Академический Документы

Профессиональный Документы

Культура Документы

Lesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-Objective

Загружено:

mister pogiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-Objective

Загружено:

mister pogiАвторское право:

Доступные форматы

LESSON

5

LECTURE

DIAPHRAGM VALVES, PINCH VALVES

AND INSTRUMENT VALVES

SUB-OBJECTIVE

At the end of thi !eon, the t"#inee $i!! %e #%!e to de&ont"#te #n

'nde"t#ndin( of Di#)h"#(& *#!*e, Pin+h *#!*e #nd Int"'&ent *#!*e,

-,. DIAPHRAGM VALVES

Most valves depend on a controlled geometry and rigid materials for

closure. The diaphragm valve operates on an entirely different basis: A

highly flexible and extensible Elastomer sheet forced down into a rigid

edge, the seat, causes closure. !f the valve body, including the seating

area, is rigid plastic or a metal with corrosion"resistant Elastomer lining,

then the diaphragm valve has an important potential advantage " high

resistance to corrosive li#uids. This is its chief application, naturally, in

water"treatment wor$ and for li#uids that might be contaminated by metal

contact.

The cushioning effect of the Elastomer diaphragm also tends to protect it

as it seals tightly on large and small foreign solids in the stream. %lurries

and waste water are therefore other applications.

The body configuration of &ig. '"( causes friction loss and disturbs flow

paths more than the straight"through type of &ig. '"). This can be a factor

in slurry and suspended"solids service. *n the other hand, the straight"

through type is not recommended for vacuum lines.

ME+,A-!+A. MA!-TE-A-+E +*/0%E A12A-+E1 +*/0%E

.E%%*- ' 3A4E ( 2A.2E% A-1 2A.2E MA!-TE-A-+E

/i(, 5--, /i(, 5-0,

A12A-+E1 +*/0%E ME+,A-!+A. MA!-TE-A-+E +*/0%E

2A.2E% A-1 2A.2E MA!-TE-A-+E .E%%*- ' 3A4E )

/i(, 5-1, /i(, 5-2,

0,. VALVE DESIGN

Two basic body designs are used for diaphragm valves:

(. The straight " through has no obstructions where the diaphragm

seats. &ig. '"5.

). The weir has a raised surface where the diaphragm seats on the

valve body &ig. '"6.

The wea$ness of the diaphragm valve is in its Elastomer diaphragm, which

can crac$ from repeated flexing or be torn by sharp"edged foreign bodies in

the fluid. %pecial design attention goes to the diaphragm itself and to the

actuator head that forces the diaphragm into closure.

The contact between head and diaphragm must be uniform to prevent

locali7ed damage to the diaphragm. This head, also called compressor,

may have radial flanges that pass through cutouts between supporting

prongs in a finger plate.

8rea$age of the diaphragm, whether from flexing, cutting or impact of the

fluid and particle load as the li#uid ma$es the sharp turn over the center

weir, will admit fluid to the bonnet space, corroding the actuating elements.

A vent plug in the bonnet allows chec$ for the presence of lea$age.

0eplacement of a defective diaphragm is not difficult, but often corrosion in

ME+,A-!+A. MA!-TE-A-+E +*/0%E A12A-+E1 +*/0%E

.E%%*- ' 3A4E 5 2A.2E% A-1 2A.2E MA!-TE-A-+E

the bonnet will re#uire more extensive repairs. %tem sealing by pac$ing or

*"rings is also advisable to prevent escape of corrosive agents to the

outside.

*ne drawbac$ of the weir"type diaphragm valve is inability to drain a

hori7ontal line through it directly. Turning the valve until the stem is about

)9 deg. Above the hori7ontal greatly improves draining ability. The straight"

through"flow design &ig. '"6, however, can drain even when the stem is

straight up.

The wide choice of metals and Elastomer for bodies and of Elastomer for

diaphragms allows the diaphragm valve to meet all power plants chemical

needs. Temperature limits range from about (:9 & for natural rubber and

8una - to as high as 5'9 & for weir"type T&E diaphragms with Elastomer

bac$ing and 699 & for all T&E diaphragms.

