Академический Документы

Профессиональный Документы

Культура Документы

Notes On A Work 1

Загружено:

yogimgurtОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Notes On A Work 1

Загружено:

yogimgurtАвторское право:

Доступные форматы

PDF Cover Page

Engineering and Intuition Serving the Soul of Music Perkins Electro-Acoustic Research Lab, Inc.

86008, 2106 33 Ave. SW, Calgary, AB; CAN T2T 1Z6

Ph: +. 1. 403. 244. 4434 Fx: +. 1. 403. 245. 4456

Web: http: // www. pearl - hifi . com

E-mail: custserv@pearl - hifi . com

Inc.

Please note that the links in the PEARL logotype above are live

and can be used to direct your web browser to our site or to

open an e-mail message window addressed to ourselves.

To view our item listings on eBay, click here.

To see the feedback we have left for our customers, click here.

This document has been prepared as a public service . Any and all trademarks

and logotypes used herein are the property of their owners.

It is our intent to provide this document in accordance with the stipulations with

respect to fair use as delineated in Copyrights - Chapter 1: Subject Matter and

Scope of Copyright; Sec. 107. Limitations on exclusive rights: Fair Use.

Public access to copy of this document is provided on the website of Cornell Law School

at http://www4.law.cornell.edu/uscode/17/107.html and is here reproduced below:

Sec. 107. - Limitations on exclusive rights: Fair Use

Notwithstanding the provisions of sections 106 and 106A, the fair use of a copyrighted work, includ-

ing such use by reproduction in copies or phono records or by any other means specied by that section,

for purposes such as criticism, comment, news reporting, teaching (including multiple copies for class-

room use), scholarship, or research, is not an infringement of copyright. In determining whether the use

made of a work in any particular case is a fair use the factors to be considered shall include:

1 - the purpose and character of the use, including whether such use is of a

commercial nature or is for nonprot educational purposes;

2 - the nature of the copyrighted work;

3 - the amount and substantiality of the portion used in relation to the copy-

righted work as a whole; and

4 - the effect of the use upon the potential market for or value of the copy-

righted work.

The fact that a work is unpublished shall not itself bar a nding of fair use if such nding is made

upon consideration of all the above factors

Verso Filler Page

AN 23.1.1 - Page 1 ! !

I

T SEEMS TO ME that somewhere along the way

almost everyone who considers himself an

audiophile has dreamed of owning fabulous-sound-

ing, high-power amplication. Unfortunately the

retail cost of such amps is so high that only a very

few people are ever able to realize such aspirations.

As with anything worth owning, the cost to design

and build good electronics is unavoidably high. Add

to that the prot margin that a retailer must secure

in order to make his business worthwhile and the

cost of great amps is in the vicinity of a decent car or

a down payment on a house.

During the 1950s and the early 60s there were all

kinds of kits available to the home builder and

although none of them was particularly high pow-

ered by todays standards, a few were then consid-

ered to be monsters. They were eagerly purchased,

constructed and enjoyed by the literal thousand.

How many Dynaco Stereo 70s are out there, giving

pleasure to this day?

With the demise of the tube in mainstream

audio during the late 60s, the rise of the transistor

and the onslaught of i nexpensi vely produced,

aggressively marketed and heavily hyped J apanese

equipment, the needs of the hobbyist were somehow

forgotten. Marketi ng became the name of the

game well, you know the rest.

The fact that many capable people would much

prefer to build a thing with their own hands than

buy it at retail seems to have been obscured almost

to the point of obliteration by self-interested manu-

facturers and their wallet-hovering marketeers.

The high-end audio-market has matured to a

state where superb products are sold for enormous

sums but not a single high-end kit is to be found.

I n spite of the considerable cost of the parts

required to build it, I believe there is a real market

for an honest-to-God, high-power amplier kit. My

plan is to make available all of the unique and

difcult-to-source parts required, such as the trans-

former set, painted and silk-screened chassis, pc-

boards, power supply caps, tubes, I so-sockets, I so-

mounts for the output tubes, etc. The sourcing of the

more usual parts such as resistors and capacitors

will be left to the individual builder. To make life as

easy as possible we will supply pre-printed order

forms made out to certain suppliers such as Digi-

Key, Sonic Frontiers and others so that all that is

required to get the common parts is to send the form

to the supplier along with the necessary funds.

I would like to form an SC280 Builders Club and

publish a newsletter every so often containing infor-

mation, tips, mods and different circuit ideas. I fully

expect that some of these kits will be bought by peo-

ple with design ideas quite different from mine, it

should be truly interesting to see what other people

come up with. With enough people building these

amps and tinkering away at them, it should be pos-

sible to offer a kit and associated circuitry that is

simply the best available.

Having invested several years work in the devel-

opment of the circuitry presented in this Audio

Note, I think the current design is a well-balanced

approach to the many inter-related problems such

an amplier presents. The power supplies in partic-

ular are well tried and sonically proven not only by

myself, but by other designers who arrived at the

same design conclusions independently and in a

couple of cases, several years before I did.

This effort has received input from many people

and is by no means solely my work. The part for

which I am responsible is the way in which all of the

various ideas have been assembled, the electrical lay-

out and the mechanical, thermal and aesthetic design.

While I was working on this and several other

tube-related projects, I undertook a massive and

thorough-going literature search that now runs to

something on the order of about a nine hundred arti-

cles. Many times Id be thinking about this amp and

dream up what was sure to be a new idea only to later

nd that someone had done it in 1956 or some such!

Prior art notwithstanding, I can say with a rea-

sonable amount of condence that no one has pro-

duced a commercial offering that uses quite the

same topology presented here. Given the cost of this

circuit and the fact that high-end audio is only really

about ten years old, its not too surprising that this

could be the case. There was essentially no market

Notes on aWork in Progress

The PEARL SC 280March, 90.

Hand-Builders of Fine Music-Reproduction Equipment Precision Electro-Acoustic Research Laboratory.

2106 33 Ave. SW, Calgary, AB; CAN T2T 1Z6

Ph: +.1.403.244.4434 Fx: +.1.403.244.7134

Web: http://www.pearl -hifi .com

E-mail: custserv@pearl -hifi .com

AN 23.1.1 - Page 2 ! !

in 1955 for a $1000.00 amplier.

