Академический Документы

Профессиональный Документы

Культура Документы

Videocon d2h Setup and Reflector Installation Guidelines

Загружено:

IndianMascot81%(21)81% нашли этот документ полезным (21 голос)

50K просмотров68 страницThis document provides guidelines for installing a reflector dish for receiving satellite signals. It describes 14 steps for the installation process, including selecting an installation site with a clear line of sight to the satellite, mounting the foot stand and mast at 90 degree angles, assembling the reflector bracket and dish, and aligning the dish to the proper azimuth and elevation angles for the location as determined by online lookup tables. Safety precautions are emphasized throughout, such as wearing protective gear while drilling and ensuring no obstructions or power lines are in the signal path.

Исходное описание:

Videocon d2h Installation, Setup and Reflector Installation Guidelines

Авторское право

© © All Rights Reserved

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides guidelines for installing a reflector dish for receiving satellite signals. It describes 14 steps for the installation process, including selecting an installation site with a clear line of sight to the satellite, mounting the foot stand and mast at 90 degree angles, assembling the reflector bracket and dish, and aligning the dish to the proper azimuth and elevation angles for the location as determined by online lookup tables. Safety precautions are emphasized throughout, such as wearing protective gear while drilling and ensuring no obstructions or power lines are in the signal path.

Авторское право:

© All Rights Reserved

81%(21)81% нашли этот документ полезным (21 голос)

50K просмотров68 страницVideocon d2h Setup and Reflector Installation Guidelines

Загружено:

IndianMascotThis document provides guidelines for installing a reflector dish for receiving satellite signals. It describes 14 steps for the installation process, including selecting an installation site with a clear line of sight to the satellite, mounting the foot stand and mast at 90 degree angles, assembling the reflector bracket and dish, and aligning the dish to the proper azimuth and elevation angles for the location as determined by online lookup tables. Safety precautions are emphasized throughout, such as wearing protective gear while drilling and ensuring no obstructions or power lines are in the signal path.

Авторское право:

© All Rights Reserved

Вы находитесь на странице: 1из 68

Reflector Installation

Guideline for Engineers

1

www.dthforum.com

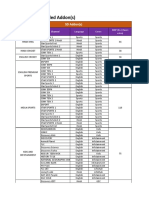

Videocon d2h Broadcasting Parameters

Our Satellite : SingTel - 2 (ST-2)

Satellite Position : 88 Degree East Longitude

ST - 2 Satellite

Sr. No.

Transponder Frequency

(Mhz)

TP No. Polarisation

1 11483 6A Vertical Low

2 11483 6B Horizontal Low

3 11546 7A Vertical Low

4 11546 7B Horizontal Low

5 11609 8A Vertical Low

6 11609 8B Horizontal Low

7 11672 9A Vertical Low

8 11672 9B Horizontal Low

9 11164 10A Vertical Low

10 11164 10B Horizontal Low

2

www.dthforum.com

Site Selection

Choose Better Mounting Option

Align Foot Mount at 90 Degree

Preparation before drilling

Drill Holes & Fix Coach Screws

Fix Foot Mount on the Wall

Assemble MAST with Foot Mount

Align MAST at 90 Degree with respect to Ground

Fix Struts with MAST aligning 180 Degree with respect to Ground

Fix bolts with MAST Bracket

Assemble MAST bracket with Antenna Bracket

Assemble Antenna bracket & MAST Bracket with Reflector

Insert Weather seal & Assemble LNBF with LNBF Clamp

Assemble LNBF Clamp & LNBF with LNBF Arm

Assemble LNBF Arm with Antenna Bracket

Adjust SKEW ( approx. ) as per Look Angle chart

Assemble Reflector Assembly with Mount Assembly

Align Elevation & Azimuth angle as per Look Angle chart of respective city

Reflector Installation Steps

3

www.dthforum.com

Step -1 : Site Selection

Survey different locations (like Balcony , Roof etc.) of the building for Reflector Installation with

customer consent

Align colored part of magnetic needle to the NORTH direction

N

E

S

W

45

135

225

315

141

Identify Line Of Sight (LOS) direction based on Azimuth Angle of your city (refer below link to know -

http://www.satsig.net/maps/satellite-dish-pointing-india.htm

Ensure Compass is held Straight & Still during locating Azimuth Angle

No Metallic ( Finger Ring) / Magnetic object should be near compass while locating Azimuth Angle

Colour Part of Needle

4

www.dthforum.com

Type Name of Installation

location here

Select Satellite from here

Click Here to

Calculate

Azimuth,

Elevation & Skew

angle of Location

for Reflector

Installation

How to Calculate Azimuth, Elevation & Skew Angle

Type link http://www.satsig.net/maps/satellite-dish-pointing-india.htm in web address bar, below Screen appear

Select Satellite as 88 E ST 1 & Type City name, then Click on Go to know Azimuth, Elevation & skew angle

5

www.dthforum.com

Select location for Reflector Installation with clear view of Satellite (Line Of Sight)

by using Magnetic compass

There should not be any partial / future obstruction in LOS like- Tree branches, Shed,

Growing Tree, Under Construction Building etc.

