Академический Документы

Профессиональный Документы

Культура Документы

Escalon Retraible para Camioneta Chevy Silverado/GMC Sierra 1500 2014

Загружено:

Sonia GarciaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Escalon Retraible para Camioneta Chevy Silverado/GMC Sierra 1500 2014

Загружено:

Sonia GarciaАвторское право:

Доступные форматы

www.amp-research.com 1/9 IM76154 rev 03.17.

14

I N S T A L L A T I O N G U I D E

TOOLS REQUIRED

q Safety goggles

q Measuring tape

q Flat blade screwdriver

q Power Drill

q 9/32 drill bit

q 13 mm socket

q Ratchet wrench and extension

q 13mm end wrench

q Wire crimpers

q Wire stripper / cutter

q 3/16 hex key wrench (allen wrench)

q 4mm hex key wrench ( allen wrench )

q Electrical tape

q Weather proof caulking (silicone sealer)

q Silicone spray

INSTALLATION TIME

1 2 3 4

SKILL LEVEL

4= Experienced

AMP RESEARCH TECH SUPPORT 1-888-983-2204 (Press 2) Monday - Friday, 6:00 AM - 5:00 PM PST

2-3 Hours

Professional installation recommended

WARRANTY

5-Year Limited Warranty

Invented, engineered and manufactured exclusively by AMP Research in the USA. May be covered by one of the following patents:

6,641,158; 6,830,257; 6,834,875; 6,938,909; 7,055,839; 7,380,807; 7,398,985; 7,584,975 2012 AMP Research. All rights reserved.

Printed in USA.

APPLICATION AMP Part #

Chevrolet Silverado1500 / GMC Sierra 1500 - Double Cab * 2014 76154-01A

Chevrolet Silverado1500 / GMC Sierra 1500- Crew Cab 2014 76154-01A

Chevrolet Silverado HD / GMC Sierra HD - Double Cab *(excludes diesel engine) 2015 76154-01A

Chevrolet Silverado HD / GMC Sierra HD- Crew Cab (excludes diesel engine) 2015 76154-01A

*Modification required to running board assembly. See Item 1 on page 3.

www.amp-research.com 2/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

INSTALLATION GUIDE

Attaching motor to Linkage assembly

The motors must be attached to the Linkage assemblies before continuing the

installation process.

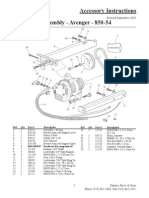

EXPLODED VIEW

80-03129-90 Motor

19-03138-90 Gear Cover

19-03179-90 Socket cap screw

19-03133-90 Washer

CAUTION: HANDLE WITH CARE.

To ensure our customers receive all components with full integrity, we pack

the motors separate from their Linkage assemblies. This requires that the

installer position and fasten the motor before continuing with the install.

Please follow the instructions below and handle the assembly carefully.

CAUTION: Dropping the assembly or any excessive impact MAY cause

damage to the motor.

Instructions:

1. Position the gear cover in place as shown if not already in place.

2. Seat motor into position on the three mounting bosses. This may require

an adjustment of the gear by moving the swing arms.

3. After seating into place, fasten the motor with the three motor mount

screws with 4mm Hex Head. Tighten screws to 36 in-lbs (4N-m). Do not

over torque.

www.amp-research.com 3/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

2 x2

10-03968-10

Idler Linkage assembly

3 x2

10-03967-10

Motor Linkage assembly

4

19-03969-90L

Wire harness

5

19-03297-A06

Controller

6

16-03970-90

ODB II Plug

7

19-03964-90

Brake Cable Bracket

8

x2

19-03138-90

Gear Cover

9

x2

80-03129-90

Motor

Note: Some Applications require modification.

