Академический Документы

Профессиональный Документы

Культура Документы

Melamine - Formaldehyde Networks With Improved Chemical Resistance

Загружено:

emac234Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Melamine - Formaldehyde Networks With Improved Chemical Resistance

Загружено:

emac234Авторское право:

Доступные форматы

You are now at www.wernerblank.

com

HOME NEWS PUBLICATIONS LECTURES PATENTS DOWNLOADS

Melamine Formaldehyde Networks with Improved Chemical Resistance

W.J. Blank, Z.A. He, E. T. Hessell and R.A. Abramshe, King Industries Inc.

Norwalk, CT. 06852

Introduction

Melamine formaldehyde resins (MFR) are used to crosslink many industrially applied

coatings. Much of the MFR used in the US. are of the hexa(methoxymethyl)melamine (HMMM)

type. As reaction partners for HMMM predominantly hydroxyl or carboxyl functional resins are

used. The reaction of HMMM with hydroxyl polymers is generally well understood. The reaction

is specific acid catalyzed with strong acid catalysts such as sulfonic acid commonly used. The

acetal linkage formed can hydrolyze under acidic conditions leading to a loss of the network

structure and attack on the film. Typical acid rain conditions are sufficient to damage the coating.

This hydrolysis reaction is accelerated at higher temperature and increased humidity. One

additional factor in the hydrolysis reaction of melamine crosslinked films is the basicity of

melamine which leads to the absorption of acid in the film. The acid sensitivity of melamine

crosslinked coatings has become more of a problem with the introduction of high solids coatings

which require higher levels of melamine resin.

1

In the automotive topcoat area this problem is

especially severe. Where many attempts have been made to replace melamine crosslinking with

other crosslinker. From a cost and performance standpoint melamine crosslinker are very

attractive, providing much of an incentive to find ways to improve the acid resistance.

The self-condensation reaction of melamine resins

2

during overbake conditions and the

ensuing embrittlement is also a result of hydrolytic instability of the crosslinks, leading to a loss

of crosslinking and the formation of a self-crosslinked network. A more stable link of the

polymer with the melamine resin should also reduce the loss of flexibility of melamine

crosslinked coatings on overbake.

Melamine formaldehyde chemistry offers many other alternative ways of crosslinking

besides reacting with hydroxyl and carboxyl groups, HMMM can react with NH and CH reactive

sites on polymers to form linkages which are potentially more resistant to hydrolysis.

APPROACHES TO IMPROVED STABILITY OF NETWORK

Reduced Melamine Resin Level and Dual Cure Systems

Blocked Isocyanates

Ketoxime

3

Malonate

4

Siloxane

5

Epoxy

6

More Stable Crosslinks

NH crosslinks

Primary Carbamate

7

,

8

Amide

Urea

CH crosslinks

Phenolic

9

Malonate blocked isocyanate

10

and Acetoacetate

SH functional.

11

Hydrophobic Backbone or Improved Hydrolytically Stable Backbone

Ester free backbone

12

Polyurethane with hydrophobic groups

13

Acrylic polymers

14

Other potential approaches

Reduced solubility of melamine

15

Reduced basicity of melamine

Combination with other amino resins

Change in hydrolysis equilibrium

Reaction of HMMM with Functional Groups

Hydroxyl Groups

The reaction of HMMM with hydroxyl functional polymers has been studied extensively.

HMMM reacts readily with hydroxyl functional compounds in the presence of an acid catalyst.

This exchange reaction proceeds at room temperature. The rate of reaction is a function of the pH

of the system. Reaction with water also proceeds leading to a hydrolysis of the crosslinked

network. Although this reaction is reversible, subsequent demethylolation and loss of

formaldehyde leads to a permanent loss of crosslinks

16

. The hydrolysis reaction can also be

accelerated in the presence of UV radiation.

