.3P=Pbs 20.96 kg/cm

2

3.4P=(Pbs+Pd)/2 -5.46929027 kg/cm

2

3.5P=Pt'-Ps' -3.48 kg/cm

2

3.6P=(Pt'-Ps'+Pd)/2 -17.6914625 kg/cm

2

3.7P=Pbt 43.21 kg/cm

2

ThegreatestabsolutevalueofMax.P{1.1-3.7} P 47.96 kg/cm

2

=1-0.907/(Pit/Dt)

2

or1-0.785/(Pit/Dt)

2

0.5584375

Tcal=FDi/3(P/(nSts))

0.5

Tcal(t1) 50.647 mm

Effectivedesignpressureforshearformular Ph ? kg/cm

2

Ph/Sts

1.6(1-Dt/Pit)

2

CheckifPh/Sts<1.6(1-Dt/Pit)

2

shearwillnotcontrol

t2 mm

min.thicknessoftheextendedportion;Tr

r=A/Di r 1.23880597

M=freaterofMoandMg M 20961804.7 kg-mm

Tr=0.98{M(r

2

-1+3.71r

2

lnr)/(Sts(A-Di)(1+1.86r

2

))}

0.5

Tr 58.607 mm

Tmin=max{Tcal(t1),(t2),Tr(tr)}+2Cats Tmin 64.607 mm

COCLUSION

Theminimumdesignthicknessis 64.6 mm

Tthereforeselectingnominalthicknessof 80.0 mm

NOTE

#SATISFACTORY#

4.EFFECTIVESHELLSIDEDESIGNPRESSURECNS9792-5.5(3)

5.EFFECTIVETUBESIDEDESIGNPRESSURECNS9792-5.5(4)

6.EFFECTIVEDIFFERENTIALDESIGNPRESSURECNS97921-3.2

7.TUBESHEETBENDINGFORMULARCNS9792-5.2

8.TUBESHEETSHEARFORMIULARCNS9792-5.2

9.TUBESHEETFORMULAR-TUBESHEETFLANGEEXTENSIONCNS9792-5.3

Tubesheet5:39 AM9/5/2014 CNS calculation 9

E-730

Outsidediameterofflange A 3217 mm

Insidediameterofflange(corroded) B 3000 mm

Bolt-circlediamter C 3176 mm

Numberofbolt n 128 set

Sizeofbolt Db 19.05 mm

Crosssectionareaperabolt Ar 195.00 mm

2

Outsidediameterofgasket do 3142 mm

Widthofgasketusedtodeterminethebasicgasketseating N 12.5 mm

Thicknessofgasket Tg 4 mm

Thicknessofhubatsmallend go 16 mm

Thicknessofhubatbackofflange g1 48 mm

Tublength h 98 mm

Corrosionallowance CA 3 mm

Intermaldesignpressure P 4.2 Kg/cm

2

G

Flangethickness t 121 mm

Max.allowablestressatdesigntemprtature Sfb 1406 Kg/cm

2

Max.allowablestressatatmtemprtature Sfa 1406 Kg/cm

2

Gasketorjointcontact-surfaceunitseatingload y 7.1 Kg/cm

2

Gasketfactor m 4.25

Allowableboltstressatdesigntemperature Sb 1757 Kg/cm

2

Allowableboltstressatatmtemperature Sa 1757 Kg/cm

2

K 1.072

FactorinvolvigK T 1.887

U 30.363

Y 27.630

Z 14.342

Factorho=(Bgo)

0.5

ho 219.089 mm

g1/go= 3.000

h/ho= 0.447

V 0.146

F 0.810

f 3.940

Factord,d=(u/v)hogo

2

d 11663983.8 mm

3

Factore,e=F/ho e 0.004 1/mm

FactorL,L=(te+1)/T+t

3

/d L 0.919

Basicgasketseatingwidth,bo=N/2 bo 6.25 mm

b 6.30 mm

? 6.25

Diameteratlocationofgasketloadreaction G 3129.50 mm

W

m1

345012.87 Kg

Factorforintergraltypeflages,F5

Hubstresscorrosionfactorintegraltypeflanges,f4

2.BOLTLOADS(CNS9791-3.3)--

Effectivegasketorjointcontactsurfaaceseatingwidth

b=0.5(bo)

0.5

forbo>6.35mm(0.25in)orb=boforbo<=6.35mm

Minrequiredboltloadfortheoperatingconditions

BOLT: SA193-B7

CALCULATION

1.FACTOR

Ratioofoutsidediameterofalangetoinsidediameterofflange,K=A/B

Factorforintergraltypeflages,V8

DESIGNDATA

MATERIALSPECIFICATION

FLANGE: SA266-4

Gasket: GRAPHITE

Bolted flange5:39 AM9/5/2014 10

W

m1

=0.785G

2

P+2b3.14159mP

W

m2

436277.51 Kg

W

m2

=3.14159bGy

Fortheoperatingconditions..

