Академический Документы

Профессиональный Документы

Культура Документы

Instrukcja XT 546 - WWW - Ebmia.pl

Загружено:

Awdhesh Singh BhadoriyaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Instrukcja XT 546 - WWW - Ebmia.pl

Загружено:

Awdhesh Singh BhadoriyaАвторское право:

Доступные форматы

XT546-246-346

Operating nstructions

Operating/1006/XT546/246/346/OP288-V01 Page 1 of 3

DispIay

Dual, 3 digit seven segment LED display

Upper display (Current value): Red colour

Lower display (Set value): Green colour

LED Indications

Relay output, Hour / Min / Sec.

(LED blinks when in run mode & stops in

hold mode)

SuppIy

90 to 270V AC / DC or 24V AC / DC, 50/60 Hz

Operating Modes

On Delay, nterval, Cyclic On first & Cyclic

Off first

Time Ranges

9.99 / 99.9 / 999 sec

9.59 min : sec, 99.9 / 999 min

9.59 hour : min, 99.9 / 999 hour

Direction

Down

ReIay Rating

5A @ 230V AC / 24V DC

Start Input

Pulse, Gate (Programmable)

Reset

On interruption of power, front panel reset &

terminal reset

Outputs

2; 1 C/O (SPDT)

Memory Retention

10 years (Fall time of DC signal <= 20ms)

Accuracy

Setting: 0.05% of set time or 50 msec

(Whichever is greater)

Repeat: 0.05%

Mounting

Panel Mounting

8FL6IfI6I0k8

Temperature

O

Operating: 0 to 50 C

O

Storage: -20 to 75 C

Humidity

95% RH

Housing

PC tinted black

Weight

XT546 : 142 gms XT246 : 180 gms

XT346 : 240 gms

8fL1 FL60I0k8

All safety related codifications, symbols and

instructions that appear in this operating manual or

on the equipment must be strictly followed to ensure

the safety of the operating personnel as well as the

instrument.

f the equipment is not handled in a manner

specified by the manufacturer it might impair the

protection provided by the equipment.

CAUTION: Read complete instructions prior to

installation and operation of the unit.

WARNING: Risk of electric shock.

WIRING GUIDELINES

WARNING:

1. To prevent the risk of electric shock power

supply to the equipment must be kept OFF

while doing the wiring arrangement. Do not

touch the terminals while power is being

supplied.

2. To eliminate electromagnetic interference use

short wires with adequate ratings; twists of the

same in equal size shall be made. For the input

and output signal lines, use shielded wires and

keep them away from each other.

3. Cable used for connection to power source, must

2

haveacross section of 1mm or greater. These

wires shall haveinsulation capacity made of at

least 1.5kV.

4. A better anti-noise effect can be expected by

using standard power supply cable for the

instrument.

WARNING:

1. When powering up for the first time, disconnect

the output connections.

2. Fuse Protection: The unit is normally supplied

without a power switch and fuses. Make wiring so

that the fuse is placed between the mains power

supply switch and the controller.(2 pole breaker

fuse- rating: 275VAC,1A for electrical circuitry is

highly recommended)

3. Since this is a built-in-type equipment (finds

place in main control panel), its output terminals

get connected to host equipment. Such equipment

shall also comply with basic EM/EMC and other

safety requirements like BSEN61326-1 and

BSEN61010 respectively.

4. Thermal dissipation of equipment is met through

ventilation holes provided on chassis of equipment.

Such ventilation holes shall not be obstructed else

it can lead to a safety hazard.

5. The output terminals shall be strictly loaded to

the manufacturer specified values/range.

2 Do not allow pieces of metal, wire clippings, or

fine metallic fillings from installation to enter the

product or else it may lead to a safety hazard that

may in turn endanger life or cause electrical

shock to the operator.

3. Circuit breaker or mains switch must be installed

between power source and supply terminals to

facilitate power 'ON' or 'OFF' function. However

this switch or breaker must be installed in a

convenient position normally accessible to the

operator.

LOAD CONNECTIONS

CAUTION:

1. The service life of the output relays depend on

the switching capacity and switching conditions.