I have invested hundreds of hours of work into

this project so far and have tried to design the cir-

cuits to be as simple, reliable and trouble-free as

possible. Tube-aging effects are essentially nullied

in the phase-inverter/driver stages by the use of a

form of feedback known as active error-correc-

tion

4

whereby the differential ampliers are made

permanently self-balancing. The output stage uses

two, manual bias-balance controls that operate in

conjunction with a third control that allows the

operating point of the amplifier to be continuously

varied over a wide range.

The tube types have been chosen on the basis of

linearity, sonics and on-going availability. The output

stage uses EL34s, while the front-end uses 3 6CG7s,

1- 5687, and two FETs. The EL34, a pure pentode, is

renown for its sweet upper registers and good, if not

overpowering bottom end response. Unlike the 6550,

this tube is not a high perveancehigh current-out-

putdevice and so must be run at a fairly high plate

voltage and rather lower plate current for a given

amount of power output. While the 6550 certainly

belts out the bottom end, the treble is often a little

edgy and this being a distortion form I cannot stand,

Ive chosen to run more EL34s at higher plate voltage.

The EL34has been produced in some European plants

for at least 30 years and one can reasonably suppose

that the bugs are out of the production processes by

now. The 6550 is presently made only in China. With

the recent demise of the Sylvania plant in Emporium,

Pa. and the GE (MPD) plant in Owensboro, Ky., there

isnt really a source of what I consider to be good

sounding, consistent and reliable 6550s. Im told that

while the Chinese items are sonically quite acceptable,

reliability can be an issue. There are apparently about

30-odd plants in China, all of which market through

the same agency, so one never really knows the origin

of a given lot of tubes. I am not out to belittle the Chi-

nese tubes, so if anyone has more accurate informa-

tion than the info I have, please ll me in!

I hope that this offering strikes a responsive

chord within some of you as I feel that building and

listening to a pair of these amps will be a richly

rewarding experience in every way. I d like to give

credit to some of the people who have helped with

the design of this amp because without their assis-

tance and encouragement this project would not

likely have been undertaken. I n no particular order,

thanks to:

Norman Crowhurst, for 20 years of the best

technical writing from which its been my

pleasure to learn.

J ack Senecal , ex of Preci si on Fi del i ty

presentl y consul tant to K rel l . We have

enjoyed many discussions relating to tube

equipment design over the years.

Chris Paul, for much help with circuit analysis

and for putting before me the active plate load

circuit used in this amplier.

Ed Logan, Logan Labs, for telling me how to

build a tube, power-output stage, and provid-

ing many useful and hard-to-come-by tidbits

of information.

Bruce DePalma, ex of Dynaco during the PAS,

Stereo 70 and Mklll era. Bruce pointed out the

value of running EL34s at high plate voltage

and low current and provi ded some very

timely encouragement.

Ken Stevens, Convergent Audio Technology:

weve enjoyed hours of lively and enlivening

discussion relating to tube audio in general

and to the operation of triode output stages in

particular.

Ed Meitner, Museatex and Meitner. Ed pro-

vided me with a lot of insight into dielectrics

and many of other peculiar phenomena, he

also coined the unforgettable phrase I nca

Firebottles.

the hundreds of people who wrote the articles

that constitute archive library I have built up

over the course of my literature search.

THE SI NGLE CHANNEL 280

Perhaps the single most daunting aspect of own-

ing a large tube amplier is the near inevitability of

ongoing and costly tube replacement. Hand in glove

with this is the steadily diminishing sonic quality

shown by aging tubes. The reason for owning tube

gear in the rst place is that it sounds better than

anything else and this fact makes tube deterioration

doubly frustrating.

I own and use an enormous amount of equip-

ment of many types; a complete and well-equipped

woodworking facility with a large table saw, jointer,

thickness planer, wood lathe, radial saws, polishing

lathe, veneer press and a large tool-room metal-

worki ng l athe; an equal l y compl ete and wel l -

equipped electronics-acoustics laboratory with dual

channel fast Fourier analyser, scopes, voltmeters,

microphones, oscillators, anechoic chamber, and

lastly, an office/design room set up with a big, Mac-

intosh desktop publishing system, a jillion megs of

application software, back-up hard drive, CD ROM,

scanner, printer, high-speed photocopier, Cerlox

binding equipment, etc.

I f the equipment I buy is not of extremely high

quality and reliability I soon nd myself in position

where I am constantly repai ri ng one thi ng or

another and chewing up a lot of time doing so.

The design of this amplier meant that I had to

AN 23.1.1 - Page 3 ! !

solve the reliability problem if I was ever going to be

able to tolerate owning it. I worked this problem

over in my mind for several years and intuitively it

always seemed to me that the very high tempera-

tures at which tubes typically operate had to be a

factor in the short working-life so often observed.

Through several bits of good fortune and a cou-

ple of co-incidences I found conformation that high

bulb temperature was denitely a problem and went

ahead to develop the line of tube coolers that PEARL

now markets. Working on the basis that whatever I

developed had to be readily and simply retro-ttable

to all kinds of existing equipment without resorting

to forced air cooling, a number of effective products

have been developed. See our Audio Note 1.3, Tube

Coolers and Equipment Reliability for the full scoop

on this.

