Академический Документы

Профессиональный Документы

Культура Документы

Guidance Notes ON Panelling Design & Joint Construction of Concrete Slabs

Загружено:

Mohammed AlkhateebИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Guidance Notes ON Panelling Design & Joint Construction of Concrete Slabs

Загружено:

Mohammed AlkhateebАвторское право:

Доступные форматы

HIGHWAYS DEPARTMENT

GUIDANCE NOTES

ON

PANELLING DESIGN & JOINT CONSTRUCTION

OF CONCRETE SLABS

Research & Development Division RD/GN/020

28th July 1995

1. Introduction

The correct layout and the correct construction of joints are important determinants of

the long term performance of concrete pavements. This Guidance Note aims to

produce information on which consistent design and construction practice can be

based.

2. Panelling Design

2.1 Overall design considerations

a) Avoid stress concentration

The design of the joint layout for concrete pavements aims to avoid physically

weak configurations or those which are likely to cause detrimental stress

concentrations. Rectangular slabs are the ideal layout and joints should be

positioned as far as possible to produce rectangular slabs. Non-rectangular

slabs such as L, T, U or H shaped slabs shall be avoided.

b) Panels tied together by longitudinal joints move as a unit

One important point to bear in mind is that adjacent panels separated by a

longitudinal joint do not move relative to each other. It follows that panels tied

together by longitudinal joints move as a unit, not individually. As shown in

Figure GN 020/01, the same direction of longitudinal movement should be

allowed for adjacent panels separated by a longitudinal joint. This will be

further discussed in paragraph 2.3.

c) On road sections with curved alignment

It is acceptable to curve the individual bays to follow the general alignment of

the road. Theoretically two adjacent panels move relative to each other along

the line joining the centroids of the two slabs. In practice it is acceptable to

construct the transverse joints right angle to the centre line of the curve and to

install the dowel bars right angle to the transverse joint (see Fig. GN 020/02)

d) Avoidance of acute-angled corners

In general corners with an internal angle of less than 80 should be avoided.

Where a joint meets the kerb line, it may be necessary to modify the joint detail

as shown in Figure GN 020/03 to avoid an acute-angled corner. However, the

angle created should be as close to 180 as possible and in no case should the

internal angle be less than 135 . The realigned section shall be 450 mm long.

Dowel bars shall be omitted from the realigned section to avoid constraining

the movement at the joint.

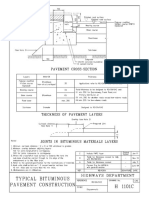

2.2 Longitudinal Joints (LJ) (see H1107)

RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs page 1 of 7

a) Design considerations

LJs are provided to reduce the slab width and limit stresses in the transverse

direction. An increase in the slab width will yield an increase in the effective

slab area for load transfer. Frequent LJs increase the number of construction

operations so there must be a balance between the number of construction

operations and the level of load to be transferred.

b) Dimensions to follow

Maximum width of slab - unreinforced - 4.5 metres

- with mesh - 4.5 metres (desirable)

- 6.0 metres (with B503 mesh)

Minimum width of slab - 1 metre

Length/width ratio - 1.6 desirable maximum

(unreinforced only) - 2.0 absolute maximum

c) Position and construction

LJs should not be formed in or near wheel tracks to avoid unfavourable loading

condition. Ideally LJs should be provided between traffic lanes at or near lane

lines, or alternatively in the centre of a lane. If necessary, a LJ can stop at any

transverse joint and not carry through the other side of the transverse joint.

LJs should normally be formed. Poured-through LJs is not allowed unless the

contractor uses a purpose-made regulating machine spanning the full width of

the slabs concerned (details discussed in paragraph 3.4)

2.3 Transverse joints (TJ) in general

a) Transverse joints to continue across carriageway but not staggered

A TJ can be an expansion joint, a contraction joint or an isolation joint. TJs

must continue across the full width of the carriageway, they should never stop

at a LJ or be staggered. As shown in Figure GN 020/04, a TJ not continuing

through an adjoining slab will create tensile stress in the adjoining slab and

cause cracking in line with the transverse joint. The exception to this

requirement is box-out joints for manholes or utility covers where it is only

required to bring one side of the box-out joint across the width of the

carriageway (discussed further in paragraph 2.6).