Consider the actual application conditions and

use the product within the rated load and

electrical service life.

2. Although the relay output is rated at 5 A it is

always necessary to use an interposing relay or

contactor that will switch the load. This avoids

damage to the controller in the event of a fault

short developing on the power output circuit.

3. Always use a separate fused supply for the

"power load circuitand do not take this from

the live and neutral terminals supplying power

to the controller.

N L

C NO

XT

LOAD

R C

XT

Snubber

MOV

XT

XT

N L

Snubber

C NO

R C

Contactor

LOAD

C

MOV

For load current less than

0.5A

For bigger loads, use

interposing relay / contactor

ELECTRICAL PRECAUTIONS DURING USE

Electrical noise generated by switching of

inductive loads can create momentary

disruption, erratic display, latch up, data loss or

permanent damage to the instrument.

To reduce noise:

a) Use of snubber circuits across loads as shown

in figure is recommended.

b) Use separate shielded wires for inputs.

ML6hkI6L Ik8LLI0k

For installing the meter

1. Prepare the panel cutout with proper dimensions

s shown below :

OutIine dimensions (in mm)

PaneI cutout

dimensions (in mm)

Side view Front bezel Panel Cutout

XT546

XT246

XT346

52 52 94 45 4 46 46

72 72 83.7 67 10 69 69

96 73 90.5 10 92 92 96

2. Remove the clamp from the controller and push

the controller into the panel cutout. nsert the

clamp from the rear side until the main is

securely fit into the panel.

3. The equipment in its installed state must not

come in close proximity to any heating sources,

caustic vapors, oils, steam, or other unwanted

process by-products.

INSTALLATION GUIDELINES

CAUTION:

1. This equipment, being built-in-type, normally

becomes a part of main control panel and in such

case the terminals do not remain accessible to the

end user after installation and internal wiring.

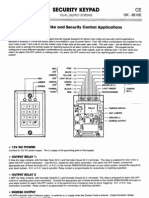

NO1

NC1

2

1

3

4

5

-

L

7

8

9

10

COM 6 11

+

N

COM1

START

12

RST

NO2

NC2

COM2

LMIkL 60kkL6I0k8

I4

IZ4

NO1

1

2

3

4

5

6

7

COM1

8

9

10

11

12

13

14 NC1

-

+

N

L

NO2

NC2

COM2

COM

RST

START

LMIkL 60kkL6I0k8

IJ4 1 10

11

12

13

14

15

16

17

18

NO1

COM1

NC1

-

+

N

L

NO2

NC2

COM2

COM

RST

START

f0k FkLL 0L86IFI0k

Operating/1006/XT546/246/346/OP288-V01 Page 2 of 3

1

Current value /

Parameter

name display

1) Display current value.

2) Display the parameter

name at the configuration

mode.

2

Set value /

Parameter

setting display

1) Display set value

2) Displays the parameter

settings at the

configuration mode.

3 Output indication

The LED is lit when the output

is ON

4 Range

1) Unit of timer

2) LED blinks when time is

in process

Functions

f0k kL18 0L86IFI0k

Key press

1) This along with the corresponding

nc key is used to enter in to program

mode, lock mode &reset mode

respectively

2) t is used to move to next configuration

parameter &stores the previous

parameter settings

2

5

4

6

7

8

9

3

60kfI60I0k Ik806I0k

Press + (PROG) key together for 3 sec continuousIy to enter into configuration. Use key (any of 3) to scroII through various

function ranges and key to set and move to next parameter.

k0L

Output

Modes

Time

Range

Start

Front

panel reset

Power on

reset

Default

Use key (any of 3) to move through various ranges.

n CycIic On function, also first OFF time is set and then On time is set.

H, M, S indication will indicate the time unit

k0L

This parameter

is prompted

only if mode

selected is

cyclic

DefauIt: Gate.

DefauIt: Yes.

DefauIt: No.

DefauIt: No.