I n any convective cooling system there is only so

much power available to move air. The effective-

ness of most such cooling or heating arrangements

can generally be increased by forcing air through

the system with a fan. I n a tube amp the trick is to

provide a balanced ow of air over all the tubes so

that they operate at very nearly the same tempera-

ture. This has been accomplished in the SC280 by

the use of a pressurized pan-type chassis. I t is basi-

cally a 25" wide x 14" front-to-back x 4" deep chassis

with the tubes and transformers mounted on the 25"

x 14" top surface. See Fig. 2 for a sketch of this. Low

noise fans are compliantly mounted on the bottom,

inside the chassis and quietly create a positive pres-

sure within the chassis. This pressure nds relief

through a number of clear acrylic plastic chimneys

seated in suitably sized holes punched in the top

deck of the chassis. With coolers tted, the tubes,

both front-end and output, reside within a directed

air ow guided by the chimneys. I n this manner,

extremel y reasonabl e bul b temperatures are

achieved and very long tube life can be rightly antic-

ipated. As an example of the effectiveness of this

arrangement is as follows:

I f an EL34 is simply plugged into a socket, to

which only lament power is supplied and

allowed to come up to temperature, the bulb

hot spot will run about 100C. I f the tube is

Air flow

PC board

C om pliant

m ounting

C om pliantly m oun-

ted sub-chassis

C lear acrylic

plastic chim ney

C hassis

50 75 100 125 150 175 200 225 250

122 167 212 257 302 347 392 437 482 527 F

275 C

1 2 3

Fig. 1.The effectiveness ofthe cooling system used in the SC 280

is show n above.

C urve 1 illustrates the bulb tem perature w ith only the lam ent run-

ning.The tube is dissipating 9 w atts of pow er into free air and is not

tted w ith a cooler nor placed in a forced-air chim ney.

C urve 3 show s the free-air bare-bulb tem perature and substantial gra-

dient w hen the tube is operated at its m axim um rated plate+screen dissipa-

tion of28 w atts.The total pow er radiated by the envelope is 37 w atts includ-

ing the lam ents contribution.Again,neither cooler nor chim ney is used.

C urve 2 show s the bulb tem perature and low gradient achieved

w ith the fan-cooler-chim ney arrangem ent used in the 280. O perating

conditions are the sam e as for curve 3;for clarity the cooler is not show n

in the illustration.The hot-spot tem perature is reduced by a w hopping

230 F.

AN 23.1.1 - Page 4 ! !

then triode connected and run at its maximum

rated screen-plus-plate dissipation of 28watts,

it will be radiating an additional 9 watts from

the lament, for a total of 37 watts of energy to

be sunk into the atmosphere. The bulb hot-

spot will then be about 250C. and a tempera-

ture gradient of 100C. will be present from the

hot spot to either end. I f the cooler-chimney-

fan arrangement is then tted, the bulb hot-

spot temperature will drop, in about 5 min-

utes, to around 130C. I n other words the tube

can be made to run nearly as cool under con-

ditions of atout-maximum dissipation as it

does under conventional operation with noth-

ing more than the lament lit! See Fig. 1

During the 50s and 60s the people at Mclntosh

produced thousands of ampliers that ran with very

low standing currents in the output tubes (essentially

Class B) and consequently, low bulb-temperatures.

These amps were famous for their incredibly long

and reliable tube performance. Other instances of

cooling vs. usable life exist by the hundred.

One situation that was instrumental in getting

me going in the cooler business has to do with some

tube-type acoustic analysis gear made by Messrs.

Bruel & Kjaer during the60s and 70s. I have a num-

ber of their level recorders that I bought for good

prices because they wouldnt run reliably. I t took me

several years of ddling to develop a series of mods

that would solve the problems in such parts as

capacitors and resistors. But it was not until I began

to pay serious attention the operating temperature of

the tubes that the problems really began to go away.

The gear was originally tted with bright J AN

tube shields (see Audio Note 1.3, Appendix 2: Figs. A

& B) and one day I decided that these had to go. I

removed not only the shields but the shiny-base

retaining-sockets and installed a powerful but some-

what noisy fan to force an air blast of about 1000

ft/min directly onto the hottest running tubes. Being

a maximum of 4" from the fan, these tubes run at a

far lower average temperature than was previously

the case. Whereas I was getting about 1 year of inter-

mittent use from a given level recorder before tube

failure, I have units in the eld that have been run-

ning at least 8 hrs a day, 5 days a week for over two

years without so much as a hiccup. Lowering bulb

temperature extends tube life!

I have talked with a few people who are under the

mistaken impression that the cathode coating in a

tube is somehow used up by the basic operation of

the tube. While the coating is chemically quite fragile

and subject poisoning by spurious gas within the tube,

damage due to ion bombardment, stripping due to

excessive demands for current or cold-cathode starts

with full B+applied; there is no fundamental reason

why a tube cannot be made to run for years on end.

This was the thinking of the people at Bell Labs

and Western Electric when they developed tubes of

such high reliability that they were installed and per-

manently sealed into trans-Atlantic telephone cables

as repeater ampliers. One cant be fooling around

replacing tubes in 2500# of water! Admittedly these

tubes were handbuilt laboratory specimens and sub-

jected to the most rigorous QC procedures possible.

The fact remains however, that with sufcient care

in construction and use, cathodes can be made to

last virtually indenitely.

During my literature search, I came across some

information regarding various life-extending mea-

sures taken by the folks who designed, built and ran

the 18,800 tube Electronic Numerical I ntegrator and

Computer.

1

Changes in operating procedures show

results quite quickly with a machine of such size and

complexity as a test bed.

Most people who have worked with tubes for any

length of time have wondered about the effect of

high-inrush-lament-current on tube life. The ENI AC

people wondered about this too and did a good deal

of work on the matter. Their conclusion was that a

cycle of daily turn-on; turn-off had no effect on the

frequency with which tubes failed. The following is a

quote from ref. 1:

A series of experiments was started, using 100

tube samples, to determine whether a graduated

application of voltage would materially reduce

the rate of failure when heaters were turned off

and on. Such experiments showed no difference

between the group of tubes to whi ch full

lament voltage was applied at once and those

receiving a gradual application of voltage.

A number of measures were implemented that

did show an increase in tube life:

the operation of laments rated for 6.3V at

6.0V. See Audio Note 1.3, Tube Coolers and

Equi pment Reli abi li ty, Fi g. 1 for further

details.

operation of plate circuitry so as to reduce

plate dissipation to

1

8 of its design centre rat-

ing. Such low-power operation lowers bulb

temperature dramatically

the heater-to-cathode potential was limited to

50V, with all heaters biased with respect to

the cathode voltage.

2

In the late 40s, the concept of bulb cooling hadnt

been discovered and wasnt used in the ENIAC project.

