Академический Документы

Профессиональный Документы

Культура Документы

Passive Tuned Harmonic Filters

Загружено:

Rajendra Prasad ShuklaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Passive Tuned Harmonic Filters

Загружено:

Rajendra Prasad ShuklaАвторское право:

Доступные форматы

Why passive tuned harmonic filters are the only global choice for energy intensive power quality

harmonics project?

This is because optimum harmonic distortion mitigation necessitates harmonic filter manufacturer to

design passive filter projects with appropriate modeling of both clients & grids incoming electrical

power systems, through a full range harmonics frequency scan. The modeling ensures elimination of

harmonics resonance throughout all possible harmonic ranges. The required engineering efforts are

necessary to effectively improve clients electric power systems immunity to harmonics resonance as

well as to mitigate both THDv (total voltage harmonic distortions) and THDi (total current harmonic

distortions). Passive filters tuning requires matching its parameters with power systems impedance

and clients variable load demands and thus tuned passive harmonic filter solution is never a mass

manufacturing process but knowledge based engineering deliverables & a service manufacturing

process. This is the domain and utility of passive tuned harmonics filter that when designed

appropriately, lasts a life time and delivers great rewards so much so that ever since its inception in

the 1970s, it always remained the only option for all power intensive projects worldwide.

Passive Tuned harmonic filter saves by reducing upto 15% Energy Bills (kWh Energy Conservation). It

cuts down upto 40% Maximum Contract Demand (KVAh Power Savings). It maintains unity Power

Factor PF (the optimum kVArh Power Conservations). It eliminates nuisance tripping problems with

protective relays, Circuit Breakers, AC VFD Motor Drives, DC Motors Drive, Data Center Computer

Servers, Internet and Communication Electronics Equipments. It comprehensively solves equipment

overheating, humming noise, vibrations, hunting, Burning and failure Issues with Electronics Cards,

AC VFD Drive cards, DC Drives Electronic card, DDC or PLC Control Cards, Power IGBT Thyristor

Boards, Data Centers Computer Hard Disks Drive, Fuses, CT PT, Switchgears, Diesel Generators DG,

Turbine Generator TG, Transformers, Cables Terminations and Lugs failures Issue. It allows upto

100% Equipment Loadings a very useful Engineering Design Tool that enables Design Engineers to

design their projects without being forced into the otherwise costly Derating options. It saves money

by slashing down upto 40% in Project Costs. It allows upto 25% increase in Production. It improves

both Product Quality and Quality Rejection Rates that by Suppressing Harmonics Distortion and

solving the problems of Electrics Power Quality Disturbances. Passive Tune Harmonic Filters truly

achieves Industries 3P Power, Productivity and Profitability.

As against; the Active Harmonic Filter Solutions are mass manufactured product but it can not

effectively Mitigate Harmonics Distortion thus it ends up in exacerbating Electronic Failures if

Equipments are not highly Derated. This is the reason and also the catch as to why Equipments like

Large VFD Mill Drives, Large DC Mills Drive or Process Transformers with high Non Linear Loads (NLL)

are so hugely Over Designed if large Amperage Active Harmonic Filters are connected across it. Please

visit us at www.enconengineers.in under Knowledge Center for a real life case study on the Pros and

Cons of Active Harmonics Filters vis--vis Tuned Passive Harmonic Filter.

Encon Harmonic Filters type Encon Ih Filters are time tested through several decades across all

Industrials, Commercials, Intelligent Buildings and Utility Projects worldwide. You may like to visit us

under Our Credentials and Knowledge Center for real life case studies, application notes, client

feedbacks letters and detailed information.

Low Voltage Harmonic Filter Specifications and Products Range.

Working Voltage: 120V, 380V, 415V, 480V, 575V, 690V, 1000V or job specific voltages

Working Current: From as low as 30A up to 6000A in one "Single Harmonic Filter Module"

and beyond 6000A with modular multiples of Harmonic Filters

Filter connection Connected in parallel with the load application

Load Application 1) Transformer End, used if non-linear-loads are small and scattered

across TRF

2) Load End, used if any non-liner-load that is big enough to merit such

connection

3) Duel Winding Transformer, method used when non-linear-loads are

extra-large.

