Академический Документы

Профессиональный Документы

Культура Документы

Advanced Motion Controls Sr30a40ac

Загружено:

ElectromateАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Advanced Motion Controls Sr30a40ac

Загружено:

ElectromateАвторское право:

Доступные форматы

SR30A-AC Series

D-69

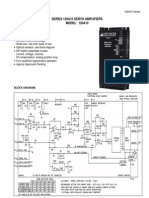

SR30A-AC SERIES BRUSHLESS SERVO AMPLIFIERS

Model: SR30A40AC

FEATURES:

Surface-mount technology

Small size, low cost, ease of use

Optical isolation, see block diagram

DIP switch selectable modes:

current, resolver velocity

Four quadrant regenerative operation

Resolver interface for sinusoidal commutation

Emulated encoder output

Commutation detection and burst mode

AC supply operation

Agency approvals:

*Photo for reference only

BLOCK DIAGRAM:

ADVANCED MOTION CONTROLS

3805 Calle Tecate, Camarillo, CA 93012 Tel: (805) 389-1935, Fax: (805) 389-1165

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A-AC Series

D-70

DESCRIPTION: The SR30A-AC Series PWM servo amplifiers are designed to drive brushless motors with 3 phase sine

wave current. An on board digital controller generates the 3 phase sine wave signals from the resolver input. The

encoder emulation outputs (A, B and I) continuously produce signals equivalent to a 1024 line encoder. All models are

fully protected against over-voltage, under-voltage, over-current, over-heating and short-circuits. The SR30A40AC

interfaces with a digital controller or can be used as a stand-alone drive, and requires a single or three-phase AC power

supply. A red/green LED and a single digital output indicate operating status. Loop gain, current limit, input gain and

offset can be adjusted using 14-turn potentiometers. The offset adjusting potentiometer can also be used as an on-board

input signal for testing purposes when SW1 (DIP-switch) is ON.

SPECIFICATIONS:

All SR30A40AC specifications are identical to the SR30A40 specifications (see SR30A series data sheets) except for:

MODEL

POWER STAGE SPECIFICATIONS SR30A40AC

AC SUPPLY VOLTAGE 45-270 VAC, 1 or 3 phase, 50-60 Hz

CONTINUOUS DC CURRENT AVAILABLE FROM

INTERNAL SUPPLY *

30 A for three phase AC input

15 A for single phase AC input

PEAK DC CURRENT AVAILABLE FROM INTERNAL

SUPPLY (MAXIMUM 2 SECONDS) *

60 A for three phase AC input

30 A for single phase AC input

INTERNAL SHUNT RESISTOR 30 @ 50 W

SHUNT SWITCH-ON VOLTAGE ** 390 V

BUS CAPACITANCE 1980 F

SHUNT FUSE (d=.25 inches, L=1.25 inches) 3 A Motor Delay rated @ 250 VAC

AC LINE FUSES (d=.25 inches, L=1.25 inches) 15 A slow blow rated @ 250 VAC

MECHANICAL SPECIFICATIONS

AC CONNECTOR: C1 Screw terminals

DC OUT AND EXTERNAL SHUNT CONNECTOR: C2* Screw terminals

MOTOR CONNECTOR: P3 Screw terminals

SIGNAL CONNECTORS: P1, P2

AMP 748390-6, AMP 748481-6

P1 is a 26 pin high density D-sub connector and

P2 is a 15 pin high density D-sub connector.

SIZE

8.00 x 6.52 x 4.06 inches

203.2 x 165.7 x 103.1 mm

WEIGHT

4.94 Lb.

2.23 Kg

* The internal bus voltage is available on C2 to power DC supply units.

** If the shunt regulator is disabled the shut down voltage is 420 VDC.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A-AC Series

D-71

These amplifiers contain a rectifier bridge and filter capacitors to generate the DC bus internally from the AC input power.

The DC bus voltage is 1.4 times AC voltage (RMS), e.g. 310 VDC from 220 VAC. During braking much of the stored

mechanical energy is fed back into the power supply and charges the bus capacitor to a higher voltage. If this voltage

reaches the amplifiers over-voltage shutdown point, output current and braking will cease. To ensure smooth braking of

large inertial loads, a built-in shunt regulator is provided in the SR30A40AC. The shunt regulator will switch on the

internal power resistor when the bus voltage reaches 390 VDC. This allows the bus capacitor to discharge and thus

lower the bus voltage. During regeneration, the regeneration LED will blink (solid green is non-regeneration mode). An

external shunt resistor can be added in parallel to the internal resistor (between C2-3 and C2-4). Recommended value is

20 ohms with a minimum 100 W rating. Removing the jumper between C2-4 and C2-5 will disable the internal shunt

resistor. If the shunt regulator becomes inoperative the over voltage protection on the amplifier will disable the drive if the

regeneration energy causes the bus voltage to exceed 425 VDC.

