Академический Документы

Профессиональный Документы

Культура Документы

Chapter 1

Загружено:

MohanKumarИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 1

Загружено:

MohanKumarАвторское право:

Доступные форматы

Chapter 1

Introduction

Ashok Leyland is a well known automobile manufacturing company in India. Ashok Leyland

believe that its historical success and future prospects are directly related to combination of

strengths. This project is titled as a study on functional areas in Ashok Leyland and tries to find

out the different aspects of manufacturing process in the company.

Corporate Office is in Guindy, Chennai.

1.1 HISTORY OF THE ORGANIZATION

Ashok Leyland is an Indian automobile manufacturing company based in Chennai, India.

Founded in 1948, and it is the second largest commercial vehicle manufacturers of commercial

vehicles, such as trucks and buses, as well as emergency and military vehicles. Operating seven

plants, Ashok Leyland also makes spare parts and engines for industrial and marine applications.

It sells about 60,000 vehicles and about 7,000 engines annually. It is the second largest

commercial vehicle company in India in the medium and heavy commercial vehicle (M&HCV)

segment. With passenger transportation options ranging from 19 seaters to 80 seaters, Ashok

Leyland is a market leader in the bus segment. The company claims to carry over 60 million

passengers a day, more people than the entire Indian rail network. In the trucks segment Ashok

Leyland primarily concentrates on the 16 ton to 25 ton range of trucks. However Ashok Leyland

has presence in the entire truck range starting from 7.5 tons to 49 tons. With a joint venture with

Nissan Motors of Japan the company made its presence in the Light Commercial Vehicles (LCV)

segment (<7.5 tons).

Early products of Ashok Leyland included the Leyland Comet bus chassis sold to many

operators including Hyderabad Road Transport, Ahmadabad Municipality, Travancore State

Transport, Bombay State Transport and Delhi Road Transport Authority. In the popular metro

cities, four out of five state transport undertaking buses come from Ashok Leyland. Some of

them like the Double Decker and Vestibule buses are unique models from Ashok Leyland, tailor

made high-density routes. Statistics reveal that the company is Indias largest exporter of

medium and heavy duty trucks. At 60 million passengers a day, Ashok Leyland buses carry more

people than the entire Indian Railway network.

Raghunandan Saran, Founder of Ashok Leyland

Ashok Motors

Ashok Leyland was founded in 1948 by Raghunandan Saran, a freedom fighter from Punjab.

After Independence he was persuaded by Indias first Prime Minister Nehru, to invest in modern

industrial venture. Thus Ashok Motors was incorporated in 1948 as a company to assemble and

manufacture Austin cars from England, and the company was named after the founders only son

Ashok Saran . The company had its headquarters in RajajiSaalai, Chennai (then Madras) with the

plant in Ennore, a small fishing hamlet in the North of Chennai. The Company was engaged in

assembly and distribution of Austin passenger cars in India.

Under Leyland

Sometime later, the founder Raghunandan Saran passed away in an air crash, prior to that he had

been negotiating with Leyland of Britain for assembly of commercial vehicles as he envisioned

commercial vehicle were more in need at that time than were passenger cars. The company later

under Madras State Government and other shareholders finalised for an investment and

technology partner and thus the British based Leyland Motors joined in 1954 with equity

participation by Leyland Motors, changing the name of the company to Ashok Leyland. Ashok

Leyland then started manufacturing commercial vehicles. Under Leylands management with

British expatriate and Indian executives the company grew in strength to become one of Indias

foremost commercial vehicle manufacturers.

The collaboration ended sometime in 1975 but the holding of British Leyland, now a major

British Auto Conglomerate as a result of several mergers agreed to assist in technology which

continued until the 1980s. Post 1975, changes in management structures saw the company launch

various advanced vehicles and pioneering innovations in the Indian market, with many of these

models continuing to this day with numerous upgrades over the years.