O

n

d

l

y

e

a

e

v

a

n

t

r

l

c

i

o

f

r

s

t

C

y

l

c

n

i

C

c

i

o

r

t

y

l

c

ff fi

s

DefauIt: ON DeIay

DefauIt: 99.9 sec

The unit wiII auto exit program mode after 30 seconds of key inactivity or by pressing key + (PROG) together continuousIy for 3 sec.

1

2

4

H

M

S

R

SET LCK RST PROG

3

5 6

7

1) + (5) key together are used to

enter in theprogrammingmode.

2) + (6) key together areusedto

enter in the lock function

3) + (7) key together areused

to enter in the front panel reset

function.

4) t is used to scroll different option

in each configuration

5) t is used to increment the set value

for corresponding digit.

F0L6I0k LLLL.

L8L MLh00.

Only if mode selected is on delay / nterval

st

To set 1 digit

nd

To set 2 digit

rd

To set 3 digit

Press + (LCK) key together continuousIy for 3 sec to enter into protection

Press + (RST) key together continuousIy for 5 sec to enter into function.

k0L

k0L

DefauIt: No.

DefauIt: UnIock.

Set time

Lock

Config.

Lock

DefauIt: UnIock.

(Note: If seIected Yes)

Description Key DispIay

Note: Press key to change the set value.

The corresponding digit will increment from

0 to 9 and then will roll over back to 0. Press

key to store set value

Note: Press keys to register and move to next

parameter

st

To set 1 digit

nd

To set 2 digit

rd

To set 3 digit

The unit will auto exit set value mode after 30 sec of

key inactivity

0 F06M 8L L0L

Reset

MODE OF OPERATION

1. On deIay, IntervaI modes:

Reset

Output

ON DeIay

T on T on

SuppIy

Start

Output

IntervaI T on T on

T on

T on

2. CycIic ON first, CycIic OFF first modes:

TypicaI appIication of Continuous start and

reset in On deIay mode:

Reset

SuppIy

Start

Output

On deIay

t t

SeIec ControIs Pvt. Ltd.

Specifications are subject to change, since development is a

continuous process

TeIephone: +91-22-40394200 / 40394202

Fax: +91-22-28471733

ToII free: 1800 227 353

Website: www.seIec.com

EmaiI: saIes@seIec.com

Operating/1006/XT546/246/346/OP288-V01 Page 3 of 3

The unit will auto exit lock mode after 30 sec of key inactivity or by pressing + (LCK) keys

continuously for 3 sec to exit the function

The unit will auto exit reset mode after 30 sec of key inactivity or by pressing + (RST) keys continuously

for 5 sec to exit the function

SuppIy

Start

Reset

Output

CycIic ON

Ton Ton Toff Toff Ton Toff

Output

CycIic OFF

Toff Toff Ton Ton Toff Ton

1. START: Pulse / Gate

a) Pulse: Timing starts on momentary

closure of switch connected between start

and common terminals

b) Gate: Timing starts at power on. When the

START and COMMON terminal is closed

timing freezes and it resumes only when the

the shorting is opened.

2. FRONT PANEL RESET: Yes/No

a) Yes: Unit can be reset from the front

panel.

b) No: Unit cannot be reset from the front

panel.

3. POWER ON RESET: Yes/No

a) Yes: Unit is reset on power interruption

b) No: Unit is not reset on power interruption.

4. DEFAULT : Yes/ No

a) Yes: All parameters are set to factory set

values.

b) No: Setting done by the user is saved.

5. PROTECTON LEVEL:

SET TME PROTECTON: Yes/No

a) Yes : Time set by the user is locked and

cannot be altered.

b) No: Time set can be changed.

CONFGURATON PROTECTON: Yes/No

a) Yes : All the settings done by the user is

locked and cannot be altered.

b) No: Configuration settings can be

changed

00l 60I00 I0l I4/Z4/J4

Note: Press key to store set value

rd

To set 3 digit

nd

To set 2 digit

st

To set 1 digit

Only if mode selected is cyclic

Note: Press key to store the set value

8LI6L 0LIL8

This device contains no user serviceable parts and requires

special equipment and specialized engineers for repair.