TJs shall continue through kerbs, edgings and their foundation and backing if

the concrete slabs are cast against the kerbs and edgings (GS 10.35(2)).

RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs page 2 of 7

b) TJ to be straight across the width of the carriageway

As shown in Figure GN 020/01, an angled TJ with all dowels bars

perpendicular to the joint will effectively become a fixed joint as it will not

allow movement in any direction. A TJ should be straight across adjoining

panels (unless separated by an isolation joint) as adjoining panels tied together

by LJs move together as a unit. An exception is when a TJ meets the kerb line

of the edge of the carriageway where a change in direction can be allowed to

avoid an acute-angled joint. As discussed in paragraph 2.1(d), the realigned

section shall be 450 mm long and the internal angle of the section shall not be

less than 135 . Dowel bars must be omitted in this realigned section to avoid

constraining movement at the joint.

2.4 Expansion joints (EJ) (H1105)

a) Spacing

The primary function of an EJ is to allow expansion movements in the

longitudinal direction. However, EJs are the most expensive type of joints to

construct and maintain. The relatively large joint width makes an EJ more

vulnerable to spalling damage. It is relevant to note that the longer the slab the

wider the joint. The number of EJs should be reduced as far as possible.

Spacing of EJ depends on several factors including the temperature at which

the concrete is placed, the frictional restraint of the subgrade/subbase and the

slab thickness. The recommended maximum spacing is as follows-

60 metres for mesh reinforced slabs;

100 metres for unreinforced slabs.

b) An EJ is not a solution for conflicting movements

An EJ allows movement only in one direction and shall not be used as a

solution where there are conflicting movements across a joint such as at road

junctions. In such situation isolation joints shall be used. Please refer to

paragraph 2.6.

2.5 Contraction joints (CJ) (H1106)

a) Spacing

The primary function of a CJ is to allow contraction movement in the

longitudinal direction. Similar to EJs, the number of CJs should be reduced as

far as possible to minimise maintenance commitment. However, sawn-through

CJs are of narrow width and therefore less susceptible to damage, in addition

RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs page 3 of 7

they do not require to be sealed thus reducing maintenance requirements. The

recommended maximum spacing is as follows-

20 metres for mesh reinforced slabs;

5 metres for unreinforced slabs.

b) Position

Besides separating a road pavement into slabs of convenient lengths, CJs

should be located where severe concentrations of tensile stresses are expected

to occur. An example is where an abrupt change in cross section occurs such

as in an L-shaped pavement and a CJ should be provided to separate it into two

rectangular slabs. Another example is the boxing out of an opening as

discussed in paragraph 2.6 below.

2.6 Isolation Joint (IJ) (H1107)

a) Functions

Isolation joints are joints across which no dowel bars or tie bars are installed

for load transfer. They are used to prevent induced cracking which may result

from misaligned joints by permitting slabs to move against each other

transversely and longitudinally. An example is at a major road junction where

it is not possible to continue a TJ on a road through the slabs of the side road.

Isolation joints are also used around manholes or utility openings for separation

purpose.

b) Isolation joints at road junctions

It is a common problem for unreinforced slab construction. Because of the

small length, there may be several CJs at a junction. It is often not possible to

continue these CJs through the slabs of the side road. It is not satisfactory to

join these CJs onto LJs of the side road because there cannot be any movement

across the LJs. The solution as shown in Figure GN 020/05 is to terminate the

CJs at an isolation joint separating the road slabs of the two roads. Where a

main road is of mesh reinforced construction and it is not necessary to provide

a TJ at the junction, the slabs of the side road can terminate at an EJ or a CJ.

c) Isolation joints around manholes or utility openings

Because of different supporting arrangement for manholes and utility openings,

it is necessary to provide isolation joints around such openings for separation

purpose. The typical layout of such box-out arrangement is shown in standard

drawings No. H 1111 and H 1112. The box-out should be orthogonal to the

road slab (rectangular and with sides parallel to the sides of the road slab). To

avoid creating lines of weakness, two TJs (an EJ or a CJ) should be provided to

RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs page 4 of 7

2.7

3.