Under Iveco and Hinduja partnership

In 1987, the overseas holding by Land Rover Leyland International Holdings Limited (LRLIH)

was taken over by a joint venture between the Hinduja Group, the Non-Resident Indian

transnational group and IVECO, part of the Fiat Group. Ashok Leylands long-term plan to

become a global player by benchmarking global standards of technology and quality was soon

firmed up. Access to international technology and a US$200 million investment programme

created a state-of-the-art manufacturing base to roll out international class products.

Hinduja Group

In 2007 the Hinduja Group also bought out IVECOs indirect stake in Ashok Leyland in 2007.

The promoter shareholding now stands at 51%. Today the company is the flagship of the Hinduja

Group, a British-based and Indian originated trans-national Conglomerate after Hindujas bought

Ivecos remaining ownership stakes.

PRODUCTS

Early Vehicles

Indias first Semi -Trailer Ashok Leyland Comet (Cab) on a Mahindra

OwenSemiTrailer10-12 Ton Capacity built in 1959.

Comet

Early products included the Leyland Comet bus which was a passenger body built on a truck

chassis sold in large numbers to many operators in India. By 1963, the Comet was operated by

every State Transport Undertaking in India, and over 8,000 were in service. It was soon joined in

production by a version of the Leyland Tiger.

The Current generation Ashok Leyland eComet 912

Titan

In 1968, production of the Leyland Titan ceased in Britain, but was restarted by Ashok Leyland

in India. The Titan PD3 chassis was modified, and a five speed heavy duty constant-mesh

gearbox was used together with the Ashok Leyland version of the O.680 engine. The Ashok

Leyland Titan was very successful and continued in production for many years.

Hino Engine

An Ashok Leyland BEST bus in Mumbai. This bus has the Hino Engine.

During early 80s Ashok Leyland entered into a collaboration with Japanese company Hino

Motors from whom technology for the H-series engines was sourced. Many indigenous versions

of H-series engine were developed with 4 and 6 cylinders and also conforming to BS2 and BS3

emission standards in India. These engines proved to be extremely popular with the customers

primarily for their excellent fuel efficiency. Most current models of Ashok Leyland come with

H-series engines.

Iveco Partnership

In late 1980s Iveco investment and partnership resulted in Ashok Leyland launching the

Cargo range of trucks based on European Ford Cargo trucks. The Cargo entered production in

1994, at Ashok Leylands new plant in Hosur, southeast of Bangalore. These vehicles used Iveco

engines and for the first time had factory-fitted cabs. Though the Cargo trucks are no longer in

production and the use of Iveco engine was discontinued, the cab continues to be used on the

Ecomet range of trucks as well as for several of Ashok Leylands military vehicles.

The Cargo was originally introduced in 7 and 9 long tons (7,100 and 9,100 kg) versions; later on

heavier-duty models from 15 to 26 long tons (15,200 to 26,400 kg) were progressively introduced.

1.2 COMPANY PROFILE

Vision

Achieving leadership in the medium/heavy duty segments of the domestic commercial vehicle

market and a significant presence in the world market through transport solution that best

anticipate customer needs, with the highest value-to-cost ratio.

Mission

Identifying with the Customer

Being the Lowest cost manufacturer

Global benchmarking our products, presence and people.

Quality Policy

Ashok Leyland is committed to achieve customer satisfaction by anticipating and delivering

superior value to the customer in relation to their own business, through the products and

services offered by the company and comply with statutory requirements. Towards this, the

quality policy of Ashok Leyland is to make continual improvements in the processes that

constitute the quality management system, to make them more robust and to enhance their

effectiveness and efficiency in achieving stated objectives leading to:

1. Superior products manufactured as also services offered by the company.

2. Maximum use of employees potential to contribute to quality and environment by

progressive up gradation of their knowledge and skills as appropriate to their functions.

3. Seamless involvement from suppliers and dealers in the mission of the company to

address customers changing needs and protection of the environment

The Five AL Values are:

1. International

2. Speedy

3. Value Creator

4. Innovative

5. Ethical

1.3 JOINT VENTURES

To avail the advantages of diversification and reap the benefits of entering profitable adjacencies,

we have forged a series of Joint Ventures (JV) with various global leaders.