Controllability 1) Fixed Filter, used if loads are generally constant or mildly variable

2) Automatically Variable Filter, used if loads are variable or highly

variable.

Switching 1) Manual, if simple operation procedure is needed

2) Automatic, if process conditions need matching switching on/off

Installation Indoor, enclosed in one free standing high quality compartmentalized

panel. Modular multiple panel sections are used for higher sized filters.

High Voltage Harmonic Filter Specification and Product Range > usually using Air Core

Reactors

Working Voltage: 2.2kV, 3.3kV, 6.6kV, 11kV, 22kV, 33kV or job specific voltages

1.0mvar, 33kv, Tune Harmonic Filter with iron core reactors

Working Current Job specific

Filter connection Connected in parallel with the load application

Load Application 1) Transformer primary end, used for mega-sized-loads like EAF, IF,

Rectiformers

2) PCC End, used for entire factory loads OR, for whole of a plant section

loads

Controllability 1) Fixed Filter, mostly HT applications use fixed filters.

2) Variable Filters, rarely used unless needed for Flicker control for

extra-large loads.

Switching 1) Manual, if simple operation procedure is needed

2) Automatic, if process conditions need matching switching on/off

Installation 1) Indoor, enclosed in one compartmentalized free standing panel.

2) Outdoor, substation type mounting

Zero Sequence 3rd (also known as Neutral or Triplen) Harmonics Filter and its

Specifications

Triplen harmonic trebling at Neutral

In a balanced 3-phase grounded wye

system currents going into neutral node

get cancelled vectorially each being

120o out of phase. Neutral current

remain ideally zero but practically at a

marginal level that depends upon phase

unbalance. Fig. 9, 3rd (Third) harmonic

current is in phase with neutral add-up

and produce very high neutral current.

The same happen with any odd multiple of third harmonic 9th, 15th, 21th and they collectively

referred as Triplen harmonics. They are vectorially in phase with neutral and also referred as Zero

Sequence harmonics. They present electrical fire risk if neutral conductor not sufficiently oversized and

circulate in power systems and transformer causing significant overheating and energy losses. Their

primary sources are computers, smps and single phase power supplies those are so common with

todays plethora of power electronic devices and electronic ballasts.

End user power distribution system conventionally use delta-star transformer wherein delta winding

connect to utility transmission as 3phase 3wire (3P3W) system and star winding to end-user loads as

3phase 4wire (3P4W) system. Triplen harmonic current from Non-Liner-Load (NLL) enter secondary

star winding and through neutral continuously circulate with the NLL as in Fig. 9. Since primary delta

winding provide ampere-turn balance it get transferred to primary delta get trapped and circulate

continuously thus power systems upstream of transformer primary get spared from Triplen harmonic

current. However circulating harmonic current remain that cause excessive heat and energy losses in

the transformer.

Zero Sequence Harmonic Filter drops the zero sequence currents on neutral wire by creating least

impedance path for the flow of third harmonic current that lead to the elimination of Triplen harmonic

current from its point of application.

Working Voltage: 120V, 240V, 380V, 415V, 480V or job specific voltage

Working Current: From as low as 10A up to 3000A of neutral current specification.

Filter connection Connected in parallel with the load application

Load Application 1) Transformer End, if the upstream power systems protection is needed

2) Load End, if trouble-shooting measures are needed for electronic

failure like in Data Center servers, work station computers, control

systems and power supplies

Controllability 1) Manual, if simple operation procedure is needed

2) Automatic, if process conditions need matching switching on/off .

Switching 1) Manual, if simple operation procedure is needed

2) Automatic, if process conditions need matching switching on/off

Installation Indoor, enclosed in one free standing high quality compartmentalized

panel. Modular multiple panel sections are used for higher sized filters.