Application Cut Length

Crew Cab 79 (No Modification Required)

Extended Cab 72 (Trim 7)

1 x2

20-03752-79

Running board assembly

D

B

(A) 19-03763-90 End cap left (x1)

(B) 19-03760-90 End cap right (x1)

(C) 19-02663-90 T-nut insert (x2)

(D) 19-02802-90 Socket cap screw (x2)

(E) 19-03761-90 End cap wedge right (x1)

(F) 19-03764-90 End cap wedge left (x1)

A

C

E

F

C

u

t D

im

e

n

sio

n

www.amp-research.com 4/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

19-02805-90

Cable tie (7)

16

19-02802-90

Socket Cap Screw

17 x8

19-02640-90

Grommet

21

19-03339-90

Cable tie (11)

19 x2

13 x5

19-03900-90

Hex Bolt w

Conical washer

19-03133-90

M5 Washer

x6

15 x4

19-03467-90

U-nut

x4

16-03608-90

Hex Bolt w

Conical washer

10

12 x4

19-03356-90

Nut w Conical

washer

14

11 x6

19-03179-90

M5 Socket Cap Screw

x20

22

19-03302-90

LED Lamp

x4

23

19-03911-90

Butt Connector

x8

19-02488-90

U Nut

18

20

19-0POSITWIST

Posi-Twist

x2

24

19-03403-90

Rubber

3

www.amp-research.com 5/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

Front Idler Linkage: Thread supplied bolt (10) in

about half way into the first sheetmetal tab / hole from

front. Set linkage over bolt and Tighten lower bolt (10)

to 16ft-lbs(22N m). Finger tighten nut (12) onto bolt

(10). Install bolt (13) and torque to 16 ft-lb (22N m).

Next torque lower nut (12) to 16 ft-lb (22N m) using

wrench to hold lower bolt in place.

Slide mounting T-nut into position, aligning the end of

the board with the rear edge of the back door. Mount

board and tighten fasteners to 10 ft-lbs. Insure linkages

are squared to body prior to torquing fasteners.

Rear Drive Linkage: Install driver side Motor Linkage in fourth sheetmetal tab / hole from front. Linkage will

then clear parking brake cable.

Note: U-nut may be needed if

threaded insert is not present

on vehicle

Install U Nut (18) into position just forward of

brake cable T junction. Use supplied bolt (13)

to hold Brake cable rod into position. NOTE:On

HD models use supplied rubber to prevent cable

contact with drive linkage on drivers side. Wrap

and secure with cable ties.

Using the two 11 cable ties, mount controller to

support arm next to battery. Plug in harness (Ensure

that locking tabs engage)

Remove power fuse. Attach power lead (RED wire)

to positive pole on the battery. Attach ground lead to

negative battery pole.

CAUTION: Do not ground wrench when engaged with

nut.

19

5

10

NOTE: U Nut may not be needed

on some model trucks.

Front of Vehicle

13

12

15

10

Rear of vehicle

Crew Cab- Approx 29 from back of cab

Extended Cab- Approx 13 from back of cab

Install rear linkages with U Nut (18) here

Set linkage into second to last sheetmetal tab / hole from rear. Use supplied bolt (10) and nut(12) to

hold in position. Install bolt (13) into upper mounting hole and snug both bolts. Torque upper bolt (13)

to 16ft-lbs(22N m) first and then torque lower bolt (10) and nut (12) to 16 ft-lb (22N m). Repeat linkage

installation on Passenger side.

NOTE: U Nut may not be needed

on some model trucks.

13

12

10

15

Note: Threaded nut may not be present

on some vehicles. Bolt will assemble the

same as step 3.

2

1

3

5 6

3

1

4 5

www.amp-research.com 6/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

Pull up the carpet and drill 9/32 hole in metal and

insert supplied rubber grommet (21).

NOTE: Seal holes

with silicone glue

and cover with tape

so carpet does not

stick to glue.

Route wire harness along the frame and back towards

rear linkages. Secure with zip ties. Push both wires

through rubber grommets.

Pull up front door sill plate covers as shown.

2

3

1

4

4

2

4

On each side of the vehicle measure from the front

edge of door line on the pinch weld to the specified

lengths below. Measure at 23 for front LED Light and

63 for rear LED Light.