As far as possible, the foregoing measures have

AN 23.1.1 - Page 5 ! !

been applied to the present amplier although power

tubes cannot be run at signicantly lower lament

voltages without a noticeable reduction in current-

output capability.

I ts quite unusual to see the output tubes run

with DC lament supplies becauseI guessmost

people think of induced-hum as the problem and

think that an output stage, with its large signals, will

not be adversely effected.

The output-tube laments in this amplier run

on DC for a very good reason: a distinct buzzing/tin-

kling sound can sometimes be heard from power-

tubes when their lament are energized by AC yet

when DC is applied the tube goes silent. This occurs

because AC-current ow through the folded up

length of insulated lament wire within the cathode

initiates a motor action that causes the lament to

contract, accordion-style, with every voltage swing

away from zero, positive or negative. As the voltage

returns to zero the lament expands to its original

shape. Thereby, it acts as a little 120Hz. shaker

within the cathode and almost certainly stimulates

guitar string resonances within itself, cathode res-

onances and probably several grid resonances. This

shaker mechanism gets things going within the tube

to such an extent that plainly audible sounds are pro-

duced. With the internals of the tube set into reso-

nance and thereby into relative motion, adverse

effects upon any musical signal amplied by the tube

can easily be imagined. This mechanism is silenced

DC is used to energize the laments.

The problems caused by acoustically induced

microphonic output have been given a lot of thought

and measures have been taken to ensure that such

coloration is kept to a minimum. I so-sockets and

compliant pc-board mountings are used throughout

and the output tubes are mounted in groups of three

on separate, compliantly mounted sub-chassis.

All of the power supply circuitry is built on con-

ventional PC boards while the signal-path circuitry is

hard-wired using a specially developed ground-

plane, hybrid construction. Normal double-sided pc-

board material is etched on one side to carry the

lament currents and on the other to provide a

ground-plane grid in the usual manner. Provision is

made for solder-type turret terminals, to which all

signal path connections are made. The PC board acts

as nothing more than a gloried terminal board and

provides the convenience of PC board construction

while maintaining the sonic superiority of point-to-

point hard-wiring.

BASI C NOTES ON THE CI RCUI TRY

Referring to the block diagram, the amplier is

seen to be comprised of three sections of ampli-

cation. Three sorts of feedback are employed, local,

loop and active common-mode error. True absolute

phase swi tchi ng i s remotely selectable and the

amplier may be driven from single-ended or bal-

anced sources. The output stage uses amply AC

bypassed solid-state regulation of the standing cur-

rent in each individual output tube, ensuring that the

amplier will hold its DC balance regardless of the

match of the DC characteristics of the output tubes

used. The front end is completely self-balancing

both AC and DCand maintains its balance regard-

less of tube aging or match.

THE FRONT END

All balanced, push-pull, tube-type output stages

must be driven by a pair of antiphase signals. One of

these drives the push side while the other drives

the pull si de of the output stage. The phase

inverters task is to provide such a signal pair and to

be able to derive it from a single-ended source. I t

must do so in an accurately balanced fashion with

regard to both amplitude and phase.

Ampliers using only a single pair of tubes in the

output stage often require that these signals be

slightly unbalanced in amplitude while being exactly

180 antiphase. This is done to account for side-to-

side gain variations in the output tubes and is usually

necessary to achieve balanced currents in the half-

primaries of the output transformer. With a push-

pullparallel output-tube conguration, reasonably

careful matching will ensure that the average-tubes

acting in the push and pull halves exhibit very similar

transfer curves. Each half of the push-pull congura-

tion can then be driven by a signal that is an exact

mirror-image of the other. As long as Class A opera-

tion is maintained, local feedback in the output stage

in combination with the high rejection of power-sup-

ply-induced common mode signals exhibited by a

good output transformer, will effectively mop-up

most of the residual, side-to-side imbalances.

Literally scores of circuits have been developed

that are pretty much capable of mirroring a single-

ended signal into a pair of equal amplitude, phase

opposed signals. The great majority of these however,

suffer from one defect or another and I have spent

several years working on high-precision, phase-split-

ti ng techni ques. The result of thi s effort i s The

Actively Plate-Loaded, Self Balancing, Ultra-Linear,

Differential Cascode, Phase-I nverter/Driver Stage. This

circuit solves virtually all of the problems encoun-

tered and does so using only four dual-triodes, two J -

FETs, one positive and one negative power supply. I t:

is DC coupled from input to output.

is exceptionally quiet.

has very high common mode rejection from

both input and feedback sources.

AN 23.1.1 - Page 6 ! !

exhibits very wide bandwidth, low distortion

both harmonic and I M.

treats even-order distortion as a common-

mode signal and substantially reduces it.

has a low output impedance.

will easily swing 200V p-p.

can be driven from any single-ended source-

i mpedance up to 100K$ wi th vi rtually no

effect on output balance.

The application of feedback is always an issue

that must be carefully considered. I n this case, feed-

back applied to V1

b

and V2

b

has the interesting effect

of linearizing the operation of the tubes (V1

a

and V2

a

)

that are upstream from the point at which feed-

back is applied. The mechanism by which this hap-

pens will be explained in Audio Note 15.0, The Cas-

code for Audio Amplication; New Developments.

THE OUTPUT STAGE

For purposes adequate to this brief introduction,

the operation of the output stage is covered in Audio

Note 2.1 & 2.1.1, A Little I nput on Audio Output

Transformers & Update. The subject will be dealt

with in considerable depth in the following, upcom-

ing Audio Notes:

3 - Basic Transformer Action.

16 - The Transformer-Coupled Output-Stage: The

Basics of Push-Pull Operation.

17 - Cathode Coupling; Optimizing the Output-

Stage.

18 - Class Distinctions; Modes of Amplier Opera-

tion.

20 - Feedback From the Output-Stage; An Exami-

nation of the Options.

21 - Triode vs. Pentode; The Grass is Greener in the

Middle!

Experienced builders will notice the unusual con-

nection of the output-tube suppressor grids. I discov-

ered that by swinging the suppressor in phase with the

plate, but at a fraction of its peak voltage, a worthwhile

quantity of secondary emission could be eliminated. A

suppressor grid looses it effectiveness as the plate volt-

age swings towards the suppressors zero potential and

the grid must be swung negative to account for this.