To fill a significant gap in our range, we have joined hands with Nissan Motor Company, Japan,

to develop and manufacture Light Commercial Vehicles, under both the Ashok Leyland and

Nissan brands, in the 2.5 to 7.5 tonne segment. The JV resides in three separate companies for

Vehicle Manufacturing, Power Train Manufacturing and Technology Development. The first

offering from this stable, the 2.5 tonne Dost, has already proven to be a great success in the

markets it has been launched thus far.

With our JV with John Deere, USA, we aim to seize the opportunities of the robustly growing

construction equipment sector with products like Backhoe Loaders, Four-wheel-drive Loaders,

Skid Steers and Excavators under both the Ashok Leyland and John Deere brands.

This is a JV with Continental AG, Germany to design, develop and adapt infotronics products

and services for automotive customers and meet the requirements of our vehicles and, at the

same time, avail of opportunities with other vehicle manufactures in India and overseas.

Ashley Alteams is a JV with the Alteams Group, Finland, and is in the business of producing

High Pressure Die Casting (HPDC) aluminum components pre-dominantly for

telecommunications and automotive sectors.

1.4 SUBSIDIARIES

Albonair GmbH

Albonair GmbH: was established with a vision of being a complete solution provider for

reducing automotive emissions and has, in the short period since inception, developed the

complete solution for Selective Catalytic Reduction (SCR) and Urea Dosing System (UDS)

conforming to Euro 4, 5 and 6 emission standards for commercial as well as passenger vehicles.

Defiance Technologies

Defiance is a Hinduja Group Company incorporated in 2009, with a focus to provide

Engineering, Manufacturing, Information Technology and Enterprise Services and Solutions for

Automotive, Aerospace, Defence, Industrial and General Manufacturing industries.

Defiance serves top global companies including 18 of the Fortune Global 500 companies. It is

led by a management team with global experience in delivering high-end solutions in

Engineering, ERP and IT services space. As a business solution focused company, Defiance has

established Centers of Excellence (CoE) to develop solutions to address key customer business

imperatives in the Engineering, Manufacturing and Enterprise domains.

Headquartered at Chennai, India, Defiance has world class development centres at Chennai,

Bangalore and Pune (India) as well as in Walldorf (Germany). Defiance Technologies has its

subsidiaries in the US, namely, Defiance Technologies Inc., and in Germany, Defiance Tech

GmbH, respectively. Defiance also has branch offices in UK, Dubai and South Africa.

Global TVS Bus Body Builders Limited

GLOBAL TVS: To address the growing demand for luxury coaches in the country, this is a joint

venture between Ashok Leyland, TVS & Sons Ltd and IRIZAR, the internationally reputed bus

body builder from Spain. As a preferred supplier, GLOBAL TVS provides a platform to

introduce new bus body concepts and designs and fully built buses of international luxury to

India.

Hinduja Leyland Finance

Incorporated in November 2008, Hinduja Leyland Finance (HLF), jointly promoted by Ashok

Leyland and the Hinduja Group, was formed to provide finance for the purchase of vehicles or

equipment. HLF received the NBFC License in March 2010 and have started operations with an

equity of Rs. 225 crores. The strength of the Company lies in its core competence in fund-based

lending for a diversified portfolio of Commercial Vehicles, Cars, Construction Equipment,

Tractors and Used Vehicles and its network that covers 19 states with over 275 locations.

ASSOCIATE COMPANIES

Hinduja foundaries

Lanka Ashok Leyland

IRIZAR TVS

Gulf Ashley Motors Ltd

1.5 CLIENTS

Indian army.

Tamilnadu State Transport Corporation (TNSTC).

Metropolitan Transport Corporation (MTC), Chennai.

State Express Transport Corporation (SETC), Chennai.

Kerala State Transport Corporation.

Maharashtra State Road Transport Corporation (MSRTC).

Andhra Pradesh State Road Transport Corporation (APSRTC).

