Академический Документы

Профессиональный Документы

Культура Документы

BP PP Capacity Planning

Загружено:

Ahmed TalaatАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BP PP Capacity Planning

Загружено:

Ahmed TalaatАвторское право:

Доступные форматы

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

El Araby Group

EL ARABY Business Blueprint

BP-PP: Capacity Planning

Confidential & Proprietary to SAP

& El Araby Group

Page

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

Re'i(ion )i(tory

Created

By:

Created

*ate:

(t

Re'ie+

By:

(t

Re'ie+

*ate:

"

nd

Re'ie+

By:

"

nd

Re'ie+

*ate:

,

rd

Re'ie+

By:

,

rd

Re'ie+

*ate:

Appro'ed

By:

Appro'al

*ate:

El Araby Group Bu(ine(( -+ner Sign-off

.a/e:

Po(ition:

Sign-off

*ate:

Signature

:

El Araby Group 0S Support 1ea/ Sign-off

.a/e:

2r 3ael Seli/ 2r A4/ed 1alaat

Po(ition:

Sign-off

*ate:

Signature

:

SAP - Con(ultant Sign-off

.a/e: A(4i(4 Sri'a(ta'a

Po(ition: Con(ultant

Sign-off *ate:

Signature:

Confidential & Proprietary to SAP

& El Araby Group

Page "

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

Pro5ect *irector6 Pro5ect 2anager( Sign-off

.a/e: 2r(& 2a4a .a((ar 2(& 2ai Raafat 2r& Sadanand

7ota(t4ane

Po(ition: El Araby Pro5ect

*irector

El Araby Pro5ect

2anager

SAP Pro5ect 2anager

Sign-off *ate:

Signature:

Confidential & Proprietary to SAP

& El Araby Group

Page ,

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

1able of Content(

1. SCENARIO OVERVIE......................................................................!

". RE#UIRE$ENTS % E&PECTATIONS...............................................'

(. SAP OR)ANISATION STRUCTURE.................................................'

!. BUSINESS PROCESS............................................................................'

4.1 BUSINESS PROCESS FLOW CHART......................................................5

4.2 BUSINESS PROCESS DESCRIPTION.......................................................7

'. C*AN)ES TO E&ISTIN) OR)ANISATION...................................+

,. -EY BUSINESS I$PROVE$ENT.....................................................+

.. /ESCRIPTION O0 0UNCTIONAL /E0ICITS.................................1

+. NOTES ON 0URT*ER I$PROVE$ENTS.......................................1

1. SYSTE$ CON0I)URATION CONSI/ERATIONS.........................1

12. /EVELOP$ENTS CONSI/ERATIONS......................................12

10.1 DATA CONVERSION CONSIDERATIONS..............................................10

10.2 INTERFACE CONSIDERATIONS...........................................................10

10.3 REPORTING CONSIDERATIONS..........................................................10

10.4 FORM CONSIDERATIONS...................................................................10

10.5 ENHANCEMENT CONSIDERATIONS....................................................10

11. AUT*ORISATION CONSI/ERATIONS......................................12

Confidential & Proprietary to SAP

& El Araby Group

Page !

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

& Scenario -'er'ie+

To be able to perform Capacity Requirement Planning in the plants during

Production Planning

Purpo(e

Capacity leveling is used in various areas of a company and at different planning

levels with the following objectives:

High capacity load

Adherence to dates

hort lead times

!ow stoc"s

The objectives of capacity leveling include:

!eveling overloads and underloads at wor" centers

Achieving optimum commitment of machines and production lines

election of appropriate resources

#ou can carry out capacity leveling in the within the following application areas:

Production planning and control

The capacity leveling process in production planning $PP% depends on the

planning level at which it is to be carried out&

't is important to distinguish between the following planning levels:

ales and operations planning $(P%

!ong)term planning $!TP%

*aterial requirements planning $*RP%

Repetitive manufacturing $R+*%

hop floor control $,C%

-hether rough)cut. production rate or detailed planning is used depends on the

planning level& #ou can easily move between the individual planning levels&

Confidential & Proprietary to SAP

& El Araby Group

Page 8

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

Planning le'el: S-P

'n ales and (perations Planning $(P%. you specify sales volumes for the long)

term and medium)term and the production activities necessary to reali/e these

sales& The system will carry out rough)cut planning to estimate the production

levels necessary to support these figures& 'n capacity leveling. the quantities to

be produced should be roughly compared to the productive capacity&

Planning le'el: L1P

'n long)term planning. you can plan several versions of the demand program

using a simulated planning run& #ou can chec" the results using special

evaluations so as to gain an early overview of future plans for production and

procurement&

Planning le'el: 2RP

Confidential & Proprietary to SAP

& El Araby Group

Page 9

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

The objective of material requirements planning $*RP% is to ensure that material

is available. that is. to plan the quantities required both by production and by

sales and distribution& *RP determines what material is needed at what date and

then creates the necessary order proposals& ,or products made in)house.

material requirements planning always generates an order proposal as a planned

order& The planned order contains specifications for the lot to be produced and

the resources required for production& The system will calculate capacity

requirements using the order specifications& These capacity requirements are the

basis of capacity leveling&

Planning le'el: RE2

Repetitive manufacturing is used for the repeated production of the same product

over a long period of time& 't is used to create and process master plans for a

defined period and a specified quantity& Repetitive manufacturing uses production

versions& #ou create a run schedule header $Planned (rders% covering a certain

period for a production version of a material& 'n the material master you specify

tas" list and 0(* alternatives as well as a production line for a production

version& The tas" lists are generally rate routings& Capacity leveling will be carried

out on the basis of a production line&

Planning le'el: S:C

hop floor control converts *RP planning data into concrete production orders& A

production order specifies what material is to be produced or what activity is to be

carried out where and at what time& 't also e1plicitly determines the wor" centers

to be used&

-hen you create a production order. the system will automatically carry out lead

time scheduling and writes capacity requirements records& Capacity leveling at

the production order level is used for detailed planning&

14e current p4a(e of i/ple/entation 4a( follo+ing (cope of Capacity

Planning in EL Araby:

Gla(( /anufacturing plant will carry out capacity evaluations $overloads

etc% and leveling to balance the wor" centers2production lines and to decide

on proper production plan across them& Capacity planning will be based on

rate based scheduling2!ead time scheduling& The basis of capacity

evaluations and leveling could be wor" center2production lines2planned order

or production orders&

La/p /anufacturing plant will carry out capacity evaluations $overloads etc%

and leveling to balance the wor" centers2production lines and to decide on

proper production plan across them& 3se of alternative resources2production

lines is also possible& Capacity planning will be based !ead time scheduling&

The basis of capacity evaluations and leveling could be wor"

center2production lines2planned order or production orders&

Confidential & Proprietary to SAP

& El Araby Group

Page $

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

A;C /anufacturing plant will carry out capacity evaluations $overloads etc%

and leveling to balance the wor" centers2production lines and to decide on

proper production plan across them& 3se of alternative resources2production

lines is also possible& Capacity planning will be based !ead time scheduling&

The basis of capacity evaluations and leveling could be wor"

center2production lines2planned order or production orders&

Pla(tic plant <under A;C Co/pany= will carry out capacity evaluations

$overloads etc% and leveling to balance the wor" centers2production lines and

to decide on proper production plan across them& 3se of alternative

resources2production lines is also possible& Capacity planning will be based

!ead time scheduling& ince this plant can also produce the products of other

manufacturing plants which are not in scope for the current phase of

implementation. so the capacity planning related to the resources of this plant

are considered partial& 4uring the ne1t phase of implementation the full

capacity of the resources will be utili/ed and the capacity planning will be then

considered as complete& 't would require the efforts of master data

maintenance upto certain e1tent& The basis of capacity evaluations and

leveling could be wor" center2production lines2planned order or production

orders&

Pla(tic plant <under )o/e 0nd co/pany= will carry out capacity evaluations

$overloads etc% and leveling to balance the wor" centers2production lines and

to decide on proper production plan across them& 3se of alternative

resources2production lines is also possible& Capacity planning will be based

!ead time scheduling& ince this plant can also produce the products of other

manufacturing plants which are not in scope for the current phase of

implementation. so the capacity planning related to the resources of this plant

are considered partial& 4uring the ne1t phase of implementation the full

capacity of the resources will be utili/ed and the capacity planning will be then