&or abrasive service, the diaphragm can be gum rubber or ethylene

propylene. The body lining need not be as flexible as the diaphragm.

Materials li$e ethylene tetrafluoroethylene ;ET&E<, polypropylene, polyvinyl

chloride, and polyvinylidene chloride are choices.

Although most diaphragm valve designs are not intended for precision

throttling, they can maintain good throttling #ualities, and some types have

relatively low pressure"deep features.

A12A-+E1 +*/0%E ME+,A-!+A. MA!-TE-A-+E +*/0%E

2A.2E% A-1 2A.2E MA!-TE-A-+E .E%%*- ' 3A4E 6

/i(, 5-5,

1,. VARIATIONS O/ THE DIAPHRAGM VALVE

Two speciali7ed variations of the diaphragm valve are good for throttling

characteristic.

(. The 3inch 2alve is e#uipped with a flexible tube that goes through

the valve body and forms flange gas$ets between the valve and the

connecting pipe &ig. '"=. 1ue to the smooth straight flow path

through a pinch valve, there is minimum pressure drop across the

valve. +losure occur through s#uee7ing together of Elastomer walls

over a wide area, rather than against a narrow metal ridge. The

ability of the pinch valve to handle abrasive and slurries has given it

wide application in such power plants services as such disposal, flue"

gas desulfuri7ation, waste water, water treatment and, in future, fuel"

slurry handling.

ME+,A-!+A. MA!-TE-A-+E +*/0%E A12A-+E1 +*/0%E

.E%%*- ' 3A4E ' 2A.2E% A-1 2A.2E MA!-TE-A-+E

/i(, 5-3, Pin+h V#!*e C't#$#4, 5-5, Boot V#!*e,

The heat of the simplest form of pinch valve is a flanged Elastomer

tube &ig. '"= mounted in a split flanged casting connected to a

compressed"air line. The tube is reinforced by fabric plies which are

carried outward over the flanges.

!n the open state, the valve, bolted between pipe flanges, transmits

fluids >ust as if it were part of the piping. Admission of compressed

air to the valve body pinches the tube into an oval shape at the

center and finally shuts off flow at the center and finally shuts off flow

completely. All pinch valves close over a long contact area, so that

the seating surfaces can envelop even large ob>ects without lea$ing

or being cut.

). The 8oot 2alve : !t?s similar to the 3inch 2alve &ig. '"@, but there are

two compressors that flex the boot to open and close, and also

provide throttling action. The double compressor is used with each

side of the boot flexing to close the valve, wear on each side

reduced"thus giving added life to the valve.

A12A-+E1 +*/0%E ME+,A-!+A. MA!-TE-A-+E +*/0%E

2A.2E% A-1 2A.2E MA!-TE-A-+E .E%%*- ' 3A4E =

2,. INSTRUMENT VALVES

All of the valve types covered in the previous pages can be specially

designed in small or miniature form and adapted not only to the special

needs of instrument and control systems but also to demanding services of

blowdown, piloting, and lea$ off.

8ar"stoc$ bodies are common and, in globe types, a ball swiveling in the

stem end &ig. '": will give the necessary ratability for seating without

damage. &or high pressure test and sampling, the disc can become a

slender rod, closing a narrow orifice &ig. '"A.

.ocation of stem pac$ing and threads is often an important factor in

evaluating instrument valves. %tem threads inside the pac$ing can provide

good support for the disc but are exposed to line fluid more than if they are

outside.

3anel mounting, fre#uently necessary for instrument valves, calls for

threading on the bonnet exterior. An alternative attachment method is by

bolts going through mounting holes in the valve body &ig. '"A.

/i(, 5-6, /i(, 5-7,

ME+,A-!+A. MA!-TE-A-+E +*/0%E A12A-+E1 +*/0%E

.E%%*- ' 3A4E @ 2A.2E% A-1 2A.2E MA!-TE-A-+E

/i(, 5--., /i(, 5---,

The low life re#uired for small instrument valves is easily obtained from

diaphragm air actuators mounted compactly on the valve body &ig. '"(9.