Please contact service center for repair on the following

numbers:

ToII free: 1800 227353 (BSNL/MTNL subscribers only)

Others: 91-22-40394200 / 40394202

NO WARRANTY ON UNT DAMAGED DUE TO

WRONG POWER SUPPLY.

Note: f the set value is 000 then timer must hold

(not work). All indications will be OFF.

Вам также может понравиться

- UT130 Manual 1Документ4 страницыUT130 Manual 1soka2030Оценок пока нет

- Ch402 - 403 - OPДокумент2 страницыCh402 - 403 - OPhp691550% (2)

- Contador Hanyoung GE4Документ4 страницыContador Hanyoung GE4Juan Felipe Vieira Gaviria0% (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142От EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Оценок пока нет

- SG808 ManualДокумент2 страницыSG808 ManualzzmeoneОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- CL 8A Install GuideДокумент6 страницCL 8A Install GuidePeque DMОценок пока нет

- Digital LED Thermometer with Microcontroller AVR ATtiny13От EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Рейтинг: 5 из 5 звезд5/5 (1)

- Manual Controlador de Temperatura TCM Scantech SERIESДокумент4 страницыManual Controlador de Temperatura TCM Scantech SERIESAlex RiveraОценок пока нет

- Im PK 1603Документ32 страницыIm PK 1603James James MorrisonОценок пока нет

- Electronic Controls Handbook: DixellДокумент41 страницаElectronic Controls Handbook: DixellFran RodriguezОценок пока нет

- Op - Tc544a - Tc244ax - Tc344ax - Dtc204a-2 - Dtc324a-2 - Op294-V05 - 04-07-13Документ3 страницыOp - Tc544a - Tc244ax - Tc344ax - Dtc204a-2 - Dtc324a-2 - Op294-V05 - 04-07-13Raja VeluОценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Speed Link Inverter Control Panel User GuideДокумент16 страницSpeed Link Inverter Control Panel User GuideKelly JonesОценок пока нет

- Microprocessor-Based Digital Electronic Controller: Vr. 01 (I - GB) - Cod.: ISTR 00540Документ5 страницMicroprocessor-Based Digital Electronic Controller: Vr. 01 (I - GB) - Cod.: ISTR 00540Oscar Fuentes QuiñilenОценок пока нет

- Em306a User ManualДокумент2 страницыEm306a User ManualNguyễnĐìnhDầnОценок пока нет

- ALTRONIC TACHOMETER INSTALLATION GUIDEДокумент22 страницыALTRONIC TACHOMETER INSTALLATION GUIDENigel RamkhalawanОценок пока нет

- I ThermДокумент4 страницыI ThermAvneet MaanОценок пока нет

- $,6Hulhv7Hpshudwxuh&Rqwuroohu0Dqxdo:) HdwxuhvДокумент6 страниц$,6Hulhv7Hpshudwxuh&Rqwuroohu0Dqxdo:) HdwxuhvMinhhung AutomationОценок пока нет

- Auber Instruments PID Temperature Controller ManualДокумент5 страницAuber Instruments PID Temperature Controller ManualEektor BonillaОценок пока нет

- ManualOmronE5CWL, ControladorДокумент1 страницаManualOmronE5CWL, ControladorJose CruzОценок пока нет

- DTB ManualДокумент13 страницDTB ManualJorge BurbanoОценок пока нет

- SELECT RC102 ManualДокумент2 страницыSELECT RC102 Manualabhaya2806Оценок пока нет

- LCD TV SERVICE MANUALДокумент17 страницLCD TV SERVICE MANUALMatias416Оценок пока нет

- Syl 151Документ4 страницыSyl 151Boris KozjanОценок пока нет

- Digital Readout System: Installation/User ManualДокумент16 страницDigital Readout System: Installation/User ManualLeonardОценок пока нет

- Manual Servicio LG 1510Документ28 страницManual Servicio LG 1510vikerrs100% (1)

- Lc1508nt Lc2018nt Service ManualДокумент17 страницLc1508nt Lc2018nt Service ManualGabriel GarciaОценок пока нет