considered as complete& 't would require the efforts of master data

maintenance upto certain e1tent& The basis of capacity evaluations and

leveling could be wor" center2production lines2planned order or production

orders&

"& Re>uire/ent( ; E?pectation(

To be able to perform capacity evaluations and perform rough cut

capacity planning based on production plant entered by sales plan

To be able to perform capacity data and formulae for calculating

capacity requirements in wor" center and production lines

To be able to perform capacity evaluations based on wor"

centers2Production !ines

To be able to perform capacity evaluations and do leveling based on

Planned (rders

To be able to perform capacity evaluations and do leveling based on

Production (rders

Confidential & Proprietary to SAP

& El Araby Group

Page @

of !

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

(ption of perform lead time scheduling while running *RP

(ption of 3ser5s decision on whether to allow the production order

release based on capacity chec"s

ystem should consider capacity on a wor" center based on efficiency.

utili/ation. shifts and start 6 end time and availability of wor" center

hould be able to allocate or disallocate capacity from wor" centers

ystem should be able to suggest alternate resource if available. in

case of a used wor" center is fully occupied

(ption of automatic dispatch of the capacity requirements and leveling

based on pre defined strategies

,& SAP -rgani(ation Structure

The production 6 planning for the manufacturing plants of +! Araby group:

7lass manufacturing 6 !amp manufacturing under !ighting

Company

Air condition manufacturing under A2C Company

-ater Heater manufacturing under Home 'nd& Company

Plastic manufacturing under the company Home 'nd&

Plastic manufacturing under A2C Company

Central -or"shop

Are into consideration in current phase of implementation for production

planning

!& Bu(ine(( Proce((

8& Bu(ine(( Proce(( :lo+ C4art

In Sale3 4 Operation Planning

Confidential & Proprietary to SAP

& El Araby Group

Page %

of !

"!!#$$%&docCapacity

Planning

,inal ales Plan

Transfer to Production Plan

Perform Rough Cut Capacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

In $RP%RE$%Pro56ction Proce33ing an5 Pro56ction E7ec6tion

Confidential & Proprietary to SAP

& El Araby Group

Page

# of

!

"!!#$$%&docCapacity

Planning

Change Planned

'ndependent requirement

*489

Production Plan

Run *RP

Review *RP !ist toc"2Requirement

!ist

Planned (rders

$Purchase2toc"

Transfer%

Planned (rders

$Production2Run chedule

header in R+*%

Perform Capacity

+valuations 6 !eveling

Convert Planned (rder into

Production (rder

Chec" Capacity situation and

Perform ,inite Capacity leveling

to deallocate or shift load from

the wor" centers if needed

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

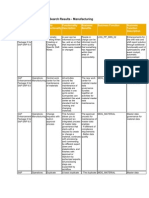

9& Bu(ine(( proce(( *e(cription

Step

A

*epart/ent B(er Role Proce(( *e(cription SAP

2odule

Capacity ituation in ales 6 (peration Planning

: Planning

Capacity

Planner2Production

cheduler

Perform Rough Cut Capacity

evaluations in (P planning

table

PP

Capacity ituation after *RP Run

9 Planning

Capacity

Planner2Production

cheduler

Chec" capacity situations in

toc"2Requirement !ist

PP

;arious (ptions of Capacity Planning

< Planning

Capacity

Planner2Production

cheduler

Perform capacity evaluations

in !TP planning table

PP

Capacity Planning in R+* Planning Table

= Planning

Capacity

Planner2Production

cheduler

Perform Capacity Planning in

R+* Planning Table based

on run schedule header$R+*

Planned (rders% from *RP

PP

eparate tools for Capacity Planning

> Planning

Capacity

Planner2Production

cheduler

Perform Capacity evaluations

based on wor"

centers2Production

!ines2Planned

(rders2Production (rders

PP

8 Planning

Capacity

Planner2Production

cheduler

Perform Capacity +valuations

based on wor"

centers2Production

!ines2Planned

(rders2Production (rders

PP

Confidential & Proprietary to SAP

& El Araby Group

Page

of

!