ORDERING INFORMATION:

Model: SR30A40ACX

X indicates current revision letter.

MATING CONNECTORS:

Manufacturer: AMP

(Tel: 1-800-522-6752)

Part numbers:

15 Pin plug 748364-1

26 Pin plug 748365-1

Pins 748333-2

Shell Kit (plastic with metal coating)

15 Pin 748677-1

26 Pin 748677-2

TYPICAL SYSTEM WIRING: See section G.

MOUNTING DIMENSIONS: See page F-14.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-61

SR30A SERIES BRUSHLESS SERVO AMPLIFIERS

Models: SR10A40, SR30A40

FEATURES:

Surface-mount technology

Small size, low cost, ease of use

Optical isolation, see block diagram

DIP switch selectable modes:

current, resolver velocity

Four quadrant regenerative operation

Resolver interface for sinusoidal commutation

Emulated encoder output

Commutation Detection and Burst Mode

Agency Approvals:

BLOCK DIAGRAM:

ADVANCED MOTION CONTROLS

3805 Calle Tecate, Camarillo, CA 93012 Tel: (805) 389-1935, Fax: (805) 389-1165

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-62

DESCRIPTION: The SR30A Series PWM servo amplifiers are designed to drive brushless motors with 3 phase sine

wave current. An on board digital controller generates the 3 phase sine wave signals from the resolver input. The

encoder emulation outputs (A, B and I) continuously produce signals equivalent to a 1024 line encoder. All models are

fully protected against over-voltage, under-voltage, over-current, over-heating and short-circuits. The SR30A series

interface with a digital controller or can be used as a stand-alone drive. Only a single unregulated DC power supply is

required. A red/green LED and a single digital output indicate operating status. Loop gain, current limit, input gain and

offset can be adjusted using 14-turn potentiometers. The offset adjusting potentiometer can also be used as an on-board

input signal for testing purposes when SW1 (DIP-switch) is ON.

SPECIFICATIONS:

MODEL

POWER STAGE SPECIFICATIONS SR10A40 SR30A40

DC SUPPLY VOLTAGE 60 - 400 VDC

PEAK CURRENT (2 sec. max., internally limited) 10 A (7.1 Arms) 30 A (21.2 Arms)

MAXIMUM CONTINUOUS CURRENT (internally limited) 5 A (3.5 Arms) 15 A (10.6 Arms)

MINIMUM LOAD INDUCTANCE* 600 H

SWITCHING FREQUENCY 20 kHz nominal

HEATSINK (BASE) TEMPERATURE RANGE 0

o

to +65

o

C, disables if > 65

o

C

POWER DISSIPATION AT CONT. CURRENT 100 W 300 W

OVER-VOLTAGE SHUT-DOWN (self reset) 425 V

BANDWIDTH (load dependent) 2.5 kHz

MECHANICAL SPECIFICATIONS

POWER CONNECTOR: P3 Screw terminals

SIGNAL CONNECTORS: P1, P2

P1 is a 26 pin high density female D-sub connector and

P2 is a 15 pin high density female D-sub connector.

SIZE

8.00 x 5.62 x 1.60 inches

203.2 x 142.9 x 40.7 mm

WEIGHT

2.12 lb.

0.99 Kg

* Low inductance motors require external inductors.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-63

PIN FUNCTIONS:

CONNECTOR PIN NAME DESCRIPTION / NOTES I/O

1 +10V @ 3 mA For customer use O

2 SIGNAL GND Reference ground SGND

3 -10V @ 3 mA For customer use O

4 +REF

5 -REF

Differential reference input, maximum 15V, 20K input resistance I

6 Velocity Input

Single ended reference input, external velocity signal, maximum 15V, 10K

input resistance

I

7 Velocity Monitor 1 V = 1500 RPM O

8 Current Monitor

This signal is proportional to the RMS current in the motor leads;

SR10A40: 1V=1.33 A SR30A40: 1V = 4 A

O

9 Current Reference

This is the command signal to the internal current-loop. The maximum peak

current rating of the amplifier always equals 7.25 V at this pin.