Praveen Travels and Sharma Transports

1.6 MILESTONES

1966-Full air brakes introduced

1967-Double Decker bus introduced

1968-Power steering offered

1979-Multi-axle trucks introduced

1980-Integral bus with air suspension

1982-Vestibule bus introduced

1992-Won self certification status for defence supplies

1993-Received ISO 9002

1997-Indias first CNG powered bus join the BEST fleet

2001-Received ISO 14001 certification for all manufacturing units

2002-Launched hybrid electric vehicle

2003-E-Comet launched

2004- 50000 vehicle produced

2006- ISO/TS 16949 corporate certification

1.7 CURRENT STATUS

We are the 2nd largest manufacturer of commercial vehicles in India, the 4th largest

manufacturer of buses in the world and the 16th largest manufacturer of trucks globally.

With a turnover in excess of US $ 2.3 billion (2012-13) and a footprint that extends across 50

countries, we are one of the most fully-integrated manufacturing companies this side of the

globe.

Over 70 million passengers use our buses to get to their destinations every day while over

700,000 trucks keep the wheels of economies moving. With the largest fleet of logistics vehicles

deployed in the Indian Army and significant partnerships with armed forces across the globe, we

help keep borders secure.

Headquartered in Chennai, India, our manufacturing footprint spreads across the globe with 8

plants; including one at Ras Al Khaimah (UAE). Our Joint Venture partners include Nissan

Motor Company (Japan) for Light Commercial Vehicles, John Deere (USA) for Construction

Equipment, Continental AG (Germany) for Automotive Infotronics and the Alteams Group for

the manufacture of high-press die-casting extruded aluminum components for the automotive

and telecommunications sectors.

1.8 FACILITIES

Ashok Leyland has seven manufacturing plants the mother plant at Ennore near Chennai, three

plants at Hosur (called Hosur I and Hosur II, along with a Press shop), the assembly plants at

Alwar, and Bhandara and state-of-the-art facility at Pantnagar. The total covered space at these

seven plants exceeds 6, 50,000 Sq.m and together employ over 11,500 personnel.

ENNORE

Spread over 135 acres, Ashok Leyland Ennore is a highly integrated Mother Plant accounting for over

40% ALL production. The plant manufactures a wide range of vehicles and house production facilities

for important aggregates such as Engines, Gear Box, Axles and other key in-house components.

HOSUR: UNIT 1

Established in 1980, Hosur-I is the engine-manufacturing center within the Ashok Leyland

production system. Apart from producing various types of diesel engines (including the engines

manufactured under license from Hino of Japan) and CNG engines, the plant also manufactures

and assembles heavy duty and special vehicles, Axles, AGBs, Marine Gear Box, etc. The facility

is spread over 103 acres and is innovatively laid out, optimizing the use of all resources.

HOSUR : UNIT 2

Ashok Leyland established this state-of-the-art production facility in 1994 at Hosur. Spread over

236 acres, Hosur II houses finishing and assembly facilities including sophisticated painting

facilities. The complex also houses one of the largest press facilities in India for pressing frame

side members. Laid out with an eye for the future, Hosur II has won acclaim from several

automotive experts who have visited the facility.

HOSUR : UNIT 2A

Ashok Leylands brand new Cab Panel Press Shop is an imposing addition to the industrial

skyline of Hosur. At 800 m above sea level, it is also the tallest in the Hosur industrial belt. This

state-of-the-art facility is housed in a 99-acre expanse with a built up area of over 15,000 sq.m.

The Shop is equipped to stamp select panels for Cargo cab, G-45 and C-45 FES - totally, 55

panels and their variants. Right now it houses eight presses and has the provision to

accommodate four more. The versatility of the presses can be utilized for making panels of

complex shapes and profiles with appropriate tooling and dies.

ALWAR(RAJASTHAN):

Established in 1982, the Alwar Unit in Rajasthan is an assembly plant for a wide range of vehicles with

an emphasis on passenger chassis, including CNG buses, situated close to the northern market.

BHANDARA(MAHARASHTRA)

Ashok Leylands Bhandara Unit houses manufacturing and assembly facilities for sophisticated

synchromesh transmission and also has facilities for assembly of vehicles.

