Академический Документы

Профессиональный Документы

Культура Документы

Chapter 1

Загружено:

samiulctg0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров14 страницsupply chain management

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документsupply chain management

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров14 страницChapter 1

Загружено:

samiulctgsupply chain management

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

International Islamic University Chittagong

Department of Business Administration

Course Title: Supply Chain Management

Program BBA

Course Synopsis

(Objective of providing this Synopsis is to assist students in condensing out the fundamental object of the topics

detailed in the course plan. This is not a substitute to basic text book referred in the course plan provided by the

Department.)

Chapter 1: Introduction

1.1 Define Supply Chain Management

Supply chain management (SCM) is the management of a network of interconnected

businesses involved in the provision of product and service packages required by the end

customers in a supply chain.

[2]

Supply chain management spans all movement and storage of raw

materials work!in!process inventory and finished goods from point of origin to point of

consumption.

"nother definition is provided by the "#$%S &ictionary when it defines S%' as the (design

planning e)ecution control and monitoring of supply chain activities with the ob*ective of

creating net value building a competitive infrastructure leveraging worldwide logistics

synchroni+ing supply with demand and measuring performance globally.(

S%' draws heavily from the areas of operations management logistics procurement

information technology and strives for an integrated approach.

"ccording to the %ouncil of Supply %hain 'anagement #rofessionals (%S%'#) supply chain

management encompasses the planning and management of all activities involved in sourcing

procurement conversion and logistics management. $t also includes the crucial components of

coordination and collaboration with channel partners which can be suppliers intermediaries

third!party service providers and customers. $n essence supply chain management integrates

supply and demand management within and across companies. 'ore recently the loosely

coupled self!organi+ing network of businesses that cooperate to provide product and service

offerings has been called the xtended nterprise.

" supply chain as opposed to supply chain management is a set of organi+ations directly linked

by one or more of the upstream and downstream flows of products services finances and

information from a source to a customer. 'anaging a supply chain is ,supply chain management,

('ent+er et al. 2--.).

[/]

Supply chain management software includes tools or modules used to e)ecute supply chain

transactions manage supplier relationships and control associated business processes.

.

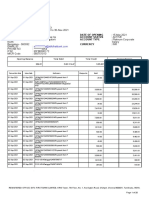

Graphics-1.1.a: Example of a Supply chain management module

1.2 Importance of SCM:

0rgani+ations increasingly find that they must rely on effective supply chains or networks to

compete in the global market and networked economy.

[.-]

$n #eter &rucker,s (.112) new

management paradigms this concept of business relationships e)tends beyond traditional

enterprise boundaries and seeks to organi+e entire business processes throughout a value chain of

multiple companies.

&uring the past decades globali+ation outsourcing and information technology have enabled

many organi+ations such as &ell and 3ewlett #ackard to successfully operate solid

collaborative supply networks in which each speciali+ed business partner focuses on only a few

key strategic activities (Scott .114). 5his inter!organi+ational supply network can be

acknowledged as a new form of organi+ation. 3owever with the complicated interactions among

the players the network structure fits neither (market( nor (hierarchy( categories (#owell .11-).

2

$t is not clear what kind of performance impacts different supply network structures could have

on firms and little is known about the coordination conditions and trade!offs that may e)ist

among the players. 6rom a systems perspective a comple) network structure can be decomposed

into individual component firms (7hang and &ilts 2--8). 5raditionally companies in a supply

network concentrate on the inputs and outputs of the processes with little concern for the

internal management working of other individual players. 5herefore the choice of an internal

management control structure is known to impact local firm performance ('int+berg .191).

$n the 2.st century changes in the business environment have contributed to the development of

supply chain networks. 6irst as an outcome of globali+ation and the proliferation of

multinational companies *oint ventures strategic alliances and business partnerships significant

success factors were identified complementing the earlier (:ust!$n!5ime( ;ean 'anufacturing

and "gile manufacturing practices.

[..]

Second technological changes particularly the dramatic

fall in information communication costs which are a significant component of transaction costs

have led to changes in coordination among the members of the supply chain network (%oase

.112).

'any researchers have recogni+ed these kinds of supply network structures as a new

organi+ation form using terms such as (<eiretsu( (=)tended =nterprise( (>irtual %orporation(

(?lobal #roduction @etwork( and (@e)t ?eneration 'anufacturing System(.