Satellite

Subscriber

Obstruction in LOS

Satellite

Subscriber

Clear LOS

Step :1 - Site Selection (Continued.. )

6

www.dthforum.com

Also consider below mentioned points during Site Selection :

Reflector Installation Location : -

Should be minimum 5 Meters away from Bare Electrical Lines (Overhead / Side)

Should be easily accessible for Maintenance / Service

Should not be accessible by Children / Pet Animals

Should be such that Rain / Water Drainage from Roof does not fall directly on

the Reflector

Should not be in the Passage

Should not be in Damp Area

Always Prefer wall Mount option for Reflector Assembly

Never Install Reflector Assembly on Water Tank or wall of the Water Tank

Step :1 - Site Selection ( Continued.. )

7

Minimum15 cmDistance should be maintained

between corner edge of the wall & hole to be drilled

Minimum 15 cm

Thickness of the Wall should be more than1.5 times of

Rawl Plug Length

60 cm

60 cm

15 cm

Reflector should never be Installed directly on the Roof

In case of Floor Mounting Reflector Should be installed on the Flat concrete base

of below mentioned Specification

Also consider below mentioned points during Site Selection (continued.)

Flat Surface

In case hole to be drilled is above shoulder height always use Ladder

Step :1 - Site Selection ( Continued.. )

8

www.dthforum.com

Check for conceal electric cables with

Line Detector

Check for Water Pipe Line, Gas Pipe line &

other cables with Customer consent

Green LED will glow

if Line detector

detects Current flow

Always check for Water line, Gas

line or any other cables before

drilling in the wall

Minimum7 cmdistance should be maintained between Electric Cable & Hole to be drilled

Ensure that Water Line, Gas Pipe, Other Cables / Customer Property is not damage

while drilling

Also consider below mentioned points during Site Selection (continued.)

Step :1 - Site Selection ( Continued.. )

9

Cable Length should be minimum from Reflector to Satellite Box in order to avoid

Signal & Voltage Drop.

Cable Should be routed with minimum number of drill holes

Location selected for Satellite Box should have proper air circulation

Select two most suitable locations for Reflector Installation

Take Customer permission for Reflector Installation at best suitable location

Also consider below mentioned points during Site Selection (continued.)

Cable Length should be

minimum

Reflector

Digital Set Top Box

Step :1 - Site Selection ( Continued.. )

10

www.dthforum.com

Step : 2 - Choose Better Mounting Option

Wall Mount

Always prefer Wall Mount as a Mounting option

Floor Mount

To be Avoided To be Preferred

11

www.dthforum.com

After Alignment of Foot Mount,

Mark 1 hole for drilling

Align Foot Mount at 90 degree with

respect to ground by using Spirit

level meter

Bubble in Center

Foot

Mount

Spirit Level

Meter

Foot Mount should be installed on Flat (Plane) surface

Mark Hole for

Drilling

Step -3 : Align Foot Mount at 90 Degree

12

Take Customer permission before drilling

Clean Drill machine & Drill bits

Set Drilling mode according to Wall ( Concrete / Brick )

Check Drill bit size according to Rawl Plug diameter

Adjust guide rod according to Rawl Plug length

(Guide Rod Setting = Rawl Plug Length + 2mm)

( Depth of Hole = Rawl Plug Length + 2mm)

Always wear Safety goggle while drilling & blowing dust

fromhole

Self Lockable Chuck Guide Rod

Drilling Mode

Selection Switch

Speed Variation Switch

Drill Machine should be in OFF mode while selecting

the mode, inserting Drill bit or adjusting Guide Rod.

Forward /Reversing

Speed Control Switch

Step -4 : Preparation before Drilling

13

Hold the drill machine with both hands while drilling

Put forward the left leg ( for a Right handed Person ) with the right index finger on Speed

Control Switch, Hold the handle with Left Hand vice versa for Left Handed person

Hold the Drill Machine Horizontally & Drill hole

perpendicular to the Wall

Slowly increase the speed by using the speed control switch

Dont let drill stop while the bit is still inside the hole

(If the drill is stuck in the hole, reverse the direction of rotation & slowly pull out the drill bit)

Dont change the rotation direction with the switch while the drill machine is ON

Dont lean on Drill Machine while drilling

Use Drill Machine with Safety Precautions to avoid injury

Safety Precautions : -

Step -5 : Drill Holes & Fix Coach Screws

14

Blow the dust from the drilled

hole

Drill the first hole

Dust Blower

Do not breathe while blowing dust.

Ensure the Drill Machine is Switched OFF immediately after drilling of holes

Hammer

Push Rawl Plug inside

the wall by using Hammer

Always use Coach Screw & Rawl Plug recommended by Company

Step -5 : Drill Holes & Fix Coach Screws (Cont..)

15

Fix coach screw with

Washer by using T-Spanner

Mark second Hole after assuring

Foot mount at 90

Degree with Spirit Level Meter

Drill Second hole

T-Spanner

Coach Screw Washer

Step -5 : Drill Holes & Fix Coach Screws (Cont..)

16

Tighten Anchor bolt by checking Foot Mount 90

o

with respect to ground

Always use Proper Size Spanner in order to avoid damage to Coach Screw

Dust should be blown from drilled holes before inserting Rawl Plug

Step -5 : Fix Foot Mount on the Wall

17

Step 6: Assemble MAST with Foot Mount

A B

C

Nut & Bolt

18

www.dthforum.com

Step 7: Align MAST at 90 Degree with respect to Ground

Align MAST at 90 Degree in front

by using Spirit Level Meter

Align MAST at 90 Degree in

side by using Spirit Level Meter

Mast at 90 Degree in X - Axis Mast at 90 Degree in Y - Axis

19

Step 8: Assemble Struts with MAST

Assemble Struts with Mast

Align both Struts at 180

o

with

respect to Ground & mark Holes

Drill Holes at marked position, fix Coach Screws & tighten both Struts by using T Spanner