Sonically the result is quite gratifying.

I t turns out that the grounded, center-tapped sec-

ondary provides an ideal source of dynamic bias for

the suppressors. To achieve proper phasing the grids

are tied to a point thatusing negative cathode-feed-

backis the cathode of the opposing tube of the

push-pull pair.

This cross coupling effects only tubes that have a

physical suppressor grid connected to pin 1 and does

not effect the operation of beam power tubes such as

KT66, 77, 88, 90, 6CA7, 6L6, 5881, 6550, 8417, etc. These

tubes suppress secondary emission by the creation of a

virtual cathode between the screen and plate and dont

rely on a physical grid; more on this later.

MAY 1991 ADDENDUM

There is some confusion regarding the 6CA7/EL34

as this tube is produced in both a two-grid, beam-

tetrode and a three-grid pentode version. Yet, no dis-

tinction is made between them and either device can

be found labeled with either number.

For those of us who concern ourselves with the

soni c characteri sti cs of tubes, thi s haphazard

labelling presents a problem because a pure pentode

and its beam-tetrode equivalent are not at all the

same beast from a sonic standpoint. The tetrode

exhibits signicant grid-current problems in the 10

to 0 control-grid-volt region, whereas the pentode

version does not and is therefore sonically superior

in capacitively coupled, xed-bias or self-biased out-

put stages. Look for more on this in Audio Note 23.2.

The pentode can be di sti ngui shed from i ts

beam-tetrode look-alike by counting the pairs of

grid-support side-rods protruding through the top

support mica and anking the cathode tubewithin

which resides the lament. With one pair of side

rods required per grid, its a simple matter to count

the rods and thereby derive the internal structure of

the tube.

Two pairs of side rods are seen in the beam-

tetrode, which I label a 6CA7. Three pairs are found

in the pentode which I call an EL34. I have created

this connotative nomenclature based on the follow-

ing thinking:

the pentodeEL34has not, to my knowl-

edge, ever been produced in North America so

I have chosen to use the non-North American

number to designate the non-North American

tube

the beam-tetrode6CA7is the version pro-

duced on this continent and others as well, so

I have given it the number used in the Ameri-

can system.

REFERENCES

1 Tube Failures in ENI AC, F.R.Micheal, Electronics, October

1947.

2 The Heater-Cathode Leakage Problem, M. Horowitz, Radio TV

News, publication date unknown, copies available from

PEARL.

3 Technical Reference Manual, Lamptronix Co. Ltd., Crystal

Lake, I ll, USA 60014.

4 The Application of Active Error-Feedback, J .R. Macdonald,

Proc. I .R.E., J uly 1955

AN 23.1.1 - Page 7 ! !

SC 280 Power Amplier

Fig. 2 - Mechanical Layout - Plan View

Fig. 2. The PEA R L SC 280 M O N O B LO C K is show n in plan view.

N ote the sym m etry of the layout. Fans w ithin the chassis force

cooling air up through all of the cooler-chim neys resulting in the

sort of tube cooling perform ance show n in Fig.1.A ll pow er-utility

AC is contained w ithin a sealed,bulkheaded com partm ent directly

below the high-isolation pow er transform er.O nly isolated, ltered

and initially recti ed AC is allow ed into the rest ofthe chassis.

The rem otely-controlled absolute-phase-sw itching circuitry is oper-

ated from an um bilical that runs from the listening position back to

either one of the am pli ers.The pair of am pli ers is connected by a

second um bilical, ensuring that the absolute phase of both am ps

sw itches sim ultaneously w ith rem ote sw itch actuation.

H igh Isolation Pow er Transform ers

T1 and T2

O utput

Transform er

AC Sw itching Fuses, etc. Inputs & O utputs

Rem ote A bsolute-Phase C ontrol

C onnections, B + & Screen Supply

Fuses

1/2 O utput Stage 1/2 O utput Stage Front End

14"

25"

M ain B + and Front End

Inductors

Superseded

A

N

2

3

.

1

.

1

-

P

a

g

e

8

!

!

S

C

2

8

0

P

o

w

e

r

A

m

p

l

i

e

r

F

i

g

.

3

-

B

l

o

c

k

D

i

a

g

r

a

m

XLR

W

i

d

e

-

B

a

n

d

O

u

t

p

u

t

-

T

r

a

n

s

f

o

r

m

e

r

Screen.

Regltr.

1

/

2

S

c

r

e

e

n

1

/

2

S

c

r

e

e

n

1

/

2

P

r

i

m

a

r

y

1

/

2

P

r

i

m

a

r

y

1

/

3

S

e

c

.

1

/

2

T

e

r

t

i

a

r

y

1

/

2

T

e

r

t

i

a

r

y

O

u

t

p

u

t

S

t

a

g

e

B

+

S

i

g

n

a

l

C

o

m

m

o

n

T

o

L

o

a

d

EL34

O utput Stage

V5 to V16

3dB Screen

Local N FB

3dB Screen

Local N FB

6dB C athode

Local N FB

6dB C athode

Local N FB

12dB Loop N FB

Front-End

V1, V2, V3

C om m on-M ode

Feedback

A ctive

C urrent

Source

Front-End

B + Regulator

RC A

Signal

C om m on

Rem ote A bsolute-

Phase C ontrol

U m bilical to the

O ther A m plifier

Input

Sw itching

(O ptional)

Rem ote

A bsolute-

Phase

Sw itching

12dB Loop N FB

V4a, b

Front-End

B - Regulator

C athode-C oupled, U ltra-

Linear O utput Stage

Self-B alancing, U ltra-Linear D ifferential

C ascode, Phase Inverter/D river Stage

1

/

6

S

e

c

.

1

/

3

S

e

c

.

1

/

6

S

e

c

.

8

$

8

$

4

$

4

$

Superseded

A

N

2

3

.

1

.

1

-

P

a

g

e

9

!

!

S

C

2

8

0

.

1

P

o

w

e

r

A

m

p

l

i

e

r

S

c

h

e

m

a

t

i

c

s

F

i

g

.

