Академический Документы

Профессиональный Документы

Культура Документы

(732-Itp-20 (V-6903) 42000-SNG-69-42000P-MS-5733-502-0000-06

Загружено:

sathi111890 оценок0% нашли этот документ полезным (0 голосов)

103 просмотров10 страницОригинальное название

(732-ITP-20 (V-6903) 42000-SNG-69-42000P-MS-5733-502-0000-06

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

103 просмотров10 страниц(732-Itp-20 (V-6903) 42000-SNG-69-42000P-MS-5733-502-0000-06

Загружено:

sathi11189Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

PETROLEUM DEVELOPMENT

OMAN L.L.C. (PDO)

Contractor J ob No. : 20036 Unit No

Vendor Doc. No. : 732/QAP/20 Rev. 06

Project Title:

SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP)

Doc..Category : Q3

Sheet

No

1 of 8

PDO Contract No.

C311194

Document Title:

INSPECTION & TEST PLAN (QAP) FOR V 6903

(LP Inlet Condensate Flash Vessel)

PDO Doc. No.

Rev. 06

SNG-69-42000P-MS-5733-502-0000

Project No.

20036

Unit Description:

INSPECTION & TEST PLAN (QAP) FOR V 6903

(LP Inlet Condensate Flash Vessel)

MR No. :- 20036-0100-M31-MR-42000 REV. 02

PURCHASE ORDER No. :- 4580041305

TAG No. : V 6903 POS. : 00050 PR ITEM No. :- 00051

VESSEL CATEGORY:- GENERAL SERVICE PRESSURE VESSEL

NACE MR-01-75

06 26/05/2014 REVISED TO INCORPORATE PDO COMMENTS S. Naik P.V.Ghanekar

05 14/04/2014 REVISED TO INCORPORATE PDO COMMENTS S. Naik P.V.Ghanekar

04 17/07/2013 ISSUE FOR APPROVAL S. Naik P.V.Ghanekar

03 10/06/2013 ISSUE FOR APPROVAL S. Naik P.V.Ghanekar

02 08/04/2013 REVISED TO INCORPORATE ABB COMMENTS S. Naik P.V.Ghanekar

01 14/01/2013 ISSUE FOR APPROVAL S. Naik P.V.Ghanekar

Rev Date Description Prepared Checked Approved

Contractor Details (Headquarters and Offices):

ABB SpA - Process Automation Division

via Luciano Lama 33

20099 Sesto S.Giovanni (MI) - Italy

Document property of ABB SpA: its reproduction, circulation and use without prior consent is forbidden

17/06/2014

Company comments on Rev. 05

shall be considered.

732/QAP/20 Page 2 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

1.0

1.1

Drawing, Design

Calculations

Review of Documents

ASME Sec. VIII Div. 1

/ 20036-0100-M31-MR-42000

ASME Sec. VIII Div. 1

/ 20036-0100-M31-MR-42000

Approved

Drawing, Design

Calculations

H R RA RA

1.2

Quality Assurance Plan,

IRR Approval

Review of documents

ASME Sec. VIII Div. 1

/ Approved Drawing

/ 20036-0100-M31-MR-42000

ASME Sec. VIII Div. 1

/ Approved Drawing

/ 20036-0100-M31-MR-42000

QAP H H RA RA

1.3

Procedures - NDE, Heat

Treatment, Hydrotest,

Hardness, PMI, Painting,

Packing transport &

preservation procedures

Documented Procedure

ASME Sec. VIII Div. 1

/ Approved Drawing

/ 20036-0100-M31-MR-42000

ASME Sec. VIII Div. 1

/ Approved Drawing

/ 20036-0100-M31-MR-42000

Procedure

Documents

H R RA RA

1.4 Pre inspection meeting

Reviewing & understanding of

technical requirements and

Approval of MTC.

Purchase order

/ 20036-0100-M31-MR-42000

Purchase order

/ 20036-0100-M31-MR-42000

Minutes of

meeting

H ---- H H

2.0

Material after receipt

(For Pressure Parts)

Plates, Pipes

H H RA RA

Forging, fittings,

Fastners, gaskets etc.

H R RA RA

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS

DOCUMENTS

MATERIAL INSPECTION

STAGE / ACTIVITY

2.1

Review of manufacturer's test

certificates, Identification co-

realting heat number, Visual

damages & Dimesional inspection,

Transfer of identity & physical

verification.