17

-N(CH

2

OCH

3

)

2

+ ROH -N(CH

2

OR)

2

+ 2 CH

3

OH

-N(CH

2

OCH

3

)

2

+ HOH -N(CH

2

OH)

2

+ 2 CH

3

OH

-N(CH

2

OH)

2

-NHCH

2

OH + CHOH

Reduced Melamine Resin Level and Dual Cure System

It has been found that coating systems which utilize less than 25 % of melamine resin

generally give acceptable acid resistance and exterior durability

18

. For the high solids polymer

systems used in the US, however this level of melamine resin is not sufficient to achieve the

required nonvolatile content. Yet increasing the melamine content has a negative impact on acid

etch resistance. Every conceivable reaction mechanism has been studied as a means to improve

this deficiency. Some of these approaches are being used to improve the resistance properties of

melamine crosslinked films.

Stability of the Methylene or Methylene Ether Linkage

Comparison of the stability of methylene bridges of different amino compounds shows

that the stability is related to the basicity of the nitrogen. An increase in basicity of either

nitrogen leads to a decrease in stability of the bond. The N-C linkage in methylene ether bonds (-

NHCH

2

OR) was found 1000 times more stable

19

than the ether bond under acidic pH conditions.

Conclusions about the stability of the methylene linkage can be drawn from the published

literature on the reactions and stability of phenol, amide, urea and imidazolidinone formaldehyde

derivatives.

Stability of the >N-CH

2

-N< Linkage

Methylene derivatives are arranged in order of increased stability.

20

Alkyl-NH-CH

2

-N<( R )

2

Cyclic structure improved stability

Triazine-NH-CH

2

-N<( R )

2

sec.-Amine

-CONH-CH

2

-N<( R )

2

sec-Amine

-CONH -CH

2

-NH-OCR Amide

Triazine-NH-CH

2

-NH- Triazine Melamine

Triazine-NH-CH

2

-NHCOOR Carbamate

Triazine-NH-CH

2

-NH-CO-R Amide

Glycoluril -CH

2

- Glycoluril Glycoluril

The stability of the >N-CH

2

-N< linkage increases with a decrease in the basicity of the

nitrogen. Simple reaction products of formaldehyde with primary amines are only stable in the

trimeric form. Melamine formaldehyde Mannich base reaction products with secondary amines

will form by simple blending the components and will react at low temperature even in the

absence of a catalyst. Mannich bases of the less basic amide with a sec. amine gives improved

stability compared to the melamine compound.

The bis-amide structures are reported to be reactive at a pH of <3.0. Melamine-carbamate

and also melamine-amide products provide further improvement in resistance properties in an

acid environment. Both self-condensed glycoluril and melamine reaction products offer even

further increase in acid resistance.

CH- Crosslinks

Malonate blocked NCO

21

R-NH-CO-CH (COOR)

2

+ -N(CH

2

OCH

3

)

2

R-NH-CO-C (COOR)

2

-N(CH

2

OCH

3

)CH

2

+ CH

3

OH

The CH groups in malonate blocked isocyanates react readily at 120C with HMMM in

the presence of a strong acid catalyst. NMR analysis confirms the presence of this crosslink. Acid

resistance of this dual (malonate bl. NCO/OH/HMMM) crosslinked network is superior to a

OH/HMMM network.

Acetoacetate

R-CO-CH

2

(COOR) + -N(CH

2

OCH

3

)

2

R-CO-CH (COOR)

-N(CH

2

OCH

3

)CH

2

+ CH

3

OH

Acetoacetates and isocyanates blocked with acetoacetates also react with HMMM, but the

reaction speed is slower and a cure temperature of 140C is required for adequate cure. The

increased stability

22

of the linkage assures less embrittlement on overbake and better acid

resistance.

Phenol

OH

CH

3

OCH

2

CH

3

OCH

2

N +

H

+

OH

CH

2

OCH

3

CH

2

N

CH

3

OH

+

Ring alkylation of phenols can either occur in the ortho or para position. This reaction

produces extremely stable links which are being used in modified phenolic end group terminated

epoxy resins in combination with HMMM to give improved chemical resistance. This reaction

also permits the synthesis of carboxyl functional melamine resins

23

by reacting salicylic acid with

HMMM.