- 1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00Документ71 страница1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00kmpoulos100% (1)

- TC513A/TC513AX/TC221A/TC203AX/TC303A/TC303AX Operating InstructionsДокумент3 страницыTC513A/TC513AX/TC221A/TC203AX/TC303A/TC303AX Operating Instructionsinstrutech50% (4)

- InstructionsДокумент4 страницыInstructionsMichael GiannakОценок пока нет

- 51 52 25 123 enДокумент2 страницы51 52 25 123 enNicole StewartОценок пока нет

- Aci6007 Mount enДокумент9 страницAci6007 Mount encacatmareОценок пока нет

- Tc-2060 Instruction Manual v0.09Документ93 страницыTc-2060 Instruction Manual v0.09Herry SusiloОценок пока нет

- LG 50pg3000 Chassis Pd83 SM (ET)Документ30 страницLG 50pg3000 Chassis Pd83 SM (ET)Christian GomezОценок пока нет

- Color Monitor: Service ManualДокумент35 страницColor Monitor: Service ManualReparatii Calculatoare TimisoaraОценок пока нет

- RTP Rata Flujo ManualДокумент18 страницRTP Rata Flujo ManualFabian PerezОценок пока нет

- Altec: Instruction ManualДокумент33 страницыAltec: Instruction Manualfrankie35Оценок пока нет

- Panasonic Pt-Ae3000 Service ManualДокумент81 страницаPanasonic Pt-Ae3000 Service ManualSimon Papukyan100% (1)

- Dkg-205 Automatic Mains Failure UnitДокумент20 страницDkg-205 Automatic Mains Failure UnitRafatОценок пока нет

- Autonics TCN Manual PDFДокумент2 страницыAutonics TCN Manual PDFDiego AlanizОценок пока нет

- Temperature Controller: User'S ManualДокумент32 страницыTemperature Controller: User'S ManualkmpoulosОценок пока нет

- DTA Manual UsuarioДокумент12 страницDTA Manual Usuario99lea99Оценок пока нет

- 1/16 & 1/32 Din Temperature Controller MANUAL (59423-2) : Mechanical InstallationДокумент2 страницы1/16 & 1/32 Din Temperature Controller MANUAL (59423-2) : Mechanical InstallationJosue ZumayaОценок пока нет

- EK10 Service ManualДокумент39 страницEK10 Service ManualLuis Felipe Ruiz100% (2)

- Earth Leakage Relays ELRV30-2-A RMS PDFДокумент2 страницыEarth Leakage Relays ELRV30-2-A RMS PDFDEADMANОценок пока нет

- Novar 305 Commissioning InstructionsДокумент8 страницNovar 305 Commissioning InstructionsJason Berry100% (2)

- EPBAX Usermanual - 412zxДокумент78 страницEPBAX Usermanual - 412zxhuney_huney064963Оценок пока нет

- Mindy A01Документ40 страницMindy A01mastablastaОценок пока нет

- DataKom 040 USERДокумент45 страницDataKom 040 USERsebastianОценок пока нет

- DK-40 Compressor Controller User ManualДокумент45 страницDK-40 Compressor Controller User ManualVykintas ImbrasasОценок пока нет

- NP200 Manu Eng 170823Документ74 страницыNP200 Manu Eng 170823JRaulk PalomaresОценок пока нет

- LG (Cl-11) Lg881y Fpd1800 LCDДокумент34 страницыLG (Cl-11) Lg881y Fpd1800 LCDGregory Adolfo AlvarezОценок пока нет

- INTERNET STANDARDSДокумент18 страницINTERNET STANDARDSDawn HaneyОценок пока нет

- Society of Automotive Engineers PDFДокумент3 страницыSociety of Automotive Engineers PDFShine0% (1)

- Disclosure To Promote The Right To InformationДокумент37 страницDisclosure To Promote The Right To Informationholowin2112Оценок пока нет

- Disclosure To Promote The Right To InformationДокумент28 страницDisclosure To Promote The Right To Informationgsv988Оценок пока нет