%oft seats are common in instrument valves, because temperatures are

often low but lea$ tightness is important.

The special needs of instrumentation call for fre#uent close grouping of

isolation, shutoff, and testing valves for such devices as meters. An

alternative to connection of valves by piping is manifold bloc$s with internal

passages and fixed locations for instrument valves. An elementary

example of this is the two"valve unit of fig. '"((.

8ecause of their narrow passages and orifices, along with close tolerances

and comparatively heavy thrusts on small seating surfaces, instrument

valves re#uire more protection by filters and strainers from dirt, metal chips,

and general debris in connected piping.

A12A-+E1 +*/0%E ME+,A-!+A. MA!-TE-A-+E +*/0%E

2A.2E% A-1 2A.2E MA!-TE-A-+E .E%%*- ' 3A4E :

Вам также может понравиться

- Lesson Plug, Ball and Butterfly Valves: Sub-ObjectiveДокумент13 страницLesson Plug, Ball and Butterfly Valves: Sub-Objectivemister pogiОценок пока нет

- Valve Maintenance1Документ11 страницValve Maintenance1mister pogiОценок пока нет

- CT WKM Gate Saf T Seal 01 PDFДокумент36 страницCT WKM Gate Saf T Seal 01 PDFchonubobbyОценок пока нет

- Fittings BookДокумент237 страницFittings BookFlorina IordanОценок пока нет

- Ficha Tecnica Astm 514Документ1 страницаFicha Tecnica Astm 514Ruben Dario Mamani ArellanoОценок пока нет

- 2011 03 02 Kelly Valves Family Low 01Документ4 страницы2011 03 02 Kelly Valves Family Low 01Sasan AbbasiОценок пока нет

- MAINTENANCE or MECHANICAL TECHNICIANДокумент2 страницыMAINTENANCE or MECHANICAL TECHNICIANapi-79058143Оценок пока нет

- Drilling Workover Rig: Ts-SinotaiДокумент12 страницDrilling Workover Rig: Ts-SinotaiRobertoVitorianoОценок пока нет

- Zero-Leakage Valve Solutions: Product & Capabilities OverviewДокумент20 страницZero-Leakage Valve Solutions: Product & Capabilities OverviewAndry HermawanОценок пока нет

- Power Tongs & Replacement Parts Index PageДокумент57 страницPower Tongs & Replacement Parts Index PagerezandriansyahОценок пока нет

- BOPP - Type - GK-Ops-Maint Procedure RevisedДокумент16 страницBOPP - Type - GK-Ops-Maint Procedure RevisedTarasОценок пока нет

- M60eh44 Man 001Документ40 страницM60eh44 Man 001Riski KurniawanОценок пока нет

- TVS WEGO Owner's Manual GuideДокумент58 страницTVS WEGO Owner's Manual GuidechrkiitmОценок пока нет

- Catalogo Fluid Control FMCДокумент80 страницCatalogo Fluid Control FMCGustavo JassoОценок пока нет

- 2a33687 Exl Back Pressure Relief Valve PDFДокумент51 страница2a33687 Exl Back Pressure Relief Valve PDFEnrique HortaОценок пока нет

- Gagemaker ProductsДокумент50 страницGagemaker ProductsMelquiades Hernández GonzálezОценок пока нет

- 2P36784, Plug ValveДокумент34 страницы2P36784, Plug ValveEdwin HernandezОценок пока нет

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualДокумент12 страницDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartОценок пока нет

- Check Valve MS PDFДокумент4 страницыCheck Valve MS PDFazeazeazeОценок пока нет

- Hi Kal Catalogue New OptДокумент16 страницHi Kal Catalogue New Optask101Оценок пока нет

- Tubing Gauge Paraffin Cutter.Документ1 страницаTubing Gauge Paraffin Cutter.Cesar Jara CobosОценок пока нет

- All Auxilary PumpsДокумент10 страницAll Auxilary PumpsRana Yasir AyubОценок пока нет

- Drillmax Gate Valve Product Bro PDFДокумент12 страницDrillmax Gate Valve Product Bro PDFMónica Fraile de ManterolaОценок пока нет