Affix lamp to rocker panel surface. Make sure the

lamp is affixed to a clean, flat surface. There is a

step down midway across the surface. Affix lamp

just outside of step down.

22

Route long end of wire harness above engine and

down through drivers side wheel well. Zip tie harness

to cowling clips on fire wall. Route short end down

passengers side.

4

6

10

8

11

6

8 9

10

7

www.amp-research.com 7/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

Vehicle Port

Vehicle Port

Powerstep

Connection Module

Powerstep

Connection Module

Vehicle Port

Pass-Through Harness

(pin-to-pin at each terminal)

New Vehicle Port

(replaces original port)

To Powerstep

Motors

To Vehicle

Power (12V)

Powerstep

Control Module

To Powerstep

Motors

To Vehicle

Power (12V)

Powerstep

Control Module

Direct to Port Option

Pass-Through Harness Option

Vehicle Port

Vehicle Port

Powerstep

Connection Module

Powerstep

Connection Module

Vehicle Port

Pass-Through Harness

(pin-to-pin at each terminal)

New Vehicle Port

(replaces original port)

To Powerstep

Motors

To Vehicle

Power (12V)

Powerstep

Control Module

To Powerstep

Motors

To Vehicle

Power (12V)

Powerstep

Control Module

Direct to Port Option

Pass-Through Harness Option

23

Using supplied butt connectors, connect the lamp

wires. Red to Red, Black to Black. Once Crimped use

heat gun to shrink tube. Close and wrap conduit with

electrical tape. Secure all loose wires with cable ties.

Pull lamp wires upward to avoid any wire snagging.

OBD II install: Use Supplied Posi Twist connectors to attach the Plug and Play Module to the

Harness. Attach matching colors on the harness to the wires on the module. Plug in module to

OBD II port on the vehicle. Secure harness with supplied tie wraps.

Note: If the OBD II pass thru harness (76404-01A) was purchased see install sheet supplied in packaging. The

pass through harness allows for an open port for diagnostics or a connection point for other accessories. See

below for a brief description.

Connect harness to motor. Secure harness with tie

wraps.

26

30

43 44

45

12 13

14

www.amp-research.com 8/9 IM76154 rev 03.17.14

AMP RESEARCH POWERST EP

T M

CHEVROL ET / GMC

CORRECT OPERATION OF LIGHTS: All four lamps will illuminate upon opening any door of vehicle. Lamps

will stay on until restowing of both Power Steps or until 5 minutes has expired with the doors open. When the

lights timeout after 5 minutes, they can be reillumintated by closing and opening any door of vehicle.

FINAL SYSTEM CHECK

Check that all doors activate the PowerStep and the LED lights work when doors open and close.

NORMAL OPERATION: When the doors open, PowerStep automatically deploys from under the vehicle.

When the doors are closed, PowerStep will automatically return to the stowed/retracted position. Note that

there is a 2-second delay before the PowerStep returns to the stowed/retracted position.

3

Reinstall fuse. Check that all doors activate the Power Step and the LED Lights work when doors

open and close. Reinstall any remaining trim panels.

Automatic power deploy:

The running boards will extend down and out when the doors are opened.

Automatic power stow:

The running boards will return to the stowed position when the doors are closed. There will be a 2-second

delay before the running boards move to the stowed position.

Automatic stop:

If an object is in the way of the moving running board, the running board will automatically stop.

To reset, clear any obstruction, then simply open and close the door to resume normal operation.

Manually set in the deployed (OUT) position for access to the roof:

your foot while at the same time closing the door. To resume normal operation, open and close the door.

Maintenance: In adverse conditions, debris such as mud, dirt, and salt may become trapped in the running

board mechanism, possibly leading to unwanted noise. If this occurs, manually set the running boards to

Avoid spraying the motors directly. After washing, apply silicone spray lubricant to the hinge pivot pins.