3.1

3.2

3.3

extend the isolation joints in the transverse direction through the whole width

of the slab as shown in Figure GN 020/04. Preferably both but at least one of

these two TJs should also be extended through all adjoining slabs across the

whole width of the carriageway. Therefore the presence of manholes and

utility openings will inevitably result in short panel lengths making

unreinforced construction more favourable.

Construction Joint (H1108)

Construction joints should be avoided wherever possible. Although a construction

joint aims at bonding the new concrete to the hardened concrete in such a manner that

the concrete appears to be monolithic and homogeneous across the joint, in practice it

is very difficult to obtain full adhesion, with the result that there is usually a plane of

weakness at construction joints.

No construction joints shall be formed within 2.5 metres of an existing or planned TJ

(GS 10.42). Since the maximum length of an unreinforced concrete slab is 5 metres, it

follows that construction joints are not allowed in unreinforced road slabs.

Joint Construction

General considerations

Clearly joints should be constructed in such a way that movement of the slabs will take

place in accordance with the design. It is necessary to pay particular attention to joint

construction as slight deviations may create constraints in movement causing the slab

to crack or spall under stress concentration. Malpractices aimed at facilitating slab

construction may inadvertently create constraints in movement leading to cracking and

additional maintenance requirements.

Tie bars

Tie bars should be straight and located at mid depth of a slab. It is important to check

that anti-corrosive sleeves are provided in the correct position (H1107) as they serve as

a physical separation to prevent future corrosion of the tie bars. Tie bars should be

securely fixed in position through openings at the side forms before concreting. The

temporary bending up of tie bars for LJs due to space limitation can be allowed

provided they are bent back to a horizontal alignment before concreting of the

adjoining slab (note that bending up of dowel bars is not permitted as discussed in

para. 3.3(a) below).

Dowel bars

a) Correct alignment and position

page 5 of 7 RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs

Dowel bars are more important than tie bars as they are the moving parts

linking adjoining slabs. Dowel bars shall be uniform in cross section and free

from burrs on the ends. They shall be straight and free from bending. Any bent

dowel bars shall be rejected and shall not be allowed to be re-formed or to be

bent back into an apparently straight alignment for use in joint construction.

The ends of dowel bars protruding out from end forms shall never be allowed

to be bent despite space limitation.

Dowel bars shall be securely fixed in position and alignment before concreting.

They shall be horizontal, perpendicular to the end forms and parallel to other

dowel bars of the same set. For pour-through construction, dowel bars shall be

securely fixed onto rigid cradle cages and the cradle cages shall be securely

fastened onto the subbase.

b) Omission of dowel bars at end kinks of TJs

It may be necessary to realign a TJ at the end to avoid forming an acute-angled

corner. Dowel bars shall not be provided in the realigned section as discussed

in paragraph 2.1(d) to avoid creating a constraint in movement of the slab.

3.4 Formed joints

A formed joint is constructed by first concreting the slab on one side of the joint

against temporary formwork. With this type of construction, it is easier to ensure that

the joint is straight and that the dowel bars or tie bars are correctly aligned. EJs and

isolation joints shall be constructed in this way. LJs also should normally be formed in

this manner.

3.5 Pour-through and sawn joints

a) Points to note in concreting

Pour-through CJs are acceptable in particular for unreinforced construction.

However, most of the elements are hidden after concreting and therefore

checking before concreting is important. Particular attention should be paid to

the following -

dowel bars are straight, horizontal, parallel to each other and securely fixed

in position and alignment onto rigid cradle cages which in turn should be

securely fastened to the subbase layer;

the alignment of a joint to be saw cut subsequently should be marked

clearly such that the marks can still be seen after concreting;

the midpoints of the dowel bars align with the joints to be formed;

concrete near the cradle cages shall be carefully compacted to avoid

dislocating the dowel bars.

RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs page 6 of 7

b) Saw cutting of joints

Joints in pour-through construction are formed by saw cutting (H1109 detail

B). Saw cutting should be done at appropriate time to avoid cracking. Delayed

saw cutting is probably the cause of most of the transverse cracks and

shrinkage cracks found in finished slabs. Experience in Hong Kong has shown

that the appropriate time for saw cutting is about 24 hours after concreting.