SR10A40: SW1-3=ON, 7.25V=10A; SW1-3=OFF, 7.25V=5A.

SR30A40: SW1-3=ON, 7.25V=30A; SW1-3=OFF, 7.25V=15A.

O

10 Burst Mode Enable Pull to ground to enable. See Burst Mode below. I

11

Inhibit/Enable

SW1-6 = ON Pull to ground to inhibit

SW1-6 = OFF pull to ground to enable

I

12

+Inhibit/Enable

I

13

-Inhibit/Enable

If SW1-6=ON, pull P1-12 to ground to inhibit (+) amplifier output and P1-

13 to inhibit (-) amplifier output.

If SW1-6=OFF, pull P1-12 to ground to enable (+) amplifier output and P1-

13 to enable (-) amplifier output.

These inputs will NOT cause a fault condition or a red LED.

I

14

Fault (LED red)

TTL level output. Becomes high during output short circuit, over-voltage,

over temperature, inhibit, and during power-up reset. Fault condition

indicated by red LED.

O

15 +5V @ 250mA

For customer use. Note: the total current on P1-15 and P2-13 combined

should not exceed 250 mA.

O

16 SIGNAL GND Reference ground SGND

17 Controller Power* Connected to P2-15. For customer use I

18 Controller Line 1* Connected to P2-10. For customer use I

19 Controller Line 2* Connected to P2-11. For customer use I

20 Encoder Channel A+

21

Encoder Channel A-

Differential RS485 encoder output (1024 lines/rev) O

22 Encoder Channel B+

23

Encoder Channel B-

Differential RS485 encoder output (1024 lines/rev)

O

24 Index+

25

Index-

Differential RS485 encoder output O

P1

26

Reserved

NOTE: All circuits on connectors P1 and P2 are optically isolated fromall circuits on connector P3.

* No connection internal to the amplifier. See block diagram.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-64

PIN FUNCTIONS:

CONNECTOR PIN NAME DESCRIPTION / NOTES I/O

1 NC No Connection

2 NC No Connection

3 NC No Connection

4 REF+

5 REF-

Differential Output. Resolver Reference. See

SW2-2 for output parameters.

O

6 SIN+

7 SIN-

Differential Input. Resolver Sine I

8 COS+

9 COS-

Differential Input. Resolver Cosine I

10 Controller Line 1* Connected to P1-18. For customer use. O

11 Controller Line 2* Connected to P1-19. For customer use. O

12 Signal GND Reference ground SGND

13 +5V @ 250mA

For customer use. Note: the total current on P1-

15 and P2-13 combined should not exceed 250

mA.

O

14 TACH

Tachometer Input, 60 K input resistance, 60 V

max.

I

P2

15 Controller power* Connected to P1-17. For customer use. O

1 MOTOR A Motor phase A connection O

2 MOTOR B Motor phase B connection O

3 MOTOR C Motor phase C connection O

4 POWER GND Power ground PGND

P3

5 HIGH VOLTAGE DC power input I

NOTE: All circuits on connectors P1 and P2 are optically isolated fromall circuits on connector P3.

* No connection internal to the amplifier. See block diagram.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-65

SWITCH FUNCTIONS:

BANK 1

SETTING

SWITCH FUNCTION DESCRIPTION

ON OFF

1-1

Test / Offset controls the sensitivity of the

"offset" pot. This is used as an on-board

reference signal in test mode.

Test Offset

1-2 Current loop gain* Decrease Increase

1-3

Current scaling. When OFF, this increases

the sensitivity of the current sense thus

reducing both peak and continuous current

limit by 50%.

100%

50%

1-4

Continuous current reduction

Continuous / peak current

limit ratio is 50%

Continuous / peak current

limit ratio is 25%

1-5 Commutation Detection Detect phase angle. See Commutation Detection below.

1-6 INHIBIT/ENABLE P1-11, 12, 13 : INHIBIT P1-11, 12, 13 : ENABLE

* See item 6.3 Current Loop Adjustments in section G for more information.

Units are shipped set for current output via SW1-3=off and in the disabled state via SW1-6=off.

BANK 2

SETTING

SWITCH FUNCTION DESCRIPTION

ON OFF

2-1

Velocity feedback. This connects the

internally generated velocity signal from

the resolver.

