Академический Документы

Профессиональный Документы

Культура Документы

B 1700

Загружено:

dio39saiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

B 1700

Загружено:

dio39saiАвторское право:

Доступные форматы

Bulletin 1700

150 & 170 SERIES

CAST

IRON

MOTORS

NEMA 182T-449T Frame

Premium Features For Extra Durability

LEESONs Inverter Rated Insulation System

(IRIS

) provides superior motor protection against

voltage spikes and is standard at no extra cost on

our 150 and 170 Series cast iron frame motors.

LEESON motors comply with EPACT, the U.S.

Department of Energy efficiency standards. The stan-

dards, which became effective in October, 1997, dictate

that most types of base-mounted three phase motors, 1

through 200 HP, meet minimum full load efficiencies.

Heavy-duty cast iron frame

and endbells for maximum

durability and structural rigidity.

Stainless steel full fact nameplate

with information on motor efficiency and

power factor. Includes wiring diagram,

bearing sizes, and motor weight.

Unique serial number.

Small size fan reduces noise

and enhances efficiency. Non-

sparking. Fan keyed to shaft.

Steel fan cover for optimum

strength. Cast iron cover available

for severe service.

12-Lead Delta windings (254T frame and

larger, 150 and 170 Series) for across-the-

line or wye delta starts. Permanently marked

leads with lugs for easy connection.

Normally-closed thermostat standard

on WATTSAVER

designs.

Oversized cast iron conduit box is

gasketed and may be rotated in 90

increments. NPT threaded entrance.

Meets latest NEC requirements.

Cast iron mounting feet. Precision-

machined for accurate alignment. Dual

mounting provisions for field replacement

flexibility. Six mounting holes on all 184,

215, 256, 286, 326, 365, 405, 445, 447

and 449T frame motors (except drip-

proof 326, 365 and 405T frames).

Locked shaft-end bearing (254T frame and

larger) makes motor suitable for all-angle mount-

ing. Bearing cap protects against entry of grease

into the motor.

Cast iron endplates for maximum rigidity

and long bearing life.

One-way, corrosion resistant condensate

drains. (TEFC models) release condensation

and moisture.

Modification to meet

IEEE 841 standard.

Factory modification

through LEESONs

ModSquad

TM

quick-ship

service. Features include

addition of shaft seals,

two-part epoxy finish and

motor test card.

1.15 Service Factor provides extra margin of power.

Class F insulation system with Class B or lower

temperature rise. Most suitable for 50 Hz operation at

1.0 service factor. Contact factory for details.

100% copper winding double-dipped and baked.

Stator press-fitted and pinned to housing. Inverter

rated insulation system.

High torques for hard-to-start loads.

Torques exceed NEMA performance

standards.

Energy performance verified by an

independent testing laboratory.

Neoprene shaft slinger (TEFC models)

protects bearings by repelling moisture and

other contaminants. Internal protection

against rust and corrosion.

Lubrication fittings on each end of motor

(254T frame and larger). Shell Dolium R

lubricant with -20F to +350F temperature

range; single shield, oversized bearings.

KITS AND ACCESSORIES

A variety of bolt-on kits and accessories are available

for use with LEESON 150 and 170 Series cast iron

motors.

BrakeKit

Includes components needed to

convert TEFC motor to brakemotor: Stearns AC

brake, replacement cast iron fan cover, shaft

extension, fan, and hardware.

Severe Duty Conversion Kit Cast iron fan

cover converts standard cast iron motor to

chemical service/severe duty motor. Full

conversion to meet IEEE 841 available as

modification through Mod-Squad

.

NEMA C Face Kit Includes all parts needed

to convert standard rigid base cast iron motor to

C face with base.

NEMA D Flange Kit Includes all parts needed

to convert standard rigid base cast iron motor to

D flange with base.

Motor Bases Heavy-gauge steel, adjustable

motor bases simplify the tensioning, maintenance

and replacement of belts. Transition bases allow

NEMA T frame motors to replace NEMA U frame

motors. Heavy-duty steel construction.

BrakeKit

Severe Duty

Conversion Kit

NEMA C Face and

D Flange Kits

150 Series

General Purpose

Inverter-Rated Motors

(5 through 200 HP)

The original LEESON heavyweights, available in

drip-proof and TEFC enclosures. Cast iron frame,

endplates and conduit box. EPACT compliant.