It is important to check that the saw cut is straight and reaches one quarter to

one third depth. Insufficient saw cut depth may cause the slab to crack at some

other location, not along the alignment of the cut. It is also important to check

that the saw cut is of uniform depth throughout the entire width of the slab.

Insufficient saw cut depth at the end of a sawn joint is a common problem as it

is necessary to bring the saw blade outside the width of the slab in order to saw

the ends to the adequate depth. If by special approval the concrete slab is to be

cast against the kerb, the provision of a gap through the kerb in line with the

saw cut line is required to allow passage of the saw blade beyond the edge of

the concrete slab at the required depth.

c) Pour-through LJs

LJs should normally be constructed as a formed joint. It is easier to control the

cross fall of the slab with a formed joint. Pour-through construction shall not

be allowed unless the contractor uses a transverse purpose-made regulating

machine spanning the full width of the slabs to be constructed which should be

supported on a carriage (the level of which shall be controlled by the average

level of not less than four points evenly spaced over at least 1.5 metre of the

supporting rail, beam, slab or similar approved on each side of the slabs) and

equipped with at least two oscillating-type transverse screeds.

RD/GN/020 - Panelling Design & Joint Construction of Concrete Slabs page 7 of 7

Вам также может понравиться

- Lords View Industrial Estate Design GuidelinesДокумент27 страницLords View Industrial Estate Design Guidelinesica sukardiОценок пока нет

- Requirements For Driveway-SidewalkДокумент9 страницRequirements For Driveway-SidewalkJorge GutierrezОценок пока нет

- Differences ACI-318-08 To 11Документ13 страницDifferences ACI-318-08 To 11Dangutu KhanbraОценок пока нет

- Reinforced Concrete Slab DesignДокумент30 страницReinforced Concrete Slab DesignPitolwala ZuzarОценок пока нет

- Reinforced Concrete Slab DesignДокумент29 страницReinforced Concrete Slab Designmansoor azam100% (1)

- STRL Design Rules of Thumb PDFДокумент11 страницSTRL Design Rules of Thumb PDFsakti prasanna sahuОценок пока нет

- TCNA - 2015 Tile Initiative Release Date March 2015 DigitalДокумент50 страницTCNA - 2015 Tile Initiative Release Date March 2015 DigitalVasilis LappasОценок пока нет

- DOT Unified DBE Directory 2011-10-10Документ348 страницDOT Unified DBE Directory 2011-10-10JAGUAR GAMINGОценок пока нет

- Site Engineering Design ChecklistДокумент13 страницSite Engineering Design ChecklistMohammed AlkhateebОценок пока нет

- 3 4 2 AparkinglotdesignДокумент4 страницы3 4 2 Aparkinglotdesignapi-299811796Оценок пока нет

- Method Statement For Road and Paving WorkДокумент32 страницыMethod Statement For Road and Paving WorkĐặng Quang Huy100% (7)

- Highway Geometric DesignДокумент76 страницHighway Geometric DesignNaman DwivediОценок пока нет

- Earthquake DesignДокумент2 страницыEarthquake DesignUmange RanasingheОценок пока нет

- Geometric Design For Highways and Railways Including Cross Sections Horizontal and Vertical Alignments Super Elevation and EarthworksДокумент21 страницаGeometric Design For Highways and Railways Including Cross Sections Horizontal and Vertical Alignments Super Elevation and EarthworksJannila PaulinoОценок пока нет

- Manholes PresentationДокумент143 страницыManholes PresentationMar MaslanОценок пока нет

- Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-TipsДокумент7 страницRules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tipsnuwan01100% (1)

- Design and Analysis of Flat SlabДокумент43 страницыDesign and Analysis of Flat Slabarun_angshuОценок пока нет

- Bridge DesignДокумент129 страницBridge DesignDaniel KariukiОценок пока нет

- Preliminary Design Rules of ThumbДокумент11 страницPreliminary Design Rules of Thumbnimal1234Оценок пока нет

- Slope StabilityДокумент32 страницыSlope StabilityMohammed Alkhateeb100% (2)

- Control of Shrinkage and Curling in Slabs On Grade: Part 3 of A 3-Part SeriesДокумент4 страницыControl of Shrinkage and Curling in Slabs On Grade: Part 3 of A 3-Part Seriesmyke_0101Оценок пока нет