On Off

2-2 Resolver Reference Voltage

4.00 Vrms

0.5 transformation ratio

4.25 Vrms

0.47 transformation ratio

2-3

Resolver Reference Frequency

5 kHz NA

2-4

Reserved

2-5

Loop integrator. This capacitor normally

ensures "error-free" operation in velocity

mode by reducing the error signal

(output of summing amplifier) to zero.

Disables the velocity /

voltage loop integrator

capacitor

Enables the velocity /

voltage loop integrator

capacitor

2-6

Integrator capacitor. This adjusts the value

of the integrator capacitor in the velocity

mode.

Increase Decrease

Contact factory for additional resolver reference voltage and/or frequency options.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-66

POTENTIOMETER FUNCTIONS:

POTENTIOMETER DESCRIPTION TURNING CW

Pot 1

This potentiometer is the loop gain adjustment in the velocity

mode. Turn this pot fully CCW in current mode.

Increases loop gain

Pot 2

Current limit. This potentiometer adjusts both the continuous

and peak current limit while maintaining a selected ratio.

Increases current limit

Pot 3

Reference in gain. This potentiometer adjusts the ratio

between input signal and output variables (voltage, current,

and velocity).

Increases reference input

gain

Pot 4

Test / Offset. Used to adjust any imbalance in the input

signal or in the amplifier. When SW1-1 (DIP switch) is ON,

the sensitivity of this pot is greatly increased allowing it to be

used as an on-board signal source for testing purposes.

N/A

TEST POINTS FOR POTENTIOMETERS: See section "G".

OPERATING MODE SELECTION:

FEEDBACK MODE

The following operating modes can be selected by setting the DIP switches according to the following chart:

Current mode

Resolver velocity mode

External velocity mode

Tachometer mode

MODE SW1-

1

SW1-

2

SW1-

3

SW1-

4

SW1-

5

SW1-

6

SW2-

1

SW2-

2

SW2-

3

SW2-

4

SW2-

5

SW2-

6

Current Mode

X X X X OFF X OFF X X OFF ON OFF

Resolver

Velocity Mode

X X X X OFF X ON X X OFF OFF X

External

velocity mode

X X X X OFF X OFF X X OFF OFF X

Tachometer

mode

X X X X OFF X OFF X X OFF OFF X

X does not affect mode.

COMMUTATION DETECTION MODE (SW1-5):

In commutation detection mode the amplifier will automatically detect the optimum phase angle by performing a test

move while monitoring motor position. Phase-offset and pole-counts are stored in non-volatile memory for further use. In

this mode the motor shaft MUST BE de-coupled from the load and free to move. It is also recommended to secure the

motor to avoid damage or injury. CAUTION: Sudden motion will occur in Commutation Detection Mode. Do not

activate commutation mode while the motor is attached to the load and do not touch the motor shaft during the

test move. To start commutation detection, follow the steps below.

1. Configure the amplifier for current mode (see table in block diagram)

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-67

2. Set the amplifier current limits to match the motor current specifications (see Current Limit Adjustments below).

Failure to do so may severely damage the motor.

3. Apply a reference signal such that a current larger than the continuous current of the motor is commanded.

A. If the on-board test pot (Pot 4 with SW1-1 ON) is used as the reference signal, the pot must be turned

CCW from the middle (0V Command) of the 14-turn pot.

B. If an external reference signal is used, this command signal must be a positive command (i.e. positive

voltage into +REF must be positive referenced to Signal GND).

4. Power up the amplifier:

A. in a disabled state (via enable/disable input P1-11 or DIP-switch SW1-6),

B. with SW1-5 OFF,

C. and with P1-10 (Burst Mode) open.

5. Once the amplifier is fully powered (with LED red), set switch SW1-5 ON.

6. Enable the amplifier (the LED will remain red).

7. Pull P1-10 (Burst Mode) to ground. The LED will turn green. At this time the motor will make one and a half

revolutions CW and one and a half revolutions CCW. If no motion occurs, power down and repeat from step 1.