Inverter-rated for continuous duty with constant

torque from 20 through 90 Hz and 5 through 90 Hz

(182T - 326T), using optional Blower Kit on TEFC

motors. Inverter protected against voltage spikes by

LEESONs exclusive IRIS

insulation system, at no

extra cost. Also stocked in NEMA C face designs,

with and without rigid base through 75 HP, including

TS designs for close coupling of pumps. NEMA C

face, D flange, Cast Iron Fan Cover and BrakeKits

TM

are available. Factory modification to IEEE 841

standards offered on a quick-ship basis through

LEESONs ModSquad

TM

program.

CSA recognized and energy

efficiency verified. Two-

year warranty.

170 Series

WATTSAVER

Inverter-Duty

Premium Efficiency Motors

(3 through 100 HP)

Premium efficiency, inverter-duty motors offered in

both drip-proof and TEFC enclosures. Mechanically

identical to the 150 Series. Designed for inverter use

with continuous duty at constant torque from 15

through 90 Hz or better and full torque at zero speed

with vector drive input and optional Blower Kit on

182T 326T frame TEFC motors. Inverter protected

against voltage spikes by LEESONs exclusive IRIS

insulation system. Efficiencies meet or exceed EPACT

and most utility rebate programs. Also stocked in

NEMA C face designs, with and without rigid base

through 75 HP, including TS designs for close

coupling of pumps. NEMA C face, D flange, Cast Iron

Fan Cover and BrakeKits

TM

are available. Factory

modification to IEEE 841 standards offered on a

quick-ship basis through LEESONs ModSquad

TM

program. CSA

recognized and energy

efficiency verified.

Three-year warranty.

The Strength of Cast Iron

Plus Low First-Cost

Optional constant-

velocity cooling

fan can befield or

factory installed.

CAST

IRON

TOUGH!

When it comes to protecting the motor in a variable frequency drive (inverter)

application, look to LEESON for the answer. Our premium efficiency,

inverter-duty WATTSAVER

motors are doubly capable.

IRIS

Insulation System

WATTSAVER

motors use second-

generation, 200C magnet wire and

an extra-heavy varnish systemas

part of our exclusive Inverter-Rated

Insulation System (IRIS

), standard at no

extra cost. This total insulation systemincludes

specially-formed phase insulation, cushioned and

sleeved connections (from the leads all the way into

the turns), and deep-penetrating, non-hygroscopic,

high-temperature varnish.

More Protection

with WATTSAVER

In addition, the premium efficiency design of the

WATTSAVER

provides more copper and steelan

extra margin of operating safety to protect against

excessive heating. As an additional assurance, the

premium efficiency ratings of WATTSAVER

motors have

been independently verified to IEEE 112B test standards.

LEESON Inverters & Accessories

Speedmaster

Inverters offer premium

performance featuresyet are some of the

industrys most compact and cost-

effective units. With big drive features

and plain-English programming, LEESON

Micro Series Drives (shown at lower left)

are an easy choice when it comes to

selecting an inverter for industrial

applications.

Inverter accessory items available through

LEESON include Encoder Kits (upper left),

Blower Fan Kits (upper right), and Remote

Keypad (lower right).

For full details on any of the Inverters,

Accessories or Kits, please see Stock

Catalog 1050.

Inverter-Duty, Premium Efficiency

WATTSAVER

Motors

Drip-Proof TEFC

150 Series 170 Series 150 Series 170 Series

Mechanical Construction

Cast iron frame and endplates G G G G

Cast iron conduit box G G G G

Convertible to F2 mounting G G G G

Pressed steel fan guard G G G G

Lifting eyebolt G G G G

Dual mounting provision (see photo on inside spread for details) G G G G

Electrical Performance

1.15 Service Factor G G G G

Exceeds NEMA Design B torque standards G G G G

Insulation System and Windings

Inverter Rated Insulation System (IRIS

) G G G G

100% Copper windings G G G G

Double-dipped and baked G G G G

Class F insulation G G G G

Voltage and Leads

Permanently marked leads G G G G

Nine (9) leads - NEMA 213T and smaller G G G G

Twelve (12) leads - NEMA 254T - 405T Wye Delta G G G G

Six (6) leads - NEMA 444T - 447T Wye Delta G G G G

Conduit Box

Cast iron box G G G G

Rotates in 90 increments G G G G

NPT threaded hole G G G G

Operating Efficiency

Energy Efficiency Verification by Canadian Standards Association G G G G

Full load efficiency & power factor on nameplate G G G G

Service Factor

1.15 Service Factor at 60 Hz G G G G

Bearings

Double-shielded bearings-NEMA 215T and smaller G G G G

Single-shielded bearings-NEMA 254T and larger G G G G

Shell Dolium R lubricant, -40F to +320F G G G G

Moisture Resistance (TEFC Only)