PANTNAGAR(UTTARAKHAND):

Set over 190 scenic acres, the Pantnagar plant of Ashok Leyland is also its largest and one of the

most integrated manufacturing facilities in Indian commercial vehicle industry. On 200,000 Sq.m

of built up area, it houses best in class industrial architecture combined with the latest

manufacturing technologies that is also ecology sensitive.

Designed on lean manufacture principles, process control for high quality of output and

flexibility to manage variety with quick changeovers are built into the machine and process

selection. The factory boasts of latest generation equipment sourced from global leaders in

Japan, USA, Europe and India.

Ashok Leylands Technical Centre, at Vellivoyalchavadi in the outskirts of Chennai, is a state-

of-the-art product development facility, that apart from modern test tracks and component test

labs, also houses Indias one and only Six Poster testing equipment.

The company has an Engine Research and Development facility in Hosur.

The new plant in the North Indian state of Uttarakhand at Patnanagar is set up at an investment

outlay of Rs.1200 crores. This plant is expected to go on stream in the year 2010 to cater mainly

to the North Indian market taking advantage of the excise duty and other tax concessions. The

facilities have been so designed as to accommodate further expansion in terms of capacity and

future models. At full capacity utilization, 75000 vehicles will roll out of the Patnanagar plant.

The company has signed an agreement with Ras Al Khaimah InvestmentAuthority (RAKIA) in

UAE for setting up a bus body building unit in the Middle East.

1.9 WELFARE MEASURES

The following are the welfare schemes available to the employees.

Canteen facilities

Medical claims

Transport facilities

Ashok Leyland school for their children

Scholarship schemes

Recreation facilities

Вам также может понравиться

- Financial Analysis by HritvikДокумент43 страницыFinancial Analysis by HritvikHritvik ChoudharyОценок пока нет

- History of ASHOK LEYLANDДокумент12 страницHistory of ASHOK LEYLANDRajanikantJadhav100% (1)

- AutomobilesДокумент60 страницAutomobilessurinder89pОценок пока нет

- Ashok Leyland PDFДокумент11 страницAshok Leyland PDFRahul Kunwar25% (4)

- Project Report On Time Study and Work Content of Captain LineДокумент53 страницыProject Report On Time Study and Work Content of Captain LineDipak TiwariОценок пока нет

- Asok LeylandДокумент11 страницAsok LeylandmojahedОценок пока нет

- Internship ReportДокумент44 страницыInternship ReportPower King Samar Baba100% (1)

- Ashok Leyland Is A Commercial Vehicle Manufacturing Company Based inДокумент20 страницAshok Leyland Is A Commercial Vehicle Manufacturing Company Based inDulcet Lyrics100% (1)

- Ashok Leyland: This Article Needs AdditionalДокумент10 страницAshok Leyland: This Article Needs AdditionalShekhar SinhaОценок пока нет

- OST of Ashok LeylandДокумент14 страницOST of Ashok LeylandDanyОценок пока нет

- Vision AshokДокумент38 страницVision Ashoktajju_121Оценок пока нет

- Ashok Leyland's ProfileДокумент12 страницAshok Leyland's ProfileNitin Khurana100% (1)

- Ashok LeylandДокумент52 страницыAshok Leylandimranjani.sk50% (2)

- Ashok LeylandДокумент12 страницAshok LeylandDwarakesh Rocky YadavОценок пока нет

- Ashok Leyland ProjectДокумент81 страницаAshok Leyland ProjectA Karthick Karthick71% (7)

- Company ProfileДокумент9 страницCompany Profile6ajaОценок пока нет

- Financial Analysis of Ashok LeylandДокумент120 страницFinancial Analysis of Ashok LeylandSiva Kumaravel0% (1)

- Ashok LeylandДокумент4 страницыAshok Leylandsodhiseema100% (1)

- The Inception of International Joint Venture - Ashok Motors and Leyland MotorsДокумент1 страницаThe Inception of International Joint Venture - Ashok Motors and Leyland MotorsKaran GulatiОценок пока нет