Totalhydrostaticendforce,H=0.785G2P H 322900.61 Kg

Hydrostaticendforceonareainsideofflange,HD=0.785B

2

P HD 296877.42 Kg

HT=H-HD HT 26023.19 Kg

GasketloadHG=Wm1-H HG 22112.26 Kg

R=(C-B)/2-g1 R 40.000 mm

Hd 64.000 mm

Ht 55.625 mm

Hg 23.250 mm

MD 19000154.88 kg-mm

MG 514110.16 kg-mm

MT 1447539.67 kg-mm

TotalflangemomentfortheoperatingconditionsMo=MD+MG+MT Mo 20961805 kg-mm

Am1 19636.5 mm

2

Am2 24830.8 mm

2

Am 24830.8 mm

2

Ab 24960.0 mm

2

W

g

437412.4 kg

M

g

10169837.3 kg-mm

Longitudinalhubstress,SH=fMo/(Lg1

2

B) SH1 1300.330 Kg/cm

2

Longitudinalhubstress,SH=fMg/(Lg1

2

B) SH2 630.869 Kg/cm

2

Radialflangestress,SR=(1.33te+1)Mo/(Lt

2

B) SR1 82.837 Kg/cm

2

Radialflangestress,SR=(1.33te+1)Mg/(Lt

2

B) SR2 40.189 Kg/cm

2

ST1 (1187.943) Kg/cm

2

ST2 (548.335) Kg/cm

2

SHismotgreaterthen1.5*Sf SH= 1300.330 < 1.5*Sf= 2635.5 Kg/cm

2

SRisnotgreaterthenSf SR= 82.837 < Sf= 1757 Kg/cm

2

STisnotgreaterthenSf ST= (548.335) < Sf= 1757 Kg/cm

2

(SH+SR)/2isnotgreaterthenSf = 691.584 < Sf= 1757 Kg/cm

2

(SH+ST)/2isnotgreaterthenSf = 375.997 < Sf= 1757 Kg/cm

2

t1 81.62 mm

t2 117.18 mm

Tm 120.18 mm

120 mm.

121 mm.

NOTE

Therequiredforthenotopertingconditionst1

Therequiredfortheopertingconditionst2

Designthicknessofflange,Tm=Mix.{t1,t2}+CA

Thedesignthicknessofflangeis

Thereforethenorminalthicknessusedof #SUFFICIENT#

4.CALCULATIONOFFLAGESTRESSES(CNS9791-3.5)

Tangentialflangestress,ST=YMo/(t

2

B)-ZSR1

Tangentialflangestress,ST=YMg/(t

2

B)-ZSR2

5.CHECKEDCODITIONS(CNS9791-3.6)

#ALLCONDITIONSARESATISFACTORY#

6.MIX.USEDTHICKNEESOFFLANGE

Totalcross-sectionalareaofboltsatrootofthreadrequiredfortheopertingconditions

Totalcross-sectionalareaofboltsatrootofthreadrequiredforgasterseating

Totalrequiredcross-sectionalareaofbolts,takenasthegreaterofAm1andAm2

Cross-sectionareaoftheboltsusingtherootdiameterofthethread

Flangdesignboltload,W

g

=(Am+Ab)Sa/2

Totalflangemomentforgasketseating,M

g

=W

g

(C-G)/2

RadialdistancefromtheboltcircletothecircleonwhichHTacts=(R+g1+hG)/2

RadialdistancefromgasketloadreactiontotheboltcirclehG=(C-G)/2

ComponentofmomentduetoHD,MD=HDHd

ComponentofmomentduetoHG,MG=HGHg

ComponentofmomentduetoHT,MT=HTHt

3.2Forgasketseating

Minrequiredboltloadforgasketseating

3.FLANGEMOMENT(CNS9791-3.4)

Differencebetweentotalhydrostaticendforceandthehydrostaticendforce

3.1Forintergralflange

RadialdistancefromBCDtopointofintersectionofhubandhubflange

RadialdistancefromtheboltcircletothecircleonwhichHDacts=R+0.5g1

Bolted flange5:39 AM9/5/2014 11

ITEM N1

Nominalpipesize 2"SCH10 NPS

Outsidediameter Do 60.3 mm.