- CQI-15 Welding ProcessДокумент52 страницыCQI-15 Welding ProcessAwdhesh Singh Bhadoriya100% (7)

- Disclosure To Promote The Right To InformationДокумент14 страницDisclosure To Promote The Right To InformationAwdhesh Singh BhadoriyaОценок пока нет

- Free 16949 QMДокумент52 страницыFree 16949 QMleewodon88% (8)

- Disclosure To Promote The Right To InformationДокумент28 страницDisclosure To Promote The Right To Informationgsv988Оценок пока нет

- INTERNET STANDARDSДокумент18 страницINTERNET STANDARDSDawn HaneyОценок пока нет

- Matsui Products PDFДокумент1 страницаMatsui Products PDFAwdhesh Singh BhadoriyaОценок пока нет

- Is 4454 1 2001 PDFДокумент15 страницIs 4454 1 2001 PDFSunitSGalimathОценок пока нет

- Blow Molding Troubleshooting GuideДокумент51 страницаBlow Molding Troubleshooting Guidesivakumar1180% (1)

- INTERNET STANDARDSДокумент18 страницINTERNET STANDARDSDawn HaneyОценок пока нет

- Disclosure To Promote The Right To InformationДокумент15 страницDisclosure To Promote The Right To InformationAwdhesh Singh BhadoriyaОценок пока нет

- Society of Automotive Engineers PDFДокумент3 страницыSociety of Automotive Engineers PDFShine0% (1)

- Society of Automotive Engineers PDFДокумент3 страницыSociety of Automotive Engineers PDFShine0% (1)

- SKF Linear BushДокумент60 страницSKF Linear BushAwdhesh Singh Bhadoriya100% (1)

- Pilot Operated Pneumatic Valve Size 1 Ttl333Документ2 страницыPilot Operated Pneumatic Valve Size 1 Ttl333Awdhesh Singh BhadoriyaОценок пока нет

- Pasport Form DDNI06330312GO0330Документ0 страницPasport Form DDNI06330312GO0330Awdhesh Singh BhadoriyaОценок пока нет

- SKF - Ozyska Barykowe ENДокумент0 страницSKF - Ozyska Barykowe ENurbinanet123Оценок пока нет

- Taper Lock BushingДокумент6 страницTaper Lock Bushingdarsh2001patelОценок пока нет

- App Format AFCAT WomenДокумент1 страницаApp Format AFCAT WomenSushmitha SatheeshОценок пока нет

- PU Fittings and Tubing SMCДокумент90 страницPU Fittings and Tubing SMCAwdhesh Singh BhadoriyaОценок пока нет

- PU FittingДокумент92 страницыPU FittingAwdhesh Singh BhadoriyaОценок пока нет

- Hydraulic Valve Aljan Ake 4D02 - CatalogueДокумент16 страницHydraulic Valve Aljan Ake 4D02 - CatalogueAwdhesh Singh BhadoriyaОценок пока нет

- Blue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualДокумент123 страницыBlue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualAwdhesh Singh Bhadoriya71% (35)

- Blue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualДокумент123 страницыBlue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualAwdhesh Singh Bhadoriya71% (35)

- Ais 037Документ1 страницаAis 037Awdhesh Singh BhadoriyaОценок пока нет

- ING-ABB-GE-BAWER-CCM-PTAP-BateriaColon-Planos - Tipicos-BomReport-LA-MCC BowellДокумент5 страницING-ABB-GE-BAWER-CCM-PTAP-BateriaColon-Planos - Tipicos-BomReport-LA-MCC BowellCarla MaldonadoОценок пока нет

- 4th LectureДокумент78 страниц4th LectureNaveed RabbaniОценок пока нет

- Ordering Information: Motor Protection Circuit BreakerДокумент14 страницOrdering Information: Motor Protection Circuit BreakerHELLOGREGОценок пока нет

- Test Manual 2657668154 - 007Документ63 страницыTest Manual 2657668154 - 007SMMAR Soluciones MecanicasОценок пока нет