Do not apply silicone, wax or protectants like Armor All to the running board stepping surface.

Caution! Keep hands away when the running board is in motion.

Congratulations onyour purchase of the

genuine AMP Research PowerStep!

Heres what you should know...

AMP RESEARCH warrants this product to be free from defects in material and workmanship for FIVE (5) YEARS FROM

DATE OF PURCHASE, provided there has been normal use and proper maintenance. This warranty applies to the original

purchaser only. All remedies under this warranty are limited to the repair replacement of the product itself, or the repair

or replacement of any component part thereof, found by the factory to be defective within the time period specifed. The

decision to repair or replace is wholly within the discretion of the manufacturer.

for instructions. You must retain proof of purchase and submit a copy with any items returned for warranty work. Upon

completion of warranty work, if any, we will return the repaired or replaced item or items to you freight prepaid. Damage

to our products caused by accidents, fre, vandalism, negligence, misinstallation, misuse, Acts of God, or by defective parts

not manufactured by us, is not covered under this warranty.

ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE CREATED HEREBY ARE

LIMITED IN DURATIONTOTHE SAME DURATION AND SCOPE AS THE EXPRESS WRITTENWARRANTY. OUR COMPANY SHALL

NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGE.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental

or consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specifc

legal rights, and you may also have other rights that vary fromstate to state.

FOR WARRANTY ISSUES WITHTHIS PRODUCT PLEASE CALL AMP RESEARCH CUSTOMER SERVICE 1-888-983-2204

5-YEAR LIMITEDWARRANTY

WARNING

Be sure to read and precisely followthe provided instructions when installing this product. Failure to do so could place the vehicle

occupants inapotentiallydangerous situation. After installingor reinstalling, re-checktoinsurethat theproduct is properlyinstalled.

AMP Research PowerStep running boards automatically move

when the doors are opened to assist entering and exiting the vehicle.

Вам также может понравиться

- F250-2008 PS Install Guide LKДокумент13 страницF250-2008 PS Install Guide LKNik SaykoОценок пока нет

- Tucson (LM) - Trailer Wiring Harness Installation (2S061-ADU10)Документ16 страницTucson (LM) - Trailer Wiring Harness Installation (2S061-ADU10)Juan VGОценок пока нет

- 4 TNV 84 TZДокумент6 страниц4 TNV 84 TZCarlos Rivera MontesОценок пока нет

- Freightliner Fld120Документ19 страницFreightliner Fld120LO Consigo Antofagasta75% (4)

- Subaru - Impreza - Workshop Manual - 1999 - 2002Документ8 373 страницыSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiОценок пока нет

- 180TCD Metric ManualДокумент6 страниц180TCD Metric ManualJose GonzalezОценок пока нет

- Number: Group: Date:: Transmission (Sales Code DG6)Документ6 страницNumber: Group: Date:: Transmission (Sales Code DG6)Mohamed AhmedОценок пока нет

- Manual en Inglés de Alarma Prestige Aps997cДокумент32 страницыManual en Inglés de Alarma Prestige Aps997cJosé Luis Farías100% (1)

- 180TCD Brake ManualДокумент5 страниц180TCD Brake ManualJose GonzalezОценок пока нет

- Harley-Davidson Dyna Shortshots Staggered Installation Instructions PART# 17217Документ4 страницыHarley-Davidson Dyna Shortshots Staggered Installation Instructions PART# 17217Isai GarzaОценок пока нет

- Webco ABS Sensor TestsДокумент4 страницыWebco ABS Sensor TestsДмитрий Пупкин0% (1)

- Argo 8x8 BrakesДокумент5 страницArgo 8x8 BrakesGeorge finkleОценок пока нет

- Manual FordMustang4Документ60 страницManual FordMustang4paradox10001Оценок пока нет

- 25F-PRCServ PDFДокумент38 страниц25F-PRCServ PDFsindelu60Оценок пока нет

- Montagem Ponteira Two Brothers para FZ6Документ3 страницыMontagem Ponteira Two Brothers para FZ6Vini_bullОценок пока нет