4

-

P

o

w

e

r

S

u

p

p

l

y

B

l

o

c

k

D

i

a

g

r

a

m

Primary Voltage-Tap

Selector Block

Dual-Choke Input

B Rectifier & Filter

Floating,

Raw DC

B+Supply

Floating,

Raw DC

B Supply

F

r

o

n

t

-

e

n

d

F

i

l

a

m

e

n

t

S

u

p

p

l

y

D

r

i

v

e

r

S

t

a

g

e

B

P

o

w

e

r

S

u

p

p

l

y

110VAC

Nominal

110VAC

Nominal

Power Transformer T1; Main B+, Screen Supply

& Output Stage Filament Supply

Manual Soft-Start

Switch

110240VAC

5060Hz.

Power Transformer T2

Front-End B Supply

Choke Input B+Rectifier

& 750V, 260 J oule, Filter Capacitor

400VDC Screen

Regulator & FIlter

C apacitor Input, O utput-

Stage Filam ent Rectifier

O utput-Tube Filam ent

Regulator, 1/Tube

Power Transformer T2;

Front End Filament Supply

V1, V2

Filament

Supply

V4

Filament

Supply

B

i

a

s

e

d

t

o

+

2

0

0

V

Floating

Output

Floating

Output

Floating

Output

Outptut

Stage B+

Signal

Common

Screen

B+

Front-End

B Regulator

Front-End

B+Regulator

B

i

a

s

e

d

t

o

+

7

5

V

B

i

a

s

e

d

t

o

2

0

0

V

V3

Filament

Supply

Superseded

AN 23.1.1 - Page 10 ! !

SC 280 Power Amplier

Fig. 5 - Front End - Component Values

V1, V2, V3 - 6C G 7, 6FQ 7

V4 - 5687, 7044, 7119

Q 1,2 - Toshiba 2SK 147 - B L

M atched pair; R 43, R 55 set

to yield 225V across V3a & V3b

Signal

G round

V4b

9

7

6

+ Input

- Input

Signal

G round

Front-End B -,

-240V N om inal

R 1

47K $

R 3

47K $

R 19

470$

470$

R 27

82.5K $

R 17

V1a V1b

V2b

33$

R 21

1

3

5

13

2F - 600V

Polyprop.

R 33

100$

2

3

1

2

3

V4a

3

1

2

1.0M $

R 31

C 1

V2a

Front-End B + ,

+ 465V N om ina

7

D S

G

D S

G

V3a

V3b

R 25

33$

100K $

R 23

158K $

R 15

330$

R 29

9

5

11

365K $

R 49

33$

R 35

33$

R 37

R 39

33$

R 41

33$

33$

R 57

10K $

R 45

R 53

10K $

100K $

R 47

100K $

R 51

33$

R 59

R 43

xx$

xx$

R 55

1

15

14

16

1/2

Tert.

1/2

Tert.

Q 1

Q 2

C 2

10f - 200V

Polyprop.

2

3

1

6

7

8

6

7

8

6

7

8

To the O ut-

put Stage

To the O ut-

put Stage

Superseded

AN 23.1.1 - Page 11 ! !

SC 280 Power Amplier

Fig. 6 - Front End - DC voltages

V1, V2, V3 - 6C G 7, 6FQ 7

V4 - 5687, 7044, 7119

Q 1,2 - Toshiba 2SK 147 - B L

Signal

G round

V4b

9

7

6

+ Input

- Input

Signal

G round

Front-End B -,

-240V N om inal

V1a V1b

V2b

1

3

5

13

2

3

1

2

3

V4a

3

1

2

V2a

Front-End B + ,

+ 465V N om inal

7

D S

G

D S

G

V3a

V3b

9

5

11

1

15

14

16

1/2

Tert.

1/2

Tert.

Q 1

Q 2

C 2

2

3

1

6

7

8

6

7

8

6

7

8

To the O ut-

put Stage

To the O ut-

put Stage

0

0

0

0

0

0

0

00

0

2.4

2.4

100 365

8.3

8.3

0

0

XX

XX

100

225

125

0

0

0 82

158

3.3

480

90

150

Superseded

AN 23.1.1 - Page 12 ! !

SC 280 Power Amplier

Fig. 7 - EL 34 Output Stage - Component Values

1

2

5

6

12

11

15

14

+650V from

Output Stage

B+Regulator

+400V from

Screen

Regulator

1

/

2

P

r

i

m

a

r

y

1

\

2

S

c

r

e

e

n

1

/

2

T

e

r

t

i

a

r

y

1

/

3

S

e

c

3

4

7

8

11

9

16

15

1

/

2

P

r

i

m

a

r

y

1

\

2

S

c

r

e

e

n

1

/

2

T

e

r

t

i

a

r

y

1

/

3

S

e

c

60V from

Bias Reg

From the

Driver

Stage

13

12

10

10

1

/

6

S

e

c

1

/

6

S

e

c

4$

Nom

8$

8$

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V15

V16

11

11

5

9

R73 150K

P1

20K

R61

22k

C3

5F

100V

C15

10F

200V

R75 150K

P2

20K

R63

22k

C5

5F

100V

C17

10F

200V

R77 150K

P3

20K

R65

22k

C9

5F

100V

C19

10F

200V

R79 150K

P4

20K

R67

22k

C11

5F

100V

C23

10F

200V

R81 150K

R69

22k

C13

5F

100V

C25

10F

200V

R83 150K

R71

22k

C21

10F

200V

P5

20K

P6

20K

C7

5F

100V

R85 10R

R109 2k2

R155 22R

R133

10R

R87 10R

R111 2k2

R157 22R

R89 10R

R113 2k2

R159 22R

R91 10R

R115 2k2

R161 22R

R93 10R

R117 2k2

R163 22R

R95 10R

R119 2k2

R165 22R

R135

10R

R137

10R

R139

10R

R141

10R

R143

10R

R121 2k2

R97 10R

R145

10R

R167 22R

R123 2k2

R99 10R

R145

10R

R169 22R

R125 2k2

R101 10R

R147

10R

R171 22R

R127 2k2

R103 10R

R149

10R

R173 22R

R129 2k2

R105 10R

R151

10R

R175 22R

R131 2k2

R107 10R

R153

10R

R177 22R

CW

4$

Nom

Superseded

AN 23.1.1 - Page 13 ! !