Thicknessofnozzle Tn 5.54 mm.

ThicknessofSTDwallpipe T(STD) 3.91 mm.

Corrosionallwannceofnozzle Can 3 mm.

Materialofnozzle SA106-B

Max.allowablestressofnozzle Sn 1202 kg/cm

2

g

Jointefficiencyofnozzle En 1

Internaldesignpressure P 6 kg/cm

2

g

Desingtemperature degree 70

Locationtobeattached Shell -

Outsidediameterofvessel 219.1 mm.

Nominalthicknessofvessel 6.35 mm.

Corrosionallwannceofvessel Cas 3 mm.

Max.allowablestressofvessel Sv 1202 kg/cm

2

g

Jointefficiencyofvessel Es 1

RequiredthicknessofnozzleTrn=PR/(SE-0.6P) Trn 0.12 mm.

Tr1=Trn+Can Tr1 3.12 mm.

Requiredthicknessofseamlessshellorhead Tr 0.52 mm.

Tr2=Tr+Cas Tr2 3.52 mm.

Min.thicknessaccordingtoCNS97886.1.5+Cas Tr3 4.60 mm.

ThegreaterofMin.{Tr2,Tr3} Tr4 4.60 mm.

Min.thicknessofSTD.wallpipeTm1=T(STD)0.875 Tm1 3.42 mm.

Tr5=Tm1+Can Tr5 6.42 mm.

ThelesserofTr4orTr5 Tr6 4.60 mm.

ThegreaterofMin.{Tr1,Tr6} Trq 4.60 mm.

Tn'=Tn0.875 Tn' 4.85 mm.

DESIGNDATA

NOZZLE

CALCULATION

NozzleNeckThicknessCNS97886.9.2

IfTn'>Trq,Thenozzleneckthicknessis"adequate" #ADEQUATE#

12

ITEM N2

Outsidediameter Dn 320.1 mm.

Thicknessofnozzle tn 60.2 mm.

Corrosionallwannceofnozzle Can 0 mm.

Materialofnozzle

Max.allowablestressofnozzle Sn 1103 kg/cm

2

g

Jointefficiencyofnozzle En 1

Internaldesignpressure P 45 kg/cm

2

g

Materialofvessel

Outsidediameterofvessel Ds 755.5 mm.

Nominalthicknessofvessel t 39.75 mm.

Corrosionallwannceofvessel Cas 3 mm.

Max.allowablestressofvessel Sv 1103 kg/cm

2

g

Jointefficiencyofvessel Es 1

Thicknessrequiredofshell,Tr=PR/(SvEn-0.6P) Tr 14.14 mm.

Thicknessrequiredofnozzle,Trn=PR/(SnEs-0.6P) Trn 4.18 mm.

TotalareaofreinforcementrequiredA=dTrF+2TnTrF(1-fr1) A 4524.83 mm

2

A11=d(Est-ftr)-2tn(Est-ftr)(1-fr1) A11 8199.14 mm

2

A12=2(t+tn)(Est-Ftr)-2tn(Est-Ftr)(1-fr1) A12 5120.30 mm

2

A1=Max.{A11,A12} A1 8199.14 mm

2

A21=5(tn-trn)fr2t A21 11134.79 mm

2

A22=5(tn-trn)fr2tn A22 16863.26 mm

2

A2=Min.{A21,A23} A2 11134.79 mm

2

A5=(Dp-d-2tn)tefr3 A5 0.00 mm

2

IfA'=A1+A2+A3+A41+A43+A5>A,Openingisadequately A' 19333.93 mm

2

A'>A

(5)Cross-sectionalareaofvariousweldsavailableasreinforcement

#ADEQUATELY#

DESIGNDATA

FACTOR

CALCULATION

ReinforementrequiredforopeningsinshellCNS97903.1

(1).Areainexcessthicknessinthevesselwallavailableforreinforcement

(2).Areainexcessthicknessinthenozzlewallavailableforreinforcement

CNS calculation 13

Ps 16.8 Kg/cm

2

g

Pt 10.5 Kg/cm

2

g

Temp.-SS

Temp.-TS

SHELL

TUBESHEEL

TUBE

FLANGE

NOZZLE

STUDBOLT

CHANNEL

PIPE

No. Description Material St(Kg/cm

2

) St/Sd

1 SA516-70 1230 1

2

3

4

5

6

S

Ph 25.20 Kg/cm

2

g

TEST Kg/cm

2

g

NOTE

HYDOSTATICTESTPRESSUREFORSHEELSIDE=1.5PS 1.00

St=Max.allowablestressattesttemperature

Sd=Max.allowablestressatdesgintemperature

SHELLSIDE-CNS978811.6.2(2)