8. Upon completion the amplifier will automatically disable (red LED).

9. To complete detection mode:

A. power off the amplifier,

B. set switch SW1-5 OFF,

C. and release P1-10 (Burst Mode).

D. remove command signal (set Pot 4 to middle if it was used in step 3A)

10. The amplifier is now operational.

BURST MODE (Pin P1-10)

In Burst Mode the amplifier will send an encoder pulse stream to the motion controller equal to the amount of pulses

between the resolver datum and the actual motor position. This allows the motion controller to register the absolute motor

position (within one motor revolution). The Burst Mode sequence is as follows:

1. Disable the amplifier.

2. Pull Burst Mode input to ground (can be done immediately after amplifier disable).

3. Upon Burst Mode input pull-down, the amplifier will first send a single index channel pulse and then 2 channel A and

2 channel B pulses (8 counts). The Burst Mode input must be pulled down for at least 2.1 milliseconds to ensure this

initial stream.

4. Upon Burst Mode input release, the amplifier will stream the appropriate amount of pulses (from datum to actual

position) with channel A leading channel B. This stream will complete in 15 milliseconds (channel line width is 3.4

microseconds).

Caution: motor shaft movement during Burst Mode will not be registered! The motor shaft must remain in position during

Burst Mode in order to work properly!

APPLICATION NOTE: For proper operation, P1-6 and P2-14 must be connected to the signal ground if they are not

being used.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

SR30A Series

D-68

SET-UP: See section "G" for engineering and installation notes.

CURRENT LIMIT ADJUSTMENTS:

These amplifiers feature separate peak and continuous current limit adjustments. The current limit adjustment Pot 2

adjusts both peak and continuous current limit at the same time. It has 12 active turns, one inactive turn at each end and

is approximately linear. Thus, to adjust the current limit turn the potentiometer counter-clockwise to zero, then turn

clockwise to the appropriate value. In many applications it is sufficient to use only the DIP-switches for current limit

adjustments. SW1-3 reduces both peak and continuous current limit by 50% when OFF. SW1-4 reduces only the

continuous current limit by 50% when OFF:

SW1-4 CONTINUOUS / PEAK CURRENT LIMIT RATIO

ON 50%

OFF 25%

P1-9 is the input to the internal current amplifier power stage. Since the output current is proportional to P1-9, the

adjusted current limit can easily be observed at this pin without connecting the motor. Note that a command signal

must be applied to the reference inputs to obtain a reading on P1-9. The maximum peak current value equals 7.25 V at

this pin and the maximum continuous current value equals 3.63 V at this pin. If SW1-3=ON, peak rated amplifier

current = 7.25 V. If SW1-3=OFF, peak rated amplifier current =7.25 V. Example: using the SR30A40 with SW1-

3=ON, 30A=7.25V and with SW1-3=OFF, 15A=7.25V.

The actual output current can be monitored at pin P1-8.

ORDERING INFORMATION:

Model: SR10A40, SR30A40X

X indicates the current revision letter.

TYPICAL SYSTEM WIRING: See section "G".

The resolver connections must be made with individually shielded, twisted wire pairs for proper operation.

MATING CONNECTORS:

Manufacturer: AMP

(Tel: 1-800-522-6752)

Part numbers:

15 Pin plug 748364-1

26 Pin plug 748365-1

Pins 748333-2

Shell Kit (plastic with metal coating)

15 Pin 748677-1

26 Pin 748677-2

MOUNTING DIMENSIONS: See page F-13.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Вам также может понравиться

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- M/V™ Series Servo Drive: Description Power RangeДокумент11 страницM/V™ Series Servo Drive: Description Power RangeElectromateОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- M/V™ Series Servo Drive: Description Power RangeДокумент11 страницM/V™ Series Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент9 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Advanced Motion Controls S100a20Документ8 страницAdvanced Motion Controls S100a20ElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- 25 A 20Документ9 страниц25 A 20s_barriosОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент11 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент7 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент9 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Amc B25a20ac SpecsheetДокумент9 страницAmc B25a20ac SpecsheetElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент7 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- B 15 A 20Документ5 страницB 15 A 20ElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент11 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент13 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент9 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент11 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент7 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- B 40 A 40Документ10 страницB 40 A 40ElectromateОценок пока нет

- Advanced Motion Controls S16a8Документ8 страницAdvanced Motion Controls S16a8ElectromateОценок пока нет

- Amc 12a8 SpecsheetДокумент9 страницAmc 12a8 SpecsheetElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Advanced Motion Controls Dq111se25a20nacДокумент7 страницAdvanced Motion Controls Dq111se25a20nacElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент9 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент7 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- BD 25 A 20Документ7 страницBD 25 A 20ElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Azb 10 A 4Документ7 страницAzb 10 A 4ElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- B 25 A 40 AcДокумент4 страницыB 25 A 40 AcElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент7 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- 7225 AcДокумент12 страниц7225 AcEdson AyalaОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- E Tended Environment: Analog Servo DriveДокумент8 страницE Tended Environment: Analog Servo DriveElectromateОценок пока нет