1

2

5

6

12

11

15

14

+650V from

Output Stage

B+Regulator

+400V from

Screen

Regulator

1

/

2

P

r

i

m

a

r

y

1

\

2

S

c

r

e

e

n

1

/

2

T

e

r

t

i

a

r

y

1

/

3

S

e

c

3

4

7

8

11

9

16

15

1

/

2

P

r

i

m

a

r

y

1

\

2

S

c

r

e

e

n

1

/

2

T

e

r

t

i

a

r

y

1

/

3

S

e

c

60V from

Bias Reg

From the

Driver

Stage

13

12

10

10

1

/

6

S

e

c

1

/

6

S

e

c

4$

4$

8$

8$

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V15

V16

11

11

5

9

R73

P1

R61

C3

C15

R75

P2

20K

R63

C5

C17

R77

P3

20K

R65

C9

C19

R79

P4

R67

C11

C23

R81

R69

C13

C25

R83

R71

C21

P5

P6

C7

R85

R109

R155

R

133

R87

R111

R157

R89

R113

R159

R91

R115

R161

R93

R117

R163

R95

R119

R165

R121

R97

R167

R123

R99

R169

R125

R101

R171

R127

R103

R173

R129

R105

R175

R131

R107

R177

28.6V

0.0V

28.6 to

60V

0.0V

.40V

0.0V

0.0V +30mV

+30mV

+30mV

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

.40V

.40V

.40V

.40V

.40V

28.6 to

60V

.40V

.40V

.40V

.40V

.40V

.40V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

0.0V

28.6V

28.6 to

60V

0.0V

28.6V

28.6 to

60V

0.0V

28.6 to

60V

28.6 to

60V

28.6V

28.6 to

60V

0.0V

28.6 to

60V

28.6V

28.6 to

60V

0.0V

28.6 to

60V

28.6V

28.6 to

60V

0.0V

28.6 to

60V

0.0V

50mV

R

135

R

137

R

139

R

141

R

143

R

143

50mV

50mV

50mV

50mV

50mV

50mV

50mV

R

143

50mV

R

145

50mV

R

147

50mV

R

149

50mV

R

151

Superseded

SC 280 Power Amplier

Fig. 8 - EL 34 Output Stage - DC Voltages

AN 23.1.1 - Page 14 ! !

Front-end C onnection B oard

Shielded Enclosure

K

1

A bsolute Phase Rem ote C ontrol U m bilical

H and-held Sw itch

RC A

Single-ended

Input

3 Pin XLR

B alanced

Input

A m plifier Inter-connecting U m bilical

5 Pin

XLR

4 Pin

XLR

4 Pin

XLR

Front-end

Input-tube

G rids

V1

V2

6VD C

Signal

G round

33$

33$

33$

33

$

33$

M ounted on

C hassis

5 Pin

XLR

4 Pin

XLR

4 Pin

XLR

SC 280.1 Power Amplier Schematics

Fig. 9 - I nput Switching & Remote-Absolute-Phase I nverting Control

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Unanswered Question - Six Talks at Harvard - Educator - About - Leonard BernsteinДокумент2 страницыThe Unanswered Question - Six Talks at Harvard - Educator - About - Leonard Bernsteinyogimgurt0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Venezuela's Carols A Mix of Cheer and Political JabsДокумент1 страницаVenezuela's Carols A Mix of Cheer and Political JabsyogimgurtОценок пока нет

- Acoustic Transducers by Donald P. Massa 110603Документ18 страницAcoustic Transducers by Donald P. Massa 110603rakialiasОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Audio Engineering Syllabus 8-9-13Документ4 страницыAudio Engineering Syllabus 8-9-13yogimgurtОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Errata PDFДокумент1 страницаErrata PDFyogimgurtОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Noise Exposure and Hearing LossДокумент4 страницыNoise Exposure and Hearing LossyogimgurtОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- What Is Sonography? What Does A Diagnostic Medical Sonographer Do? What Are The Career Opportunities?Документ2 страницыWhat Is Sonography? What Does A Diagnostic Medical Sonographer Do? What Are The Career Opportunities?yogimgurtОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Contact With Your TubesДокумент5 страницContact With Your TubesyogimgurtОценок пока нет

- Audio Component Grounding-InterconnectionДокумент44 страницыAudio Component Grounding-InterconnectionyogimgurtОценок пока нет

- On The Specification of Moving-Coil Drivers For Low Frequency Horn-Loaded Loudspeakers (W. Marshall Leach, JR)Документ10 страницOn The Specification of Moving-Coil Drivers For Low Frequency Horn-Loaded Loudspeakers (W. Marshall Leach, JR)yogimgurtОценок пока нет

- Optimal Time-Domain Noise Reduction FiltersДокумент88 страницOptimal Time-Domain Noise Reduction FiltersyogimgurtОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Loosing Shake RattleДокумент6 страницLoosing Shake RattleyogimgurtОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Frankland Tube ElectДокумент34 страницыFrankland Tube ElectyogimgurtОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- J 1365-2044 2009 05994 XДокумент9 страницJ 1365-2044 2009 05994 XVito Luca ARNETTAОценок пока нет

- Analog Multi Track Buyers GuideДокумент6 страницAnalog Multi Track Buyers GuideyogimgurtОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Two Year Claritycap Research Programme Finally Answers An Audio Capacitors Influence On Sound Quality.Документ6 страницTwo Year Claritycap Research Programme Finally Answers An Audio Capacitors Influence On Sound Quality.yogimgurtОценок пока нет

- AcroSound Output TransДокумент18 страницAcroSound Output TransyogimgurtОценок пока нет

- Periodicity and PerceptionДокумент5 страницPeriodicity and PerceptionyogimgurtОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Scenarios:: Three Greg HanksДокумент5 страницScenarios:: Three Greg HanksyogimgurtОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Emt CleanДокумент5 страницEmt CleanyogimgurtОценок пока нет