Вам также может понравиться

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОт EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОценок пока нет

- Design PV WasiniДокумент32 страницыDesign PV WasiniKevin Kimani MainaОценок пока нет

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОт EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОценок пока нет

- Design and Contruction of Automatic Phase Selector PDFДокумент51 страницаDesign and Contruction of Automatic Phase Selector PDFKadiri IbrahimОценок пока нет

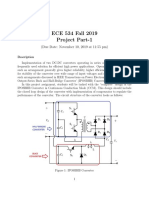

- ECE 534 Project 1 F19Документ6 страницECE 534 Project 1 F19JAY CHHEDAОценок пока нет

- Synopsis Proposal For 2021Документ4 страницыSynopsis Proposal For 20212k18-EE-243 Vethushan VinnayagamoorththiОценок пока нет

- Conductor Size, General: Table C-2 NEC References For Conductor SizingДокумент4 страницыConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NОценок пока нет

- WhatsNew 2016 en PDFДокумент54 страницыWhatsNew 2016 en PDFMiguel CbОценок пока нет

- Capacitor Switching Transients ProblemsДокумент5 страницCapacitor Switching Transients Problemsaris09yekofОценок пока нет

- DHBVN IT DistributionДокумент21 страницаDHBVN IT DistributionSambit GantayatОценок пока нет

- An Example of Calculating The Number of Indoor Lighting FixturesДокумент3 страницыAn Example of Calculating The Number of Indoor Lighting FixturesJoseph B Delos ReyesОценок пока нет

- Sizing GenДокумент5 страницSizing GenMind of BeautyОценок пока нет

- Design Calculations For Buck-Boost Converters: Michael Green Advanced Low Power SolutionsДокумент12 страницDesign Calculations For Buck-Boost Converters: Michael Green Advanced Low Power SolutionsnandhakumarmeОценок пока нет

- Model of MINI UPS SystemДокумент38 страницModel of MINI UPS Systemanand_sah51133% (3)

- Spec For 33kv SystemДокумент27 страницSpec For 33kv SystemkjfenОценок пока нет

- Lecture-4 Power Quality and HarmonicsДокумент13 страницLecture-4 Power Quality and HarmonicsjameelahmadОценок пока нет

- User Manual For MPPT-5015A 3015AДокумент22 страницыUser Manual For MPPT-5015A 3015Afacosta_auОценок пока нет

- International Refereed Journal of Engineering and Science (IRJES)Документ8 страницInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comОценок пока нет

- EEE 805 Assignment Questions For Chapter 20Документ11 страницEEE 805 Assignment Questions For Chapter 20ayeniОценок пока нет

- Project Title: A Presentation OnДокумент23 страницыProject Title: A Presentation OnAnonymous qh5UUGTОценок пока нет

- Design and Implementation of A G P Photovoltaic Maximum Power Point TrackerДокумент55 страницDesign and Implementation of A G P Photovoltaic Maximum Power Point TrackerBilal KanjОценок пока нет

- Schematic Diagram of The On Grid Solar SystemДокумент9 страницSchematic Diagram of The On Grid Solar SystemAsterism TechPro RajasthanОценок пока нет

- Star-Delta Starter: Electrical Notes & ArticlesДокумент25 страницStar-Delta Starter: Electrical Notes & Articlesprabhanshu241991100% (1)

- Chapter On1 and Two-1Документ25 страницChapter On1 and Two-1Roqeebat OdunayoОценок пока нет

- Determination of The Minimum Distance Between Adjacent Rows of Solar Panels To Avoid Shading EffectДокумент21 страницаDetermination of The Minimum Distance Between Adjacent Rows of Solar Panels To Avoid Shading EffectKhadija MehjebinОценок пока нет

- Novel Method PMDC Motor Speed ControlДокумент15 страницNovel Method PMDC Motor Speed ControlTravis WoodОценок пока нет

- Solar Micro ControllerДокумент18 страницSolar Micro ControllerElangovanОценок пока нет