[.2]

$n general such

a structure can be defined as (a group of semi!independent organi+ations each with their

capabilities which collaborate in ever!changing constellations to serve one or more markets in

order to achieve some business goal specific to that collaboration( ("kkermans 2--.).

1.3 Functions of Supply Chain Management:

Supply chain management is a cross!function approach including in managing the movement of

raw materials into an organi+ation certain aspects of the internal processing of materials into

finished goods and the movement of finished goods out of the organi+ation and toward the end!

consumer. "s organi+ations strive to focus on core competencies and becoming more fle)ible

they reduce their ownership of raw materials sources and distribution channels. 5hese functions

are increasingly being outsourced to other entities that can perform the activities better or more

cost effectively. 5he effect is to increase the number of organi+ations involved in satisfying

customer demand while reducing management control of daily logistics operations. ;ess control

and more supply chain partners led to the creation of supply chain management concepts. 5he

purpose of supply chain management is to improve trust and collaboration among supply chain

partners thus improving inventory visibility and the velocity of inventory movement.

Several models have been proposed for understanding the activities required to manage material

movements across organi+ational and functional boundaries. S%0A is a supply chain

management model promoted by the Supply %hain %ouncil. "nother model is the S%' 'odel

proposed by the ?lobal Supply %hain 6orum (?S%6). Supply chain activities can be grouped

into strategic tactical and operational levels. 5he %S%'# has adopted 5he "merican

#roductivity B Cuality %enter ("#C%) #rocess %lassification 6ramework

S'

a high!level

industry!neutral enterprise process model that allows organi+ations to see their business

processes from a cross!industry viewpoint.

[1]

4

Strategic:

Strategic network optimi+ation including the number location and si+e of warehousing

distribution centers and facilities.

Strategic partnerships with suppliers distributors and customers creating

communication channels for critical information and operational improvements such as

cross docking direct shipping and third!party logistics.

#roduct life cycle management so that new and e)isting products can be optimally

integrated into the supply chain and capacity management activities.

Segmentation of products and customers to guide alignment of corporate ob*ectives with

manufacturing and distribution strategy.

$nformation technology chain operations.

Dhere!to!make and make!buy decisions.

"ligning overall organi+ational strategy with supply strategy.

$t is for long term and needs resource commitment.

Tactical level:

Sourcing contracts and other purchasing decisions.

#roduction decisions including contracting scheduling and planning process definition.

$nventory decisions including quantity location and quality of inventory.

5ransportation strategy including frequency routes and contracting.

Eenchmarking of all operations against competitors and implementation of best practices

throughout the enterprise.

'ilestone payments.

6ocus on customer demand and 3abits.

Operational level:

&aily production and distribution planning including all nodes in the supply chain.

#roduction scheduling for each manufacturing facility in the supply chain (minute by

minute).

&emand planning and forecasting coordinating the demand forecast of all customers and

sharing the forecast with all suppliers.

Sourcing planning including current inventory and forecast demand in collaboration

with all suppliers.

$nbound operations including transportation from suppliers and receiving inventory.

#roduction operations including the consumption of materials and flow of finished

goods.

0utbound operations including all fulfillment activities warehousing and transportation

to customers.

0rder promising accounting for all constraints in the supply chain including all

suppliers manufacturing facilities distribution centers and other customers.

8

6rom production level to supply level accounting all transit damage cases B arrange to

settlement at customer level by maintaining company loss through insurance company.

'anaging non!moving short!dated inventory and avoiding more products to go short!

dated.

1.4 ro!lems to !e addressed !y SCM:

Supply chain management must address the following problemsF

Distri!ution "et#or$ ConfigurationF number location and network missions of

suppliers production facilities distribution centers warehouses cross!docks and

customers.

Distri!ution StrategyF questions of operating control (centrali+ed decentrali+ed or

shared)G delivery scheme e.g. direct shipment pool point shipping cross docking direct

store delivery (&S&) closed loop shippingG mode of transportation e.g. motor carrier

including truckload ;ess than truckload (;5;) parcelG railroadG intermodal transport

including trailer on flatcar (506%) and container on flatcar (%06%)G ocean freightG

airfreightG replenishment strategy (e.g. pull push or hybrid)G and transportation control

(e.g. owner!operated private carrier common carrier contract carrier or third!party

logistics (4#;)).