- D115 Ca001b en PДокумент170 страницD115 Ca001b en PisidroscribdОценок пока нет

- 1SFL527002R1311 Af205 30 11 13 Contactor PDFДокумент5 страниц1SFL527002R1311 Af205 30 11 13 Contactor PDFrehanОценок пока нет

- UA110-30-00 220-230V 50Hz / 230-240V 60Hz Contactor: General InformationДокумент3 страницыUA110-30-00 220-230V 50Hz / 230-240V 60Hz Contactor: General InformationJuliano AlmeidaОценок пока нет

- BNP C3015 PDFДокумент231 страницаBNP C3015 PDFibraheemОценок пока нет

- MOTOR STARTER CONTROL CIRCUITДокумент17 страницMOTOR STARTER CONTROL CIRCUITSabari MОценок пока нет

- Microprocessor and PLC Applications Workshop Manual: Unit DCL-2-246Документ35 страницMicroprocessor and PLC Applications Workshop Manual: Unit DCL-2-246Binar Arum OktaviaОценок пока нет

- Siemens Price List (Low Voltage Control Products) PDFДокумент18 страницSiemens Price List (Low Voltage Control Products) PDFMd. Nazmul KarimОценок пока нет

- Isomax Tc-Annex S2x80enДокумент27 страницIsomax Tc-Annex S2x80enbandoiuОценок пока нет

- Relays Selection GuideДокумент11 страницRelays Selection GuideNaresh KumarОценок пока нет

- LIELBA EdibonДокумент27 страницLIELBA EdibondondidendiОценок пока нет

- CONTACTORS & OCR (HiMC, HiTH) PDFДокумент79 страницCONTACTORS & OCR (HiMC, HiTH) PDFFILIN VLADIMIRОценок пока нет

- Baldor Section20 StartersДокумент6 страницBaldor Section20 StartersRichard MorenoОценок пока нет

- Hydroware Troubleshooting PDFДокумент44 страницыHydroware Troubleshooting PDFSatheesh Rama100% (2)

- Ebook Electric Machines Principles Applications and Control Schematics 2Nd Edition Dino Zorbas Solutions Manual Full Chapter PDFДокумент34 страницыEbook Electric Machines Principles Applications and Control Schematics 2Nd Edition Dino Zorbas Solutions Manual Full Chapter PDFalexandercampbelldkcnzafgtw100% (9)

- IEEE Std. 45.6-2016 - IEEE Recommended Practice For Electrical Installations On Shipboard - Electrical Testing PDFДокумент39 страницIEEE Std. 45.6-2016 - IEEE Recommended Practice For Electrical Installations On Shipboard - Electrical Testing PDFrenegadeОценок пока нет

- 1SBC104032D0201 DC Operated Ring Tongue CatalogueДокумент51 страница1SBC104032D0201 DC Operated Ring Tongue CataloguetrungabcОценок пока нет

- MCCB and Switchgear Components GuideДокумент25 страницMCCB and Switchgear Components GuideSAMUEL HERYADIОценок пока нет

- OMRON - Floatless Level ControllerДокумент21 страницаOMRON - Floatless Level Controllerhafizi07Оценок пока нет

- Siemens Smart Control Panel DesignДокумент2 страницыSiemens Smart Control Panel Designaling alingОценок пока нет

- Emergency Lighting Discharge Test KitsДокумент2 страницыEmergency Lighting Discharge Test KitsA.K.A. HajiОценок пока нет

- Zapi H2 Traction ControllerДокумент5 страницZapi H2 Traction ControllerHartanto DwiОценок пока нет

- SEW Brake Service GuideДокумент40 страницSEW Brake Service GuideIlayaraja BoopathyОценок пока нет

- Yaskawa Inverter Training ManualДокумент146 страницYaskawa Inverter Training ManualNguyễnVănThiệnОценок пока нет

- Eim 11 2ndДокумент3 страницыEim 11 2ndCristina Aquino-SajoniaОценок пока нет

- SwitchesДокумент0 страницSwitchesREDDYGAARI ABBAYIОценок пока нет

- Alpm F8339101Документ80 страницAlpm F8339101smarthome797979Оценок пока нет