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

$& C4ange( to E?i(ting -rgani(ation

Plastic manufacturing facility will be defined as separate plant which

will be included for capacity planning. although it would be partial

allocation considering the current scope of implementation

Production activities will be performed separately at plastic

manufacturing plant

@& 7ey Bu(ine(( 0/pro'e/ent

Automatic functions available to perform capacity evaluations and

leveling

;alidations available to allow the user to decide on further business

functions in case of critical capacity

7raphical representations available

7ood standard reports available

%& *e(cription of :unctional *eficit(

Ref&

A

*e(cription of :unctional *eficit( Reco//endation to :ul

fill :unctional *eficit(

:& ?one

#& .ote( on :urt4er 0/pro'e/ent(

Advance planner and optimi/er $AP(% implementation in future could be

considered for demand planning $4P%. upply ?etwor" Planning $?P%

and Production Planning 6 4etailed cheduling $PP4% modules which

would further enhance and help improving the processes at +l Araby

considering big volume of data and transactions&

& Sy(te/ Configuration Con(ideration(

tandard ;alue Parameters

,ormulae

tandard ;alue @ey for wor" centers2production lines

Confidential & Proprietary to SAP

& El Araby Group

Page

" of

!

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

Capacity profiles

trategy

"& *e'elop/ent( Con(ideration(

,& *ata Con'er(ion Con(ideration(

Ref&

A

*e(cription of -b5ect( ; *ata to be

Con'erted

*ata Con'er(ion

2et4od <CA116

LS236

*e'elop/ent=

Reference

*e'elop/ent

Specification

.u/ber

:& ?one

!& 0nterface Con(ideration(

Ref&

A

*e(cription of Sy(te/ ; Proce(( to be

0nterfaced

Reference 0nterface

Specification *ocu/ent

.u/ber

:& ?one

8& Reporting Con(ideration(

Ref&

A

*e(cription of Report Re>uire/ent( Reference Report

*e'elop/ent

Specification

:& tandard reports will be used. development of

reports are not required&

9& :or/ Con(ideration(

Ref&

A

*e(cription of :or/( Reference En4ance/ent

Specification .u/ber

: ?one

$& En4ance/ent Con(ideration(

Ref&

A

*e(cription of En4ance/ent

Re>uire/ent(

Reference En4ance/ent

Specification .u/ber

: ?one

@& Aut4ori(ation Con(ideration(

Rough Cut Capacity A *CBB

toc" Requirement !ist A *4C=

!TP toc" Requirement !ist A *C=

Confidential & Proprietary to SAP

& El Araby Group

Page

, of

!

"!!#$$%&docCapacity

Planning

Project EL ARABY

BUSINESS BLUEPRINT

Capacity Planning

Planning table)!TP A *,C

Planning Table)R+* A *,>C

Capacity +valuation A C*>C2C*>92C*C:

Capacity !eveling A C*9:2C*9D2C*<:

Confidential & Proprietary to SAP

& El Araby Group

Page

! of

!

"!!#$$%&docCapacity

Planning

Вам также может понравиться

- Sap MRP ConfigurationДокумент31 страницаSap MRP ConfigurationtoralberОценок пока нет

- Production Planning and Detailed Scheduling (PP/DS) in SCMДокумент50 страницProduction Planning and Detailed Scheduling (PP/DS) in SCMVijay HajnalkerОценок пока нет

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesОт EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesОценок пока нет

- APO Technical Workshop For LG ChemicalДокумент12 страницAPO Technical Workshop For LG ChemicalVenkata Sarma0% (1)

- Gatp BOP CompДокумент41 страницаGatp BOP CompVishal ..Оценок пока нет

- SAP S/4HANA Retail: Processes, Functions, CustomisingОт EverandSAP S/4HANA Retail: Processes, Functions, CustomisingРейтинг: 5 из 5 звезд5/5 (1)

- Apo - Expert CVДокумент10 страницApo - Expert CVvijay_apoОценок пока нет

- Sap Apo: Global ATP Production Planing & Detailed SchedulingДокумент22 страницыSap Apo: Global ATP Production Planing & Detailed SchedulingMeОценок пока нет

- A Beginner's Guide To PI Sheets: 2 Configuration RequirementsДокумент12 страницA Beginner's Guide To PI Sheets: 2 Configuration RequirementsAmir AliОценок пока нет