%rade&'ffs in (ogistical )cti*itiesF 5he above activities must be well coordinated in

order to achieve the lowest total logistics cost. 5rade!offs may increase the total cost if

only one of the activities is optimi+ed. 6or e)ample full truckload (65;) rates are more

economical on a cost per pallet basis than ;5; shipments. $f however a full truckload of

a product is ordered to reduce transportation costs there will be an increase in inventory

holding costs which may increase total logistics costs. $t is therefore imperative to take a

systems approach when planning logistical activities. 5hese trade!offs are key to

developing the most efficient and effective ;ogistics and S%' strategy.

InformationF $ntegration of processes through the supply chain to share valuable

information including demand signals forecasts inventory transportation potential

collaboration etc.

In*entory ManagementF Cuantity and location of inventory including raw materials

work!in!process (D$#) and finished goods.

Cash&Flo#F "rranging the payment terms and methodologies for e)changing funds

across entities within the supply chain.

Supply chain e)ecution means managing and coordinating the movement of materials

information and funds across the supply chain. 5he flow is bi!directional. S%' applications

provide real!time analytical systems that manage the flow of product and information throughout

the enterprise supply chain network.

1.+ SCM Components:

H

Successful S%' requires a change from managing individual functions to integrating activities

into key supply chain processes. "n e)ample scenarioF the purchasing department places orders

as requirements become known. 5he marketing department responding to customer demand

communicates with several distributors and retailers as it attempts to determine ways to satisfy

this demand. $nformation shared between supply chain partners can only be fully leveraged

through process integration.

Supply chain business process integration involves collaborative work between buyers and

suppliers *oint product development common systems and shared information. "ccording to

;ambert and %ooper (2---) operating an integrated supply chain requires a continuous

information flow. 3owever in many companies management has reached the conclusion that

optimi+ing the product flows cannot be accomplished without implementing a process approach

to the business. 5he key supply chain processes stated by ;ambert (2--8)

[.8]

areF

%ustomer relationship management

%ustomer service management

&emand management style

0rder fulfillment

'anufacturing flow management

Supplier relationship management

#roduct development and commerciali+ation

Aeturns management

'uch has been written about demand management. Eest!in!%lass companies have similar

characteristics which include the followingF a) $nternal and e)ternal collaboration b) ;ead time

reduction initiatives c) 5ighter feedback from customer and market demand d) %ustomer level

forecasting

0ne could suggest other key critical supply business processes which combine these processes

stated by ;ambert such asF

a. %ustomer service management

b. #rocurement

c. #roduct development and commerciali+ation

d. 'anufacturing flow managementIsupport

e. #hysical distribution

f. 0utsourcingIpartnerships

g. #erformance measurement

h. Darehousing management

a) %ustomer service management process

%ustomer Aelationship 'anagement concerns the relationship between the organi+ation and its

customers. %ustomer service is the source of customer information. $t also provides the customer

with real!time information on scheduling and product availability through interfaces with the

/

company,s production and distribution operations. Successful organi+ations use the following

steps to build customer relationshipsF

determine mutually satisfying goals for organi+ation and customers

establish and maintain customer rapport

produce positive feelings in the organi+ation and the customers

b) #rocurement process

Strategic plans are drawn up with suppliers to support the manufacturing flow management

process and the development of new products. $n firms where operations e)tend globally

sourcing should be managed on a global basis. 5he desired outcome is a win!win relationship

where both parties benefit and a reduction in time required for the design cycle and product

development. "lso the purchasing function develops rapid communication systems such as

electronic data interchange (=&$) and $nternet linkage to convey possible requirements more

rapidly. "ctivities related to obtaining products and materials from outside suppliers involve

resource planning supply sourcing negotiation order placement inbound transportation

storage handling and quality assurance many of which include the responsibility to coordinate

with suppliers on matters of scheduling supply continuity hedging and research into new

sources or programs.

c) #roduct development and commerciali+ation

3ere customers and suppliers must be integrated into the product development process in order

to reduce time to market. "s product life cycles shorten the appropriate products must be

developed and successfully launched with ever shorter time!schedules to remain competitive.