Sd(Kg/cm

2

)

1230

Designpressure

SHELLSIDE

TUBESIDE

DesignTemperature

SHELLSIDE

TUBESIDE

HYDOSTATIC TEST5:39 AM9/5/2014 14

Вам также может понравиться

- 电线电缆设计、研发、分析改善计算公式大全Документ128 страниц电线电缆设计、研发、分析改善计算公式大全Tien Dung PhanОценок пока нет

- Tonycalcelate EnglishДокумент17 страницTonycalcelate Englishevrim77Оценок пока нет

- NB/T 47021-2012 甲型平焊法兰Документ11 страницNB/T 47021-2012 甲型平焊法兰huangjlОценок пока нет

- NB/T 47023-2012 长颈对焊法兰Документ21 страницаNB/T 47023-2012 长颈对焊法兰huangjlОценок пока нет

- T 901210 CNДокумент8 страницT 901210 CNbehnamdaftary2Оценок пока нет

- B38H CopperДокумент28 страницB38H Coppergago tvОценок пока нет

- Silicone Shrink TubeДокумент7 страницSilicone Shrink TubeLee VinceОценок пока нет

- 1第一章基礎知識Документ25 страниц1第一章基礎知識Joshua ShihОценок пока нет

- 施工架計算書 中部以北附錄一R1Документ19 страниц施工架計算書 中部以北附錄一R1Yang Wu100% (2)

- Datasheet - Laminado Kingboard FR4Документ2 страницыDatasheet - Laminado Kingboard FR4christopher_garОценок пока нет

- D7745 CNДокумент6 страницD7745 CNli geneОценок пока нет

- Pra01 5Документ34 страницыPra01 5ronaldsiu2012Оценок пока нет

- 1000 20000W激光切割机配套空压机技术参数选型参考Документ14 страниц1000 20000W激光切割机配套空压机技术参数选型参考HasanОценок пока нет

- 燃气管道设计计算书Документ10 страниц燃气管道设计计算书laurenjiaОценок пока нет

- JB4712 2007支座 (除鞍座外) 校核Документ19 страницJB4712 2007支座 (除鞍座外) 校核fanfeiОценок пока нет

- 固体火箭发动机设计Документ32 страницы固体火箭发动机设计hycОценок пока нет

- QD91H V4Документ2 страницыQD91H V4daniel180778Оценок пока нет

- 液压系统计算公式汇总Документ29 страниц液压系统计算公式汇总Seal GzyyОценок пока нет

- 贝壳7寸注水封隔器 zh (牛哥版)Документ13 страниц贝壳7寸注水封隔器 zh (牛哥版)高守Оценок пока нет

- 反應器超音波TOFD檢測簡報 台塑Документ51 страница反應器超音波TOFD檢測簡報 台塑yhwu01Оценок пока нет

- QUICK856AD 使用说明Документ16 страницQUICK856AD 使用说明ouyangxin1991Оценок пока нет

- IRVX04支撐結構 S29 3 核定0版Документ24 страницыIRVX04支撐結構 S29 3 核定0版api-3801400100% (1)

- GBT 4323-2017 弹性套柱销联轴器Kopling Pin Lengan ElastisДокумент13 страницGBT 4323-2017 弹性套柱销联轴器Kopling Pin Lengan ElastisIsmail AdhaОценок пока нет

- Ct Dr成像业务知识Документ72 страницыCt Dr成像业务知识lhp393241163Оценок пока нет

- 输气管道课设参考Документ14 страниц输气管道课设参考jiv24Оценок пока нет

- 附錄b 結構計算書 s0 12 s0 13施工架防墜Документ15 страниц附錄b 結構計算書 s0 12 s0 13施工架防墜陳俊佐Оценок пока нет

- 硬度報告Документ9 страниц硬度報告臧君翰Оценок пока нет

- 镍基合金简介Документ39 страниц镍基合金简介krenОценок пока нет

- 第七章Документ82 страницы第七章邱創森Оценок пока нет

- At-8420Документ1 страницаAt-8420廖健翔Оценок пока нет

- 台北市內湖區石潭段P055新建工程補強方案Документ20 страниц台北市內湖區石潭段P055新建工程補強方案Zach ChenОценок пока нет

- CTSO-2C706 航空抗燃磷酸酯液压油Документ10 страницCTSO-2C706 航空抗燃磷酸酯液压油shan DОценок пока нет