- Drive Belt Inspection and Testing ProcedureДокумент13 111 страницDrive Belt Inspection and Testing ProcedureJuan Harmond Bambang WirawanОценок пока нет

- 04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation InstructionsДокумент10 страниц04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation Instructionstrimoca_234178616Оценок пока нет

- HAR-1005 LT1 Fuel Injection Wiring Harness InstructionsДокумент14 страницHAR-1005 LT1 Fuel Injection Wiring Harness InstructionsJacob Hernandez100% (2)

- Hybrid Racing 92-95 Civic AC Install Guide v1.1Документ14 страницHybrid Racing 92-95 Civic AC Install Guide v1.1Hybrid Racing60% (5)

- Crostrek InstalaДокумент26 страницCrostrek InstalaJose Antonio Bolivar PalaciosОценок пока нет

- Et500plus Install ManualДокумент26 страницEt500plus Install ManualDirk HennОценок пока нет

- Hi-7 and Hi-8 Race Ignition Systems: Battery ConsiderationsДокумент8 страницHi-7 and Hi-8 Race Ignition Systems: Battery ConsiderationssphinxxxxОценок пока нет

- Factory Wiring Harness - GMC Surb - ScoscheДокумент1 страницаFactory Wiring Harness - GMC Surb - Scoscheajhillgolf100% (1)

- GC30 assembly instructionsДокумент5 страницGC30 assembly instructionsDalibor DanevskiОценок пока нет

- IE RS3 8V Downpipe InstallДокумент29 страницIE RS3 8V Downpipe InstallMartin UnknownОценок пока нет

- POWERBLOCДокумент17 страницPOWERBLOCcyril DESPRATОценок пока нет

- Intake Manifold Replacement - Lower Removal ProcedureДокумент15 страницIntake Manifold Replacement - Lower Removal ProcedureDoug Besaw JrОценок пока нет

- 30-1 Clutch Mechanism ServiceДокумент22 страницы30-1 Clutch Mechanism Servicemefisto06cОценок пока нет

- Alternator Installation Instructions for Avenger 850-54Документ6 страницAlternator Installation Instructions for Avenger 850-54cristi_stoiciucОценок пока нет

- Manitou 2001 Magnum Service ManualДокумент12 страницManitou 2001 Magnum Service ManualEdha AliОценок пока нет

- TB Mag ManualДокумент60 страницTB Mag Manualyanina25Оценок пока нет

- Volvo - S40 - Workshop Manual - 2000 - 2002Документ2 846 страницVolvo - S40 - Workshop Manual - 2000 - 2002George Sandu0% (2)

- SU CARBURETOR INSTALLATION INSTRUCTIONSДокумент8 страницSU CARBURETOR INSTALLATION INSTRUCTIONSSiddeОценок пока нет

- 06-09 Honda S2000 Instructions r3-2Документ18 страниц06-09 Honda S2000 Instructions r3-2nicolasОценок пока нет

- DefoggerДокумент7 страницDefoggerkiovas33Оценок пока нет

- Alternador Delco Remy Installation Instructions 24si 28siДокумент6 страницAlternador Delco Remy Installation Instructions 24si 28sijorge_chaparro_1Оценок пока нет

- B&M Megashifter Installation ManualДокумент8 страницB&M Megashifter Installation ManualPaolo TirafortiОценок пока нет

- Install OurboardДокумент18 страницInstall OurboardMartin A Gomez RОценок пока нет

- Manual Rontan - Winglux - Rev 0Документ25 страницManual Rontan - Winglux - Rev 0mcginity0% (1)

- HAR-1019 VORTEC Harness Instructions 9Документ14 страницHAR-1019 VORTEC Harness Instructions 9Jacob HernandezОценок пока нет

- HAR-1015 VORTEC DBW Harness Instructions 5Документ14 страницHAR-1015 VORTEC DBW Harness Instructions 5Jacob HernandezОценок пока нет