- Chapter 1: IntroductionДокумент33 страницыChapter 1: Introductionrckadam18Оценок пока нет

- Product Range of The Company IncludesДокумент1 страницаProduct Range of The Company IncludesHarshith GowdaОценок пока нет

- Introduction of Organization Ashok Leyland Is A Commercial Vehicle Manufacturing Company Based inДокумент9 страницIntroduction of Organization Ashok Leyland Is A Commercial Vehicle Manufacturing Company Based inGirish GuptaОценок пока нет

- Institute of Management Technology: Ratio Analysis of Ashok LeylandДокумент55 страницInstitute of Management Technology: Ratio Analysis of Ashok Leylandsahil100% (4)

- Ashok LeylandДокумент7 страницAshok LeylandNicholas ReillyОценок пока нет

- Ashok Leyland Report 2011-2012Документ76 страницAshok Leyland Report 2011-2012Mukesh Kumar Rajpurohit100% (1)

- Ashok LeylandДокумент59 страницAshok LeylandManjeet SinghОценок пока нет

- SRM University: Production AND Operations ManagementДокумент22 страницыSRM University: Production AND Operations ManagementSalai SelvakodiОценок пока нет

- Ashok LeylandДокумент78 страницAshok LeylandKajal Kaundal33% (3)

- An Intership Report 2019 7Документ53 страницыAn Intership Report 2019 7Dhayananthan RajaОценок пока нет

- Ashok LeylandДокумент3 страницыAshok LeylandKushal KhuranaОценок пока нет

- Technological Leadership, Achieved Through Tie-Ups With International Technology Leaders and Through Vigorous In-HouseДокумент1 страницаTechnological Leadership, Achieved Through Tie-Ups With International Technology Leaders and Through Vigorous In-Houseashokronit100% (2)

- Ashok Leyland Desk ResearchДокумент55 страницAshok Leyland Desk ResearchAbhishek TsОценок пока нет

- Ashok Leyland: Company ProfileДокумент3 страницыAshok Leyland: Company ProfileShraddha Acharya100% (1)

- A Internship Report of Automobile IndustДокумент26 страницA Internship Report of Automobile IndustAniket ChoudharyОценок пока нет

- Ashok Leyland Is An IndianДокумент2 страницыAshok Leyland Is An Indianprachi kaleОценок пока нет

- Ashok LeylandДокумент5 страницAshok LeylandAbel JohnОценок пока нет

- Ashok LeylandsДокумент24 страницыAshok Leylandsbhavna100% (4)

- Financial Analysis of Ashok LeylandДокумент71 страницаFinancial Analysis of Ashok LeylandpaishuОценок пока нет

- Ashok Leyland LTDДокумент1 страницаAshok Leyland LTDaaryamannarang199Оценок пока нет

- Vehicle Segments On Ashok LeylandДокумент61 страницаVehicle Segments On Ashok LeylandStartechnico TechnocratsОценок пока нет

- Inplant Training SeminarДокумент24 страницыInplant Training SeminarAbdul RahamanОценок пока нет

- 05 Ashok Leyland Pages 25 (187) To 47Документ47 страниц05 Ashok Leyland Pages 25 (187) To 47Dilip PanditОценок пока нет

- Project On Production Process OFДокумент15 страницProject On Production Process OFtarun-neha100% (2)

- Topic Page NoДокумент4 страницыTopic Page NoDiwakar SinghОценок пока нет

- Production Process of Ashok LeylandДокумент14 страницProduction Process of Ashok LeylandUlagaariyan PremkumarОценок пока нет

- Chapter 1Документ12 страницChapter 1Zaint0p GamingОценок пока нет

- Ashok Leland Produce Varius VehiclesДокумент37 страницAshok Leland Produce Varius VehiclesRiddhesh PatelОценок пока нет

- Ashok LeylandДокумент32 страницыAshok LeylandJatin AroraОценок пока нет

- About Ashok LeylandДокумент6 страницAbout Ashok LeylandIyyan ParamanandamОценок пока нет