ASME Sec. -II A/B

Data sheet /

Approved Drawing / TDC /

SP 2069, DEP 31.22.20.31

& NACE MR-01-75

ASME Sec. -II A/B

Data sheet /

Approved Drawing

Material Test

Certificates,

Identification

reports

1) ALL CS materials shall be killed or

semi killed & Carbon content shal

be 0.23% max.

2) Mateial for shell & head shall be

supplied in normalised condition.

Chemical composition :

Carbon (c) =0.20 % (Max) for plate,

0.25 % for forgings,

0.23% for seamless pipe,

Sulfur (s) =0.003 % (Max)

Vanadium (V) +Niobium (NB)

=0.03 (Max)

Carbon Equivalent (CE) =0.43%

(t 50mm)

4) Forged products above 50 mm thick shall be

100 % ultrasonically examined

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

732/QAP/20 Page 3 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS STAGE / ACTIVITY

2.2

Non Pressure Parts

(including internals,

supports etc.)

Review of Material Test

Certificates

ASME Sec.-II A,

Approved Drawing,

SP 2069, DEP 31.22.20.31

ASME Sec. -II A,

Approved Drawing

Material Test

Certificates

H --- R R

3.0

3.1 Shop Weld & Test Plan

WPS,PQR,WPQ

& Consumable, NDT Plan

ASME Sec. IX /

Approved Drawing /

DEP 30.10.60.18 & 31.22.20.31

ASME Sec. IX Weld Plan H R RA RA

3.2 PQR Welding parameters

ASME Sec. IX /

Approved Drawing /

DEP 31.10.60.18

ASME Sec. IX /

Approved Drawing

WPS/ PQR H R RA RA

3.3 WPQ Qualification requirements

ASME Sec. IX /

Approved Drawing /

DEP 31.10.60.18

ASME Sec. IX /

Approved Drawing

WPQ H R RA RA

3.4 Welding Consumable Chemical & mechanical properties

ASME Sec. II part C /

DEP 31.10.60.18

ASME Sec. II part C

Batch Test

Certificate

R R R R

4.0

Visual & Dimensional inspection

including profile check & minimum

thickness mesurement

H W W

Dye Penetrant Test

(to detect cracks inside & outside

knuckle surface area)

H R W

Normalising of dished ends.

Heat Treatment

Chart

H R R

Simulation Test Coupon of

normalised dished end.

Inspection

Report

H W H W Test Coupon for physical test

RT - Full for weld seams in dished

ends.

RT Report H R R

RT films review.

WELDING INSPECTION WPS & PQR

Inspection of Formed Components

4.1

Inspection of Formed

Components

(Dished ends)

ASME Sec. VIII Div. 1 /

Approved Drawing / SP 2069

Appendix 8,SP 1176,

DEP 31.22.20.31 CL 4.10,

SNG-69-42000P-MS-

6038-517-0000,

SNG-69-42000P-MS-

6038-539-0000,

SNG-69-42000P-MS-

6026-525-0000,

SNG-69-42000P-MS-

6038-536-0000

ASME Sec. VIII Div. 1 /

Approved Drawing

Inspection report

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

732/QAP/20 Page 4 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS STAGE / ACTIVITY

5.0

Visual & dimensional inspection,

weld edge, root - gap, offset,

alignment & cleanliness etc. for

long seams of shell, dished end &

nozzles

H H

10%

W

5%

W

Visual & dimensional inspection,

weld edge, root - gap, offset,

alignment & cleanliness etc. for

circular seam, neck to flange,

nozzles on shell/head

H W

10%

W

5%

W

PT of weld edges to detect linear

discontinuties.

ASME Sec. VIII Div. 1/

Approved Drawing /

SNG-69-42000P-MS-

6038-539-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R

10%

W

5%

W

5.2

Intermediate Inspection

of welds

Visual / Interpass temperature / PT

insp. after backchip

ASME Sec. VIII Div. 1 & Sec. IX /

Approved Drawing

/ SNG-69-42000P-MS-

6038-517-0000 /SNG-69-42000P-

MS-6038-539-0000

ASME Sec. VIII Div. 1

& Sec. IX

Inspection

Report

H R S S

Visual inspection for reinforcement,

undercuts,

surface defects etc.