Mercaptan

RSH + >NCH

2

OCH

3

+ >NCH

2

-SR + CH

3

OH

Reaction of HMMM with mercaptan presents an elegant way to determine the reaction

mechanism of melamine resins. The mercapto linkage cannot be reprotonated and therefore the

reaction does not reverse. A potential advantage in this reaction is a lower cure temperature and

improved resistance properties.

Hydrophobic Backbone or Hydrolytically Stable Backbone

Several approaches have been taken to improve the resistance properties of melamine

crosslinked films by increasing the steric hindrance of the ether linkage or reducing the amount

of ester linkages and replacing these linkages with hydrolytically more stable urethane bonds.

Although the sec. carbamate groups in urethanes are potentially reactive with melamine resins,

no publications have specifically discussed this subject. The presence of hydrophobic side chains

in polyurethanes has a significant effect on the acid resistance in the film. Indications are that the

large differences in solubility parameter between hydrophobic side chains and the urethane

backbone causes phase separation and an enrichment of the hydrophobic chains on the surface,

decreasing the wetting of the surface thereby increasing the acid resistance.

Other Approaches

Surface analysis of crosslinked coatings exposed to acid rain show surface leaching of

melamine and pitting to be the primary mode of deterioration. The probable mechanism is

presumably the hydrolysis of the ether bonds between polymer and melamine resin, leading to

clusters of melamine self-condensate on the surface, which in time will further degrade or leach

from the surface. One publication claims further hydrolysis of melamine to ammeline and

ammelide

24

. This mechanism might apply to laboratory studies, but it is questionable under

natural exposure conditions if the solubility of melamine might not dominate the surface loss.

The basic nature of melamine crosslinked films permits the formation of acid / base complexes

with reduced water solubility.

One of the factors contributing to the acid sensitivity problem of melamine crosslinked

coatings is the basic nature of melamine. Melamine has a pKa value of 8.95. Substituted

melamine derivatives with an increase basicity have shown as expected improved cure response

but poorer resistance properties.

Improvement in acid resistance should also be possible by combining melamine

chemistry with other amino aldehyde compounds with reduced basicity. This approach could

reduce not only the basicity of the film but would also permit the built up of an amino self-

condensed networks with better resistance properties. Imidazolidinone derivatives are one of the

prime candidates for such a modification.

Recently carbamate functional formaldehdye free triazine derivative have been introduced

into the market

25

. These materials perform similar to activated ester in crosslinking hydroxyl

functional polymers.

Conclusions

The versatility of melamine chemistry is only now starting to be explored. A driving force

is the required improvements in acid resistance for automotive topcoats. One of the approaches

taken is the improvement in acid resistance which can be achieved by deviating from the typical

ether crosslinks obtained with hydroxyl functional polymers. Other approaches are the

combination of melamine crosslink chemistry with other crosslinking mechanism.

Modification of the melamine molecule to reduce basicity of the nitrogen holds some

promise as does the elimination of formaldehyde chemistry all together.

Reference.

1

W.J.Blank J.Coat.Techn. Vol. 54, No. 687, Pg 26-41, April 1982.

2

W.J.Blank J.Coat.Techn. vol. 51, No. 656, pg. 61-70 Sept. 1979

3

Bederke, Klaus; Duecoffre, Volker; Graef, Knut; Schubert, Walter (Herberts GmbH, Germany). Ger. DE 4223182

C1 22 Jul 1993,: DE 92-4223182 15 Jul 1992.

4

Roeckrath, Ulrike; Wigger, Georg; Poth, Ulrich (BASF Lacke und Farben A.-G., Germany). Ger. Offen. DE

4204518 A1 19 Aug 1993,

5

Fukuda, Mitsuhiro; Yokoyama, Tetsuya; Nakahata, Akimasa; Nakao, Yasushi; Yabuta, Motoshi (Kansai Paint Co

Ltd, Japan). Jpn. Kokai Tokkyo Koho JP 05271608 A2 19 Oct 1993

6

Marutani, Yoshiaki; Oosawa, Mika (Mazda Motor, Japan). Jpn. Kokai Tokkyo Koho JP 08164362 A2 25 Jun 1996

7

Singer, Debra L.; Swarup, Shanti; Mayo, Michael A. (PPG Industries, Inc., USA). PCT Int. Appl. WO 9410213

A1 11 May 1994.