Re-check 180

o

by keeping Spirit Level Meter with respect to Ground

Connect this side with

Mast (More flat surface)

Bubble in Center

Check Strength of the Mast & Foot Mount by gentle Shaking

Re - Check MAST for 90 Degree from both axis to get Peak signals

Bubble in Center

20

www.dthforum.com

Step 9: Assemble MAST bracket with LNBF arm

Arrow mark shows

upward direction

Antenna Bracket

LNBF Arm

21

Step 10: Fix bolts with MAST Bracket

Keep the bolts slightly loose for Final Azimuth alignment

Square groove

arrangement for

locking Bolt head

Nut should be

fixed from

this side

22

www.dthforum.com

Insert Mast Bracket inside Antenna Bracket as shown above

Insert the Bolt

Head from inside

in Square groove

Step 11: Assemble MAST bracket with Antenna Bracket

Top View Back View Side View

Mast Bracket

Antenna Bracket

23

www.dthforum.com

Step12 : Insert Weather Seal & Assemble LNBF with LNBF Clamp

LNBF + LNBF Clamp

Keep the bolts slightly loose for Final SKEW alignment

Insert Weather Seal

LNBF Clamp with Screws

24

www.dthforum.com

Step 13: Assemble LNBF Clamp & LNBF with LNBF Arm

LNBF Arm

25

Step 14 : Assemble Antenna bracket assembly with Reflector

Always tighten Bolts diagonally

Note : Reflector surface should not get deformed or damaged while handling Reflector

Nuts & Bolts

26

Step 15: Align Elevation & Azimuth angle as per Look

Angle of respective city

The vertical movement of Reflector

to Track the Satellite is called

Elevation adjustment

The Horizontal movement of

Reflector to track the Satellite is

called Azimuth adjustment

scale for

Elevation Angle

marking

Magnetic Compass

Elevation Azimuth

27

Step 16: Adjust SKEW (approx.) as per Look Angle Chart

For example : If SKEW angel is - 37.2 degree

1 Division = 5 Degree

Division marking for LNBF rotation = 37.2 / 5 = 7.4

Align 0 mark of LNBF clamp with approx. 7.4 division (Clockwise) on LNBF.

Adjust approximate SKEW as per division marking available on LNBF

Clock wise rotation for

negative Polarization angle

Rotate LNBF Clock wise from LNBF connector for negative (-) Polarisation angle.

Rotate LNBF Anti Clock wise from LNBF connector for Positive (+) Polarisation angle.

5 Degree

28

Slightly Rotate sensitivity knob anti-clock wise. The Indicator needle will move lower ( Left ) side

Again align Reflector till indicator needle reaches to maximum signal level ( Right ) side.

Step 17 : Sat Finder Tracking Procedure

Repeat this process till you get maximum signals. Track the Reflector to a maximum

signal level & sensitivity knob to anti-clock direction as much as possible.

29

After getting maximum signal, tighten Azimuth & Elevation bolts

Signal should not decreased during & after tightening

Tightening Azimuth bolts Tightening Elevation bolts

Step 17 : Sat Finder Tracking Procedure (Contd)

30

Then fine tune the Skew till indicator needle reaches to maximum Signal level

Rotate sensitivity knob anti-clock wise till some extent

Again adjust Skew till indicator needle reaches to maximum Signal level

Repeat this process till you get maximum signals. Adjust the Skew to a maximum

signal level & sensitivity knob to anti-clock direction as much as possible

Step 17 : Sat Finder Tracking Procedure (Contd)

31

After getting maximum signal, tighten LNBF clamp screws

After Peak Tracking Switch OFF the Satellite Box & Remove the Sat Finder Connections

Step 17 : Sat Finder Tracking Procedure (Contd)

32

www.dthforum.com

Step 18 : Check Signal Quality & Strength in

Satellite Management Screen for all TP

Check Signal Quality & Strength bars for Green Colour in all 10 Transponders

Ensure must be Green in all Transponder

11483 (V) 11546 (V) 11609 (H)

11609 (V) 11672 (H) 11672 (V)

33

After tightening all Nut, Bolt & screws mark the Azimuth, Elevation & Skew Adjustment with

Permanent marker

Always write Customer Flat Number or ID with Permanent Maker on Back Side of

Reflector

Also inform the same to customer.

Elevation Azimuth

Skew

Step 19 : Mark Azimuth, Elevation & Skew Angles

34

Cable Preparation and

Conectorisation

35

Cable Preparation & Connectorisation

Cable Parts & Connectors

Cable Preparation & Connectorisation Tools

Cable Preparation Process

Dos & Dont of Cable Preparation

Cable Preparation Process Continued

Connectorisation Process

36

RG 6 Cable

Cable Parts & Connectors

Bonded Aluminum

Foil Shield

Center conductor

Dielectric

Aluminum

Braided Shield

Jacket

RG 6 Connector (Gilbert)

RG 6 Connector (PPC)

Connectorisation is the process of connecting Connector with Cable.

37

Cable Preparation & Connectorisation - Tools

RG 6 Cable Preparation Tool Cable Cutter

RG 6 Compression Tool

38

Step 1 : Cut the Cable straight ( Perpendicular to the Cable ) by using Cable Cutter

Cable Preparation Process

Crushed Angled

Cable should never be Cut angled, Crushed

39

Step 2 : After Cutting the Cable, give Circular shape to dielectric using fingers

Do not use Cable Stripper, Pliers or other tools for giving round shape

Usage of Cable Stripper / Plier for giving round shape may damage the Cable Parts

Never use Cable Stripper Never use Plier

Cable Preparation Process

40

Step 3 : Insert cable in Preparation Tool

Cable should always

Flush with the stopper

Cable inserted too short,

Not touching Stopper

Cable Preparation Process

41

Step 4 : Hold Cable near Preparation Tool.