ASME Sec. VIII Div. 1 & Sec. V /

Approved Drawing / SNG-69-

42000P-MS-6038-517-0000

ASME Sec. VIII Div. 1

& Sec. V / Approved Drawing

Inspection

Report

H W W W

Welder Identification stamp on completed weld

(Die stamp)

Dye Penetrant Test

ASME Sec. VIII Div. 1 /

Approved Drawing

/ SNG-69-42000P-MS-

6038-539-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R S S

PT shall also be carried out for the tack

welds(after removal & ground flush) utilized to

aid construction.

Radiography Test

ASME Sec. VIII Div. 1 /

Data sheet / Approved Drawing/

SNG-69-42000P-MS-

6038-536-0000

ASME Sec. VIII Div. 1 RT Report H R RA RA Review of Radiography films

Inspection during fabrication

ASME Sec. VIII Div. 1 /

Approved Drawing

/ SNG-69-42000P-MS-

6038-517-0000

ASME Sec. VIII Div. 1

/ Approved Drawing

Inspection

Report

5.3 Inspection of completed welds

5.1

Weld edge perparation & setup

of pressure parts

(Long seam, circular seam,

nozzle neck to flange, nozzle on

shell/head)

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

732/QAP/20 Page 5 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS STAGE / ACTIVITY

Visual /

Dimensional Inspection

H R R R

PT for fillet welds of

lifting lugs and other

pressure bearing welds

H R R R

Final visual &

dimensional Inspection

ASME Sec. VIII Div 1

/ Approved Drawing /

SNG-69-42000P-MS-

6038-517-0000

ASME Sec. VIII Div 1

/ Approved Drawing

Inspection

Report

H W H H

MT of finish welds

ASME Sec. VIII Div. 1

& Sec. V , DEP 31.22.20.31 /

Approved Drawing

/ SNG-69-42000P-MS-

6038-540-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R S S

RT of finish welds

ASME Sec. VIII Div. 1/

Data sheet /

Approved Drawing

/SNG-69-42000P-MS-

6038-536-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R RA

Mechanized UT of branch weld

ASME Sec. VIII Div. 1 /

Data sheet /

Approved Drawing /

SNG-69-42000P-MS-

6038-525-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R W W

5.6

Post Weld Heat Treatment

of equipment

Review of

Heat Treatment Cycle

ASME Sec. VIII Div. 1/

Approved Drawing

/ SNG-69-42000P-MS-

6026-519-0000

ASME Sec. VIII Div. 1/

Approved Drawing

Heat Treatment

Chart

H R RA R

PWHT of equipment

Soaking Temperature :- 61010C.

Inspection of the

equipment before PWHT

5.5

5.4

Fitment & Welding

of Internal & External

attachments etc.

ASME Sec. VIII Div. 1

& Sec. V / Approved Drawing

/ SNG-69-42000P-MS-

6038-517-0000,

SNG-69-42000P-MS-

6038-539-0000

ASME Sec. VIII Div. 1

& Sec. V / Approved Drawing

Inspection

Report

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

732/QAP/20 Page 6 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS STAGE / ACTIVITY

RT of Pressure part

bult welds

ASME Sec. VIII Div. 1/

Data sheet / Approved Drawing

/SNG-69-42000P-MS-

6038-536-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R RA

MT of Pressure part

welds

ASME Sec. VIII Div. 1/

Approved Drawing

/SNG-69-42000P-MS-

6038-540-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R RA

Mechanized UT of branch weld

ASME Sec. VIII Div. 1 /

Data sheet /

Approved Drawing /

SNG-69-42000P-MS-

6038-525-0000

ASME Sec. VIII Div. 1

Inspection

Report

H R W W

Hardness test of welds,

HAZ

ASME Sec. VIII Div. 1 /

Approved Drawing / SP 2069

Appendex-8, DEP 31.22.20.31 CL

6.2 / SNG-69-42000P-MS-

6061-526-0000

ASME Sec. VIII Div. 1 /

Approved Drawing

Hardness test

report

H R W W

248 HV10 maximum for ferritic metals in

process services, including H2 and sour service

conditions.