8

Ohrbom, Walter H.; Rehfuss, John W.; Menovcik, Gregory G.; Taylor, Robert J. (Basf Corporation, USA). Eur.

Pat. Appl. EP 710676 A1 8 May 1996.

9

Kuo, Thauming; Foster, Charles H.; Chang, Yeong Ho (Eastman Kodak Co., USA). U.S. US 5306567 A 26 Apr

1994.

10

Mayenfels, Peter; Wigger, Georg; Bartol, Fritz; Roeckrath, Ulrike; Poth, Ulrich (BASF Lacke + Farben AG,

Germany). Ger. Offen. DE 4324947 A1 26 Jan 1995.

11

Rehfuss, John W. (BASF Corp., USA). Eur. Pat. Appl. EP 544183 A1 2 Jun 1993.

12

Gardon, John L. (Akzo Coatings Inc., Troy, MI 48007-7062, USA). Proc. 25th Anniv. Symp. Polym. Inst., 287-

307. Edited by: Frisch, Kurt C.; Eldred, Elanore W. Technomic: Lancaster, Pa.

13

Blank, Werner J. (USA). PCT Int. Appl. WO 9532999 A1 7 Dec 1995.

14

Sato, Atsushi; Kawamura, Masataka; Monma, Yasuhiro; Shibato, Kishio (Basf Lacke + Farben AG; NOF Corp.,

Germany). PCT Int. Appl. WO 9600756 A1 11 Jan 1996.

15

King Industries unpublished information.

16

AATCC Test Method 112-1975 Private communications King Industries Inc.

17

Bauer, D. R.; Mielewski, D. F. (Res. Lab., Ford Motor Co., Dearborn, MI 48121, USA). Polym. Degrad. Stab.,

40(3), 349-55 (English) 1993.

18

King Industies unpublished information of Florida exposure data of HMMM crosslinked acrylic high solids and

low solids coatings.

19

A. Berge, et. al., Europ. Polymer J. 5, 1717, 1969

20

King Industries data and collected from different literature sources.

21

King Industries unpublished information

22

King Industries unpublished information, publication under preparation.

23

W.J. Blank US. Pat. 3,945,961

24

Magaino, Shinichi; Fukazawa, Yoshiyuki; Uchida, Hiroshi; Kawaguchi, Akihiro; Yamazaki, Ryuichi (Ind. Res.

Inst. Kanagawa Prefect., Yokohama 236, Japan). Kenkyu Hokoku - Kanagawa-ken Kogyo Shikensho, 65, 47-51

(Japanese) 1994.

25

Kuang, Jong Wu; Quinn, Richard (Cytec Technology Corp., USA). PCT Int. Appl. WO 9615185 A1 23 May

1996,

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Daftar Harga Obat Asuransi 24Документ23 страницыDaftar Harga Obat Asuransi 24Widu Jalak SlpОценок пока нет

- Psychotropic Drugs: Western Mindanao State UniversityДокумент41 страницаPsychotropic Drugs: Western Mindanao State UniversityAmie CuevasОценок пока нет

- Daftar Ed Tablet Desember M-Z 2020: NO Nama Obat Jumlah Obat ED PabrikДокумент6 страницDaftar Ed Tablet Desember M-Z 2020: NO Nama Obat Jumlah Obat ED PabrikMelvy RochaLinnaОценок пока нет

- Frac List of Fungicide Common Names (2016v2) PDFДокумент6 страницFrac List of Fungicide Common Names (2016v2) PDFFederico Posada GarcesОценок пока нет

- Chemcad Unifac GroupsДокумент6 страницChemcad Unifac Groupssnikt7863443Оценок пока нет