Cable Preparation Process

42

Step 5 : Rotate tool 3 times in clockwise direction and 3 times in Anti -

Clockwise direction

3 times Anti Clock-wise rotation 3 times Clock-wise rotation

Cable Preparation Process

43

Cable Preparation Process

Step 6 : Hold Cable and Pull out Preparation Tool

After Preparation, Length of the various Parts of Cable should be as mentioned below

1/4

1/4

5/16

44

Dos & Dont of Cable Preparation

1/4

Center

Conductor

too long

Center

Conductor

too short

Dielectric

too long

Dos Topic Dont

Dielectric Length Always dielectric length should be

1 / 4 inch

Dielectric should Never be too

long or too short.

Length of Center

Conductor

Always Center Conductors length

should be 5 / 16 inch

Center Conductor should Never

be too long or too short.

5/16

Dielectric

too short

There should not be any Scratch

on Center Conductor

45

Dos & Dont of Cable Preparation

Braids

too long

Dos Topic Dont

Aluminum Braids

Length

Aluminum Braids Length should

be 1 / 4 inch

Aluminum Braids Length should

never be too long or too short.

Braids

too short

1/4

Use Preparation

Tool

Always use company approved

Preparation tool

Never use knife, Cutter, blade or

other than company approved

tools for cable preparation

46

Step 7 : Fold back AluminumBraided Shield 180

o

on the jacket

Cable Preparation Process (Continued)

Unfold the Braids

Turn the braids perpendicular

to the cable length

Fold back the Aluminum braids 180 degree

on the jacket

Braid wire should not damage.

At least 95% braid should be there.

Fold all braid wires on Jacket.

No braid should be on foil / Center Conductor.

Precautions : -

47

Step 8 : Clean the Center Conductor with Soft dry Cloth

Aluminum Braid / Foil should never touch center conductor.

Cable Preparation Process (Continued)

48

Connectorisation Process

Step 9 : Insert Cable into RG-6 connector (Gently push the connector)

Insert cable into connector

Dielectric should flush with

Post of the connector

Dielectric should never be below or above the Connector Post

Dielectric below the Connector Post Dielectric above the Connector Post

49

Step 10 : Insert RG-6 Connector in to the Compression Tool & compress.

Connector inserted

for compression

Compressing the Connector Connector fully Compressed

Connectorisation Process

50

Step 11 : Take out fully Compressed Connector fromcompression Tool.

Connectorisation Process

Di Electric flush with Post

Connector Fully

Compressed

Straight Center Conductor

Aluminum Braid / Foil not

touching center conductor.

51

Cable Routing

52

Cable Routing Guidelines

Cable Routing Guidelines

Weather Seal Application

C Bend near LNBF

Service Loop near Mast

Application of Cable Tie

S Bend Application

C Bend on edge of the wall

C Bend while laying cable at 90

0

U Loop & Sealant Application

Through Hole for Cable Laying

P Clip Application

Cable Routing Precautions ( Dos & Dont )

53

Cable Routing Guidelines

Weather Seal Application

Benefits : -

Ensure / Check for Weather Seal, It should be fixed at LNBF port before connecting

the connector to LNBF

Connect the Cable to LNBF

Tighten Connector by Hand

Finally Tighten the connector

with open ended spanner

Weather Seal prevents Water Ingress / Seepage inside the cable

Weather Seal prevents Cable Damage, Satellite Box Failure & Connector Corrosion due

to Water Ingress/ Seepage

54

C Bend should be always made near LNBF

Prevents Cable Damage near Connector at LNBF end

Less Signal Losses ( as the Sharp Bend is avoided )

C Bend

Tie Wrap

Cable Routing Guidelines

C Bend near LNBF

Benefits : -

By Application of C Bend the Bend Radius is maintained, thereby : -

55

Service loop ( Only One Round ) should be tied with Mast

Service Loop can be used for future service Applications like Re - Connectorisation etc.

Cable Routing Guidelines

Service Loop near Mast

Benefits : -

( 8~ 9 inch Diameter )

( 0.20 ~ 0.22 Meter Diameter )

Service Loop

56

Loose / Hanging Cable should be properly tied with Cable Tie / P Clip

Tail of the Cable Tie should be trimmed properly with maximum tail length of 5mm (after cutting)

Always use Company Approved Cable Tie

Prevents Cable damage due to rubbing with wall edges / metallic parts

Improves Aesthetic Look of the Installation

Cable Routing Guidelines

Application of Cable Tie

Benefits : -

Avoid over tightening of Tie warp as it may damage Cable Jacket which may results in

Water Ingress / Seepage

Width of Cable Tie should be more than 5mm

Precautions : -

57

S Bend

( Outer Edge

of Wall )

Cable Routing Guidelines

S Bend on edge of the wall

Benefits : -

By Application of S - Bend the Bend Radius is maintained, thereby : -

Less Signal Losses ( as the Sharp Bend is avoided )

Prevents Cable Damage due to friction with Wall (Outer Edge Case )

Always use Two P Clips

( Opposite Direction )

while putting any bend / Loop

S - Bend should be always made, while routing the Cable vertically from one

side of wall to other side of the wall

58

Cable Routing Guidelines

C Bend on edge of the wall ( Inner & Outer )