- SAP APO DP Interview Questions by NKDДокумент7 страницSAP APO DP Interview Questions by NKDnileshОценок пока нет

- Asad Shoaib: SAP IBP (Integrated Business Planning) /SAP SCM (Supply Chain Management) ConsultantДокумент5 страницAsad Shoaib: SAP IBP (Integrated Business Planning) /SAP SCM (Supply Chain Management) Consultantptcl1Оценок пока нет

- Level of BOM SNP HeuristicДокумент15 страницLevel of BOM SNP HeuristicAvrinz AvrinzОценок пока нет

- LO935 Flexible Planning: Release 640 04/06/2006Документ220 страницLO935 Flexible Planning: Release 640 04/06/2006KRISHNAОценок пока нет

- Supply PlanningДокумент34 страницыSupply Planningharry4sapОценок пока нет

- Mahendran P - SAP PPДокумент4 страницыMahendran P - SAP PPMahendran ParamasivanОценок пока нет

- Apo CTPДокумент4 страницыApo CTPAnkush Agrawal100% (1)

- PPDS For Process IndustryДокумент6 страницPPDS For Process IndustryVinay KumarОценок пока нет

- Alternative Materials in BOM & Production OrderДокумент16 страницAlternative Materials in BOM & Production Ordersrinivasa varmaОценок пока нет

- SAP - PP-PI Training 09 Aug'02 To 15 Aug'02 Gaurav RastogiДокумент58 страницSAP - PP-PI Training 09 Aug'02 To 15 Aug'02 Gaurav RastogiDHL123Оценок пока нет

- SAP PP - Demand ManagementДокумент10 страницSAP PP - Demand ManagementKoustubha KhareОценок пока нет

- Sap PP SampleДокумент17 страницSap PP SampleSunny Sapsd100% (1)

- Sap PP AbbreviationsДокумент2 страницыSap PP Abbreviationsatul82950% (1)

- IBP-Demand PlanningДокумент7 страницIBP-Demand PlanningAzza ShoukrОценок пока нет

- PP-Interview Questions: Skip To End of MetadataДокумент3 страницыPP-Interview Questions: Skip To End of MetadataShiva KumarОценок пока нет

- Quality Certificate - Goods ReceiptДокумент5 страницQuality Certificate - Goods Receiptbcg_503Оценок пока нет

- Test-king.C TSCM42 65 PDFДокумент26 страницTest-king.C TSCM42 65 PDFMarcos Hernandez100% (1)

- SAP Certified Application - HANA PPДокумент1 страницаSAP Certified Application - HANA PPSAP E-learnОценок пока нет

- Business Process Procedure: Quality ManagementДокумент16 страницBusiness Process Procedure: Quality ManagementSameer BagalkotОценок пока нет

- SOP and LTPДокумент10 страницSOP and LTPVijaya Bhasker JОценок пока нет

- Sap SCMДокумент21 страницаSap SCMAffizul AzuwarОценок пока нет

- Carrying Out The Planning Run Using MRP LiveДокумент3 страницыCarrying Out The Planning Run Using MRP LiveAmar ReddyОценок пока нет

- S4220 (Sap S/4hana 1909)Документ2 страницыS4220 (Sap S/4hana 1909)Tanmoy KarmakarОценок пока нет

- SAP PI Evaluation Test: Date: 22-Feb - 2016Документ3 страницыSAP PI Evaluation Test: Date: 22-Feb - 2016Rahul YadavОценок пока нет

- SAP PP Process BatchДокумент9 страницSAP PP Process BatchvrkattulaОценок пока нет

- Engineering Change Management: SAP PP TablesДокумент2 страницыEngineering Change Management: SAP PP TablesartwaniparasОценок пока нет

- Production Planning-Process Industries: Training On in SAP R/3Документ25 страницProduction Planning-Process Industries: Training On in SAP R/3Vinod NagarahalliОценок пока нет

- EHP5 Enhancements in PP ModuleДокумент8 страницEHP5 Enhancements in PP ModulekiranmagarОценок пока нет

- Task List PP SapДокумент33 страницыTask List PP Sapratnesh_xpОценок пока нет

- Managing Supply Chain RiskДокумент8 страницManaging Supply Chain Riskwasim786nasirОценок пока нет