One-way condensate drains G G

Neoprene shaft slinger G G

Neoprene gland between conduit box and frame G G G G

Fully gasketed conduit box G G G G

Internal components protected against corrosion G G G G

Paint Finish

Blue paint G G

Green epoxy paint G G

Nameplate

Stainless steel G G G G

Unique serial number G G G G

Connection diagram G G G G

Agency Listings

Canadian Standards Association certification LR62104 G G G G

Canadian Standards Association #EEV78720-1 Energy Efficiency Verification G G G G

Warranty

Two-year, materials and workmanship G G

Three-year, materials and workmanship G G

Product Features

BULLETIN 1700 1/00

Specifications subject to change without notice. PRINTED IN U.S.A. LEESON ELECTRIC, 2000

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Dell Compellent Sc4020 Deploy GuideДокумент184 страницыDell Compellent Sc4020 Deploy Guidetar_py100% (1)

- THE DOSE, Issue 1 (Tokyo)Документ142 страницыTHE DOSE, Issue 1 (Tokyo)Damage85% (20)

- Apg-Iso 19011 - 2015 PDFДокумент3 страницыApg-Iso 19011 - 2015 PDFFunda SecginОценок пока нет

- IEC 61109 Composite InsulatorДокумент87 страницIEC 61109 Composite Insulatordio39sai100% (1)

- Kathy Davis - Dancing Tango - Passionate Encounters in A Globalizing World-New York University Press (2015)Документ236 страницKathy Davis - Dancing Tango - Passionate Encounters in A Globalizing World-New York University Press (2015)Csongor KicsiОценок пока нет

- CS709 HandoutsДокумент117 страницCS709 HandoutsalexОценок пока нет

- EN 3P LIQUID LEVEL CONTROL RELAY MANUAL English PDFДокумент5 страницEN 3P LIQUID LEVEL CONTROL RELAY MANUAL English PDFdio39saiОценок пока нет

- Jakarta's Silent KillerДокумент20 страницJakarta's Silent KillerFahmi LutfiОценок пока нет

- APG-Audit Planning PDFДокумент4 страницыAPG-Audit Planning PDFdio39saiОценок пока нет

- APG ValueVsConsultancy2015 PDFДокумент3 страницыAPG ValueVsConsultancy2015 PDFdio39saiОценок пока нет

- How To Deal With ConsultantsДокумент2 страницыHow To Deal With Consultantsfl_in1Оценок пока нет

- APG ReviewNonconformity2015 PDFДокумент4 страницыAPG ReviewNonconformity2015 PDFdio39saiОценок пока нет

- APG DemonstrateConformity2015Документ3 страницыAPG DemonstrateConformity2015dio39saiОценок пока нет

- APG DocumentNonconformity2015 PDFДокумент4 страницыAPG DocumentNonconformity2015 PDFdio39saiОценок пока нет

- Audit Evidence CollectionДокумент2 страницыAudit Evidence Collectionfl_in1Оценок пока нет

- APG AuditTrail2015 PDFДокумент3 страницыAPG AuditTrail2015 PDFAlberto J SorianoОценок пока нет

- ISO 9001 Auditing Practices Group: Aligning The QMS With The Achievement of Organizational and Business SuccessДокумент32 страницыISO 9001 Auditing Practices Group: Aligning The QMS With The Achievement of Organizational and Business SuccessSelvaraj SimiyonОценок пока нет

- APG AuditReports2015 PDFДокумент5 страницAPG AuditReports2015 PDFAlberto J SorianoОценок пока нет

- APG Checklist2015 PDFДокумент3 страницыAPG Checklist2015 PDFdio39saiОценок пока нет

- EMS APG Life Cycle PerspectiveДокумент4 страницыEMS APG Life Cycle Perspectivedio39saiОценок пока нет

- EMS APG ImprovementДокумент3 страницыEMS APG Improvementdio39saiОценок пока нет

- EMS APG Audit and Certification of The Reliability of Environmental InformationДокумент4 страницыEMS APG Audit and Certification of The Reliability of Environmental Informationdio39saiОценок пока нет

- EMS APG Risks and OpportunitiesДокумент3 страницыEMS APG Risks and Opportunitiesdio39saiОценок пока нет

- EMS APG Auditing External ProvidersДокумент4 страницыEMS APG Auditing External Providersdio39saiОценок пока нет

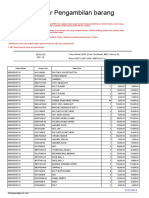

- My - Picklist mt15 Headlamp CompleteДокумент3 страницыMy - Picklist mt15 Headlamp Completedio39saiОценок пока нет

- MTN250 MT-25 HeadlightДокумент2 страницыMTN250 MT-25 Headlightdio39sai100% (1)