- Networking The Conference CenterДокумент6 страницNetworking The Conference CenteryogimgurtОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Tape Transport TheoryДокумент6 страницTape Transport Theoryyogimgurt100% (1)

- Installing The StudioДокумент7 страницInstalling The StudioyogimgurtОценок пока нет

- Push Pull Theory MITДокумент24 страницыPush Pull Theory MITyogimgurtОценок пока нет

- Caring For Your StudioДокумент5 страницCaring For Your StudioyogimgurtОценок пока нет

- Ultra Linear Output StagesДокумент20 страницUltra Linear Output StagesyogimgurtОценок пока нет

- Toroidal Trans MythsДокумент6 страницToroidal Trans MythsyogimgurtОценок пока нет

- Latte BubblesДокумент1 страницаLatte BubblesyogimgurtОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Laser Ignition For Combustion Engines: January 2004Документ21 страницаLaser Ignition For Combustion Engines: January 2004Shekhar ShekharОценок пока нет

- 65-Finite-Element-Analysis-Of-Pipes-Conveying-Fluid Mounted-On-Viscoelastic-FoundationsДокумент14 страниц65-Finite-Element-Analysis-Of-Pipes-Conveying-Fluid Mounted-On-Viscoelastic-FoundationsDaniel Andres VargasОценок пока нет

- L 19 - Mse628a - 30 10 19Документ25 страницL 19 - Mse628a - 30 10 19Dhanishtha SinghОценок пока нет

- Microplan - Katalog 2009 ENДокумент18 страницMicroplan - Katalog 2009 END.T.Оценок пока нет

- Report 3 Schlieren Visualisation of Over-Expanded NozzleДокумент6 страницReport 3 Schlieren Visualisation of Over-Expanded NozzleAbhishek DhakneОценок пока нет

- Polymers: Fabrication and Characterization of Aluminum Nanoparticle-Reinforced CompositesДокумент10 страницPolymers: Fabrication and Characterization of Aluminum Nanoparticle-Reinforced CompositesTRNADEWОценок пока нет

- Lincolnweld 888 & LA-85Документ2 страницыLincolnweld 888 & LA-85Pablo PazОценок пока нет

- ME101 Lecture08 KD PDFДокумент25 страницME101 Lecture08 KD PDFR MathewОценок пока нет

- Module22 - Consequence Analysis - Effect ModelДокумент52 страницыModule22 - Consequence Analysis - Effect ModelMinh ThưОценок пока нет

- Materiales CompuestosДокумент167 страницMateriales CompuestosTatiana MerchanОценок пока нет

- UNU - Geothermal Well TestingДокумент30 страницUNU - Geothermal Well TestingZakariyaОценок пока нет

- Cat Apem Ermec Nuevo Catalogo General de Pulsadores Interruptores Apem Big Blue 2011 12Документ589 страницCat Apem Ermec Nuevo Catalogo General de Pulsadores Interruptores Apem Big Blue 2011 12Josue BerzunzaОценок пока нет

- 2011 Exam GeotechnicalДокумент9 страниц2011 Exam GeotechnicalAhmed AwadallaОценок пока нет

- Error Analysis in Physics PDFДокумент2 страницыError Analysis in Physics PDFKrystal0% (1)

- Conduction A Long Simple BarДокумент5 страницConduction A Long Simple Bardiaa ibrahimОценок пока нет

- Ujian Nasional Bahasa Inggris SMA Tahun 1994Документ6 страницUjian Nasional Bahasa Inggris SMA Tahun 1994Andhika A. SetiyonoОценок пока нет

- Pump Specifications Elv Series Submersible Sump Pump With Oiltector ControlДокумент7 страницPump Specifications Elv Series Submersible Sump Pump With Oiltector ControlAnonymous PCsoNCt0mFОценок пока нет

- Fmath p2 j99Документ6 страницFmath p2 j99SeanОценок пока нет

- Project - Silicon Solar Cell-CoДокумент55 страницProject - Silicon Solar Cell-CoSudheer SebastianОценок пока нет

- D R 800 Dust Concentration Meter: Before Starting Any Work, Read The Operating Instructions (The Manual) !Документ154 страницыD R 800 Dust Concentration Meter: Before Starting Any Work, Read The Operating Instructions (The Manual) !Phạm Thanh SơnОценок пока нет

- Acara 4 GranulometriДокумент63 страницыAcara 4 GranulometriHana Riwu KahoОценок пока нет

- SP Question BankДокумент2 страницыSP Question BankAbhishek GhoshОценок пока нет

- Interface and Density Profiling PresentationДокумент50 страницInterface and Density Profiling PresentationheriОценок пока нет

- Chemistry Question Bank For JEE Advance Part 1Документ55 страницChemistry Question Bank For JEE Advance Part 1gfffdssseОценок пока нет

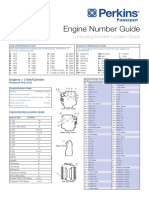

- Engine Number Guide (2-Page)Документ2 страницыEngine Number Guide (2-Page)Abdul KhaliqОценок пока нет

- Science: Modified Strategic Intervention MaterialДокумент32 страницыScience: Modified Strategic Intervention MaterialMar Angelo TangcangcoОценок пока нет

- C184 E037bДокумент48 страницC184 E037bNeyda Flores VasquezОценок пока нет

- Yes, No, Maybe... : Boolean AlgebraДокумент23 страницыYes, No, Maybe... : Boolean AlgebraAulia UllahОценок пока нет

- Formulario Magnitudes Corriente Alterna Monofásica Corriente Alterna Trifásica P Q S VДокумент2 страницыFormulario Magnitudes Corriente Alterna Monofásica Corriente Alterna Trifásica P Q S VMario Andrade100% (1)

- Question and Ans.3Документ153 страницыQuestion and Ans.3gangoorsgОценок пока нет

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesОт EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesРейтинг: 5 из 5 звезд5/5 (1)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosОт EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosРейтинг: 5 из 5 звезд5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsОт EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialОт EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialРейтинг: 3.5 из 5 звезд3.5/5 (3)