- Training ManualДокумент295 страницTraining ManualVictorОценок пока нет

- Tailrod Hydraulic Gate ValveДокумент2 страницыTailrod Hydraulic Gate ValveTopoilServ100% (1)

- MetalisEnergy TechnicalBrochureДокумент60 страницMetalisEnergy TechnicalBrochureAshok SureshОценок пока нет

- BALON Floating Valve - Installation and Repair Manual 2Документ13 страницBALON Floating Valve - Installation and Repair Manual 2Rudi Syarif Hidayat HarahapОценок пока нет

- Cameron 700668 From Project Sales Corp, IndiaДокумент1 страницаCameron 700668 From Project Sales Corp, IndiaProject Sales CorpОценок пока нет

- COS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronДокумент5 страницCOS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronYudaОценок пока нет

- Subsea Tree design considerationsДокумент47 страницSubsea Tree design considerationsWilliam EvansОценок пока нет

- Kelly Valve - MaintenanceДокумент5 страницKelly Valve - Maintenancelalberto96Оценок пока нет

- Air/Hydraulic Pump: Tel: (201) 512-9500 Fax: (201) 512-9615Документ12 страницAir/Hydraulic Pump: Tel: (201) 512-9500 Fax: (201) 512-9615Danielly GersonОценок пока нет

- Collet Connector SystemsДокумент3 страницыCollet Connector SystemsalphadingОценок пока нет

- Berkeley Ownwes ManualДокумент28 страницBerkeley Ownwes ManualMoses Alvarado100% (1)

- China Guanghan Petroleum 2 FZ 35-35 RAMSДокумент1 страницаChina Guanghan Petroleum 2 FZ 35-35 RAMSTiffany DacinoОценок пока нет

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopДокумент34 страницыTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanОценок пока нет

- 1604 FZ35-35U FZ35-70U闸板防喷器 用户手册A1 英文Документ40 страниц1604 FZ35-35U FZ35-70U闸板防喷器 用户手册A1 英文Jaya Manggala SaktiОценок пока нет

- Tesco Corporation: Unit #: Date: Operating DaysДокумент1 страницаTesco Corporation: Unit #: Date: Operating Daysboy tryadiОценок пока нет

- Control Valve Eng. TipsДокумент3 страницыControl Valve Eng. TipsRatnakar PatilОценок пока нет

- xg01 Koso Kent Introl PDFДокумент22 страницыxg01 Koso Kent Introl PDFhaidinuОценок пока нет

- IND Drawworks DLS 163Документ11 страницIND Drawworks DLS 163Jose Luis MazzoniОценок пока нет

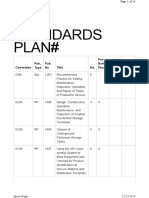

- API Standards ListДокумент14 страницAPI Standards ListMirzaОценок пока нет

- Gate ValveДокумент27 страницGate ValveYogesh Kumar Bhatnagar0% (1)

- HH SwivelДокумент3 страницыHH SwivelHoracio LafuenteОценок пока нет

- Checking Valves Design and TypesДокумент7 страницChecking Valves Design and Typesmister pogiОценок пока нет

- PS Valve ServiceДокумент40 страницPS Valve ServiceamojodiОценок пока нет

- FMC Flowline Product CatalogДокумент80 страницFMC Flowline Product CatalogRodrigo França100% (2)

- BPV Specification and Drawings PDFДокумент4 страницыBPV Specification and Drawings PDFParag PadoleОценок пока нет

- CatalogueДокумент429 страницCatalogueHarkamal SinghОценок пока нет

- Lot 8 Dafora Appendix B Standards and Specifications DaforaДокумент81 страницаLot 8 Dafora Appendix B Standards and Specifications DaforaZamfirMarianОценок пока нет

- Grove g4n Gate Valve BrochureДокумент24 страницыGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- B+V Manual - CLS 100-150 - 621100-Y-BC-D Rev 005Документ30 страницB+V Manual - CLS 100-150 - 621100-Y-BC-D Rev 005Leonardo Rachen RodriguezОценок пока нет