- CCPR Eicher MotorsДокумент9 страницCCPR Eicher Motors8650Оценок пока нет

- Eicher Motors LimitedДокумент6 страницEicher Motors Limitedantony0% (1)

- Ashok Leyland: Company ProfileДокумент5 страницAshok Leyland: Company ProfileMukesh kannan MahiОценок пока нет

- PG No. Chapter 1 Introduction: Objectives Scopes Assumption LimitationsДокумент62 страницыPG No. Chapter 1 Introduction: Objectives Scopes Assumption LimitationsUtkarsh BansalОценок пока нет

- Ashok Leyland, Hosur - Industry, Company ProfileДокумент10 страницAshok Leyland, Hosur - Industry, Company Profilevijay50% (2)

- Ashok Leyland and How They Sustained During Global MeltdownДокумент16 страницAshok Leyland and How They Sustained During Global MeltdownPrabhakar DashОценок пока нет

- SCM Ashok LeylandДокумент17 страницSCM Ashok LeylandDiksha Badoga100% (1)

- Production Process of Ashok Leyland: AbstractДокумент14 страницProduction Process of Ashok Leyland: AbstractAswani B Raj100% (4)

- Tes 3Документ2 страницыTes 3Alex Gonçalves de SouzaОценок пока нет

- 05b4 - E70 Adaptive Headlight SystemДокумент28 страниц05b4 - E70 Adaptive Headlight SystemAthira Sobhana Ramachandran100% (1)

- AP13120210000068DLДокумент1 страницаAP13120210000068DLakhil SrinadhuОценок пока нет

- Kessler PowertrainДокумент3 страницыKessler PowertrainMohamed Rashed100% (1)

- 11-ПОМПЫ-2018 02 07Документ418 страниц11-ПОМПЫ-2018 02 07Алексей ТозикОценок пока нет

- Catálogo WB93R Inglés DigitalДокумент16 страницCatálogo WB93R Inglés DigitalAZIRI FARID100% (1)

- Auto RickshawДокумент42 страницыAuto RickshawSubramanya Dg0% (1)

- SonnaxVol8TransCatalog PDFДокумент108 страницSonnaxVol8TransCatalog PDFAlejandro RoldanОценок пока нет

- ARP 95 Ammann Tandem Vibrating Rollers ARP T4i en 2Документ8 страницARP 95 Ammann Tandem Vibrating Rollers ARP T4i en 2MuhaiminОценок пока нет

- HJ5500 DLRДокумент1 страницаHJ5500 DLRAlex ValleОценок пока нет

- Manual Gearbox 02TДокумент16 страницManual Gearbox 02TSleepy HollowОценок пока нет

- Ather450X SpecificationsSheetДокумент4 страницыAther450X SpecificationsSheetNitin DevnaniОценок пока нет

- Mercedes e Class Estate 2011 s212 Owners Manual 01Документ409 страницMercedes e Class Estate 2011 s212 Owners Manual 01Ana Cagorovic PavicevicОценок пока нет

- 01-69 Central Locking System OBD PDFДокумент55 страниц01-69 Central Locking System OBD PDFRaheel FaroukОценок пока нет

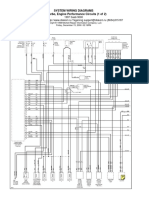

- System Wiring Diagrams 2.3L Turbo, Engine Performance Circuits (1 of 2)Документ29 страницSystem Wiring Diagrams 2.3L Turbo, Engine Performance Circuits (1 of 2)Karlis VilcinsОценок пока нет

- VALEO - Passeneger Car Wiping 2009 - 2010 PDFДокумент52 страницыVALEO - Passeneger Car Wiping 2009 - 2010 PDFgeorge_scalaОценок пока нет

- Upkeep Spot Check FormДокумент6 страницUpkeep Spot Check FormJohn Bert OnrubiaОценок пока нет

- Audi Drive Select A4 b8 Facelift/prefaceliftДокумент11 страницAudi Drive Select A4 b8 Facelift/prefaceliftMitrutz VintilaОценок пока нет