Benefits : -

By Application of C Bend / PVC Bend the Bend Radius is maintained, thereby : -

Less Signal Losses ( as the Sharp Bend is avoided )

Prevents Cable Damage due to friction with Wall (Outer Edge Case )

C Bend ( Inner Edge of Wall ) C Bend ( Outer Edge of Wall ) PVC Bend ( Outer Edge of Wall )

C-Bend should be always made while routing the Cable at Inner & Outer Edge of the Wall

Cable should be laid through PVC Conduit or use Double sided Tape in case of Outer Edge

59

Cable Routing Guidelines

C Bend while laying the cable

Benefits : -

By Application of C - Bend the Bend Radius is maintained, thereby : -

Less Signal Losses ( as the Sharp Bend is avoided )

C Bend

C - Bend should be always made while routing the Cable on the wall from vertical

to horizontal or vice versa

More than

90

o

60

Cable Routing Guidelines

U Loop ( Drip Loop ) before cable entry in house

Sealant Application

Benefits : -

By Application of U Loop & Sealant the below mentioned can be prevented

Water Ingress / Seepage inside the house

Satellite Box Failure due to water Ingress / Seepage

Sealant Application

Without any air gap

U Loop

U Loop should be always made before cable entry in the house

Sealant should be applied from both sides of the hole with no air Gap

Use appropriate bit for Wooden or steel Frame

C Bend ( more than 90 degree )

Height

Minimum 20cm

Diameter

Minimum 12cm

61

Cable Routing Guidelines

Through Hole for Cable laying

It is recommended to drill through hole for Cable entry from Inside to Outside

Inside

House

Outside

30

o

Angle

Wall

Through Hole for Cable entry should have a slope towards outside the House

While drilling through Hole drill machine should not be in hammer Mode

There should not be any damage on the inside / outside surface of the wall

62

Cable Routing Guidelines

P Clip Application

Nail of the P Clip should be downwards,

in case of Horizontal laying of Cable

Nail should be

downwards

Cable should not deform / damage while P-clipping with hammer

P Clip should neither be loose nor over tightened

Always use company approved/recommended proper Diameter P-Clips

Cabling should be Straight

P-Clip should not be equi distance

Precautions : -

63

Kinking / Bending

of the Cable

Benefit :-

Protect Cable from damage.

Cable Routing Precautions ( Dos & Dont )

Dos Topic Dont

Take care while pulling cable to

prevent cable from Kink / cut.

Disadvantage :-

Chances of missing few channels

Never use Kinked / Bend Cable.

64

Cable Routing

on horizontal

surface

Cable Routing Precautions ( Dos & Dont )

Dos Topic Dont

Always lay the cable on vertical side

of the Parapet wall.

Never lay cable on top of the

Parapet wall / horizontal surface.

Benefit :-

Less chances of Cable Damage.

Minimize chances of water

seepage while water logging (if

Cable is damage)

Disadvantage :-

Higher Chances of Cable Damage.

Higher chances of water Ingress /

Seepage (if Cable is damage)

65

Cable Routing Precautions ( Dos & Dont )

Dos Topic Dont

Always 7cm ( minimum ) distance

should be maintained between

Electrical Lines & Signal Cable.

Always route Cable 5 meters

(minimum) away from overhead /

side Bare Electrical line.

Never route cable with Electrical

Lines.

Never route Cable near overhead/

side bare Electrical.

Cable Routing

near Electrical

Cable

Electrical Lines

Signal Cable

Benefit :-

Less chances of Signal

Interference.

Disadvantage :-

Picture Freezing may occur due to

Interference.

Minimum 7 cm.

66

Cable Routing Precautions ( Dos & Dont )

Dos Topic Dont

Always neatly keep one round ( 8~ 9

inch /0.2 ~ 0.22 Meter Diameter ) of

Service Loop near Satellite Box.

Tighten the Connector finally with

spanner at Satellite Box IF input port.

Never leave loose cable near

Satellite Box.

Never leave loose connector at

Satellite Box end.

Cable Routing

near Satellite Box

Benefit :-

Less chances of cable damage.

Avoid loose connectivity.

Disadvantage :-

Chances of Cable Damage.

Chances of Picture Freezing / No

Signal

67

Demonstration of Videocon d2h Services

Once Installation completed, Check for :

Good Signal in all Transponder (Green Bar for Signal Strength & Signal Quality)

Cable is properly connected in Product & product properly connected with Power Socket (no loose connection)

Channel & Services opted by Customer activated

Once Installation/ Activation completed, Please Call all family members present at home for Demonstration

68

Вам также может понравиться

- War RoomДокумент88 страницWar RoomDada Sasa100% (1)

- Y. C. Fung - Biomechanics - Motion, Flow, Stress, and Growth-Springer-Verlag New York (1990)Документ582 страницыY. C. Fung - Biomechanics - Motion, Flow, Stress, and Growth-Springer-Verlag New York (1990)saurabh kumar gupta100% (2)

- The Theory of Motivation in Dog Training: By: Ed FrawleyДокумент30 страницThe Theory of Motivation in Dog Training: By: Ed Frawleyrodrigue angbohОценок пока нет

- Method Statement For Installation of Clean Agent Fire Suppression SystemДокумент6 страницMethod Statement For Installation of Clean Agent Fire Suppression Systemamg007100% (1)

- Siremobil Compact MaintenanceДокумент22 страницыSiremobil Compact MaintenanceRafael Tejeda100% (1)