6.0

6.1

Final Visual &

Dimensional Inspection

(Internal & External)

Dimensions, completeness

of the assembly, as built thickness

measurement

ASME Sec. VIII Div. 1 & Sec. V /

Approved Drawing

/ DEP 30.22.20.31, SNG-69-

42000P-MS-6038-554-0000

ASME Sec. VIII Div. 1 & Sec. V /

Approved Drawing

Inspection

Report

H H H H

6.2 Positive Material Identification

PMI examination

of alloy materials

ASME Sec. II A

/ DEP 31.10.00.10 & SP 2069,

SNG-69-42000P-MS-

6180-523-0000

ASME Sec. II A PMI Report H R W W

6.3

Pneumatic test

of Nozzle RF pads

Leak check

ASME Sec. VIII Div. 1 & Sec. V

/ Approved Drawing / DEP

30.22.20.31 CL 6.9, SNG-69-

42000P-MS-6180-520-0000

ASME Sec. VIII Div. 1 & Sec. V

/ Approved Drawing

Test Report H R RW

10%

W

NDE after PWHT 5.7

FINAL INSPECTION

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

732/QAP/20 Page 7 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS STAGE / ACTIVITY

6.4

Trial assembly

of supplied Internals

Trial fitting of internals

P.O. /

Internals supplier Drawings

P.O. /

Internals supplier Drawings

Inspection

Report

H W W

6.5

Interior & exterior

cleaning

All completed equipment shall be

cleaned internally and externally to

remove scale, weld spatter,dirt,

and foreign material.

Approved Drawing

/ DEP 31.22.20.31

Approved Drawing

Inspection

Report

H R R

6.6

Hydrostatic Testing

(Horizontal)

Leak check /

Pressure drop

ASME Sec. VIII Div. 1/

Approved Drawing

/ DEP 30.22.20.31 CL 6.9,

SP 2069 / SP 2051CL 6.4.4,

SNG-69-42000P-MS-

6180-520-0000

ASME Sec. VIII Div. 1/

Approved Drawing

Inspection

Report

H H H H

6.7 Drying of equipment Cleanliness

Approved Drawing

/ DEP 30.22.20.31 CL 6.9,

SP 2069 CL 6.2

Approved Drawing

Inspection

Report

H ----

6.8

External & Internal

Surface preparation

Visual Inspection for

worksmanship, profile check

H ----

6.9

Painting

(Internal & External)

Visual inspection for workmanship,

DFT checking, Adhesion

H ---- W W

Painting shall be checked for surface chloride

contaimination , Holiday / pinhole, Adhesion test

& DFT test.

Criteria of Acceptability as per specification SP-

1246 Part-1 Table B1

7.0

Inspection of Mandatory &

Commissioning spares

Verification of spares

20036-0100-M31-MR-42000 /

Approved Drawing / P.O.

20036-0100-M31-MR-42000 /

Approved Drawing / P.O.

Spares List H ---- H

7.1

Verification of Name plate

and authorise for ASME

certification mark

Name plate review Approved Drawing Approved Drawing

Inspection

Report

H H H

Approved Drawing /

Data Sheet

/SP -1246, (PCS-1/9) /

SNG-69-42000P-MS-

6180-521-0000

Approved Drawing /

Data Sheet

/SP -1246, (PCS-1/9)

Inspection

Report

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

732/QAP/20 Page 8 of 8....

CLIENT QAP No. : 732/QAP/20 Rev. 06

P.O. No. DATE : 19/05/2014

EQUPT. No. CODE OF CONSTRUCTION : ASME SEC VIII DIV 1 ED 2010 ADDENDA 2011

PROJECT NAME : SAIH NIHAYDA CONDENSATE STABILIZATION PLANT (SNCP) DRG. No. : 732-E-20

CONTRACTOR JOB No. INSPECTION : AI (LR Insurance, Inc.)

SPECIFICATIONS FOR

PRESSURE VESSELS

:SP 2069 Rev. 0,

SP 2051 Rev. 2,

DEP 31.10.00.10 Sep. 2011,

SP 2041 Rev. 2,

DEP 30.10.60.18 May 2004

& NACE MR 0175.

SP 1176 Rev. 2,

DEP 30.10.02.17 Feb. 2011

GR A.I. ABB PDO

SP 1246 Part 1,2,3,4 Rev. 2 & Part 5 Rev. 3,

DEP 31.22.20.31- Gen. Feb. 2011,

SL.