"ccording to ;ambert and %ooper (2---) managers of the product development and

commerciali+ation process mustF

.. coordinate with customer relationship management to identify customer!articulated

needsG

2. select materials and suppliers in con*unction with procurement and

4. develop production technology in manufacturing flow to manufacture and integrate into

the best supply chain flow for the productImarket combination.

d) 'anufacturing flow management process

5he manufacturing process produces and supplies products to the distribution channels based on

past forecasts. 'anufacturing processes must be fle)ible to respond to market changes and must

accommodate mass customi+ation. 0rders are processes operating on a *ust!in!time (:$5) basis in

minimum lot si+es. "lso changes in the manufacturing flow process lead to shorter cycle times

meaning improved responsiveness and efficiency in meeting customer demand. "ctivities related

to planning scheduling and supporting manufacturing operations such as work!in!process

storage handling transportation and time phasing of components inventory at manufacturing

9

sites and ma)imum fle)ibility in the coordination of geographic and final assemblies

postponement of physical distribution operations.

e) #hysical distribution

5his concerns movement of a finished productIservice to customers. $n physical distribution the

customer is the final destination of a marketing channel and the availability of the

productIservice is a vital part of each channel participant,s marketing effort. $t is also through the

physical distribution process that the time and space of customer service become an integral part

of marketing thus it links a marketing channel with its customers (e.g. links manufacturers

wholesalers retailers).

f) 0utsourcingIpartnerships

5his is not *ust outsourcing the procurement of materials and components but also outsourcing

of services that traditionally have been provided in!house. 5he logic of this trend is that the

company will increasingly focus on those activities in the value chain where it has a distinctive

advantage and outsource everything else. 5his movement has been particularly evident in

logistics where the provision of transport warehousing and inventory control is increasingly

subcontracted to specialists or logistics partners. "lso managing and controlling this network of

partners and suppliers requires a blend of both central and local involvement. 3ence strategic

decisions need to be taken centrally with the monitoring and control of supplier performance and

day!to!day liaison with logistics partners being best managed at a local level.

g) #erformance measurement

=)perts found a strong relationship from the largest arcs of supplier and customer integration to

market share and profitability. 5aking advantage of supplier capabilities and emphasi+ing a long!

term supply chain perspective in customer relationships can both be correlated with firm

performance. "s logistics competency becomes a more critical factor in creating and maintaining

competitive advantage logistics measurement becomes increasingly important because the

difference between profitable and unprofitable operations becomes more narrow. ".5. <earney

%onsultants (.12H) noted that firms engaging in comprehensive performance measurement

reali+ed improvements in overall productivity. "ccording to e)perts internal measures are

generally collected and analy+ed by the firm including

.. %ost

2. %ustomer Service

4. #roductivity measures

8. "sset measurement and

H. Cuality.

=)ternal performance measurement is e)amined through customer perception measures and

(best practice( benchmarking and includes .) customer perception measurement and 2) best

practice benchmarking.

2

h) Darehousing management

"s a case of reducing company cost B e)penses warehousing management is carrying the

valuable role against operations. $n case of perfect storing B office with all convenient facilities

in company level reducing manpower cost dispatching authority with on time delivery loading

B unloading facilities with proper area area for service station stock management system etc.

1., Define (ogistics Management:

!ogistics is the process of strategically managing the procurement" movement and storage of materials" parts

and finished inventory (and the related information flo#s) through the organi$ation and its marketing channels

in such a #ay that current and future profitability are maximi$ed through the cost%effective fulfilment of orders

;ogistics management is the governance of supply chain functions. ;ogistics management

activities typically include inbound and outbound transportation management fleet management

warehousing materials handling order fulfillment logistics network design inventory

management supplyIdemand planning and management of third party logistics services

providers. 5o varying degrees the logistics function also includes customer service sourcing and

procurement production planning and scheduling packaging and assembly. ;ogistics

management is part of all levels of planning and e)ecution !! strategic operational and tactical. $t

is an integrating function which coordinates all logistics activities as well as integrates logistics

activities with other functions including marketing sales manufacturing finance and

information technology.

../.. !ogistics &ersus Supply 'hain (anagement

De describe below four unique perspectives on the relationship between logistics and S%'.