- Blockchain Deck PDFДокумент65 страницBlockchain Deck PDFsankhaОценок пока нет

- Chan vs. ChanДокумент2 страницыChan vs. ChanMmm GggОценок пока нет

- Metalkraft - Decking and Roofing Brochure - NEWДокумент6 страницMetalkraft - Decking and Roofing Brochure - NEWParthasarathi H RОценок пока нет

- ISBB CompilationДокумент6 страницISBB CompilationElla SalesОценок пока нет

- Mathematical Models For Facility LocationДокумент28 страницMathematical Models For Facility LocationaddayesudasОценок пока нет

- Asian Paints Research PaperДокумент4 страницыAsian Paints Research PaperSunil RathodОценок пока нет

- Bituminous MixesДокумент13 страницBituminous MixesRanjit SinghОценок пока нет

- Anti Vawc PrimerДокумент6 страницAnti Vawc PrimerCiddy Montemayor100% (1)

- Internship Report: Bachelor of Engineering IN Civil EngineeringДокумент30 страницInternship Report: Bachelor of Engineering IN Civil EngineeringVennela Talanki0% (1)

- Wound Dressing ChecklistДокумент3 страницыWound Dressing ChecklistBUAHIN JANNA100% (1)

- TWO-TW 50-140 23oct2019Документ2 страницыTWO-TW 50-140 23oct2019Mohd NorsyamimОценок пока нет

- Aerospace IndustryДокумент9 страницAerospace IndustryShashank SinhaОценок пока нет

- ENVR1401 - Lab 12 - Solid Waste Wastewater Exercise - 2021 PDFДокумент8 страницENVR1401 - Lab 12 - Solid Waste Wastewater Exercise - 2021 PDFCasey AngellОценок пока нет

- Vtu Final Year Project Report Front PagesДокумент7 страницVtu Final Year Project Report Front PagesshwethaОценок пока нет

- CMA MicroprojectДокумент21 страницаCMA Microprojectshubhampawar99900Оценок пока нет

- Prokon BasicsДокумент61 страницаProkon BasicsmaddumasooriyaОценок пока нет

- RajatДокумент22 страницыRajatRajat PalОценок пока нет

- Tender No NWC Poc 025 2015 2016 Soin Koru Dam ConstructionДокумент30 страницTender No NWC Poc 025 2015 2016 Soin Koru Dam ConstructionHesbon MoriasiОценок пока нет

- GS & Engg. Aptitude (Practice Book) 2020 - Sampe PageДокумент23 страницыGS & Engg. Aptitude (Practice Book) 2020 - Sampe PageRANJIT MAITIОценок пока нет

- Express News ProjectДокумент30 страницExpress News ProjectSidra KhanОценок пока нет

- Foundation Design - Insitu TestingДокумент22 страницыFoundation Design - Insitu TestingSnow YoshimaОценок пока нет

- Price - Part Star TecДокумент1 страницаPrice - Part Star TecAkhmarrezal Abu KassimОценок пока нет

- DTW Project PDFДокумент13 страницDTW Project PDFyuvarajujwal madineniОценок пока нет

- Sintex Industries Companyanalysis92384293424Документ16 страницSintex Industries Companyanalysis92384293424Vijay Gohil100% (1)

- Arunachal Pradesh ProjectДокумент16 страницArunachal Pradesh ProjectAayushi BhargavaОценок пока нет

- ANNEX V - Tender THA20RIC25 For SyriaДокумент13 страницANNEX V - Tender THA20RIC25 For SyriaHuỳnh Quý Thiên100% (1)

- BOBS Standards Catalogue - June 2014Документ131 страницаBOBS Standards Catalogue - June 2014King Ken Molefane0% (1)

- Qcad - QuestionsДокумент6 страницQcad - Questionsjhonsver SALVATIERRA DE LA CRUZОценок пока нет

- The Construction and Upgrading To Bituminous Standard and Re-Alignment of Approximately 78 KM of Rd54 Road From Chief Mukungule's Area (Mwaleshi River) - Lufila-Kakoko To Kalalantekwe - Lot 2Документ210 страницThe Construction and Upgrading To Bituminous Standard and Re-Alignment of Approximately 78 KM of Rd54 Road From Chief Mukungule's Area (Mwaleshi River) - Lufila-Kakoko To Kalalantekwe - Lot 2Omar Abdel Aziz IbrahimОценок пока нет

- MDДокумент17 страницMDJay ShindeОценок пока нет

- Proceedings of UMI 2018Документ122 страницыProceedings of UMI 2018ramya2603100% (2)

- 18CV72 - Design of RCC and Steel NotesДокумент259 страниц18CV72 - Design of RCC and Steel Notesyk3372013Оценок пока нет

- Amendments To The M&E BuildingДокумент70 страницAmendments To The M&E BuildingSinh luong vuОценок пока нет

- Success of Activa: Presented By:Sapna SengarДокумент12 страницSuccess of Activa: Presented By:Sapna Sengarjassi nishadОценок пока нет

- 1 - ADITYA Project ReportДокумент42 страницы1 - ADITYA Project ReportMonty SharmaОценок пока нет

- Resume: Tamilnadu Government Best Employee of The State Gold Medalist - 2015Документ130 страницResume: Tamilnadu Government Best Employee of The State Gold Medalist - 2015Hodcse FxecОценок пока нет

- LG Swot PDFДокумент8 страницLG Swot PDFKeshav AnandОценок пока нет

- Bar Bending Schedule OF Box CulvertДокумент1 страницаBar Bending Schedule OF Box CulvertErnesto LopezОценок пока нет