- Midterm Exam Fall 2012Документ5 страницMidterm Exam Fall 2012Asanka RodrigoОценок пока нет

- Spec VSDДокумент8 страницSpec VSDNicodemus Ervino MandalaОценок пока нет

- SMPS PresentationДокумент33 страницыSMPS PresentationGeorge AntonyОценок пока нет

- Design and Implementation of A Solar Power SystemДокумент6 страницDesign and Implementation of A Solar Power SystemEditor IJTSRDОценок пока нет

- Electrical Power ProjectДокумент12 страницElectrical Power ProjectsrnkaОценок пока нет

- 17ee82 - Ida - Mod 4 NotesДокумент18 страниц17ee82 - Ida - Mod 4 NotesManish Kumar SahaniОценок пока нет

- Subject Name: Electric Drive Subject Code: 6EE4-05: Introduction: Objective, Scope and Outcome of The CourseДокумент9 страницSubject Name: Electric Drive Subject Code: 6EE4-05: Introduction: Objective, Scope and Outcome of The CourseAbhíñåv PrâjãpätîОценок пока нет

- Advancements in Inverter TechnologyДокумент9 страницAdvancements in Inverter TechnologyAyush KumarОценок пока нет

- Numerical RelaysДокумент38 страницNumerical Relaysashutosh2009Оценок пока нет

- Demand Side ManagementДокумент13 страницDemand Side ManagementGaurav SapkotaОценок пока нет

- HVDC ReportДокумент3 страницыHVDC ReportSueja MalligwadОценок пока нет

- How To Size MCBДокумент4 страницыHow To Size MCBpravin chawleОценок пока нет

- Static RelaysДокумент11 страницStatic RelaysBharathwaj SreedharОценок пока нет

- Metering For Linemen: Current TransformersДокумент3 страницыMetering For Linemen: Current TransformersEBEОценок пока нет

- Adc PDFДокумент62 страницыAdc PDFAkhilesh TewaryОценок пока нет

- Power System Stability On Island Networks: Digsilent GMBHДокумент36 страницPower System Stability On Island Networks: Digsilent GMBHTesfahun GirmaОценок пока нет

- Reactive Power CompensationДокумент30 страницReactive Power CompensationRamit Gera100% (1)

- Start Sequence of MotorsДокумент4 страницыStart Sequence of MotorsSamuel AdamuОценок пока нет

- Arc Voltage Torch Height Controller: XPTHC-100 Instruction ManualДокумент18 страницArc Voltage Torch Height Controller: XPTHC-100 Instruction Manualwanilo100% (1)

- 2-Contractors and RelaysДокумент13 страниц2-Contractors and RelaysMais AlsharifОценок пока нет

- PCB Design & Manufacturing CURRICULUMДокумент19 страницPCB Design & Manufacturing CURRICULUMSunita kumariОценок пока нет

- Chapter - 1 1.1 OverviewДокумент21 страницаChapter - 1 1.1 OverviewTirumalarao PechettyОценок пока нет

- FuseologyДокумент9 страницFuseologyalvincent72Оценок пока нет

- Brochure SIMARIS Software ToolsДокумент8 страницBrochure SIMARIS Software ToolsDavid LovatoОценок пока нет

- Multi TekДокумент41 страницаMulti TekWasim AbbasОценок пока нет

- Effects of Harmonics On Power SystemsДокумент6 страницEffects of Harmonics On Power SystemsLammie Sing Yew LamОценок пока нет

- Energy Audit of A 400-220 KV Substation - A Case Study PDFДокумент8 страницEnergy Audit of A 400-220 KV Substation - A Case Study PDFRajuОценок пока нет

- UJTДокумент43 страницыUJTRahul KiniОценок пока нет

- Fan Selection GuideДокумент4 страницыFan Selection GuideamitbslpawarОценок пока нет

- Unit3 - Electrical SystemДокумент57 страницUnit3 - Electrical SystemNethaji BKОценок пока нет

- Substation AutomationДокумент12 страницSubstation AutomationSujan DebnathОценок пока нет