- Series 120A10 Servo Amplifiers MODEL: 120A10: FeaturesДокумент5 страницSeries 120A10 Servo Amplifiers MODEL: 120A10: FeaturesElectromate100% (1)

- Analog Servo Drive: Description Power RangeДокумент7 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Series 120A10 Servo Amplifiers MODEL: 120A10: FeaturesДокумент5 страницSeries 120A10 Servo Amplifiers MODEL: 120A10: FeaturesElectromateОценок пока нет

- Series 120A10 Servo Amplifiers MODEL: 120A10: FeaturesДокумент5 страницSeries 120A10 Servo Amplifiers MODEL: 120A10: FeaturesElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Control Circuit Wiring Variador V1000 YaskawaДокумент8 страницControl Circuit Wiring Variador V1000 YaskawaAndrés RamírezОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Exor X5 Wireless Press ReleaseДокумент1 страницаExor X5 Wireless Press ReleaseElectromateОценок пока нет

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseДокумент1 страницаElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateОценок пока нет

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionДокумент1 страницаIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateОценок пока нет

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesДокумент1 страницаGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateОценок пока нет

- Electromate Recertified As A Great Place To Work' Press ReleaseДокумент1 страницаElectromate Recertified As A Great Place To Work' Press ReleaseElectromateОценок пока нет

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesДокумент2 страницыNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateОценок пока нет

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaДокумент1 страницаElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateОценок пока нет

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardДокумент2 страницыElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateОценок пока нет

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsДокумент1 страницаPOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateОценок пока нет

- Electromate Elated With Win at The 2022 Business Achievement AwardsДокумент2 страницыElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateОценок пока нет

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsДокумент1 страницаNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateОценок пока нет

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMДокумент2 страницыAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateОценок пока нет

- Kollmorgen Debuts EKM Series Servo MotorsДокумент1 страницаKollmorgen Debuts EKM Series Servo MotorsElectromateОценок пока нет

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesДокумент2 страницыElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateОценок пока нет

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotДокумент2 страницыMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateОценок пока нет

- Meet The World's Most Precise Six-Axis RobotДокумент1 страницаMeet The World's Most Precise Six-Axis RobotElectromateОценок пока нет

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesДокумент2 страницыADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateОценок пока нет

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseДокумент1 страницаNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateОценок пока нет

- Electromate Extends Its Product Portfolio To Include Robots From MecademicДокумент1 страницаElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateОценок пока нет

- Electromate Recognized With 2021 AHTD Foundation AwardДокумент1 страницаElectromate Recognized With 2021 AHTD Foundation AwardElectromateОценок пока нет

- New Integrated Spindle Drives Available From JVLДокумент1 страницаNew Integrated Spindle Drives Available From JVLElectromateОценок пока нет

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseДокумент2 страницыElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateОценок пока нет

- New 100 Amps Peak FlexPro Servo Drives Available From AMCДокумент1 страницаNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateОценок пока нет

- ADVANCED Motion Controls Releases The FM060-25-CMДокумент1 страницаADVANCED Motion Controls Releases The FM060-25-CMElectromateОценок пока нет

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Документ2 страницыElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateОценок пока нет

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsДокумент2 страницыElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateОценок пока нет

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesДокумент2 страницыExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateОценок пока нет

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsДокумент1 страницаNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateОценок пока нет

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsДокумент1 страницаNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateОценок пока нет

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonДокумент1 страницаMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateОценок пока нет

- A-761E Manual PDFДокумент107 страницA-761E Manual PDFsergОценок пока нет

- CAD Workstation Form FactorДокумент30 страницCAD Workstation Form FactorjaimeОценок пока нет

- Suvt PM ReportДокумент3 страницыSuvt PM ReportRohit SaxenaОценок пока нет

- DNC / File Transfer Settings For Fanuc 21im: Set The Following Parameters On The Machine: Parameter ValueДокумент3 страницыDNC / File Transfer Settings For Fanuc 21im: Set The Following Parameters On The Machine: Parameter ValueHien NguyenОценок пока нет