- Construction JointsДокумент4 страницыConstruction JointsAvelino De Leon Jr100% (1)

- Injection SystemДокумент8 страницInjection SystemMohammed Alkhateeb100% (1)

- Steel Bridges Types History ConstructionДокумент113 страницSteel Bridges Types History ConstructionyhproОценок пока нет

- Paper Reinforced Concrete SlabsДокумент32 страницыPaper Reinforced Concrete SlabsTHRESNAОценок пока нет

- Reinforced Concrete Slab PDFДокумент8 страницReinforced Concrete Slab PDFArun NesamОценок пока нет

- BS 7533 Part 7Документ44 страницыBS 7533 Part 7Saud PathiranaОценок пока нет

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОт EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОценок пока нет

- Link Slab Deck JointsДокумент20 страницLink Slab Deck JointsAnton Husen PurboyoОценок пока нет

- Reinforced Concrete Buildings: Behavior and DesignОт EverandReinforced Concrete Buildings: Behavior and DesignРейтинг: 5 из 5 звезд5/5 (1)

- Complete Streets Design Guideline Manual 1Документ86 страницComplete Streets Design Guideline Manual 1Tariq ToffaОценок пока нет

- Detail Design of Bridge Abutment 1Документ4 страницыDetail Design of Bridge Abutment 1mohammad azimОценок пока нет

- AbutmentДокумент8 страницAbutmentuchennaОценок пока нет

- IStructE Manual for the design of concrete building structures to Eurocode 2Документ4 страницыIStructE Manual for the design of concrete building structures to Eurocode 2Andrei MorosanОценок пока нет

- Design Plate Girders Understanding Components FunctionsДокумент79 страницDesign Plate Girders Understanding Components FunctionsMohamed ShabibОценок пока нет

- Quickstart For Roadway Modeling Using Openroads-Practice WorkbookДокумент42 страницыQuickstart For Roadway Modeling Using Openroads-Practice Workbookbhavin_trnsprtОценок пока нет

- Pages From HILTI - Anchor Fastening Technology ManualДокумент65 страницPages From HILTI - Anchor Fastening Technology ManualmurdicksОценок пока нет

- Concrete Block Paving Standards Update in UKДокумент6 страницConcrete Block Paving Standards Update in UKΓιάννης ΜούσιαςОценок пока нет

- CORUS Composite Steel Highway BridgesДокумент28 страницCORUS Composite Steel Highway BridgessuvraОценок пока нет

- Grasscrete: Sustainable Building Materials and TecnologyДокумент16 страницGrasscrete: Sustainable Building Materials and TecnologyShruti DeogiriОценок пока нет

- Guidelines For Design of Integral AbutmentsДокумент10 страницGuidelines For Design of Integral Abutmentsc1366Оценок пока нет

- Simply Supported and Continuous BridgesДокумент31 страницаSimply Supported and Continuous BridgesNoman Ali79% (14)

- Chapter 7: Box Girder BridgesДокумент26 страницChapter 7: Box Girder BridgesPacha Khan KhogyaniОценок пока нет

- LRFD Bridge Design Guide for Integral AbutmentsДокумент156 страницLRFD Bridge Design Guide for Integral AbutmentsChristine Hermawan100% (1)

- Bridge Bearing Devices and Girder AnchoragesДокумент11 страницBridge Bearing Devices and Girder Anchoragessiva_civil4051Оценок пока нет

- Joints PDFДокумент12 страницJoints PDFpoornimavenkatramanОценок пока нет

- A Comparative Study of Conventional RC Girder Bridge and Integral BridgeДокумент20 страницA Comparative Study of Conventional RC Girder Bridge and Integral Bridgesanket panchalОценок пока нет

- Joints in Structural Members: Unit IvДокумент10 страницJoints in Structural Members: Unit IvArun Akhil KunalaОценок пока нет

- TB Lecture20 Example of PT Two Way SlabsДокумент39 страницTB Lecture20 Example of PT Two Way SlabsBridget Anne BenitezОценок пока нет

- 5G-2 PCC Joints TypesДокумент22 страницы5G-2 PCC Joints TypesGiovanni Arango100% (1)

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeДокумент5 страницGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaОценок пока нет

- Concrete Pavement JointsДокумент3 страницыConcrete Pavement JointsSOORI4373Оценок пока нет