- OHSAS Project Group Guidance for Migrating to ISO 45001Документ11 страницOHSAS Project Group Guidance for Migrating to ISO 45001Collen TsvangirayiОценок пока нет

- EN 3P LIQUID LEVEL CONTROL RELAY MANUAL English PDFДокумент5 страницEN 3P LIQUID LEVEL CONTROL RELAY MANUAL English PDFdio39saiОценок пока нет

- MTN250 MT-25 HeadlightДокумент2 страницыMTN250 MT-25 Headlightdio39sai100% (1)

- Jakarta's Silent KillerДокумент20 страницJakarta's Silent KillerFahmi LutfiОценок пока нет

- Control Liquid Levels with EN-3P RelayДокумент5 страницControl Liquid Levels with EN-3P Relaydio39saiОценок пока нет

- Oiml D10Документ11 страницOiml D10WilljetОценок пока нет

- Pub 100427Документ5 страницPub 100427Engr Nabeel AhmadОценок пока нет

- USDA Guide To CanningДокумент7 страницUSDA Guide To CanningWindage and Elevation0% (1)

- Qad Quick StartДокумент534 страницыQad Quick StartMahadev Subramani100% (1)

- Ovr IbДокумент27 страницOvr IbAriel CaresОценок пока нет

- Pfr140 User ManualДокумент4 страницыPfr140 User ManualOanh NguyenОценок пока нет

- DOE Tank Safety Workshop Presentation on Hydrogen Tank TestingДокумент36 страницDOE Tank Safety Workshop Presentation on Hydrogen Tank TestingAlex AbakumovОценок пока нет

- U2 All That You Can't Leave BehindДокумент82 страницыU2 All That You Can't Leave BehindFranck UrsiniОценок пока нет

- Statistical Decision AnalysisДокумент3 страницыStatistical Decision AnalysisTewfic SeidОценок пока нет

- Unit 14 Ergonomics Design: AND ProductДокумент24 страницыUnit 14 Ergonomics Design: AND ProductRämêşh KątúřiОценок пока нет

- Marshall Stability Test AnalysisДокумент5 страницMarshall Stability Test AnalysisZick Zickry50% (2)

- Pemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchДокумент16 страницPemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchAri HendriawanОценок пока нет

- Photosynthesis Lab ReportДокумент7 страницPhotosynthesis Lab ReportTishaОценок пока нет

- Learning Activity Sheet: 3 Quarter Week 1 Mathematics 2Документ8 страницLearning Activity Sheet: 3 Quarter Week 1 Mathematics 2Dom MartinezОценок пока нет

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewДокумент8 страницIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARAОценок пока нет

- 2018 NAMCYA CHILDREN'S RONDALLA ENSEMBLE GuidelinesДокумент3 страницы2018 NAMCYA CHILDREN'S RONDALLA ENSEMBLE GuidelinesJohn Cedrick JagapeОценок пока нет

- Iphoneos 31Документ159 страницIphoneos 31Ivan VeBoОценок пока нет

- Mrs. Universe PH - Empowering Women, Inspiring ChildrenДокумент2 страницыMrs. Universe PH - Empowering Women, Inspiring ChildrenKate PestanasОценок пока нет

- 3d Control Sphere Edge and Face StudyДокумент4 страницы3d Control Sphere Edge and Face Studydjbroussard100% (2)

- What's Wrong With American Taiwan Policy: Andrew J. NathanДокумент14 страницWhat's Wrong With American Taiwan Policy: Andrew J. NathanWu GuifengОценок пока нет

- Reading and Writing Q1 - M13Документ13 страницReading and Writing Q1 - M13Joshua Lander Soquita Cadayona100% (1)

- Emergency Management of AnaphylaxisДокумент1 страницаEmergency Management of AnaphylaxisEugene SandhuОценок пока нет

- 2021 JHS INSET Template For Modular/Online Learning: Curriculum MapДокумент15 страниц2021 JHS INSET Template For Modular/Online Learning: Curriculum MapDremie WorksОценок пока нет

- Seminar Course Report ON Food SafetyДокумент25 страницSeminar Course Report ON Food SafetyYanОценок пока нет

- Staffing Process and Job AnalysisДокумент8 страницStaffing Process and Job AnalysisRuben Rosendal De Asis100% (1)

- Steps To Christ AW November 2016 Page Spreaad PDFДокумент2 страницыSteps To Christ AW November 2016 Page Spreaad PDFHampson MalekanoОценок пока нет

- Lab StoryДокумент21 страницаLab StoryAbdul QadirОценок пока нет