- TesteFinal Inglês Redes1UFCD 6660Документ6 страницTesteFinal Inglês Redes1UFCD 6660EllyAlmОценок пока нет

- Computer Port (Hardware) : This Article Has Multiple Issues. Please HelpДокумент11 страницComputer Port (Hardware) : This Article Has Multiple Issues. Please HelpeddieОценок пока нет

- Charging and Discharging A Capacitor (LAB 3) IrnaДокумент7 страницCharging and Discharging A Capacitor (LAB 3) IrnaIrna FarhanaОценок пока нет

- Win StepsДокумент463 страницыWin StepsAnonymous 105zV1Оценок пока нет

- Programming Guide (For ZPL II, ZBI 2, Set-Get-Do, Mirror, WML) (En)Документ10 страницProgramming Guide (For ZPL II, ZBI 2, Set-Get-Do, Mirror, WML) (En)Edson HualaОценок пока нет

- Oracle 12c Performance TuningДокумент322 страницыOracle 12c Performance Tuningdarelaw10100% (1)

- 81bcc820a219dbe69a858024c89b249fДокумент16 страниц81bcc820a219dbe69a858024c89b249fhamza malikОценок пока нет

- Wiring BassДокумент2 страницыWiring BassSufyan TsauriОценок пока нет

- Job Hazard Analysis Changing A Tire ExampleДокумент4 страницыJob Hazard Analysis Changing A Tire ExampleNur Hidayah Ishak Hizam94% (32)

- Aegps Manual Fluxpower Hpi Installation enДокумент44 страницыAegps Manual Fluxpower Hpi Installation enAbdus SalamОценок пока нет

- Array Solutions: Model AS-AYL-4 - 4-Way K9AY Loop SystemДокумент10 страницArray Solutions: Model AS-AYL-4 - 4-Way K9AY Loop SystemJoe G.Оценок пока нет

- Devices and The InternetДокумент5 страницDevices and The InternetTôiLàHíОценок пока нет

- R Series RP RH AnalogДокумент14 страницR Series RP RH AnaloghaggОценок пока нет

- Aixcmds 3Документ836 страницAixcmds 3Marcelo FariaОценок пока нет

- DSE52xx DSE53xx PC Software ManualДокумент106 страницDSE52xx DSE53xx PC Software ManualGustavo Adolfo Alviarez LabradorОценок пока нет

- Datasheet OTB32 DOC-0000393703Документ5 страницDatasheet OTB32 DOC-0000393703Rachel OdendaalОценок пока нет

- EsasДокумент47 страницEsasLovelle Belaca-olОценок пока нет

- Bollhoff Helicoil Plus 2Документ49 страницBollhoff Helicoil Plus 2Ace Industrial SuppliesОценок пока нет

- IAM - 0004 - EN - SINUMERIK 840D810D MMCHMI Installation and Start-Up Guide (IAM) - 04.00 EditionДокумент34 страницыIAM - 0004 - EN - SINUMERIK 840D810D MMCHMI Installation and Start-Up Guide (IAM) - 04.00 EditionJackam kamОценок пока нет

- Types and Components of Computer Systems: Learning ObjectivesДокумент19 страницTypes and Components of Computer Systems: Learning ObjectivesHendra SusantoОценок пока нет

- 11g DBCA and DB - RECOVERY - FILE - DEST - Bug 6373164 Oracle DBA - A Lifelong Learning ExperienceДокумент2 страницы11g DBCA and DB - RECOVERY - FILE - DEST - Bug 6373164 Oracle DBA - A Lifelong Learning ExperienceAlberto Hernandez HernandezОценок пока нет

- BCP-8000 User's ManualДокумент36 страницBCP-8000 User's ManualAsad PatelОценок пока нет

- Cavendish ManualДокумент6 страницCavendish ManualbertosamОценок пока нет

- Virtual-Memory PpsДокумент15 страницVirtual-Memory PpsPrasanna Kumar DasОценок пока нет

- Indentor Office DGM (Audit Despatch GM (F) : SSGC/FP/10699Документ2 страницыIndentor Office DGM (Audit Despatch GM (F) : SSGC/FP/10699Irfan RazaОценок пока нет

- IQBoard DVT V7.0 User Manual (English)Документ25 страницIQBoard DVT V7.0 User Manual (English)0q0100% (1)

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)