- 8 - One Way Slabs SДокумент23 страницы8 - One Way Slabs SHamaaaОценок пока нет

- AD 317 - Use of Integral Crossheads in Skew Highway BridgesДокумент2 страницыAD 317 - Use of Integral Crossheads in Skew Highway Bridgessymon ellimacОценок пока нет

- Chapter 10-2 Analysis and Design of One-Way SlabsДокумент10 страницChapter 10-2 Analysis and Design of One-Way Slabssajjad.ghazai2001Оценок пока нет

- 如何撰写英语科技论文 (1) - 潘 晨 - 000294Документ59 страниц如何撰写英语科技论文 (1) - 潘 晨 - 000294malachi.chikodzoОценок пока нет

- Technical Advisory Slab PAVEMENTДокумент6 страницTechnical Advisory Slab PAVEMENTNoli PaladОценок пока нет

- Construction Joints:: Beams and SlabsДокумент4 страницыConstruction Joints:: Beams and SlabsJulius Fernan VegaОценок пока нет

- Multi-girder Bridge Design and Structural ConsiderationsДокумент6 страницMulti-girder Bridge Design and Structural ConsiderationsSwamy ManiОценок пока нет

- Fatigue-Resistant Detail Design Guide For Ship StructuresДокумент6 страницFatigue-Resistant Detail Design Guide For Ship Structuresy_596688032Оценок пока нет

- Joint Detaisl in Rigid PavementДокумент7 страницJoint Detaisl in Rigid PavementprmraoОценок пока нет

- Paper - Integral BridgesДокумент10 страницPaper - Integral BridgesviralisursОценок пока нет

- Plate GirdersДокумент9 страницPlate GirdersTapabrata2013Оценок пока нет

- Inspection and Maintenance of Steel Girders-5Документ10 страницInspection and Maintenance of Steel Girders-5vpmohammedОценок пока нет

- BDM Section 11 2021Документ48 страницBDM Section 11 2021ximpasseОценок пока нет

- Guidance Note Attachment of Bearings No. 2.08: ScopeДокумент2 страницыGuidance Note Attachment of Bearings No. 2.08: ScoperohitОценок пока нет

- SMD Technical Manual-2011Документ20 страницSMD Technical Manual-2011karfire1982Оценок пока нет

- Rules of ThumbДокумент14 страницRules of ThumbAntoniette Samantha Nacion100% (1)

- Section 25 Prestressed Concrete Beams 1.25.1 DrawingsДокумент7 страницSection 25 Prestressed Concrete Beams 1.25.1 Drawingshamada252010Оценок пока нет

- 14 - Section 7.1 - Integral Abutments (E) PDFДокумент38 страниц14 - Section 7.1 - Integral Abutments (E) PDFDr. MOHAMED ALZAINОценок пока нет

- Bridge Deck TypesДокумент39 страницBridge Deck TypesGabriel BroascaОценок пока нет

- (LECT-21,22) Prestressed Concrete SlabsДокумент22 страницы(LECT-21,22) Prestressed Concrete SlabsSushil MundelОценок пока нет

- 1.5. Incremental LaunchingДокумент5 страниц1.5. Incremental LaunchingBALRAJОценок пока нет

- Guidance Note Bracing Systems No. 1.03: ScopeДокумент4 страницыGuidance Note Bracing Systems No. 1.03: ScopeRaquel CarmonaОценок пока нет

- Lecture 3 Design of 2 Way SlabsДокумент6 страницLecture 3 Design of 2 Way SlabsOlesea NesterencoОценок пока нет

- تصميم معماريДокумент14 страницتصميم معماريMohammed AlkhateebОценок пока нет

- Lecture6 (Asphalt Mixtures)Документ18 страницLecture6 (Asphalt Mixtures)Mohammed AlkhateebОценок пока нет

- Lecture2 (Highway Location-Highway Alignment)Документ6 страницLecture2 (Highway Location-Highway Alignment)Shane RodriguezОценок пока нет

- Lecture2 (Highway Location-Highway Alignment)Документ6 страницLecture2 (Highway Location-Highway Alignment)Shane RodriguezОценок пока нет