- Unit 4 Power Quality Management in Smart Grid Emc - Electromagnetic CompatibilityДокумент18 страницUnit 4 Power Quality Management in Smart Grid Emc - Electromagnetic CompatibilityMathumathi TОценок пока нет

- TN System - Protection Against Indirect Contact - Electrical Installation GuideДокумент4 страницыTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaОценок пока нет

- La Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciДокумент1 страницаLa Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciRajendra Prasad ShuklaОценок пока нет

- La Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciДокумент1 страницаLa Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciRajendra Prasad ShuklaОценок пока нет

- TN System - Protection Against Indirect Contact - Electrical Installation GuideДокумент4 страницыTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaОценок пока нет

- TN System - Protection Against Indirect Contact - Electrical Installation GuideДокумент4 страницыTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaОценок пока нет

- MU040 - KRT EngHandbook Lowres PDFДокумент24 страницыMU040 - KRT EngHandbook Lowres PDFRajendra Prasad ShuklaОценок пока нет

- T: Direct Connection of A With Earth Point (French: Terre)Документ5 страницT: Direct Connection of A With Earth Point (French: Terre)Rajendra Prasad ShuklaОценок пока нет

- EDS 01-0045 Overhead Line Ratings PDFДокумент10 страницEDS 01-0045 Overhead Line Ratings PDFRajendra Prasad ShuklaОценок пока нет

- Earth Loop Impedance Tests PDFДокумент20 страницEarth Loop Impedance Tests PDFRajendra Prasad Shukla100% (1)

- ZS Chart - 090315 - Final PDFДокумент2 страницыZS Chart - 090315 - Final PDFRajendra Prasad ShuklaОценок пока нет

- 46 Cable Volatge Drop For Different Size of Cables 1.9.15Документ33 страницы46 Cable Volatge Drop For Different Size of Cables 1.9.15Rajendra Prasad ShuklaОценок пока нет

- 33 Short Circuit Current at Various Point of Distribution System 1.9.15Документ8 страниц33 Short Circuit Current at Various Point of Distribution System 1.9.15Rajendra Prasad ShuklaОценок пока нет

- ZS Chart - 090315 - Final PDFДокумент2 страницыZS Chart - 090315 - Final PDFRajendra Prasad Shukla50% (2)

- Whitepaper Grounding Electrodes Explained PDFДокумент9 страницWhitepaper Grounding Electrodes Explained PDFRajendra Prasad ShuklaОценок пока нет

- EDS+08-0121+LV+Supplies+to+HOT+Sites+and+National+Grid+Sites PDF 1 PDFДокумент29 страницEDS+08-0121+LV+Supplies+to+HOT+Sites+and+National+Grid+Sites PDF 1 PDFRajendra Prasad ShuklaОценок пока нет

- ENA - EREC - G81-1 - Issue 3 - (2016) - Final - v3 PDFДокумент23 страницыENA - EREC - G81-1 - Issue 3 - (2016) - Final - v3 PDFRajendra Prasad ShuklaОценок пока нет

- User'S Guide Operating & Maintenance: Constant Current RegulatorДокумент70 страницUser'S Guide Operating & Maintenance: Constant Current RegulatorJavier Eduardo Alzate BogotaОценок пока нет

- Dem A MasterДокумент13 страницDem A MasterEduardo MoralesОценок пока нет

- Static Voltage Stabilizer PDFДокумент17 страницStatic Voltage Stabilizer PDFFlo Mirca100% (3)

- This Bhel ProjectДокумент51 страницаThis Bhel ProjectRaj_005Оценок пока нет

- QSR InstrumentationControl PDFДокумент275 страницQSR InstrumentationControl PDFDonny FitradiОценок пока нет

- LeroySumer - LSA 47.2 S4 M7 PDFДокумент12 страницLeroySumer - LSA 47.2 S4 M7 PDFSureshkumar Kulanthai VeluОценок пока нет