- Fundamental & Technical Analysis of Automobile IndustryДокумент40 страницFundamental & Technical Analysis of Automobile Industryajstyle379Оценок пока нет

- DL 7 PDFДокумент96 страницDL 7 PDFtallknightОценок пока нет

- Firad Common Rail NozzlesДокумент3 страницыFirad Common Rail NozzlesTamer RabieОценок пока нет

- Copia de Re - Maxima - Cargo PDFДокумент62 страницыCopia de Re - Maxima - Cargo PDFLuisa Fernanda Alpala PatiñoОценок пока нет

- Subaru Legacy MY05-09 Service Manual CompleteДокумент4 537 страницSubaru Legacy MY05-09 Service Manual Completemvillalonm88% (16)

- Cashless Facility Garages ListДокумент1 страницаCashless Facility Garages Listkrishna-almightyОценок пока нет

- Datsun GO CVT Brochure A4 WebДокумент2 страницыDatsun GO CVT Brochure A4 WebmrsrinathОценок пока нет

- A SeriesДокумент12 страницA SeriesPhilippine Bus Enthusiasts SocietyОценок пока нет

- Asian-Ngv - May 10Документ44 страницыAsian-Ngv - May 10Sunil Parnami100% (1)

- w638 Fuse Box and Relay Diagram 1996 2003Документ5 страницw638 Fuse Box and Relay Diagram 1996 2003Radek Caver Johánek50% (2)

- Top Gear Episode List - WikipediaДокумент16 страницTop Gear Episode List - WikipediaanwharОценок пока нет

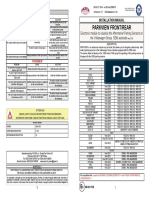

- Parkview FRONT REAR Rev 3 - 13 Da Vers 28 - 85Документ2 страницыParkview FRONT REAR Rev 3 - 13 Da Vers 28 - 85zdenev389Оценок пока нет

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityОт EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityРейтинг: 5 из 5 звезд5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveОт EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveОценок пока нет

- Algorithms to Live By: The Computer Science of Human DecisionsОт EverandAlgorithms to Live By: The Computer Science of Human DecisionsРейтинг: 4.5 из 5 звезд4.5/5 (722)

- Reality+: Virtual Worlds and the Problems of PhilosophyОт EverandReality+: Virtual Worlds and the Problems of PhilosophyРейтинг: 4 из 5 звезд4/5 (24)

- Cyber War: The Next Threat to National Security and What to Do About ItОт EverandCyber War: The Next Threat to National Security and What to Do About ItРейтинг: 3.5 из 5 звезд3.5/5 (66)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldОт EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldРейтинг: 4.5 из 5 звезд4.5/5 (55)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyОт EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyРейтинг: 3.5 из 5 звезд3.5/5 (111)

- Generative AI: The Insights You Need from Harvard Business ReviewОт EverandGenerative AI: The Insights You Need from Harvard Business ReviewРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewОт EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewРейтинг: 4.5 из 5 звезд4.5/5 (104)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyОт EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyРейтинг: 4 из 5 звезд4/5 (51)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumОт EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumРейтинг: 3 из 5 звезд3/5 (12)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОт EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОценок пока нет

- AI Superpowers: China, Silicon Valley, and the New World OrderОт EverandAI Superpowers: China, Silicon Valley, and the New World OrderРейтинг: 4.5 из 5 звезд4.5/5 (398)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessОт EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessОценок пока нет

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОценок пока нет

- Chip War: The Quest to Dominate the World's Most Critical TechnologyОт EverandChip War: The Quest to Dominate the World's Most Critical TechnologyРейтинг: 4.5 из 5 звезд4.5/5 (227)

- An Ugly Truth: Inside Facebook's Battle for DominationОт EverandAn Ugly Truth: Inside Facebook's Battle for DominationРейтинг: 4 из 5 звезд4/5 (33)

- The Future of Geography: How the Competition in Space Will Change Our WorldОт EverandThe Future of Geography: How the Competition in Space Will Change Our WorldРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectОт EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectРейтинг: 4.5 из 5 звезд4.5/5 (20)