- Variable Speed Drive Installation and Maintenance InstructionsДокумент6 страницVariable Speed Drive Installation and Maintenance Instructionsvirus40Оценок пока нет

- WESTFALIA CatalogueДокумент8 страницWESTFALIA CatalogueValerică HizanuОценок пока нет

- Smooth9.17HRO Manual 112805Документ32 страницыSmooth9.17HRO Manual 112805dfjklasdfrvОценок пока нет

- Dynojet Power Commander Installation Royal EnfieldДокумент5 страницDynojet Power Commander Installation Royal EnfieldAle PattinoОценок пока нет

- Mallory Points Ignition Conversion ModuleДокумент4 страницыMallory Points Ignition Conversion Modulepaul_a_rodriguezОценок пока нет

- FMDV32 - Golf MK8 GTI Fitting InstructionsДокумент9 страницFMDV32 - Golf MK8 GTI Fitting InstructionsIvo MozaraОценок пока нет

- John Deere Z355E ZTrak Mower (S.N.010001-) Service Repair Technical Manual (TM140319)Документ16 страницJohn Deere Z355E ZTrak Mower (S.N.010001-) Service Repair Technical Manual (TM140319)zhuangfuqian31Оценок пока нет

- Manual Taller ARN 125 CC (Idioma Ingles)Документ85 страницManual Taller ARN 125 CC (Idioma Ingles)Cordobessa50% (2)

- HAR-1018 VORTEC Harness Instructions 8Документ14 страницHAR-1018 VORTEC Harness Instructions 8Jacob HernandezОценок пока нет

- Caution: MeterДокумент4 страницыCaution: MeterHafidz FidzОценок пока нет

- Front Wheel Bearing Removal & InstallationДокумент3 страницыFront Wheel Bearing Removal & Installationkaushik_rajan_2Оценок пока нет

- Honda Service Bulletin 03-022Документ8 страницHonda Service Bulletin 03-022bruyoni100% (1)

- PortaPump Service ManualДокумент5 страницPortaPump Service ManualSarah PerezОценок пока нет

- CTS-V Conversion PDFДокумент7 страницCTS-V Conversion PDFAnonymous XbqU3gYDmОценок пока нет

- EK 99-00 Wire Harness Instructions 4.0Документ29 страницEK 99-00 Wire Harness Instructions 4.0Hybrid Racing100% (4)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideОт EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideРейтинг: 4.5 из 5 звезд4.5/5 (8)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsОт EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsРейтинг: 5 из 5 звезд5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Ford Y-Block Engines: How to Rebuild & ModifyОт EverandFord Y-Block Engines: How to Rebuild & ModifyРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Installation Manual C20 D6 Spec E-GДокумент162 страницыInstallation Manual C20 D6 Spec E-GSonia GarciaОценок пока нет

- Tablaturas de Canciones de The Legend of Zelda en OcarinaДокумент13 страницTablaturas de Canciones de The Legend of Zelda en OcarinaSonia GarciaОценок пока нет

- Escalón Retraible para Camioneta JEEP 2007Документ9 страницEscalón Retraible para Camioneta JEEP 2007Sonia GarciaОценок пока нет

- Michael Aaron Piano Course Lessons Grade 2 No.23 The Breakers (P.32)Документ2 страницыMichael Aaron Piano Course Lessons Grade 2 No.23 The Breakers (P.32)Sonia Garcia100% (10)

- Joou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - EdoujinДокумент25 страницJoou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - Edoujinaura.nazhifa10020% (1)

- Alpacon Degreaser BIO GENДокумент2 страницыAlpacon Degreaser BIO GENFahmi Ali100% (1)

- SELECTING A DISTILLATION COLUMN CONTROL STRATEGYДокумент12 страницSELECTING A DISTILLATION COLUMN CONTROL STRATEGYinstrutech0% (1)

- Speeduino Manual-7Документ16 страницSpeeduino Manual-7Makson VieiraОценок пока нет