5hese four perspectives areF traditionalist relabelling unionist inter!sectionist

6our unique perspectives Jdefined

5raditionalistF

S%' is one small part of logistics.

1

(ogistics

SCM

=ducators can easily accomplish this by adding a S%' lecture to the logistics management

course or by inserting a S%' chapter into a logistics te)tbook. S%' analysts would broaden the

scope of logistics analysis

AelabellingF

5he relabelling perspective simply renames logisticsG what was logistics is now S%'.

'ore recently Simchi!;evi et al. (2---) confessed that they KKdo not distinguish between

logistics and supply chain managementLL.

Aelabelling narrows the scope of S%' since S%' equals logistics.

MnionistF

5his perspective treats logistics as a part of S%'G S%' completely subsumes logistics.

.-

(ogistics

SCM

SCM

(ogistics

SCM

Stock B ;ambert (2--.) suggest KKsupply chain management is the management of eight key

business processesF(.) customer relationship management (2) customer service management (4)

demand management (8) order fulfillment(H)manufacturing flow management (/)procurement

(9) product development and commerciali+ation and (2) returnsLL.

5hese processes subsume or include much of logistics purchasing marketing and operations

management.

$nter!sectionistF

5he intersection concept suggests S%' is not the union of logistics marketing operations

management purchasing and other functional areas.

5he supply chain manager would be involved in the negotiations but not the purchase order

transmission. "t the intersection S%' co!ordinates crossfunctional efforts across multiple firms.

S%' is strategic not tactical. counterparts.

Summari+e in to a conclusions

$mplications for ;ogistics =ducators

AelabellersF

under a new nameF KKS%'LL.

MnionistsF

remove logistics management cover the essentials of logistics

$nter!sectionistsF

champion an interdisciplinary S%' ma*or

5raditionalistsF

add a S%' lecture to the logistics management course.

..

(ogistics

1.- Define .ertical Integration:

$n microeconomics and management the term *ertical integration describes a style of

management control. >ertically integrated companies in a supply chain are united through a

common owner. Msually each member of the supply chain produces a different product or

(market!specific) service and the products combine to satisfy a common need. $t is contrasted

with hori+ontal integration. >ertical integration has also described management styles that bring

large portions of the supply chain not only under a common ownership but also into one

corporation (as in the .12-s when the 6ord Aiver Aouge %omple) began making much of its

own steel rather than buy it from suppliers).

>ertical integration is one method of avoiding the hold!up problem. " monopoly produced

through vertical integration is called a vertical monopoly.

@ineteenth!century steel tycoon "ndrew %arnegie,s e)ample in the use of vertical integration

[.]

led others to use the system to promote financial growth and efficiency in their businesses.

.2

).*.a(+ diagram illustrating vertical integration and contrasting it #ith hori$ontal integration)

1.7.1 Types:

>ertical integration is the degree to which a firm owns its upstream suppliers and its downstream

buyers. %ontrary to hori+ontal integration which is a consolidation of many firms that handle the

same part of the production process vertical integration is typified by one firm engaged in

different parts of production (e.g. growing raw materials manufacturing transporting

marketing andIor retailing).

5here are three varietiesF backward (upstream) vertical integration forward (downstream)

vertical integration and balanced (both upstream and downstream) vertical integration.

" company e)hibits !ac$#ard *ertical integration when it controls subsidiaries that

produce some of the inputs used in the production of its products. 6or e)ample an

automobile company may own a tire company a glass company and a metal company.

%ontrol of these three subsidiaries is intended to create a stable supply of inputs and

ensure a consistent quality in their final product. $t was the main business approach of

6ord and other car companies in the .12-s who sought to minimi+e costs by integrating

the production of cars and car parts as e)emplified in the 6ord Aiver Aouge %omple).

.4

" company tends toward for#ard *ertical integration when it controls distribution

centers and retailers where its products are sold.

Examples:

0ne of the earliest largest and most famous e)amples of vertical integration was the %arnegie

Steel company. 5he company controlled not only the mills where the steel was made but also the

mines where the iron ore was e)tracted the coal mines that supplied the coal the ships that

transported the iron ore and the railroads that transported the coal to the factory the coke ovens

where the coal was cooked etc. 5he company also focused heavily on developing talent

internally from the bottom up rather than importing it from other companies.