NO

G.R.ENGINEERING PRIVATE LTD. -TARAPUR

INSPECTION & TEST PLAN (QAP) FOR V 6903

: ABB S.p.A - Italy.

: 4580041305 DTD 02-12-2012.

: V 6903.

: 20036

TYPE OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

FORMAT OF

RECORD

Scope of Inspection

REMARKS STAGE / ACTIVITY

7.2

Attachment of Stamped name

plate on the equipment

Name plate attachment

confirmation

Approved Drawing Approved Drawing

Rub off

/ Photo copy of

Name Plate

H W

7.3

Inspection Release Note /

Despatch Clearance

Verification of documents & issue

of IRN

20036-0100-M31-MR-42000 /

Approved Drawing / P.O.

20036-0100-M31-MR-42000 /

Approved Drawing / P.O.

IRN R --- H R

7.4

Signing of Manufacturer's

Data Report (MDR)

Review of MDR

ASME Sec. VIII Div. 1 /

Approved Drawing

ASME Sec. VIII Div. 1

/Approved Drawing

MDR H H H R

7.5

Check of packing

& packing list

Visual Inspection

/ Varification

P.O.

/ 20036-0100-M31-MR-42000

P.O.

/ 20036-0100-M31-MR-42000

Packing list H --- W

7.6

Manufacturing Record Book

(MRB)

Review of MRB

P.O.

/ 20036-0100-M31-MR-42000

P.O.

/ 20036-0100-M31-MR-42000

MRB H ---- H R

Legends :

S. NAIK P. V. GHANEKAR

QA Engineer QA Manager Authorised Inspector

H- Hold ( Do not proceed without approval), W- Witness(Give due notice, work may proceed after schedule date), R- Document Review,RA- Approval of Documents RW-Random Witness, S- Survellance, NDE- Non Destructive Examination,

PT - Dye Penetrant Test, RT - Radiographic Examination, UT - Ultrasonic Test, P.O.- Purchase Order, CS - Carbon steel, PMI - Positive Material Identification, TDC - Technical Delivery Condition, HAZ - Heat Affected Zone

Form No. GR 11 Rev. 02 FOR DETAILED NON DESTRUCTIVE EXAMINATION REQUIREMENTS REFER ANNEXURE "A"

Вам также может понравиться

- 3 2 1 PDFДокумент4 страницы3 2 1 PDFsathi11189Оценок пока нет

- Design and Estimation of Dry Dock PDFДокумент78 страницDesign and Estimation of Dry Dock PDFsathi1118950% (2)

- Floating Dry Dock SpecificationДокумент2 страницыFloating Dry Dock Specificationsathi11189Оценок пока нет

- Vedam MistakesДокумент1 страницаVedam Mistakessathi11189Оценок пока нет

- Floating Dry Dock SpecificationДокумент34 страницыFloating Dry Dock Specificationknowme73Оценок пока нет

- Total Number of Lesize Divisions of Opposite Sides Should Be SameДокумент28 страницTotal Number of Lesize Divisions of Opposite Sides Should Be Samesathi11189Оценок пока нет

- Maxsurf TrainingДокумент3 страницыMaxsurf Trainingsathi11189Оценок пока нет

- ANSYS EnvironmentДокумент27 страницANSYS Environmentsathi11189Оценок пока нет

- CantilДокумент17 страницCantilsathi11189Оценок пока нет

- HT 8!!inch IterateДокумент5 страницHT 8!!inch Iteratesathi11189Оценок пока нет

- Cantilever Beam TyuДокумент22 страницыCantilever Beam Tyusathi11189Оценок пока нет

- Valve CenterДокумент242 страницыValve Centersathi11189Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Pharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)Документ13 страницPharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)wangzahОценок пока нет

- IR in Coil CoatingДокумент3 страницыIR in Coil CoatingJanine Ellyze EvangelistaОценок пока нет

- Gen Chem 2Документ2 страницыGen Chem 2Ream MairОценок пока нет

- EVS UNIT 2 NotesДокумент21 страницаEVS UNIT 2 NotesNivashini VindhyaОценок пока нет

- MUY COMPLETO - CNC CNF Towards The Scale-Up Production of Cellulose Nanocomposites Using Melt ProcessingДокумент63 страницыMUY COMPLETO - CNC CNF Towards The Scale-Up Production of Cellulose Nanocomposites Using Melt ProcessingDerek ZoolanderОценок пока нет