- Lecture5 (Pavement Materials) - For MergeДокумент18 страницLecture5 (Pavement Materials) - For MergeMohammed AlkhateebОценок пока нет

- Lecture 1 (Development of Roads and Highway)Документ4 страницыLecture 1 (Development of Roads and Highway)Mohammed AlkhateebОценок пока нет

- 2nd TrainingДокумент11 страниц2nd TrainingMohammed AlkhateebОценок пока нет

- NTPEP Geotextile Audit Work-Plan - tcm29-27577Документ15 страницNTPEP Geotextile Audit Work-Plan - tcm29-27577Mohammed AlkhateebОценок пока нет

- CBR TEST PARAMETERSДокумент13 страницCBR TEST PARAMETERSsmart.engineerОценок пока нет

- en-INT - Flocrete SP42.21052012022601Документ2 страницыen-INT - Flocrete SP42.21052012022601Mohammed AlkhateebОценок пока нет

- 33 05 13 Manholes and Structures 10Документ4 страницы33 05 13 Manholes and Structures 10Mohammed AlkhateebОценок пока нет

- معادلة تقييم الاداءДокумент12 страницمعادلة تقييم الاداءqoseОценок пока нет

- CBR TEST PARAMETERSДокумент13 страницCBR TEST PARAMETERSsmart.engineerОценок пока нет

- A LARSA Publication - March 2012Документ12 страницA LARSA Publication - March 2012Mohammed AlkhateebОценок пока нет

- Lake Hodges Stress Ribbon Bridge: JournalДокумент8 страницLake Hodges Stress Ribbon Bridge: JournalMohammed AlkhateebОценок пока нет

- A LARSA Publication - March 2012Документ12 страницA LARSA Publication - March 2012Mohammed AlkhateebОценок пока нет

- Creation of ColunmДокумент11 страницCreation of ColunmMohammed AlkhateebОценок пока нет

- Expansion Joint Use in Concrete BarriersДокумент60 страницExpansion Joint Use in Concrete BarriersKavish SobronОценок пока нет

- Highway Plans and SpecificationsДокумент2 страницыHighway Plans and SpecificationsOwen Radaza PiranteОценок пока нет

- Site Improvement Plans ChecklistДокумент7 страницSite Improvement Plans ChecklistEjaz Ahmed RanaОценок пока нет

- Ward 15 Trafic Study HandoutДокумент4 страницыWard 15 Trafic Study HandoutMegan-Ellyia GreenОценок пока нет

- HighwayДокумент53 страницыHighwayYad Abdulla HsseinОценок пока нет

- Concrete Crack Width GuideДокумент50 страницConcrete Crack Width GuidewackokidОценок пока нет

- Rural Road Construction Project ReportДокумент33 страницыRural Road Construction Project ReportNandu KingsОценок пока нет

- Wearing Coat ThicknessДокумент1 страницаWearing Coat ThicknessanjanaОценок пока нет

- Granite Paver BlocksДокумент7 страницGranite Paver Blocksahtin618Оценок пока нет

- FBD 2A - Schedule of Prices Quantities MEPДокумент19 страницFBD 2A - Schedule of Prices Quantities MEPSalman MoghulОценок пока нет

- Highway Eng I, Chapter ThreeДокумент87 страницHighway Eng I, Chapter Threefentawmelaku1993Оценок пока нет

- NYSDOT Item Spec ListДокумент1 302 страницыNYSDOT Item Spec ListPeter NolanОценок пока нет

- CAR PARK DESIGN BRIEFДокумент51 страницаCAR PARK DESIGN BRIEFDavid TomlinsonОценок пока нет

- Highway Reviewer FinalsДокумент67 страницHighway Reviewer Finalsedrian sergs ballezaОценок пока нет

- 4 For RoadДокумент12 страниц4 For RoadFraidon SarwaryОценок пока нет

- Over Runnable Area-DownloadДокумент3 страницыOver Runnable Area-DownloadMurthyThendelaОценок пока нет

- Rock Creek West 2 Livability Study - Appendix DДокумент43 страницыRock Creek West 2 Livability Study - Appendix DDistrict Department of TransportationОценок пока нет

- May 20, 2011 Strathmore TimesДокумент28 страницMay 20, 2011 Strathmore TimesStrathmore TimesОценок пока нет