- Piping and Equipment IsolationДокумент8 страницPiping and Equipment IsolationBilal Mustafa Siddiqui100% (1)

- Web Servers ExplainedДокумент15 страницWeb Servers ExplainedIman AJОценок пока нет

- GRADE-7 computer-MODULEДокумент4 страницыGRADE-7 computer-MODULECzz ThhОценок пока нет

- Cel2106 SCL Worksheet Week 8Документ3 страницыCel2106 SCL Worksheet Week 8Hazwanee ZainalОценок пока нет

- B. Com II Year Economics Previous Year QuestionsДокумент11 страницB. Com II Year Economics Previous Year QuestionsShashiMohanKotnalaОценок пока нет

- Emily Act 3 GraficoДокумент13 страницEmily Act 3 Graficoemily lopezОценок пока нет

- FS 1 Observations of Teaching-Learning in Actual School EnvironmentДокумент8 страницFS 1 Observations of Teaching-Learning in Actual School EnvironmentJessie PeraltaОценок пока нет

- Sheikh Zayed Grand Mosque - Largest in UAEДокумент2 страницыSheikh Zayed Grand Mosque - Largest in UAEKyla SordillaОценок пока нет

- Please Note That Cypress Is An Infineon Technologies CompanyДокумент22 страницыPlease Note That Cypress Is An Infineon Technologies Company20c552244bОценок пока нет

- Essential Components of an Effective Road Drainage SystemДокумент11 страницEssential Components of an Effective Road Drainage SystemRaisanAlcebarОценок пока нет

- The Muscle and Strength Training Pyramid v2.0 Training by Eric Helms-9Документ31 страницаThe Muscle and Strength Training Pyramid v2.0 Training by Eric Helms-9Hamada MansourОценок пока нет

- Module 3 - Subsequent To AcquisitionДокумент8 страницModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTREROОценок пока нет

- Unit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Документ19 страницUnit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Zara Nabilah87% (15)

- ISO 22301 Mandatory DocumentДокумент2 страницыISO 22301 Mandatory Documenttrackuse100% (1)

- VNL-Essar Field Trial: Nairobi-KenyaДокумент13 страницVNL-Essar Field Trial: Nairobi-Kenyapoppy tooОценок пока нет

- MicroProcessadores ZelenovskyДокумент186 страницMicroProcessadores ZelenovskyDavid SantosОценок пока нет

- Service ManualДокумент14 страницService ManualOlegОценок пока нет

- GI Tags Complete ListДокумент17 страницGI Tags Complete Listrameshb87Оценок пока нет

- Family Nursing Care PlanДокумент2 страницыFamily Nursing Care PlanSophia Ella OnanОценок пока нет

- Adult Education and Lifelong Learning Peter JarvisДокумент63 страницыAdult Education and Lifelong Learning Peter JarvisKatherine Uran RamirezОценок пока нет

- Using Social Stories With Students With Social Emotional and Behavioral Disabilities The Promise and The Perils (2019)Документ17 страницUsing Social Stories With Students With Social Emotional and Behavioral Disabilities The Promise and The Perils (2019)SarahОценок пока нет

- USB and ACPI Device IDsДокумент10 страницUSB and ACPI Device IDsKortiyarshaBudiyantoОценок пока нет

- Automotive Relay PDFДокумент3 страницыAutomotive Relay PDFSimon MclennanОценок пока нет

- Small-Scale Fisheries Co-op ConstitutionДокумент37 страницSmall-Scale Fisheries Co-op ConstitutionCalyn MusondaОценок пока нет

- VPN Risk Report Cybersecurity InsidersДокумент20 страницVPN Risk Report Cybersecurity InsidersMaria PerezОценок пока нет

- Horses To Follow: Ten To Follow From Timeform'S Team of ExpertsДокумент12 страницHorses To Follow: Ten To Follow From Timeform'S Team of ExpertsNita naОценок пока нет