- Lorhan-Texpro Solution - V3.0Документ41 страницаLorhan-Texpro Solution - V3.0sihalim17100% (1)

- (Q&A) 2022 SAP IBP Inventory Buffer Management StrategiesДокумент8 страниц(Q&A) 2022 SAP IBP Inventory Buffer Management StrategiesFernando Daniel LealОценок пока нет

- S/4 Hana Eppds Demo: ManufacturingДокумент8 страницS/4 Hana Eppds Demo: ManufacturingSuraj Pratap PhalkeОценок пока нет

- Can MRP Be Carried Out For One Particular Level of A BomДокумент10 страницCan MRP Be Carried Out For One Particular Level of A BomVipul ShuklaОценок пока нет

- GATPДокумент29 страницGATPajay78_hiОценок пока нет

- Shifting?: Think NG ofДокумент14 страницShifting?: Think NG ofRavikanth AluriОценок пока нет

- QMДокумент69 страницQMKristine Jhoy Nolasco Secopito100% (1)

- Open SQL Editor: Saps'Word - We Sap For Your CauseДокумент5 страницOpen SQL Editor: Saps'Word - We Sap For Your CauseVinod NagarahalliОценок пока нет

- Production Planning For Process Industries-ecc6.0-Ver1Документ86 страницProduction Planning For Process Industries-ecc6.0-Ver1NadeemОценок пока нет

- SAP Production Planning TableДокумент2 страницыSAP Production Planning TableAndre Dwi CahyaОценок пока нет

- SNP OptimizerДокумент66 страницSNP Optimizerkramesh86Оценок пока нет

- Aa Alternative Items in BOMДокумент14 страницAa Alternative Items in BOMAhmed TalaatОценок пока нет

- APO DP Characteristics-Based ForecastigДокумент18 страницAPO DP Characteristics-Based Forecastigsrinivas0212Оценок пока нет

- SAP PP 30 Interview Questions and Answers For 2018Документ18 страницSAP PP 30 Interview Questions and Answers For 2018Hemamber ReddyОценок пока нет

- 01 - Introduction and Course OverviewДокумент6 страниц01 - Introduction and Course OverviewDebebookОценок пока нет

- Comparison of SAP PP Vs SAP PPДокумент1 страницаComparison of SAP PP Vs SAP PPShashank Mani TripathiОценок пока нет

- SAP PP TrainingДокумент4 страницыSAP PP TrainingitprofessionalsnetwoОценок пока нет

- DP Sap ApoДокумент54 страницыDP Sap Apoakeey4uОценок пока нет

- AgendaДокумент1 страницаAgendaAhmed TalaatОценок пока нет

- Fulltext PDFДокумент42 страницыFulltext PDFAhmed TalaatОценок пока нет

- Ful Description of Game TheryДокумент22 страницыFul Description of Game TheryAhmed TalaatОценок пока нет

- MRP Strategy Group - 10Документ17 страницMRP Strategy Group - 10Ahmed TalaatОценок пока нет

- XWWFF 33333 DCCДокумент37 страницXWWFF 33333 DCCAhmed TalaatОценок пока нет

- Upload RTG 123Документ10 страницUpload RTG 123Ahmed TalaatОценок пока нет

- Chess The Complete Beginner's Guide by Henry IngramДокумент83 страницыChess The Complete Beginner's Guide by Henry IngramAhmed Talaat100% (1)

- Role Id Role Name: EL - PP - POVAR - 001 Production Order VarianceДокумент2 страницыRole Id Role Name: EL - PP - POVAR - 001 Production Order VarianceAhmed TalaatОценок пока нет

- Stock at VendorДокумент7 страницStock at VendorAhmed TalaatОценок пока нет

- DTL1ZZДокумент607 страницDTL1ZZAhmed TalaatОценок пока нет

- Grandmaster Versus Amateur: Jacob Aagaard & John ShawДокумент15 страницGrandmaster Versus Amateur: Jacob Aagaard & John ShawAhmed Talaat100% (1)

- Forms Authority RequestДокумент1 страницаForms Authority RequestAhmed TalaatОценок пока нет

- AZ - MM - Procurement of Non Stock MaterialДокумент24 страницыAZ - MM - Procurement of Non Stock MaterialAhmed TalaatОценок пока нет