[2]

;ater on

%arnegie even established an institute of higher learning to teach the steel processes to the ne)t

generation.

/"D

.8

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Accounting 25th Edition Warren Solutions Manual 1Документ36 страницAccounting 25th Edition Warren Solutions Manual 1edwardharrisontqdrjcogix100% (21)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 2021 BEA1101 Study Unit 5 SolutionsДокумент13 страниц2021 BEA1101 Study Unit 5 SolutionsKhanyisileОценок пока нет

- A R RoqueДокумент73 страницыA R RoqueTwish BarriosОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Chapter 16 ClassroomДокумент31 страницаChapter 16 Classroompauline02039567% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- AccountingДокумент20 страницAccountingNehal NabilОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Answers: Job Costing: Journal-Entry EmphasisДокумент7 страницAnswers: Job Costing: Journal-Entry EmphasisJONATHAN LANCE JOBLEОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Sme BookДокумент397 страницSme BookVivek Godgift J0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- ERP Implementation at NestleДокумент5 страницERP Implementation at NestleLes Cano50% (2)

- Statement of Account: Date of Opening Account Status Account Type Currency Mr. R NishanthДокумент20 страницStatement of Account: Date of Opening Account Status Account Type Currency Mr. R NishanthNish NíShänthОценок пока нет

- California Power Plant: Analysis of Transportation Option For Coal MaterialДокумент9 страницCalifornia Power Plant: Analysis of Transportation Option For Coal Materialadelina zianОценок пока нет

- Deferred Tax Lecture SlidesДокумент38 страницDeferred Tax Lecture Slidesmd salehinОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- SCM 2015 Understanding SCM RevisedДокумент40 страницSCM 2015 Understanding SCM RevisedsumeetpatnaikОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Fybcom Second Open Merit List 2022 23Документ5 страницFybcom Second Open Merit List 2022 23Gamer nestОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- MA1 - De thi giua ky - HK2 - 21-22 - send-đã chuyển đổiДокумент4 страницыMA1 - De thi giua ky - HK2 - 21-22 - send-đã chuyển đổiThu ThanhОценок пока нет

- Teresita Buenaflor Shoes Worksheet 1 RegineДокумент24 страницыTeresita Buenaflor Shoes Worksheet 1 RegineBaby Babe100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- CASHДокумент28 страницCASHJereme PascuaОценок пока нет

- AA015 Chapter 3 Q1Документ13 страницAA015 Chapter 3 Q1norismah isaОценок пока нет

- Supply Chain Synchronization Lessons From Hyundai Motor CompanyДокумент14 страницSupply Chain Synchronization Lessons From Hyundai Motor CompanyIshan S. GosarОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- CH 23 Statementofcashflowssolutionsinteraccounting16thedition-171116132124Документ71 страницаCH 23 Statementofcashflowssolutionsinteraccounting16thedition-171116132124Lina SakhiОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Accounting TransactionsДокумент28 страницAccounting TransactionsPaolo100% (1)

- Internet #4Документ13 страницInternet #4Suresh SubramaniОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Supply Chain ManagementДокумент8 страницSupply Chain Managementaryan_hrsОценок пока нет

- FA2 Mock Exam 2 (Tutorial-8)Документ10 страницFA2 Mock Exam 2 (Tutorial-8)Chit SnowОценок пока нет

- Kunci Jawaban Jurnal PT JAYATAMA P3Документ14 страницKunci Jawaban Jurnal PT JAYATAMA P3sepriyadiОценок пока нет

- ACTBFAR Exercise Set #1 - Ex 4 - PS SpacingДокумент3 страницыACTBFAR Exercise Set #1 - Ex 4 - PS SpacingNikko Bowie PascualОценок пока нет

- Soal Uts Lab Ak. KeuanganДокумент3 страницыSoal Uts Lab Ak. KeuanganAltaf HauzanОценок пока нет

- Personal Assignment Week 4-GovernДокумент6 страницPersonal Assignment Week 4-GoverndivaОценок пока нет

- Umer Solution 2Документ21 страницаUmer Solution 2shoaiba1Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Problem 4Документ2 страницыProblem 4Ayra PelenioОценок пока нет

- CEP Course On Supply Chain ManagementДокумент5 страницCEP Course On Supply Chain ManagementdebkinkarОценок пока нет