- Report For Nyamasaria Bridges 3Документ32 страницыReport For Nyamasaria Bridges 3Simon Gikonyo100% (1)

- Smart Pole EOI Patna PDFДокумент19 страницSmart Pole EOI Patna PDFICT WalaОценок пока нет

- DTH IndustryДокумент37 страницDTH IndustrySudip Vyas100% (1)

- Wireless Ac Motor Speed Control Using RF CommunitionДокумент2 страницыWireless Ac Motor Speed Control Using RF CommunitionAnil ReddyОценок пока нет

- Sample-B O QДокумент39 страницSample-B O QKeyur Gajjar50% (2)

- P5-A (New Revised) - RafziyatДокумент2 страницыP5-A (New Revised) - RafziyatMirza Waqar BaigОценок пока нет

- KSCST Project ReportДокумент10 страницKSCST Project ReportGururaj TavildarОценок пока нет

- Myth of The Toronto Condo Bubble BookletДокумент20 страницMyth of The Toronto Condo Bubble BookletEquity PrivateОценок пока нет

- KGF 2.0Документ23 страницыKGF 2.0Pavan Kumar Shetty100% (1)

- Industrial Training ReportДокумент42 страницыIndustrial Training ReportShubham SatheОценок пока нет

- Container Corporation of India Limited (A Govt. of India Undertaking)Документ20 страницContainer Corporation of India Limited (A Govt. of India Undertaking)Ritu ParekhОценок пока нет

- Industrial Visit ReportДокумент6 страницIndustrial Visit ReportEngr Muhammad EhsanОценок пока нет

- Supplementary ExamsДокумент4 страницыSupplementary ExamsYash ParmarОценок пока нет

- BJT Fabrication: Discrete Devices Planar IntegratedДокумент73 страницыBJT Fabrication: Discrete Devices Planar Integratedjayalaxmi HОценок пока нет

- Motivation Letter Dari Essay ForumДокумент41 страницаMotivation Letter Dari Essay ForumkemalaОценок пока нет

- Btech LpuДокумент8 страницBtech LpudfsdgvfdhdОценок пока нет

- Industrial Summer Training Report at Construction Site of CPWD PDFДокумент62 страницыIndustrial Summer Training Report at Construction Site of CPWD PDFSUDHANSHU75% (4)

- Case Study DerrickДокумент2 страницыCase Study DerrickNibhrat LohiaОценок пока нет

- ChetnaДокумент23 страницыChetnaRanjeet KumarОценок пока нет

- Population Forecast by Different MethodsДокумент3 страницыPopulation Forecast by Different MethodsAman KaurОценок пока нет

- Training Report On AVRДокумент30 страницTraining Report On AVRkshtjgptОценок пока нет

- Summer Internship Project Work OnДокумент28 страницSummer Internship Project Work OnVikramОценок пока нет

- Inst Manual CeilingFloorДокумент16 страницInst Manual CeilingFloorANDERSON HERRERAОценок пока нет

- DTH Installation ProcedureДокумент6 страницDTH Installation Procedurenagbush2100% (2)

- Benkelman Beam: Product ManualДокумент8 страницBenkelman Beam: Product ManualAlok Singh RajawatОценок пока нет

- Installation Procedure For AntennaДокумент8 страницInstallation Procedure For AntennaAsraf AliОценок пока нет

- Rosemount 1195 Integral Orifice Primary Element: Quick Installation GuideДокумент16 страницRosemount 1195 Integral Orifice Primary Element: Quick Installation GuideJosé Carlos Batista SilvaОценок пока нет

- Selfsat User Manual H10DEngДокумент21 страницаSelfsat User Manual H10DEngMario MltОценок пока нет

- Tata Sky ALC Channel ListДокумент13 страницTata Sky ALC Channel ListIndianMascot33% (3)

- Fastway Complete HD and SD Channel ListДокумент7 страницFastway Complete HD and SD Channel ListIndianMascot25% (4)

- Tata Sky PacksДокумент273 страницыTata Sky PacksIndianMascotОценок пока нет

- d2h AddonsДокумент9 страницd2h AddonsIndianMascotОценок пока нет

- DTH Forum Exclusive - List of Permitted TV Channels in India As On 30/09/2016Документ68 страницDTH Forum Exclusive - List of Permitted TV Channels in India As On 30/09/2016IndianMascotОценок пока нет

- For DTH Forum India: PrefaceДокумент2 страницыFor DTH Forum India: PrefaceIndianMascotОценок пока нет

- List of Permitted Private Satellite TV Channels As On 09-04-2015Документ55 страницList of Permitted Private Satellite TV Channels As On 09-04-2015IndianMascotОценок пока нет

- How To Pair Radio Frequency Remote in Videocon d2hДокумент3 страницыHow To Pair Radio Frequency Remote in Videocon d2hIndianMascot67% (6)

- Master List of Permitted TV Channels To Be Uploaded As On 30-11-2015Документ53 страницыMaster List of Permitted TV Channels To Be Uploaded As On 30-11-2015IndianMascotОценок пока нет

- For DTH Forum India: Chapter 2 - Planning of Satellite CapacityДокумент20 страницFor DTH Forum India: Chapter 2 - Planning of Satellite CapacityIndianMascotОценок пока нет

- For DTH Forum India: Chapter 4 - Leasing of Satellite CapacityДокумент10 страницFor DTH Forum India: Chapter 4 - Leasing of Satellite CapacityIndianMascotОценок пока нет

- For DTH Forum India: Chapter 1 - IntroductionДокумент8 страницFor DTH Forum India: Chapter 1 - IntroductionIndianMascot100% (1)