- Ace Top Hen OnДокумент6 страницAce Top Hen OnQuynh NgaОценок пока нет

- Daftar Obat Prak 2Документ3 страницыDaftar Obat Prak 2Riza AsariОценок пока нет

- Import and Export of HAzardous RuleДокумент40 страницImport and Export of HAzardous RulesushilОценок пока нет

- Crude Oil GC Data Sheet: Cpi Asri 01Документ32 страницыCrude Oil GC Data Sheet: Cpi Asri 01Kati YoewonoОценок пока нет

- List of DrugsДокумент11 страницList of DrugsCocoОценок пока нет

- PNF 8th EditionДокумент7 страницPNF 8th EditionDanisaWajeОценок пока нет

- 8 Esters Have Many Uses Due To Their Characteristic Aromas and Often Have CommonДокумент3 страницы8 Esters Have Many Uses Due To Their Characteristic Aromas and Often Have CommonMohamed MuhajireenОценок пока нет

- Tabel ObatДокумент6 страницTabel Obatiik abdulkholikОценок пока нет

- Laporan Penggunaan April 2023Документ7 страницLaporan Penggunaan April 2023Fitri Andesfan PutriОценок пока нет

- Generic Menu CardДокумент32 страницыGeneric Menu CardZurerx Mindoro100% (4)

- Antidepressant DrugsДокумент10 страницAntidepressant DrugsHazel Joy Galamay - GarduqueОценок пока нет

- Schedule 4 Appendix D Drugs (Prescribed Restricted Substances)Документ2 страницыSchedule 4 Appendix D Drugs (Prescribed Restricted Substances)GUrpreet SinghОценок пока нет

- Arch Pharmalabs - ManufacturingДокумент10 страницArch Pharmalabs - ManufacturingArch PharmalabsОценок пока нет

- Kuis Emesis 4-MergedДокумент16 страницKuis Emesis 4-Mergedibnu an nafisОценок пока нет

- List of Organic Reagents: I. Reducing AgentsДокумент10 страницList of Organic Reagents: I. Reducing AgentsJatin BhasinОценок пока нет

- Lokasi: Toko Kode Nama Produk Barcode Stok: Laporan Detail Saldo StockДокумент38 страницLokasi: Toko Kode Nama Produk Barcode Stok: Laporan Detail Saldo StockRahma DelfyantiОценок пока нет

- STE CONCHEM Q1M5 DFDJNHSДокумент28 страницSTE CONCHEM Q1M5 DFDJNHSKaira StellaОценок пока нет

- 05a Qualitative Analysis For Organic CompoundsДокумент5 страниц05a Qualitative Analysis For Organic CompoundsReyo VillanuevaОценок пока нет

- Organic Chemistry Reacions SummaryДокумент22 страницыOrganic Chemistry Reacions SummaryvgettinfatОценок пока нет

- Recent Advances On The Synthesis of Azoles, Azines and Azepines Fused To BenzimidazoleДокумент85 страницRecent Advances On The Synthesis of Azoles, Azines and Azepines Fused To BenzimidazoleNickly NickОценок пока нет

- Other Substances: HPLC VariablesДокумент11 страницOther Substances: HPLC VariablesPapaindoОценок пока нет

- Formulariun Review No 1A 2A 2L 2K 2OДокумент142 страницыFormulariun Review No 1A 2A 2L 2K 2ORISKA.SILVIAОценок пока нет

- Méthodes de Dissolution FDAДокумент129 страницMéthodes de Dissolution FDACH NarimaneОценок пока нет

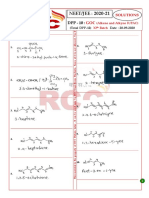

- NEET/JEE: 2020-21: SolutionsДокумент4 страницыNEET/JEE: 2020-21: Solutionsshantinath123gmailcoОценок пока нет

- Acidity Basicity QuestionДокумент16 страницAcidity Basicity QuestionPriyÃnka KumariОценок пока нет