- Electromagnetic Vacuum CleanerДокумент41 страницаElectromagnetic Vacuum CleanervinothОценок пока нет

- Net Metering Installation Checklist - Gertrudes Santos - 07-01-2022Документ4 страницыNet Metering Installation Checklist - Gertrudes Santos - 07-01-2022Nina Rachell RodriguezОценок пока нет

- Woodward Zastitni RelejiДокумент8 страницWoodward Zastitni RelejiRusty AllenОценок пока нет

- Donald Lee Smith: A Practical Guide To Free-Energy Devices Author: Patrick J. KellyДокумент123 страницыDonald Lee Smith: A Practical Guide To Free-Energy Devices Author: Patrick J. KellySvajunas tesla100% (1)

- Polarity Test On Single Phase Transformers and Three Phase Transformer ConnectionsДокумент14 страницPolarity Test On Single Phase Transformers and Three Phase Transformer ConnectionsPavan DakoreОценок пока нет

- A Full-Bridge DC-DC Converter With Zero-Voltage-Switching Over The Entire Conversion RangeДокумент8 страницA Full-Bridge DC-DC Converter With Zero-Voltage-Switching Over The Entire Conversion RangeNirmal mehtaОценок пока нет

- Saes P 100Документ31 страницаSaes P 100wastazoheb_700349353Оценок пока нет

- Substation/Switch Yard: Presented by Ankit Kumar REG - NO-11907132 ROLL - NO-07 Section-K19By Group - 1Документ38 страницSubstation/Switch Yard: Presented by Ankit Kumar REG - NO-11907132 ROLL - NO-07 Section-K19By Group - 1Ankit Kumar100% (1)

- WP51-PowerEquipmentandDataCenterDesign v1 PDFДокумент51 страницаWP51-PowerEquipmentandDataCenterDesign v1 PDFServasfloresОценок пока нет

- 800kva Cast Dry TransformerДокумент1 страница800kva Cast Dry TransformerAnonymous sAmJfcV100% (1)

- 01 MachinesДокумент64 страницы01 MachinesWeldingSupply.com.au0% (1)

- Gerador DQL - C - D - E - Manual de PeçasДокумент78 страницGerador DQL - C - D - E - Manual de PeçasAdilson Melo de MouraОценок пока нет

- GSM Based Energy MeterДокумент125 страницGSM Based Energy MeterHari Babu100% (1)

- Electrofisher User ManualДокумент26 страницElectrofisher User ManualAdrian FilipОценок пока нет

- Synchro T-R Pair TheoryДокумент2 страницыSynchro T-R Pair TheoryKaustubh DesaiОценок пока нет

- X010004 REV2 DC6 ManualДокумент20 страницX010004 REV2 DC6 ManualLuis Javier Resendiz GonzalezОценок пока нет

- GES Silicon SleeveДокумент2 страницыGES Silicon SleeveDeepu ChaturvediОценок пока нет

- Areva 1 PDFДокумент229 страницAreva 1 PDFSimratSandhuОценок пока нет

- Take Transformers MCQ Test & Online Quiz To Test Your KnowledgeДокумент5 страницTake Transformers MCQ Test & Online Quiz To Test Your Knowledgexuyen tranОценок пока нет

- User Manual For TDC3100 (V1.3.0)Документ27 страницUser Manual For TDC3100 (V1.3.0)edgarcooОценок пока нет

- CEA Draft Regulation For Construction of Electrical Plants - Aug'10Документ132 страницыCEA Draft Regulation For Construction of Electrical Plants - Aug'10kalgithОценок пока нет

- Instruction Manual: 5COV475800 - LPT - Rev00Документ8 страницInstruction Manual: 5COV475800 - LPT - Rev00Ratheesh KumarОценок пока нет

- Rationalized User Specification: Part 3: Procedures For Measurement and ReportingДокумент25 страницRationalized User Specification: Part 3: Procedures For Measurement and ReportingrendaninОценок пока нет

- Cigre TB 755Документ127 страницCigre TB 755karl0z86100% (2)