- 钢管结构计算1 2Документ10 страниц钢管结构计算1 2Hanson LiuОценок пока нет

- SBIL测井操作手册Документ27 страницSBIL测井操作手册majid aziziОценок пока нет

- 100年土木技師結構設計Документ5 страниц100年土木技師結構設計Eric ChienОценок пока нет

- Abs Ag15a1 SpecДокумент2 страницыAbs Ag15a1 SpecĐỗ Thành NhươngОценок пока нет

- GB50341储罐设计计算Документ31 страницаGB50341储罐设计计算wdyouQОценок пока нет

- 機械工程實驗 (二) 實驗二Документ6 страниц機械工程實驗 (二) 實驗二Jia Ming ThamОценок пока нет

- 機械工程實驗 (二) 實驗二Документ6 страниц機械工程實驗 (二) 實驗二Jia Ming ThamОценок пока нет

- Absorber Calc SheetДокумент17 страницAbsorber Calc SheetMuhammad Sheraz GorayaОценок пока нет

- AC-05AS (Cooling Ton: 3RT) : Technical Parameter TableДокумент5 страницAC-05AS (Cooling Ton: 3RT) : Technical Parameter TableMark GardunoОценок пока нет

- 工艺计算Документ25 страниц工艺计算xm861122Оценок пока нет

- 管线及储罐散热量计算Документ9 страниц管线及储罐散热量计算wdyouQОценок пока нет

- 管线及储罐散热量计算Документ9 страниц管线及储罐散热量计算wdyouQОценок пока нет

- Kuka Cables Data Sheet PV Cable 6mm2Документ1 страницаKuka Cables Data Sheet PV Cable 6mm2Solar ProjectsОценок пока нет

- A10VSO力士乐泵Документ40 страницA10VSO力士乐泵back1949Оценок пока нет

- EPIДокумент4 страницыEPIitsoeasywaiОценок пока нет

- 限流孔板计算书Документ5 страниц限流孔板计算书wdyouQОценок пока нет

- KOYO TRDДокумент31 страницаKOYO TRDcq_Оценок пока нет

- Ultra Coolant冷却剂参数Документ2 страницыUltra Coolant冷却剂参数Daneyal BabarОценок пока нет

- 立式热虹吸再沸器HTRI优化设计 PDFДокумент34 страницы立式热虹吸再沸器HTRI优化设计 PDFaaaОценок пока нет

- HD 22.4 S42004 额定电压450750V及以下交联绝缘电缆 第4部分:软线和软电缆或橡套欧洲标准委员会协调文件-H07RN-FДокумент25 страницHD 22.4 S42004 额定电压450750V及以下交联绝缘电缆 第4部分:软线和软电缆或橡套欧洲标准委员会协调文件-H07RN-FMary MaОценок пока нет

- 15-What is Material Selection Diagram Its Purpose Development and Example PDF什么是材料选择图?其目的、发展和示例 PDFДокумент10 страниц15-What is Material Selection Diagram Its Purpose Development and Example PDF什么是材料选择图?其目的、发展和示例 PDFjun dongОценок пока нет

- 安全閥性能測試結果報告表Документ1 страница安全閥性能測試結果報告表左亦藤Оценок пока нет

- Specification of ShrinkДокумент3 страницыSpecification of ShrinkJack WuОценок пока нет

- 中石化LDPE牌号Документ5 страниц中石化LDPE牌号tuonidaishui1Оценок пока нет

- MKP62 EtcДокумент4 страницыMKP62 EtcdiegooliveiraEEОценок пока нет

- 28 DS 468 TM1 CAN SAE J1939 24V Screw Flange - ZHДокумент9 страниц28 DS 468 TM1 CAN SAE J1939 24V Screw Flange - ZHF. Z.Оценок пока нет

- 贝壳7寸注水封隔器 (牛哥普通版)Документ14 страниц贝壳7寸注水封隔器 (牛哥普通版)高守Оценок пока нет

- GB∕T 35013-2018 承压设备合于使用评价Документ135 страницGB∕T 35013-2018 承压设备合于使用评价Tom TaoОценок пока нет

- 15 - Acs 1000 - PM - C1Документ35 страниц15 - Acs 1000 - PM - C1申志鹏Оценок пока нет

- V1000中文手冊 compressedДокумент423 страницыV1000中文手冊 compressed普登科技Оценок пока нет

- 电力电子学 教材wordДокумент340 страниц电力电子学 教材word陈晨Оценок пока нет

- 燃气轮机发电机组启动调试大纲 (强烈推荐)Документ55 страниц燃气轮机发电机组启动调试大纲 (强烈推荐)meirangongОценок пока нет