- Fluid End Modules and Acceesaries: IdecoДокумент2 страницыFluid End Modules and Acceesaries: IdecolionelОценок пока нет

- F Type Cup TesterДокумент2 страницыF Type Cup Testermarcusa85Оценок пока нет

- Kandle Oilfield Products Catalog (Drilling)Документ30 страницKandle Oilfield Products Catalog (Drilling)Claudio Villablanca100% (1)

- Case Study VR Lubricator ToolДокумент2 страницыCase Study VR Lubricator ToolVictorОценок пока нет

- Bowen Coarse Thread Safety Joints: Instruction ManualДокумент7 страницBowen Coarse Thread Safety Joints: Instruction ManualGhinet Teodor-ioanОценок пока нет

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- Profile of the International Pump Industry: Market Prospects to 2010От EverandProfile of the International Pump Industry: Market Prospects to 2010Рейтинг: 1 из 5 звезд1/5 (1)

- How To Acclimate Strawberry Plants - Stark Bro'sДокумент5 страницHow To Acclimate Strawberry Plants - Stark Bro'smister pogiОценок пока нет

- 20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZДокумент12 страниц20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZmister pogi100% (1)

- Growing Catfish in The PhilippinesДокумент4 страницыGrowing Catfish in The Philippinesmister pogiОценок пока нет

- Air Con 03 OverДокумент30 страницAir Con 03 Overmister pogiОценок пока нет

- 4air Con05Документ6 страниц4air Con05mister pogiОценок пока нет

- How To Acclimate Strawberry Plants - Stark Bro'sДокумент5 страницHow To Acclimate Strawberry Plants - Stark Bro'smister pogiОценок пока нет

- Atty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC ProceedingsДокумент15 страницAtty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC Proceedingsmister pogiОценок пока нет

- SWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and SystemsДокумент8 страницSWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and Systemsmister pogiОценок пока нет

- Manual For Welding InspectorДокумент308 страницManual For Welding Inspectormister pogi100% (1)

- Stub End LengthДокумент1 страницаStub End Lengthmister pogi100% (1)

- Msfpt2 LesДокумент9 страницMsfpt2 Lesmister pogiОценок пока нет

- Air Con 02 OverДокумент50 страницAir Con 02 Overmister pogiОценок пока нет

- Lesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration SystemsДокумент4 страницыLesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration Systemsmister pogiОценок пока нет

- 4air Con02Документ9 страниц4air Con02mister pogiОценок пока нет

- Air Con 01overДокумент19 страницAir Con 01overmister pogiОценок пока нет

- Turbine 3Документ11 страницTurbine 3mister pogiОценок пока нет

- 4air Con04Документ24 страницы4air Con04mister pogiОценок пока нет

- Lesson Introduction To CompressorsДокумент12 страницLesson Introduction To Compressorsmister pogiОценок пока нет

- Lesson Basic Air Conditioner SystemsДокумент7 страницLesson Basic Air Conditioner Systemsmister pogiОценок пока нет

- 3air Con02Документ12 страниц3air Con02mister pogiОценок пока нет

- Lesson Heat Pumps and Complete Air Conditioning SystemДокумент14 страницLesson Heat Pumps and Complete Air Conditioning Systemmister pogiОценок пока нет

- 3air Con03Документ10 страниц3air Con03mister pogiОценок пока нет

- 10air Con04Документ7 страниц10air Con04mister pogiОценок пока нет

- Lesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet ValvesДокумент15 страницLesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet Valvesmister pogiОценок пока нет

- 10air Con03Документ10 страниц10air Con03mister pogiОценок пока нет

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsДокумент26 страницLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiОценок пока нет

- Lesson Heating and CoolingДокумент8 страницLesson Heating and Coolingmister pogiОценок пока нет

- Lesson Rigging SafetyДокумент14 страницLesson Rigging Safetymister pogiОценок пока нет

- Turbine 2Документ32 страницыTurbine 2mister pogiОценок пока нет

- Lesson Basic RiggingДокумент15 страницLesson Basic Riggingmister pogiОценок пока нет