- For DTH Forum India: Executive SummaryДокумент6 страницFor DTH Forum India: Executive SummaryIndianMascotОценок пока нет

- For DTH Forum India: Chapter 5 - Conclusion and RecommendationsДокумент4 страницыFor DTH Forum India: Chapter 5 - Conclusion and RecommendationsIndianMascotОценок пока нет

- For DTH Forum India: Chapter 3 - Allocation of Satellite CapacityДокумент6 страницFor DTH Forum India: Chapter 3 - Allocation of Satellite CapacityIndianMascotОценок пока нет

- Monthly Operation Report From DTH OperatorДокумент1 страницаMonthly Operation Report From DTH OperatorIndianMascotОценок пока нет

- d2h Mobile TVДокумент25 страницd2h Mobile TVIndianMascotОценок пока нет

- Registered MSO List As On 22.8.2014Документ16 страницRegistered MSO List As On 22.8.2014IndianMascotОценок пока нет

- Hathway A-La-Carte Delhi Channels and Price ListДокумент1 страницаHathway A-La-Carte Delhi Channels and Price ListIndianMascotОценок пока нет

- List of Permitted Private Satellite TV Channels As On 31-08-2014Документ55 страницList of Permitted Private Satellite TV Channels As On 31-08-2014IndianMascotОценок пока нет

- Consultation Paper On Regulatory Framework For Platform ServicesДокумент36 страницConsultation Paper On Regulatory Framework For Platform ServicesIndianMascotОценок пока нет

- Consultation Paper On Issue/Extension of DTH LicenseДокумент30 страницConsultation Paper On Issue/Extension of DTH LicenseIndianMascotОценок пока нет

- Hathway Mumbai A La Carte Channels Price ListДокумент1 страницаHathway Mumbai A La Carte Channels Price ListIndianMascot50% (2)

- Hathway Bangalore Package and A-La-Carte Price ListДокумент2 страницыHathway Bangalore Package and A-La-Carte Price ListIndianMascot100% (1)

- Hathway Kolkata A-La-Carte Channel and Price ListДокумент1 страницаHathway Kolkata A-La-Carte Channel and Price ListIndianMascot33% (12)

- List of Permitted Private Satellite TV Channels in India As On 02.12.2013Документ47 страницList of Permitted Private Satellite TV Channels in India As On 02.12.2013IndianMascot0% (1)

- TRAI Recommendations On Media OwnershipДокумент115 страницTRAI Recommendations On Media OwnershipIndianMascotОценок пока нет

- Peritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionДокумент10 страницPeritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionAjeng SuparwiОценок пока нет

- Disease PreventionДокумент14 страницDisease PreventionJoan InsonОценок пока нет

- Pressure MeasurementДокумент293 страницыPressure MeasurementGlen Lauren PerezОценок пока нет

- Foundations of Group BehaviorДокумент31 страницаFoundations of Group BehaviorRaunakОценок пока нет

- Permatex, Inc - Ultra Gasket Sealant 1ozДокумент3 страницыPermatex, Inc - Ultra Gasket Sealant 1ozjaredf@jfelectric.comОценок пока нет

- ЗОШИТ для ДЗ №2 Microsoft WordДокумент44 страницыЗОШИТ для ДЗ №2 Microsoft WordдимаОценок пока нет

- Multiscale Modeling of Bone Tissue MechanobiologyДокумент12 страницMultiscale Modeling of Bone Tissue MechanobiologyLina AvilaОценок пока нет

- FPGA-based System For Heart Rate Monitoring PDFДокумент12 страницFPGA-based System For Heart Rate Monitoring PDFkishorechiyaОценок пока нет

- A-Level: Psychology 7182/1Документ20 страницA-Level: Psychology 7182/1Queen Bee (Tt)Оценок пока нет

- Ansi Asa S3.22 - 2014Документ54 страницыAnsi Asa S3.22 - 20147620383tlОценок пока нет

- Bradycardia AlgorithmДокумент1 страницаBradycardia AlgorithmGideon BahuleОценок пока нет

- Lab Risk AssessmentДокумент8 страницLab Risk Assessmentaqilah haronОценок пока нет

- digiPHONENT UG enДокумент44 страницыdigiPHONENT UG enIrving Javier Leal OrtizОценок пока нет

- Treeleaf Basic Zazen InstructionsДокумент16 страницTreeleaf Basic Zazen InstructionsFaisal sarhiОценок пока нет

- Real Time EvaluationДокумент3 страницыReal Time Evaluationأيوب علاءОценок пока нет

- Timbers Lesson 2Документ18 страницTimbers Lesson 2bright possibleОценок пока нет

- The Necessity of Using Neurophysiological Methods For Diagnosing Communication Disorders. by Akhsaful To Tawhida Jahan MamДокумент11 страницThe Necessity of Using Neurophysiological Methods For Diagnosing Communication Disorders. by Akhsaful To Tawhida Jahan MamAkhsaful ImamОценок пока нет

- Form No. 2E Naya Saral Naya Saral Its - 2E: (See Second Proviso To Rule 12 (1) (B) (Iii) )Документ2 страницыForm No. 2E Naya Saral Naya Saral Its - 2E: (See Second Proviso To Rule 12 (1) (B) (Iii) )NeethinathanОценок пока нет

- Homoeopathic Treatment of Complicated Sebaceous Cyst - A Case StudyДокумент5 страницHomoeopathic Treatment of Complicated Sebaceous Cyst - A Case StudyDr deepakОценок пока нет