- Univan Hs PrimerДокумент1 страницаUnivan Hs PrimerWorapat Puttakasem0% (1)

- Chelidonium Majus PDFДокумент40 страницChelidonium Majus PDFbhaskarsgОценок пока нет

- Aircraft Materials BrochureДокумент6 страницAircraft Materials BrochureAdnan ColoОценок пока нет

- Pre-IB Chemistry Mid-Term Review List (Nagel)Документ3 страницыPre-IB Chemistry Mid-Term Review List (Nagel)Helie100% (1)

- Mil-B-007883 Brazing - Cancelled - See Cancellation NoteДокумент26 страницMil-B-007883 Brazing - Cancelled - See Cancellation NoteChris NenovОценок пока нет

- Alkaline Ionised Water BookletДокумент25 страницAlkaline Ionised Water Bookletmichelle_wong_6Оценок пока нет

- Synthesis of 2 - (2,4-Diaminothiazol-5-Oyl) BenzothiazolesДокумент4 страницыSynthesis of 2 - (2,4-Diaminothiazol-5-Oyl) BenzothiazolesABBS FEN REJI T. F.Оценок пока нет

- API - RP - 571 - Edited - 42 - Questions - PDF - Filename UTF-8''API RP 571 Edited - 42 QuestionsДокумент5 страницAPI - RP - 571 - Edited - 42 - Questions - PDF - Filename UTF-8''API RP 571 Edited - 42 Questionsأحمد صبحى100% (1)

- ISSN:2157-7048: Executive EditorsДокумент10 страницISSN:2157-7048: Executive EditorsElaziouti AbdelkaderОценок пока нет

- General Chemistry 2: 2 Semester - Module 2 Types of Solids, Phase Changes and DiagramsДокумент20 страницGeneral Chemistry 2: 2 Semester - Module 2 Types of Solids, Phase Changes and DiagramsKrisha Mae Oao Calumpit100% (2)

- Petromole F GradesДокумент4 страницыPetromole F GradesmehrsaОценок пока нет

- 3.2MSDS Super PellДокумент2 страницы3.2MSDS Super PellQori Eka Safitri100% (1)

- IOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeДокумент187 страницIOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeFerryОценок пока нет

- Contextualized Learners ModuleДокумент23 страницыContextualized Learners ModuleSou MeiОценок пока нет

- 2007 - Shellac in PolymerДокумент43 страницы2007 - Shellac in PolymerAnonymous x7VY8VF7Оценок пока нет

- CY100 Engineering Chemistry Syllabus 2016Документ2 страницыCY100 Engineering Chemistry Syllabus 2016Siju N. AntonyОценок пока нет

- Entropy Examples and EquationsДокумент2 страницыEntropy Examples and EquationsRome BautistaОценок пока нет

- How To Eliminatdadde Outgassing, The Powder Coating Faux PasДокумент2 страницыHow To Eliminatdadde Outgassing, The Powder Coating Faux PasSandra ArianaОценок пока нет

- ks3 Acids and Alkalis Whats Your Idea PowerpointДокумент11 страницks3 Acids and Alkalis Whats Your Idea PowerpointManha abdellahОценок пока нет

- Sarthak Dadkar EVS Assn 2 PDFДокумент3 страницыSarthak Dadkar EVS Assn 2 PDFAjuba AbujaОценок пока нет

- Marcet BoilerДокумент10 страницMarcet BoilerDhia EmpayarОценок пока нет

- MSDS Bare Essentials CleanserДокумент5 страницMSDS Bare Essentials CleanserPure PawsОценок пока нет

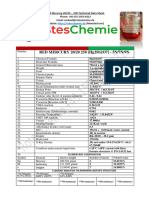

- Red Mercury 2020 Technical Data SheetДокумент2 страницыRed Mercury 2020 Technical Data SheetThe UniversОценок пока нет

- Enhanced Oil Recovery: SyllabusДокумент24 страницыEnhanced Oil Recovery: SyllabusAkmuhammet MammetjanovОценок пока нет

- Flange Sealing Guide - EN PDFДокумент64 страницыFlange Sealing Guide - EN PDFAli AlizadehОценок пока нет