- Quality AwardsДокумент22 страницыQuality AwardsbhavinpvОценок пока нет

- Top Distributors 2022Документ17 страницTop Distributors 2022Glorianne Mylene LedesmaОценок пока нет

- MBA in Hospitality (By EHL) PDFДокумент12 страницMBA in Hospitality (By EHL) PDFPyae PyaeОценок пока нет

- CMPM 1Документ9 страницCMPM 1Cuttie Anne GalangОценок пока нет

- Case 03Документ21 страницаCase 03Anonymous CmcvwSgkОценок пока нет

- Advertising PlaybookДокумент53 страницыAdvertising PlaybookMariana FerronatoОценок пока нет

- Material Management Multiple Choice Questions With Answers 2Документ5 страницMaterial Management Multiple Choice Questions With Answers 2alemayehu83% (6)

- Chapter 1Документ47 страницChapter 1TERRIUS AceОценок пока нет

- Characteristics of Supply Chain Management and The Implication For Purchasing and Logistics StrategyДокумент22 страницыCharacteristics of Supply Chain Management and The Implication For Purchasing and Logistics StrategyNguyen Quoc Chuong100% (1)

- SAFe For Teams Digital Workbook (5.1.1)Документ159 страницSAFe For Teams Digital Workbook (5.1.1)Bogdan Stan100% (1)

- 3a. Entrepreneurship and Business PlanningДокумент26 страниц3a. Entrepreneurship and Business PlanningAudityaErosSiswanto50% (2)

- Esm 1Документ5 страницEsm 1tamratderejeОценок пока нет

- POPM - Quizlet 47Документ10 страницPOPM - Quizlet 47Adbhut KumarОценок пока нет

- TemplatesДокумент17 страницTemplatesdinesh pharmaОценок пока нет

- Appraisal Form - AccountsДокумент2 страницыAppraisal Form - Accountski_anand100% (1)

- Bus 5611 Wa Unit 2Документ5 страницBus 5611 Wa Unit 2Hassan Suleiman SamsonОценок пока нет

- IT in SCMДокумент15 страницIT in SCMrohanc_10Оценок пока нет

- QIPV3 - Quick Overview December2016Документ11 страницQIPV3 - Quick Overview December2016sara btnОценок пока нет

- ICCT Colleges Foundations, Inc.: Chapter 3 - ActivityДокумент2 страницыICCT Colleges Foundations, Inc.: Chapter 3 - ActivityEugene AlipioОценок пока нет

- HR AuditДокумент36 страницHR AuditTarandeep Singh100% (1)

- Q.2 What Approach Has Hubtown Taken To Create Its Human Resources Strategy?Документ1 страницаQ.2 What Approach Has Hubtown Taken To Create Its Human Resources Strategy?sakshiОценок пока нет

- Intermediate Management Accounting Project 1Документ4 страницыIntermediate Management Accounting Project 1Dhanraj VenugopalОценок пока нет

- Business Systems AnalystДокумент2 страницыBusiness Systems Analystapi-78357108Оценок пока нет

- 002-Cavinato 1999 - Fitting Purchasing To The 5 Stages of Strategic ManagementДокумент9 страниц002-Cavinato 1999 - Fitting Purchasing To The 5 Stages of Strategic ManagementChetanОценок пока нет

- Week 7 - Lecture Slides - Measures of SuccessДокумент27 страницWeek 7 - Lecture Slides - Measures of SuccessAiman AbousherОценок пока нет

- Vinay R Prasad ": DeliverablesДокумент3 страницыVinay R Prasad ": DeliverablesVinay PrasadОценок пока нет

- Resource AllocationДокумент3 страницыResource AllocationSukesh R50% (2)

- Topic 8: "Sustainability Report Principles": DINI RAHMADIANTI (1610531008) BELINDA NABILA (1610533020)Документ3 страницыTopic 8: "Sustainability Report Principles": DINI RAHMADIANTI (1610531008) BELINDA NABILA (1610533020)Indah IndrianiОценок пока нет

- Information Technology in ManagenentДокумент14 страницInformation Technology in ManagenentjinseearnakerilОценок пока нет

- Final Project of BSPДокумент6 страницFinal Project of BSPMuhammad Ali KhanОценок пока нет